U-shaped plug board stamping die and U-shaped plug board stamping method

A stamping die and inserting plate technology, which is applied to the stamping of U-shaped inserting plates and the field of U-shaped inserting plate stamping dies, can solve the problems of wasting steel plates, etc., and achieve the effects of ensuring accuracy, improving the ease of processing, and increasing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

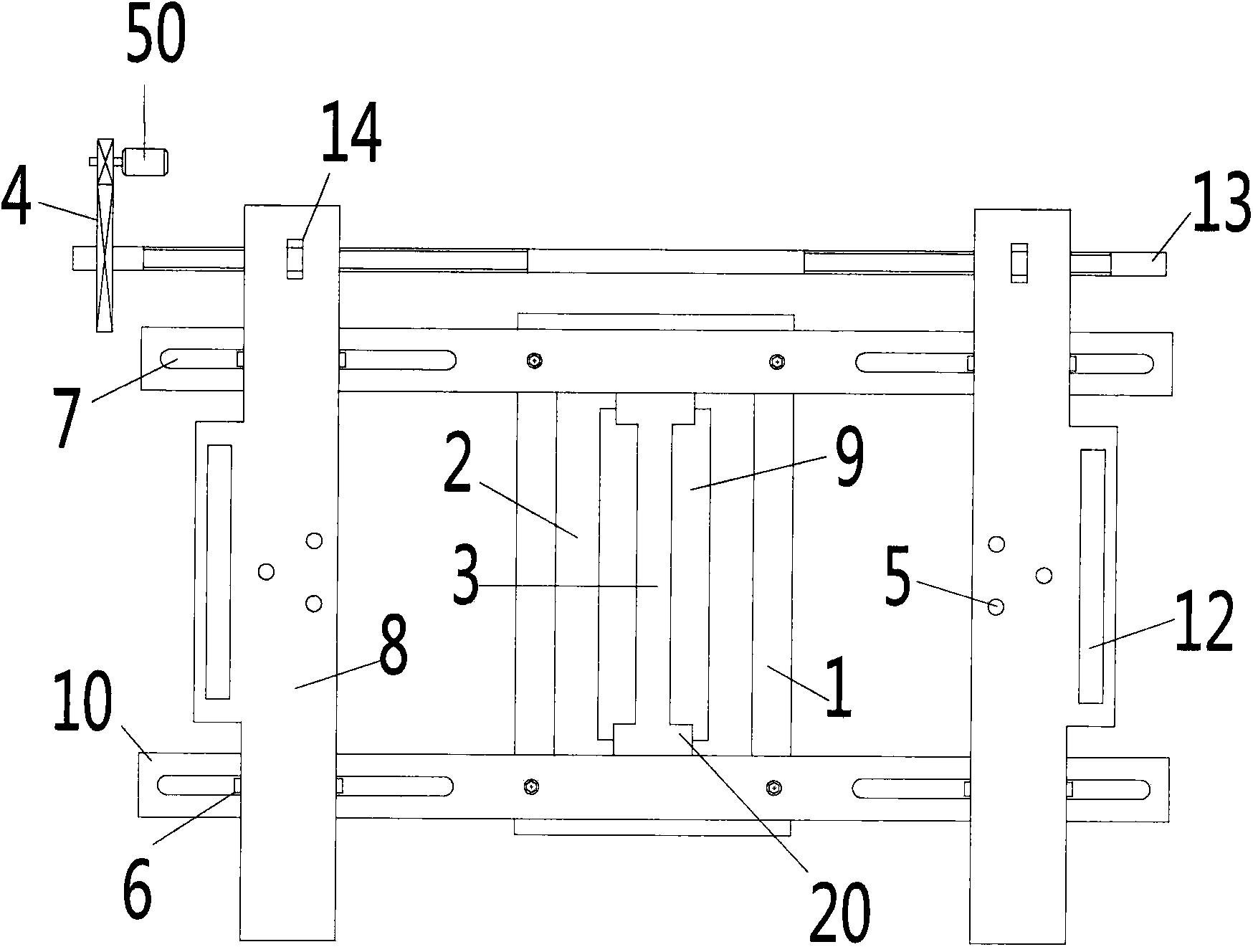

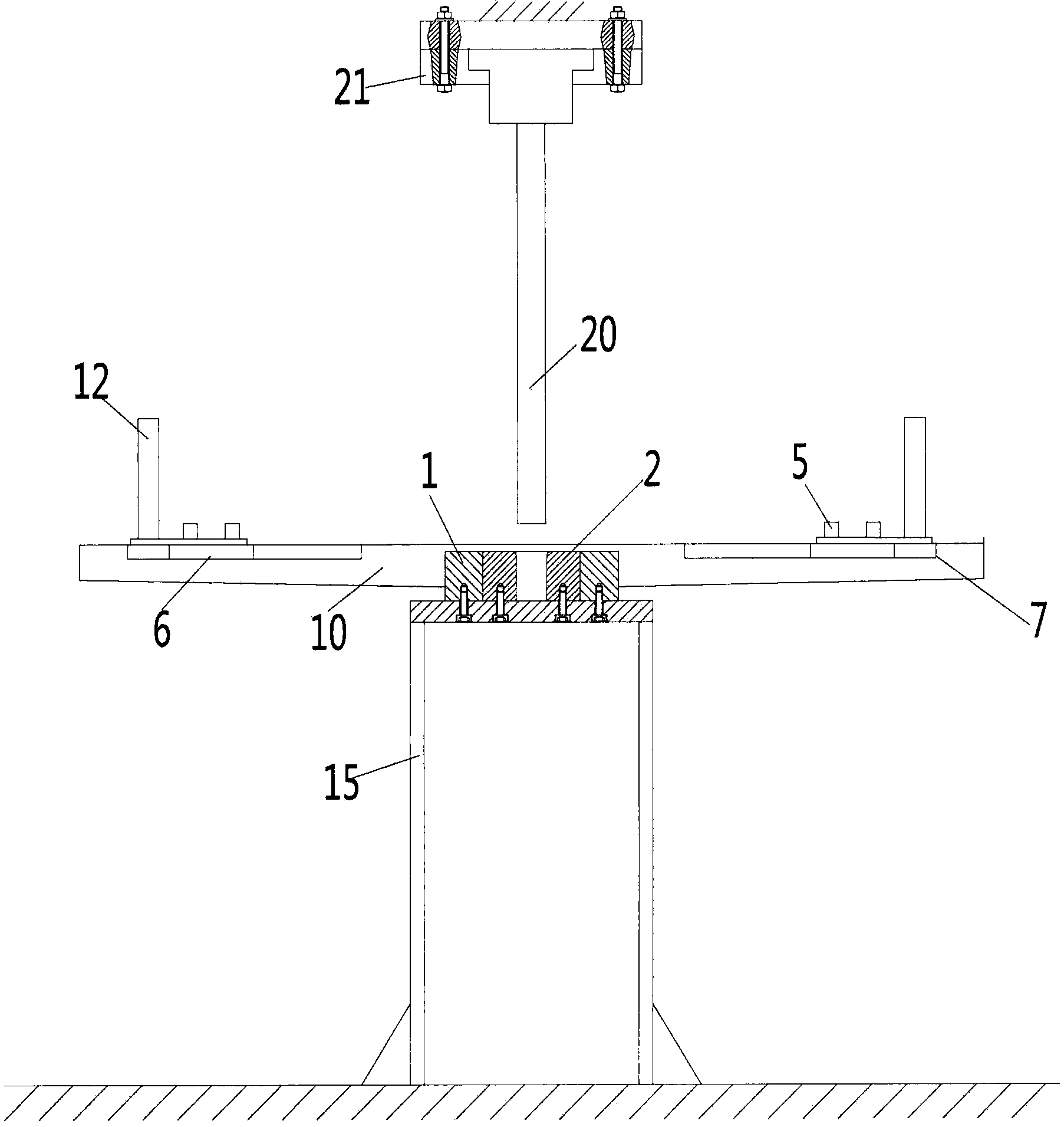

[0039] See Figure 1 to Figure 4 , a U-shaped punching plate stamping die, comprising a lower die support frame 15, a lower die 2 provided with a stamping through hole 9 in the middle, a lower die sleeve 1 set on the lower die 2, an upper die and a positioning part, the lower die 2 and The lower die sets 1 are all fixed on the lower die support frame 15 by bolts, and the top lateral sides of the stamping through hole 9 are provided with 90° arc chamfers 30 .

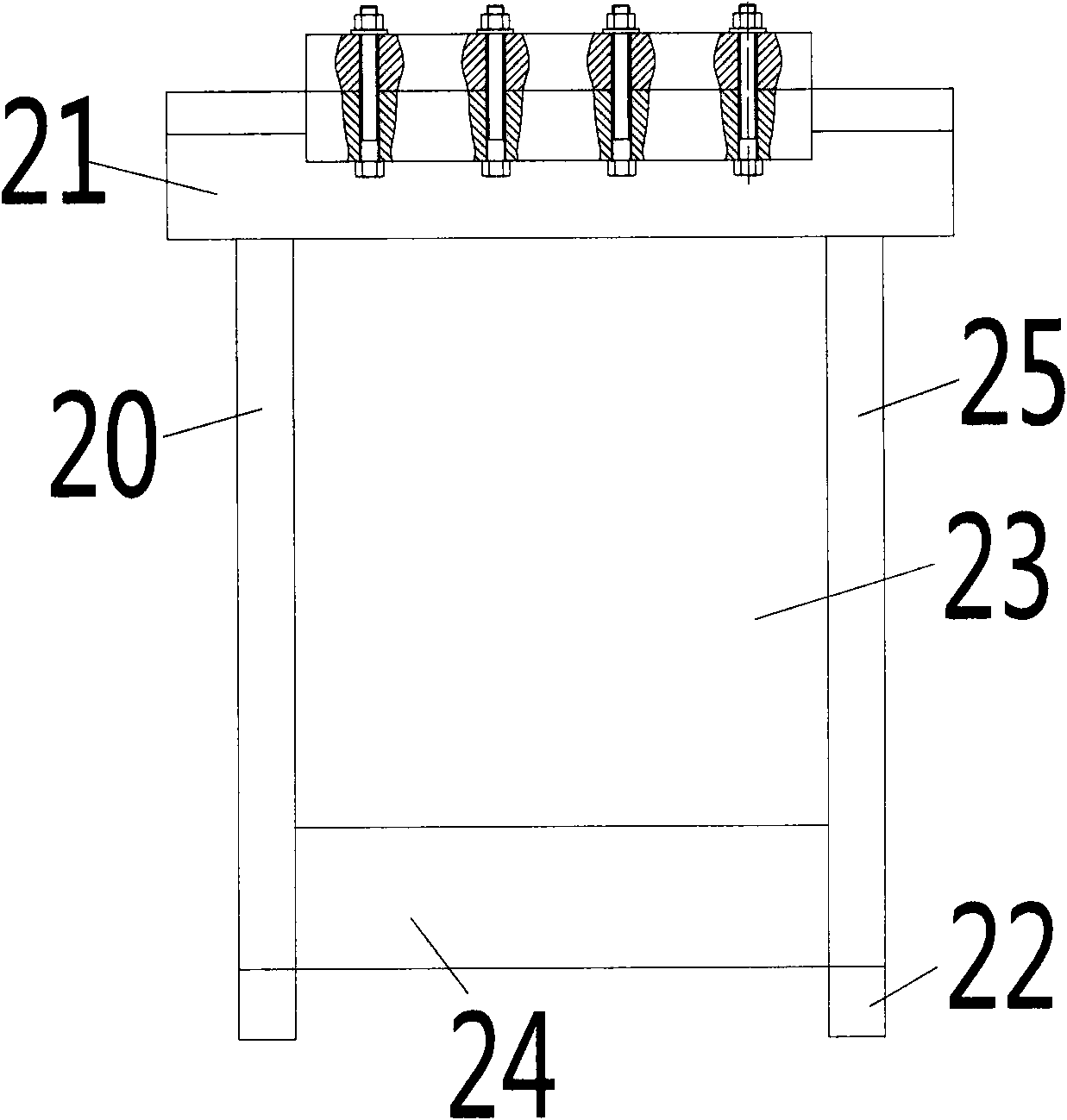

[0040] Upper die comprises the punch 3 that is made up of punch end 24 and punch body 23, two clamping arms 20 and the upper die seat 21 of fixed punch 3 and two clamping arms 20, and clamping arm 20 comprises clamping The clamping section 25 at both ends of the punch 3 and the resisting section 22 protruding from the punch end 24 and abutting against the steel plate during stamping are composed. The punch end 24 and the punch body 23 are separate structures and are connected by bolts. When the punch 3 needs to be repla...

Embodiment 2

[0045] A kind of stamping method of U-shaped flashboard, the method has used the U-shaped flashboard stamping die described in embodiment 1, comprises:

[0046] 1. Use Q345B or Q235B carbon structural steel with a thickness of 8mm-14mm as the raw material, first cut into the steel plate required for punching U-shaped insert plate, and then open three on both sides of the steel plate and position on the moving plate 8 The positioning hole corresponding to the pin 5;

[0047] 2. Make sure the thickness of the U-shaped plate is K, then loosen the bolts between the punch end 24 and the punch body 23, replace the replaced punch end 24, and then re-fix with the bolts so that the replaced punch The thickness D of the head end 24 is equal to the size of the opening after the U-shaped board is formed;

[0048] 3. The width of the punched through hole 9 is set to E, and the radius of the 90° arc chamfer 30 on both sides of the top of the punched through hole 9 is set to R; The total g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com