Semiconductor structure and forming method of semiconductor structure

A semiconductor, fork-shaped structure technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, nanotechnology for information processing, etc. The effect of enhancing the isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background art, the performance of the existing fork-shaped nanosheets still needs to be improved. Now analyze and illustrate in conjunction with specific embodiment.

[0040] It should be noted that the "surface" in this specification is used to describe the relative positional relationship in space, and is not limited to direct contact.

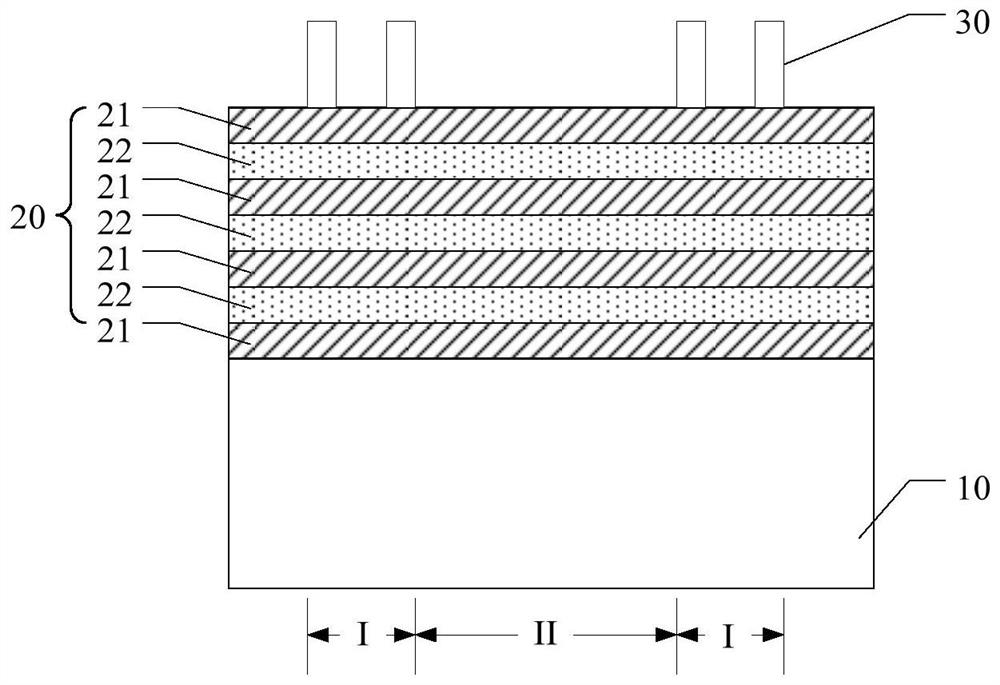

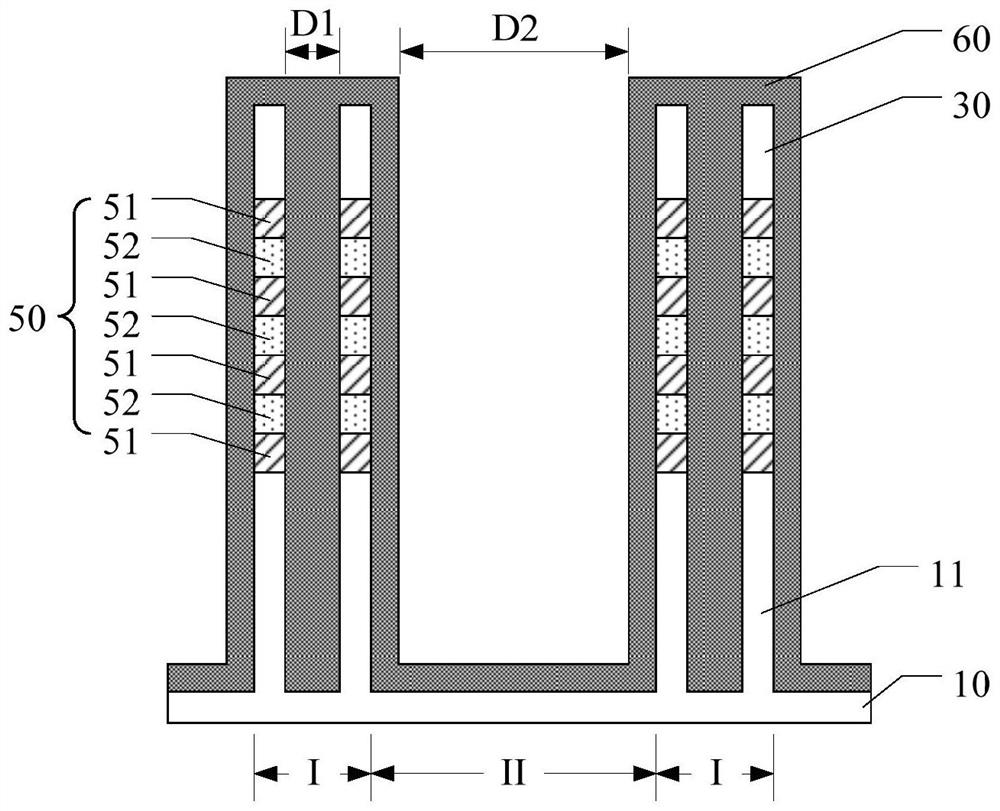

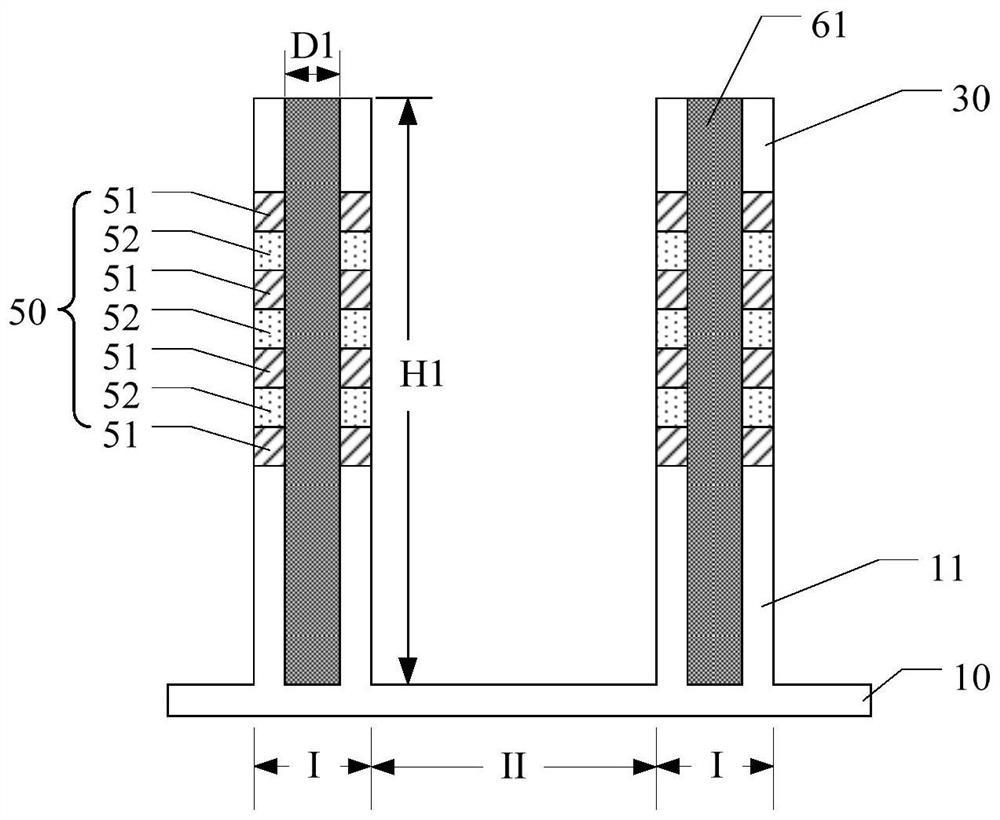

[0041] Figure 1 to Figure 3 It is a schematic cross-sectional structure diagram of a semiconductor structure.

[0042] Please refer to figure 1 , provide a substrate 10, the substrate 10 includes several first regions I, and the second region II between adjacent first regions I; form a composite nanosheet material layer 20 on the substrate 10; Two separate mask structures 30 are formed on the surface of the composite nanosheet material layer 20 in the first region I.

[0043] The composite nanosheet material layer 20 includes: several sacrificial material layers 21 , and nanosheet material layers 22 located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com