Low-voltage circuit breaker energy storage lock machining process and multi-station progressive die used in low-voltage circuit breaker energy storage lock machining process

A multi-station progressive die and low-voltage circuit breaker technology, which is applied in metal processing equipment, perforating tools, forming tools, etc., can solve problems such as yield rate and low production efficiency, and improve product yield rate, compatibility and adaptability Strong performance, the effect of improving the accuracy of the hole position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

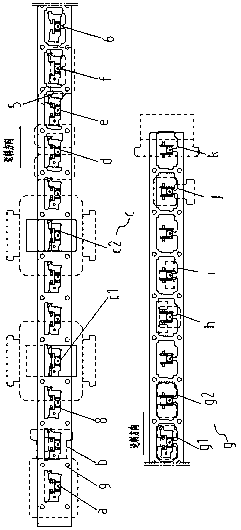

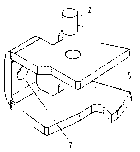

[0046] Example 1. A low-voltage circuit breaker energy storage lock processing technology, such as Figure 1-4 shown, including the following steps:

[0047] a. Punch guide pinholes and flashes: punch out the upper edge 1 flash of the part, and punch guide pinholes 9 on the strip at the same time;

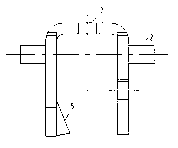

[0048] b. Leveling: ensure the perpendicularity between the unfolded part plane and the cylinder 2;

[0049] c. Forming: forming the cylinder 2 to ensure the diameter and shape tolerance of the cylinder 2;

[0050] d. Edge trimming: punching the left edge 3 and the right edge 4 of the unfolded part at the same time;

[0051] e. Bending: bend the upper right corner of the unfolded part to form a warping angle 5;

[0052] f. Trimming: Die-cut the lower edge 10 of the unfolded part, and reserve the connecting rib 6 to connect with the strip material;

[0053] g. Forming and bending: bending and forming the unfolded parts to form bent parts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com