A method for improving the molding performance of pottery clay or porcelain clay

A technology of molding performance and porcelain clay, which is applied to household appliances, other household appliances, clay products, etc., can solve the problems of changing the properties of the clay, large discharge pressure, and reduced firing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

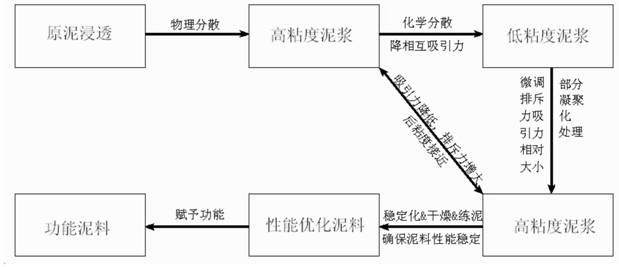

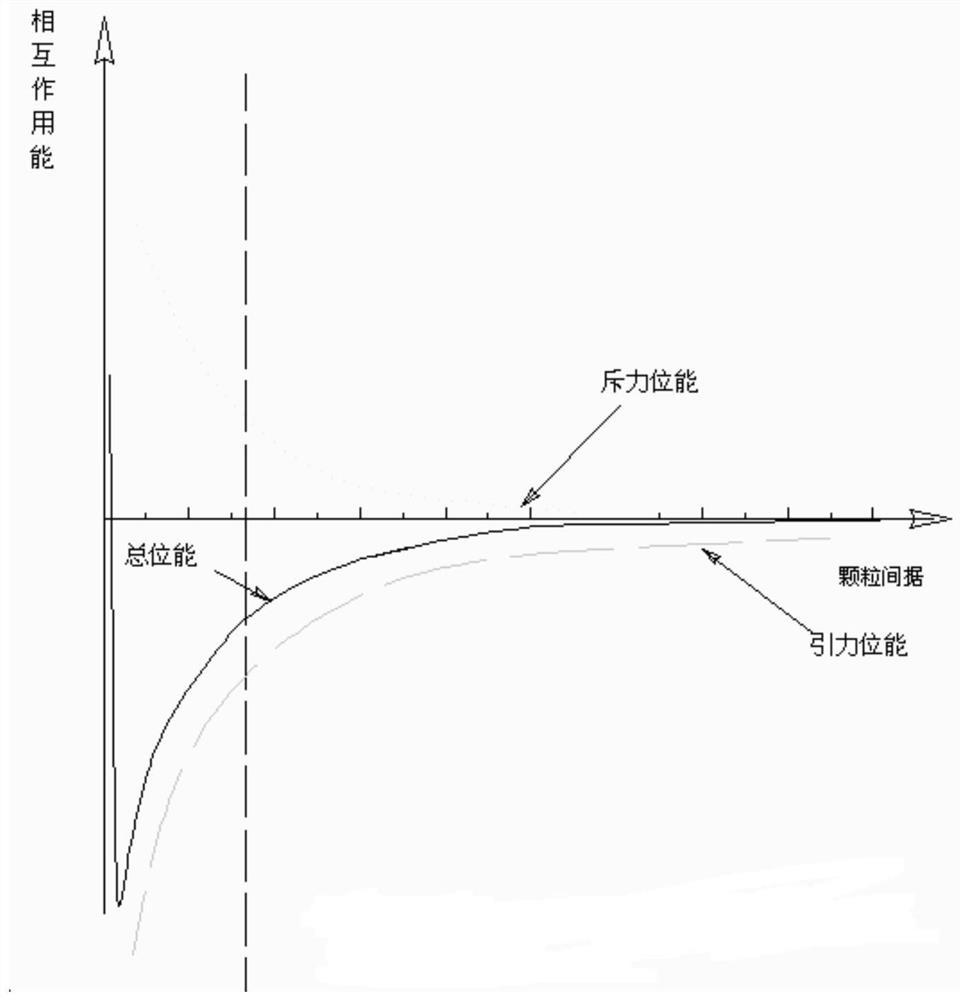

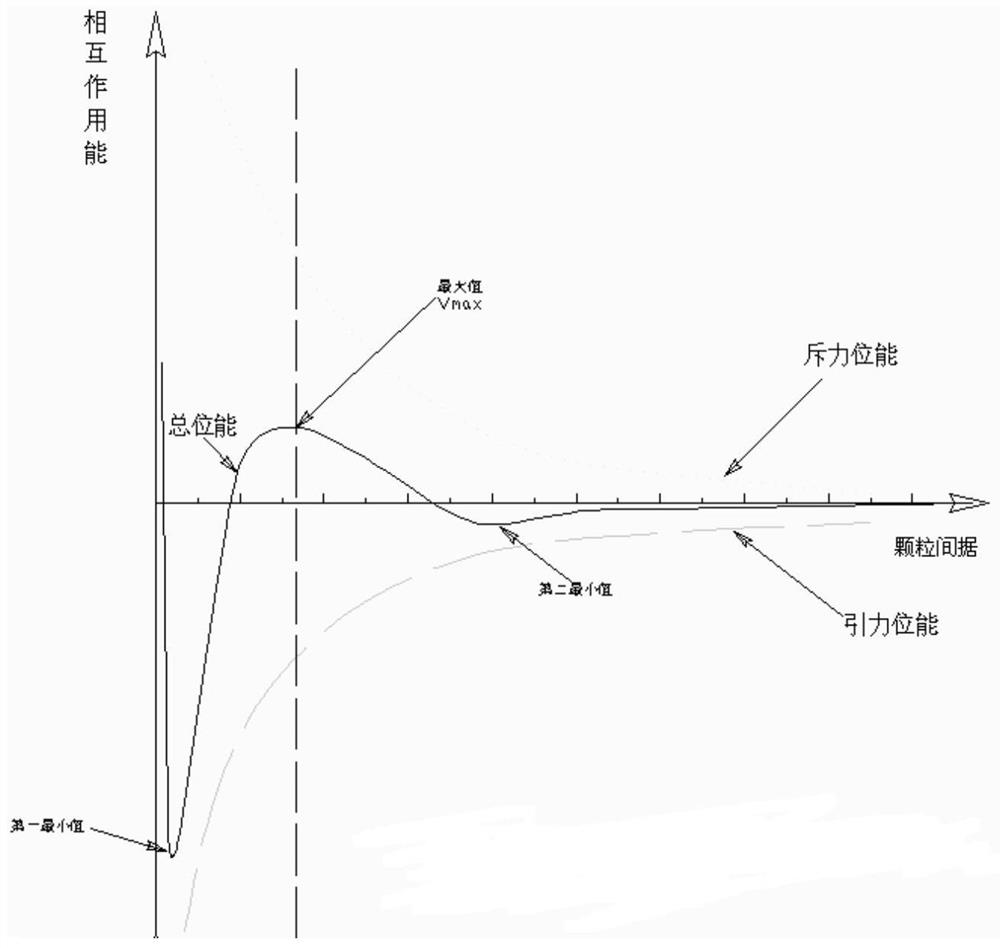

Method used

Image

Examples

Embodiment 1

[0115] The bone china clay produced in Shandong has an original water content of 23.2%, a plasticity index of 2, and a plasticity index of 2.5. The clay is high-toughness hard clay, and the yield strength is 23.4KPa. The compressive strength of the blank is 357.4KPa, and the fired density is 98.5%.

[0116] Treat the clay as follows:

[0117] A) Soak the porcelain mud with water for 24 hours, drain the remaining water and add a small amount of water until the total amount is 30% of the weight of the original mud, and beat until the mud is uniform;

[0118] B) adding water glass (i.e. sodium polysilicate) accounting for 6.5 ‰ of the weight of the original mud and trisodium phosphate accounting for 6.5 ‰ of the weight of the original mud in the mud, beating evenly with a beater to obtain a dispersed mud;

[0119] C) adding a solution of sodium polymethacrylate to the obtained dispersion mud, sodium polymethacrylate accounts for 1‰ of the weight of the original mud, shearing and...

Embodiment 2

[0124] The white porcelain clay produced in Liling, Hunan Province has an original water content of 24.5%, a plasticity index of 3.1, and a plasticity index of 2.9. The density of the porcelain obtained by firing the mud-shaped green body is 97.9% of the theoretical density, and the compressive fracture strength of the green body is 168KPa (containing the reinforcing agent sodium humate).

[0125] Treat the clay as follows:

[0126] A) Soak the porcelain mud with water for 24 hours, pour out the remaining water, add a small amount of water until the total amount is 25-32% of the weight of the original mud, and beat until the mud is uniform;

[0127] B) Adding NP-40 (nonylphenol polyoxyethylene ether) accounting for 5‰ of the weight of the original mud and anhydrous sodium carbonate accounting for 2.5‰ of the weight of the original mud to the mud, beating evenly with a beater to obtain a dispersed mud;

[0128] C) adding a solution made of 0.5‰ of lysine and 0.15‰ of polyacryl...

Embodiment 3

[0133] The black pottery mud produced in Changbai Mountain, Jilin Province has an original water content of 25.5%, a plasticity index of 2.1, and a plasticity index of 2.3. The mud is low-toughness hard mud, with a yield strength of 24.4KPa and a tensile deformation ratio of 145%. The density of the porcelain obtained by molding the green body by using the obtained modified porcelain clay and firing is 98.4% of the theoretical density, and the compressive fracture strength of the green body is 195KPa.

[0134] Treat clay as follows:

[0135] A) In a sealed state, submerge the clay with n-propanol and soak it for 24 hours. After pouring out the excess liquid, add 1% ethanol accounting for the dry weight of the original mud, so that the total amount of liquid is 25% to 32% of the weight of the original mud. until the mud is uniform;

[0136] B) adding polyethylene glycol 4000 accounting for 3 ‰ of the original mud weight and sodium dodecylbenzenesulfonate accounting for 1 ‰ of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com