Patents

Literature

278results about How to "Change flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

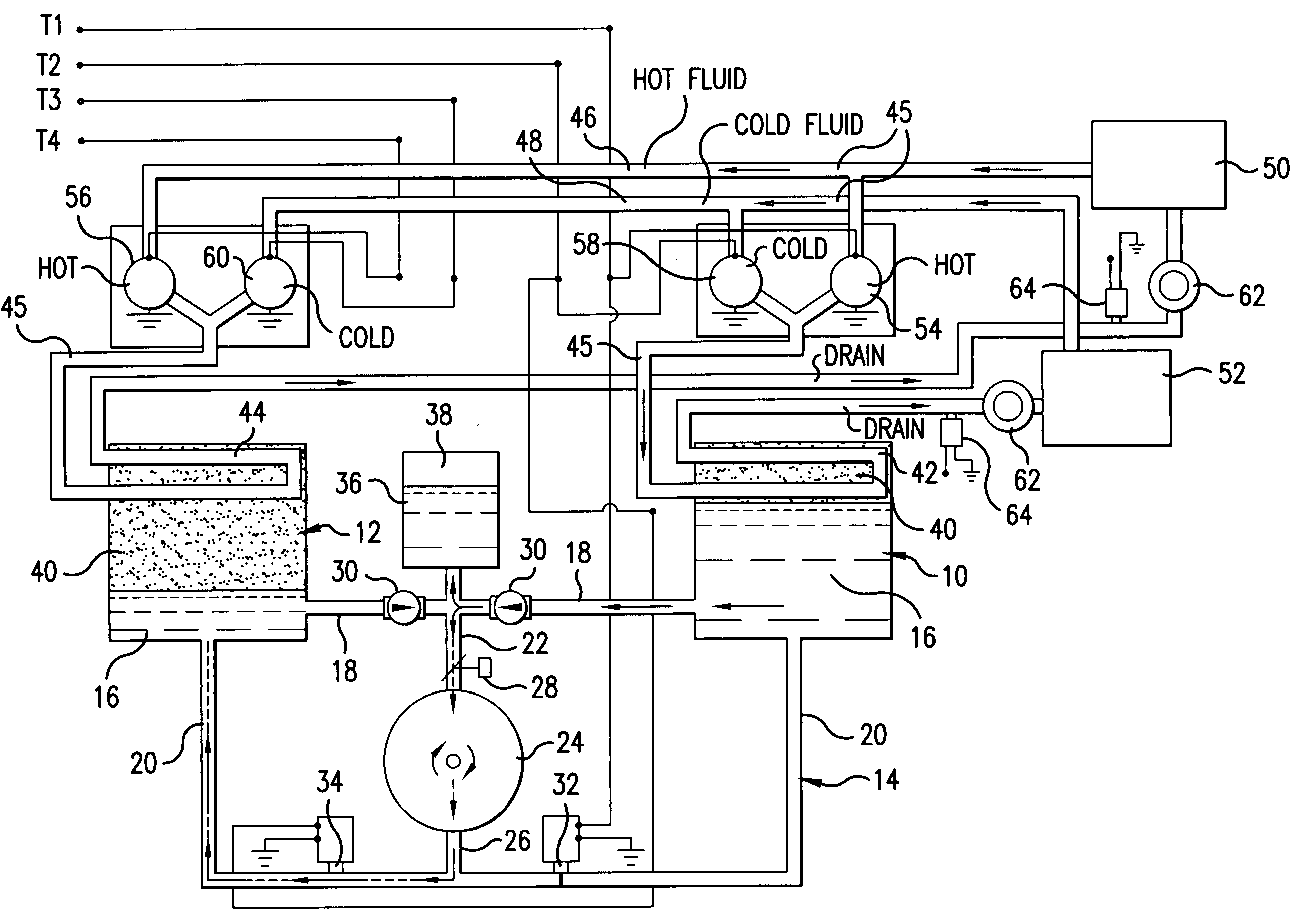

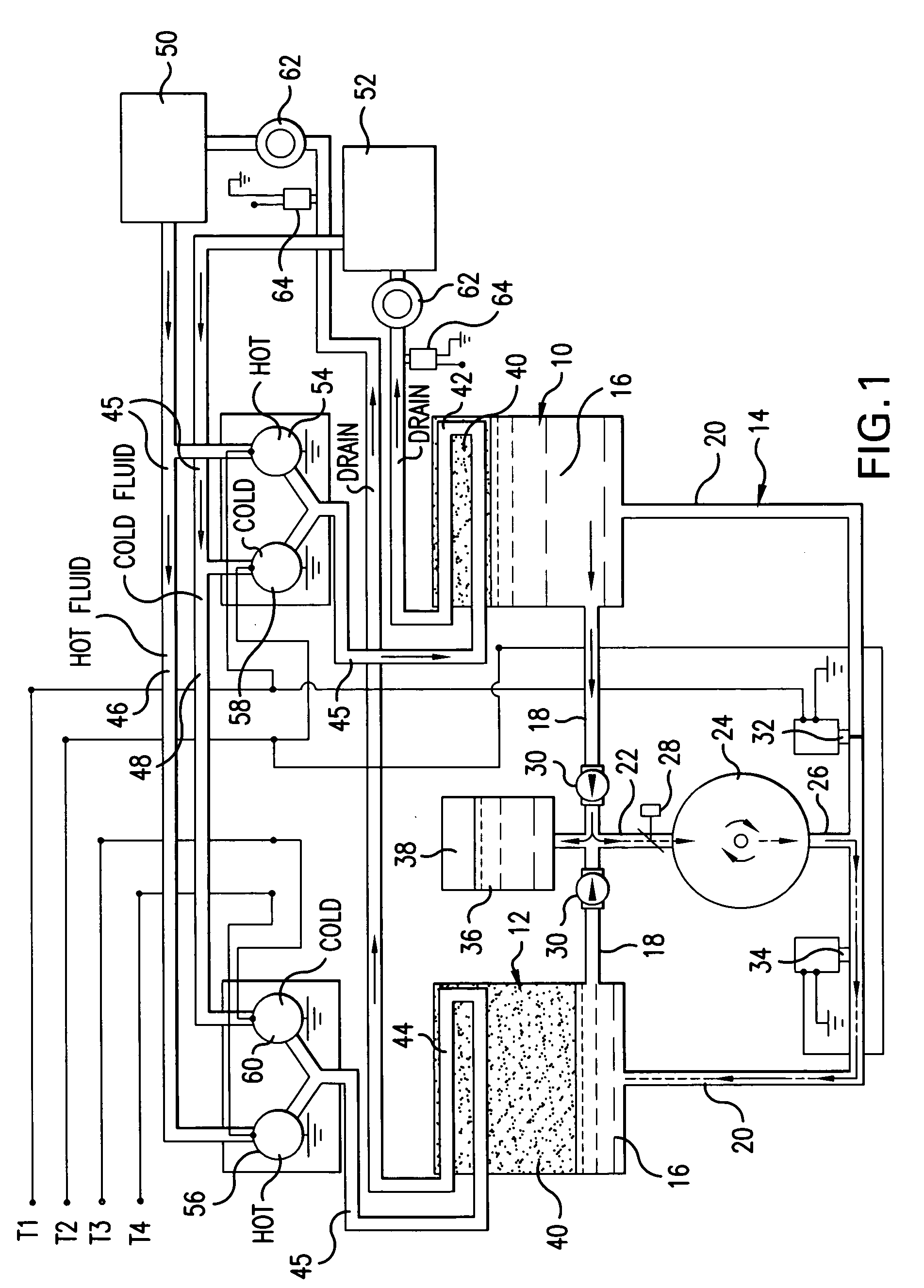

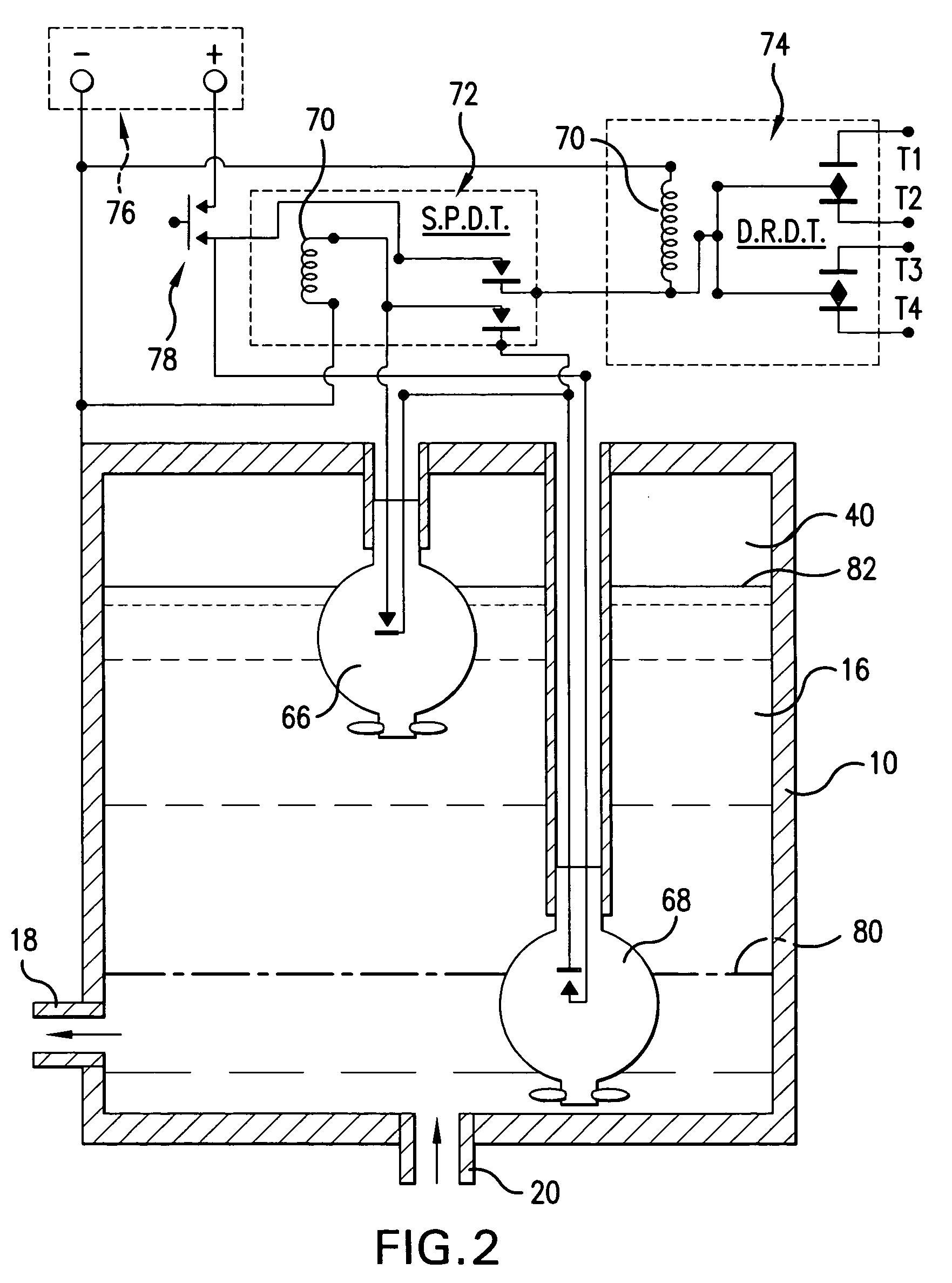

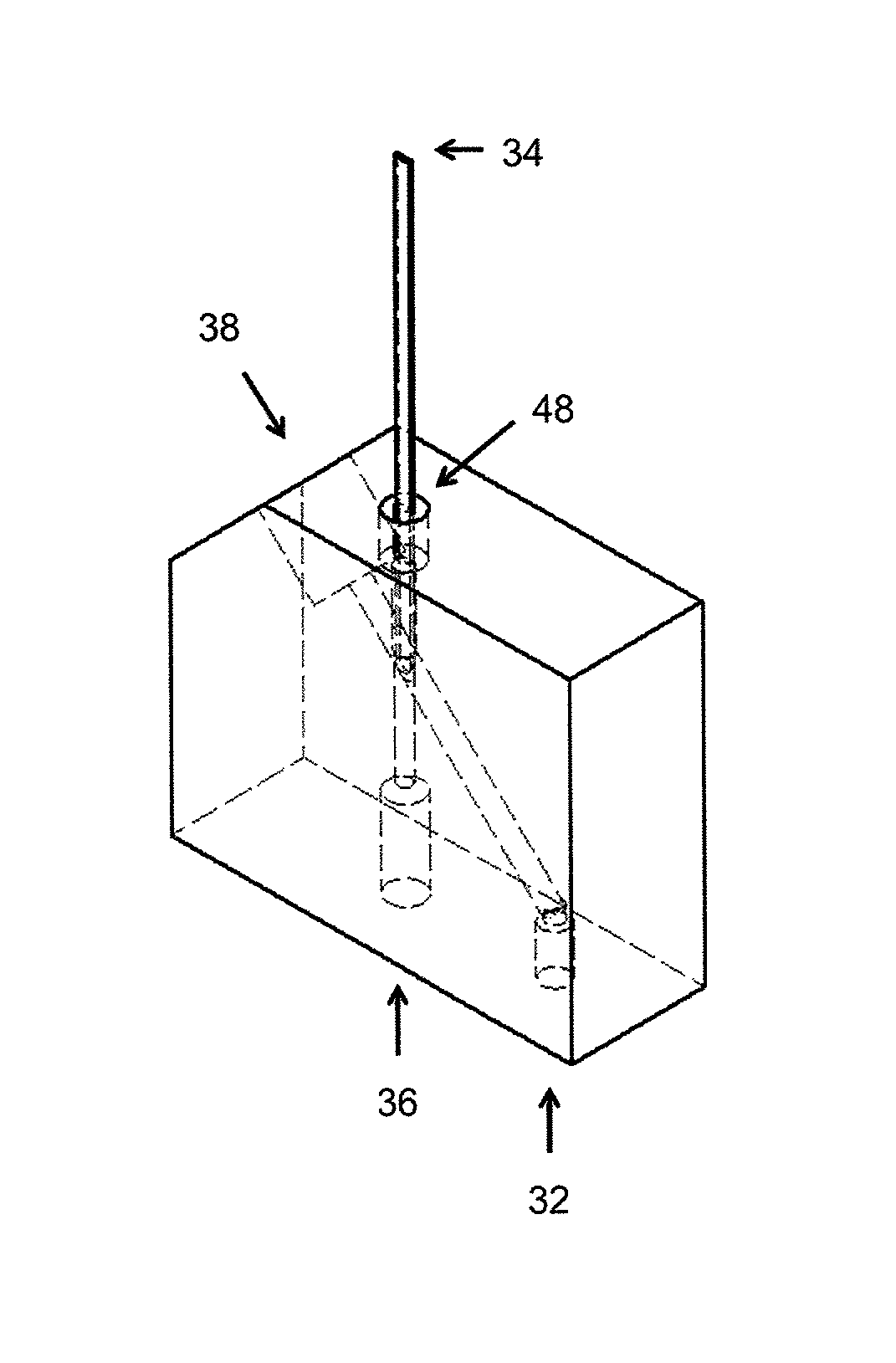

Vapor pump power system

InactiveUS20060059912A1Small temperature differenceIncrease pressureGas turbine plantsSteam engine plantsPower stationEngineering

A power plant with at least two pressure vessels containing a hydraulic fluid. A heat exchanging assembly is in heat transferring association with the pressure vessels. The hydraulic conduit is hydraulically connected with the pressure vessels. A power outlet device is in hydraulic association with the conduit between the vessels and is configured for outputing power from the flow of the hydraulic fluid. A controlling mechanism is operably associated with the heat exchanging assembly to cause the heat exchanging assembly to alternately increase the pressure in one of the pressure vessels compared to the other. Thus, hydraulic fluid is caused to flow through the power outlet device alternately between the pressure vessels to produce power from the power output device.

Owner:ROMANELLI PAT

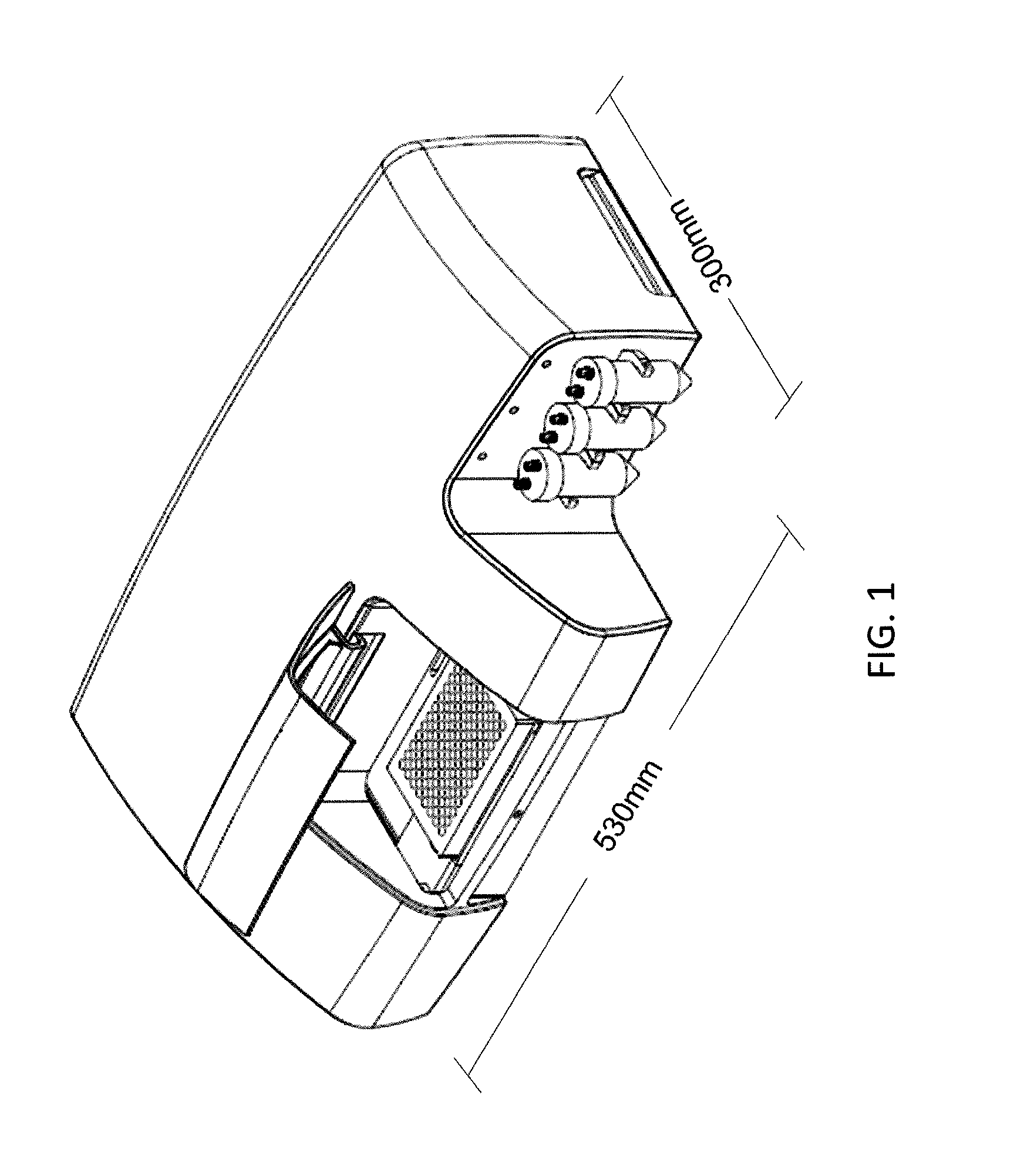

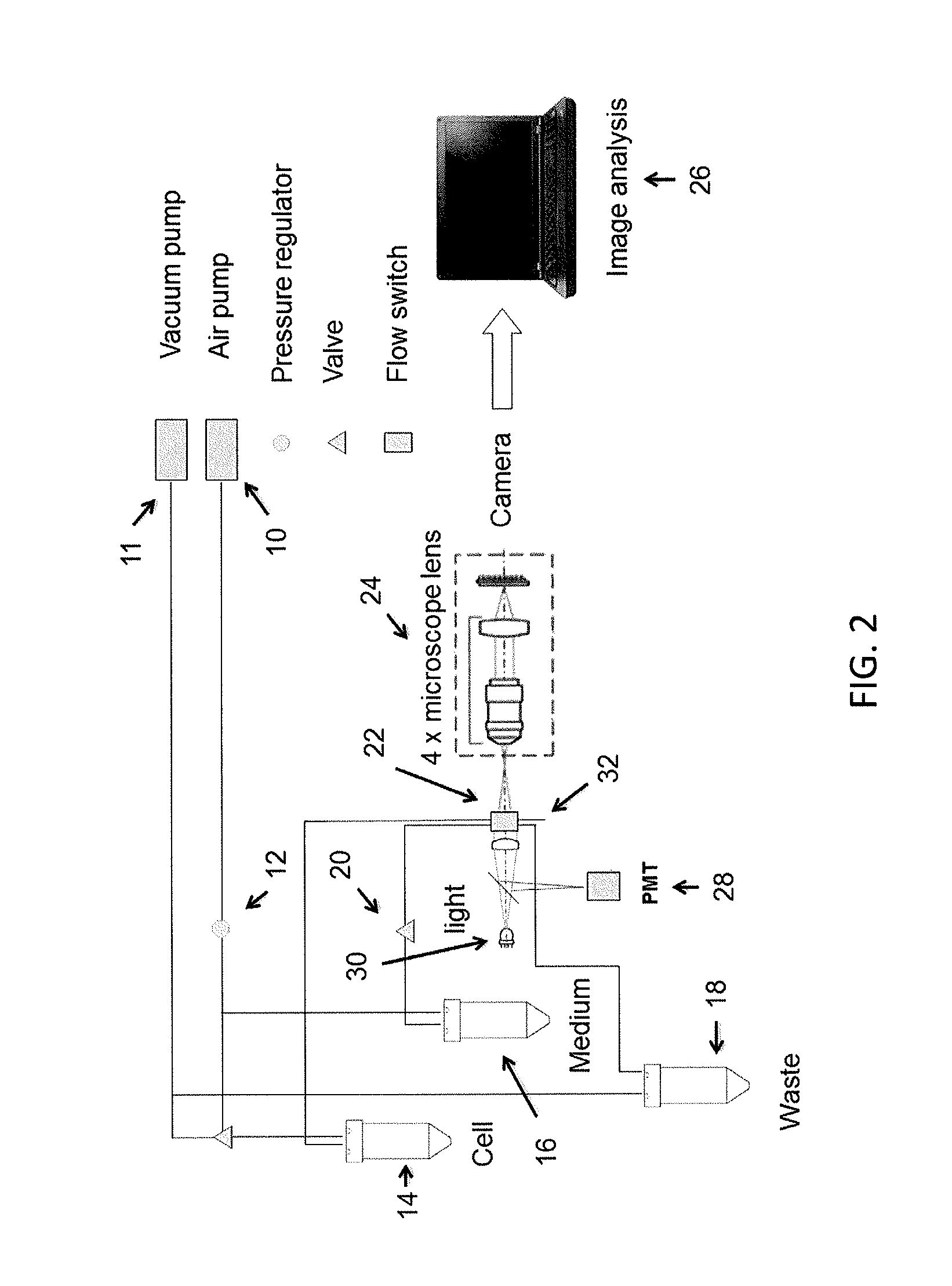

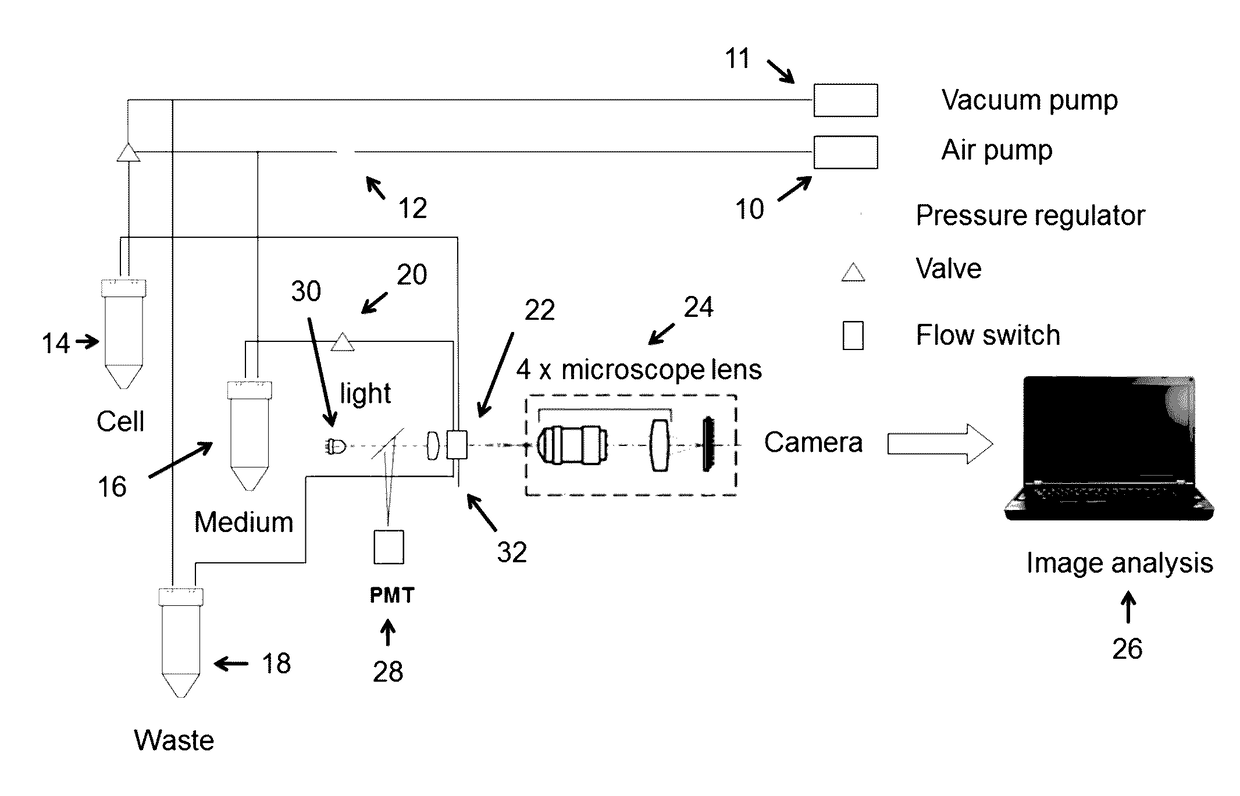

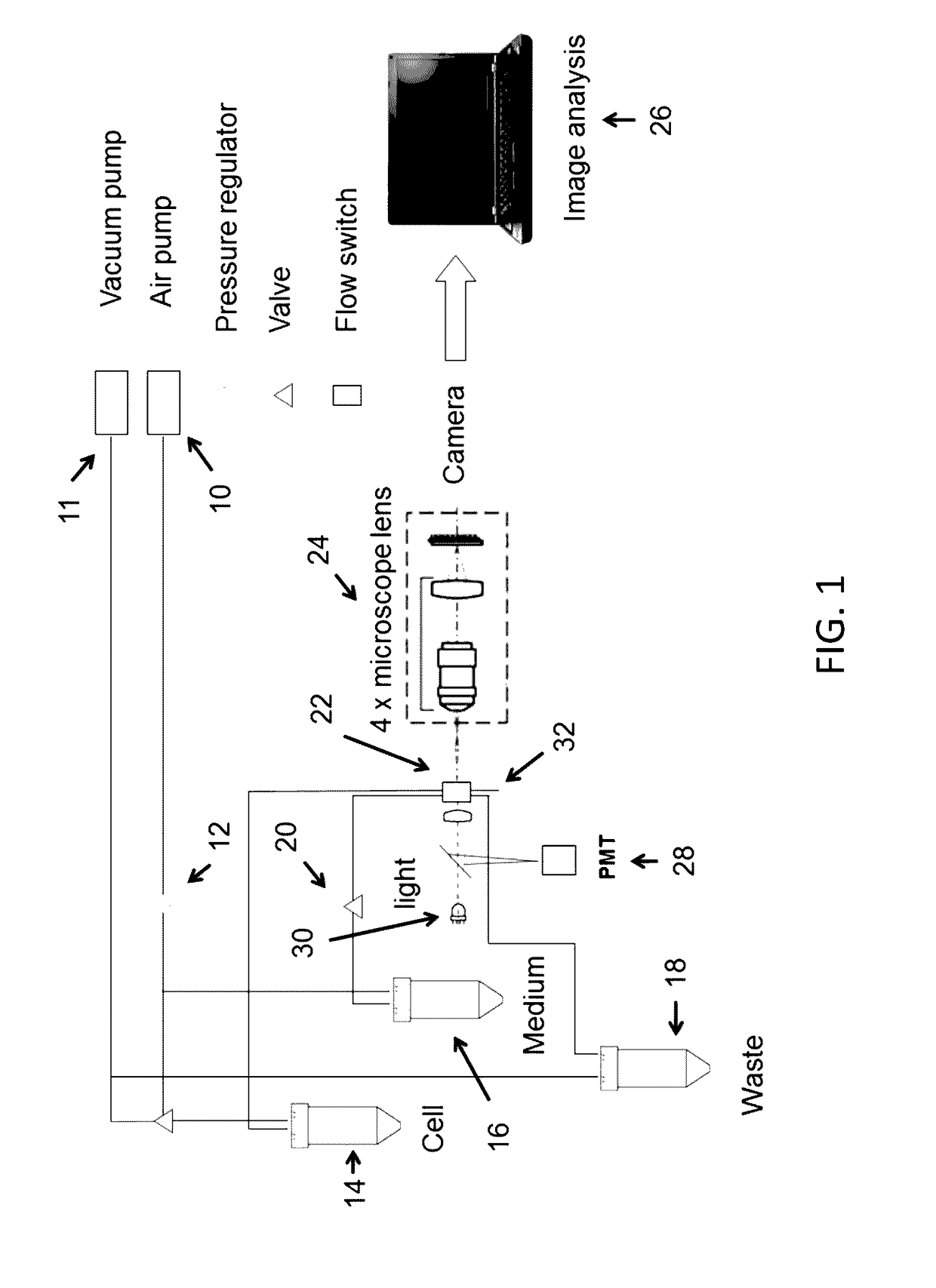

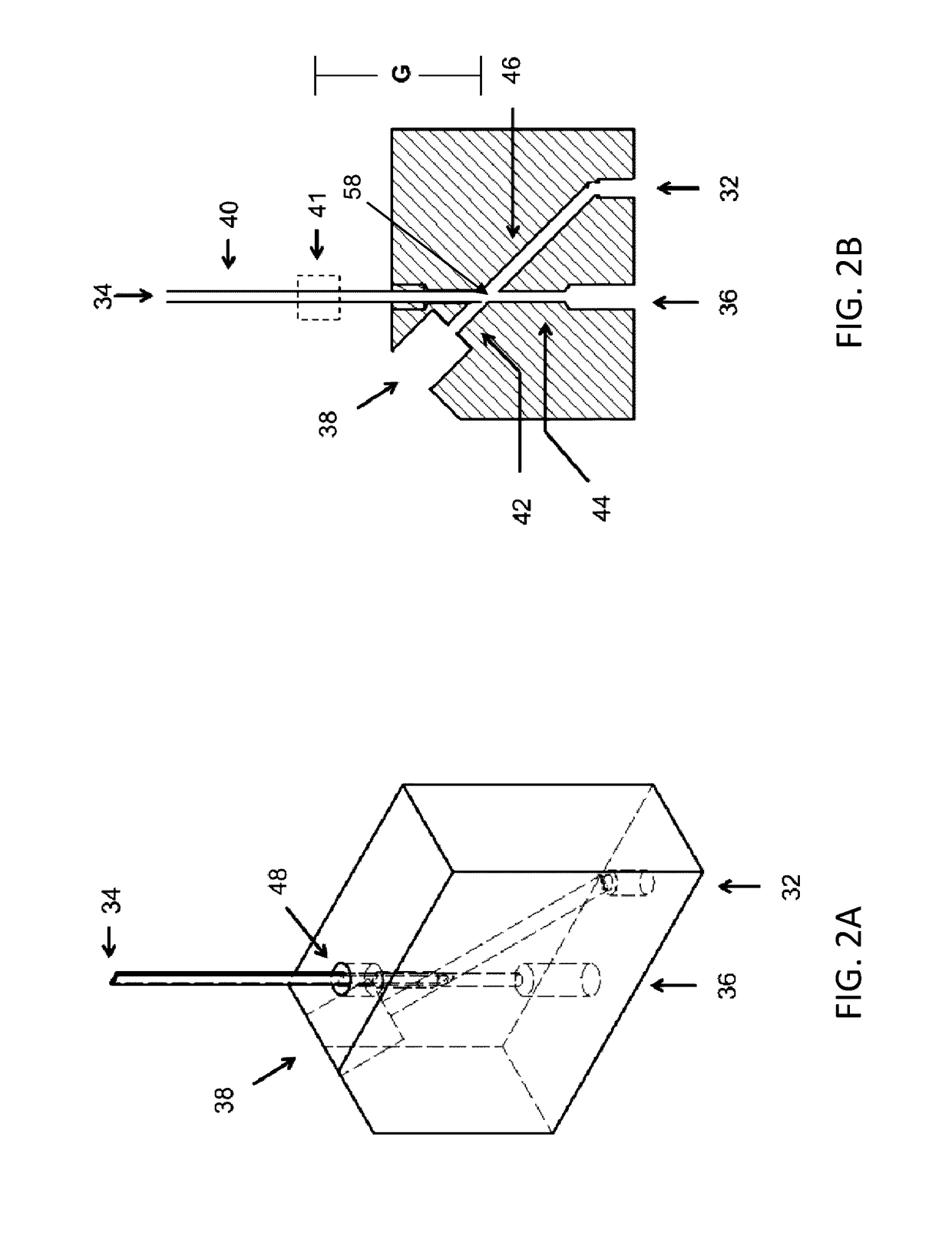

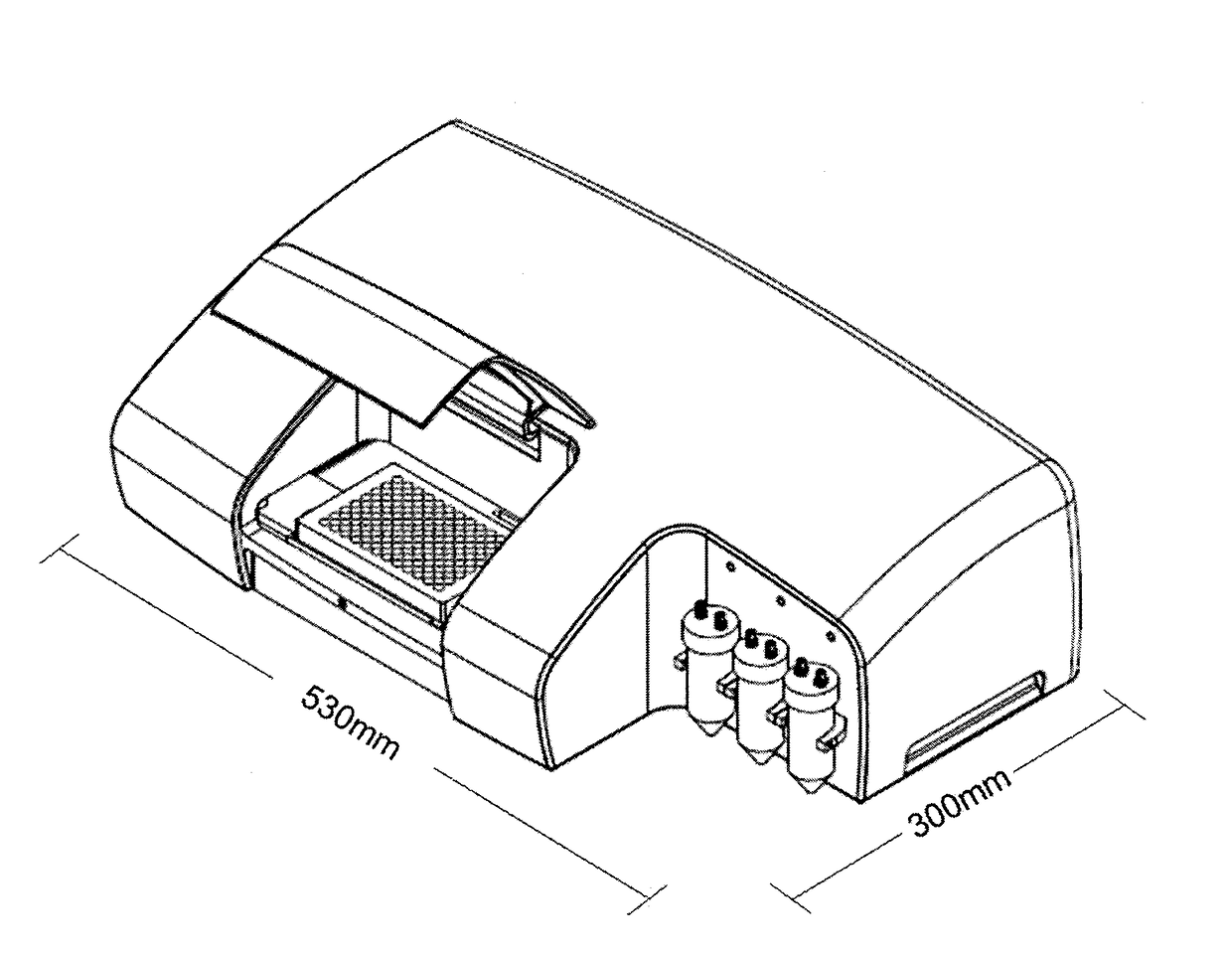

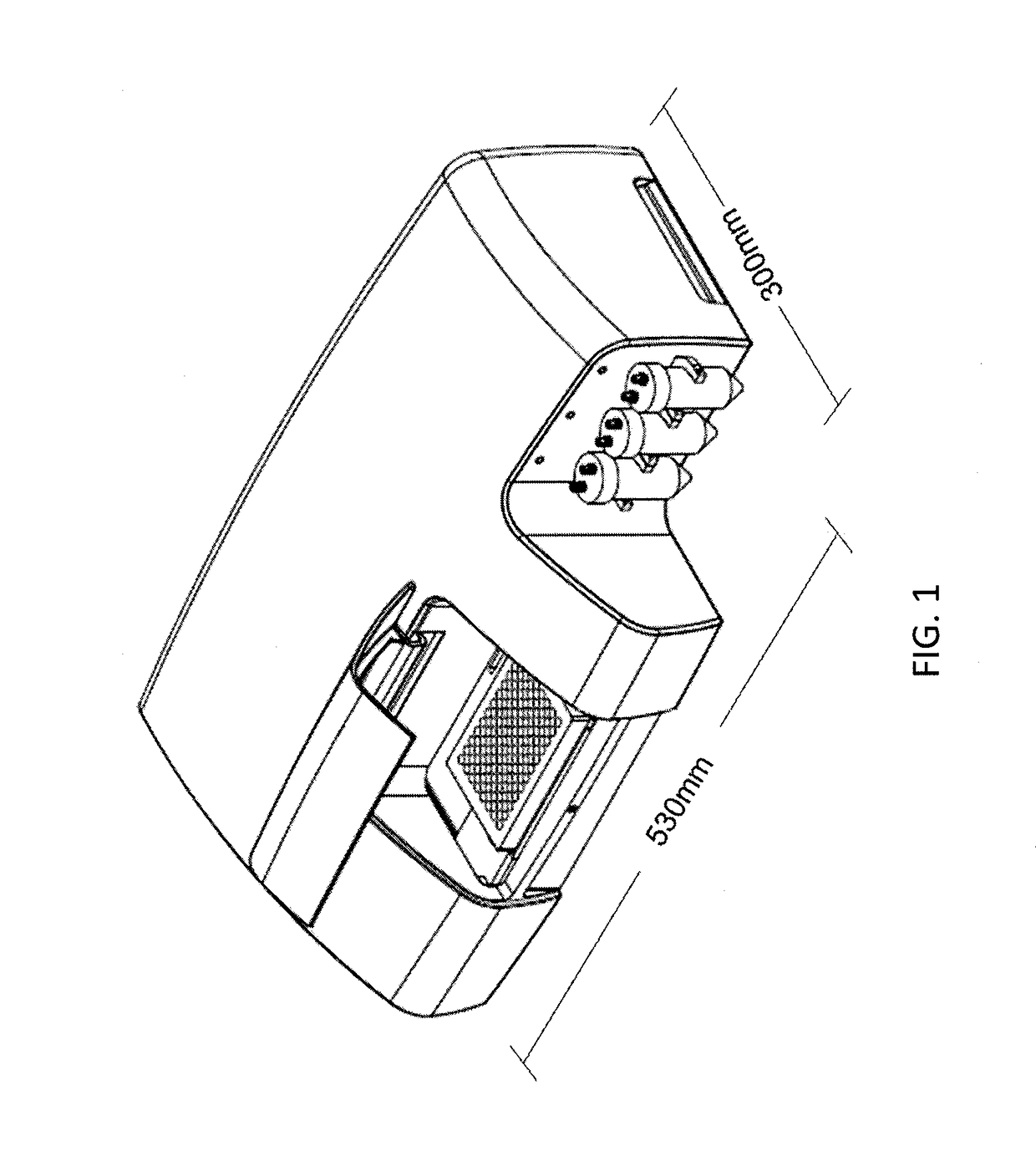

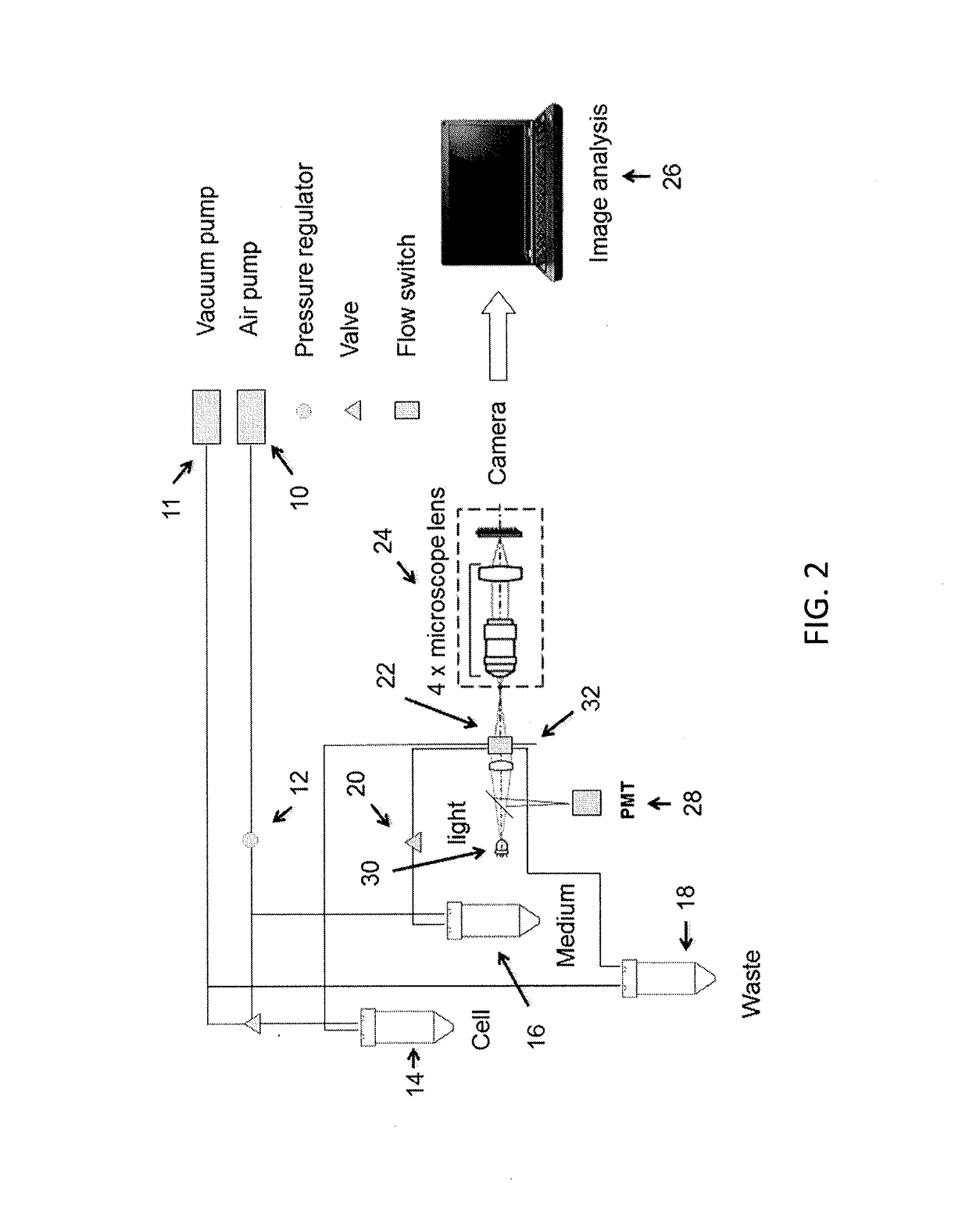

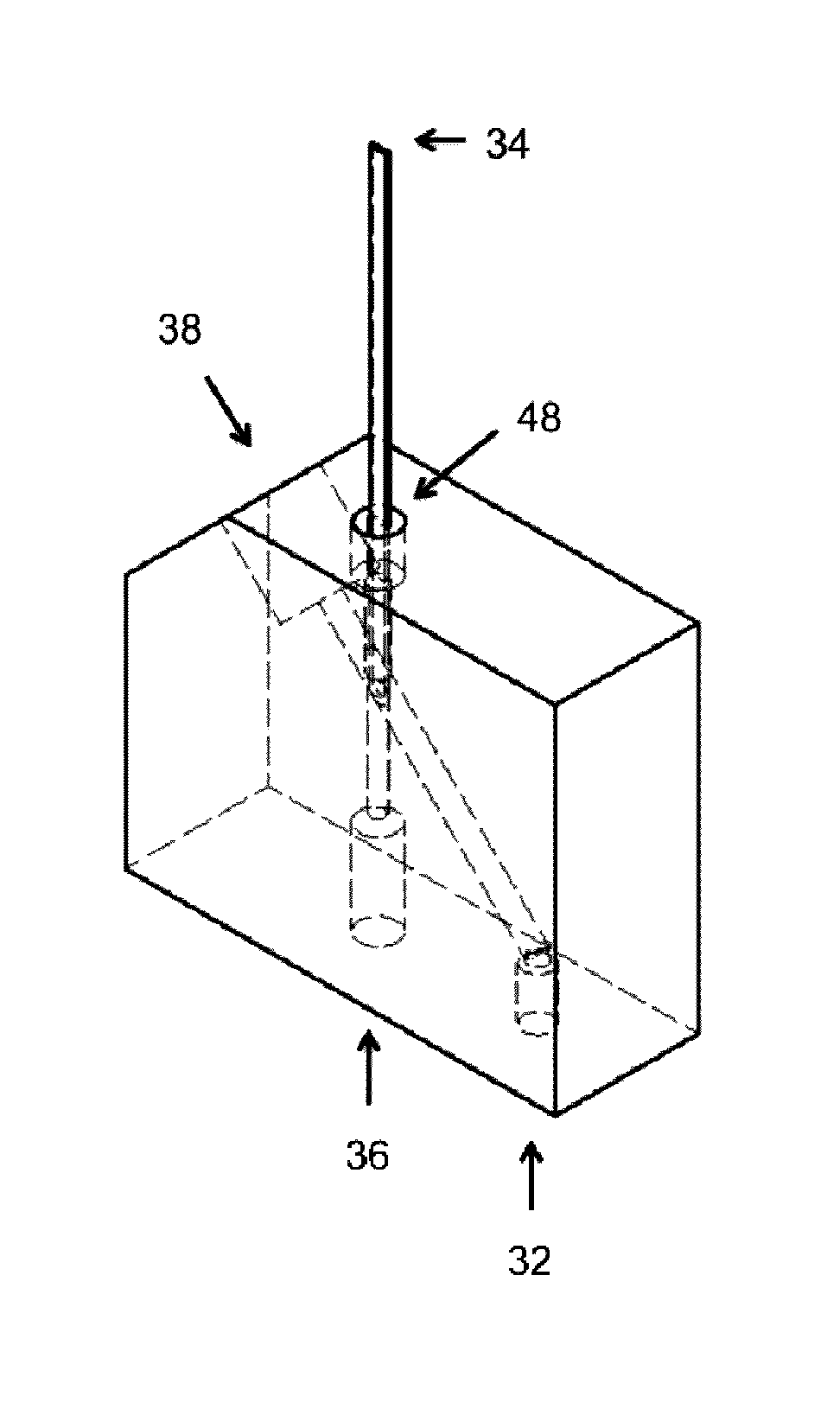

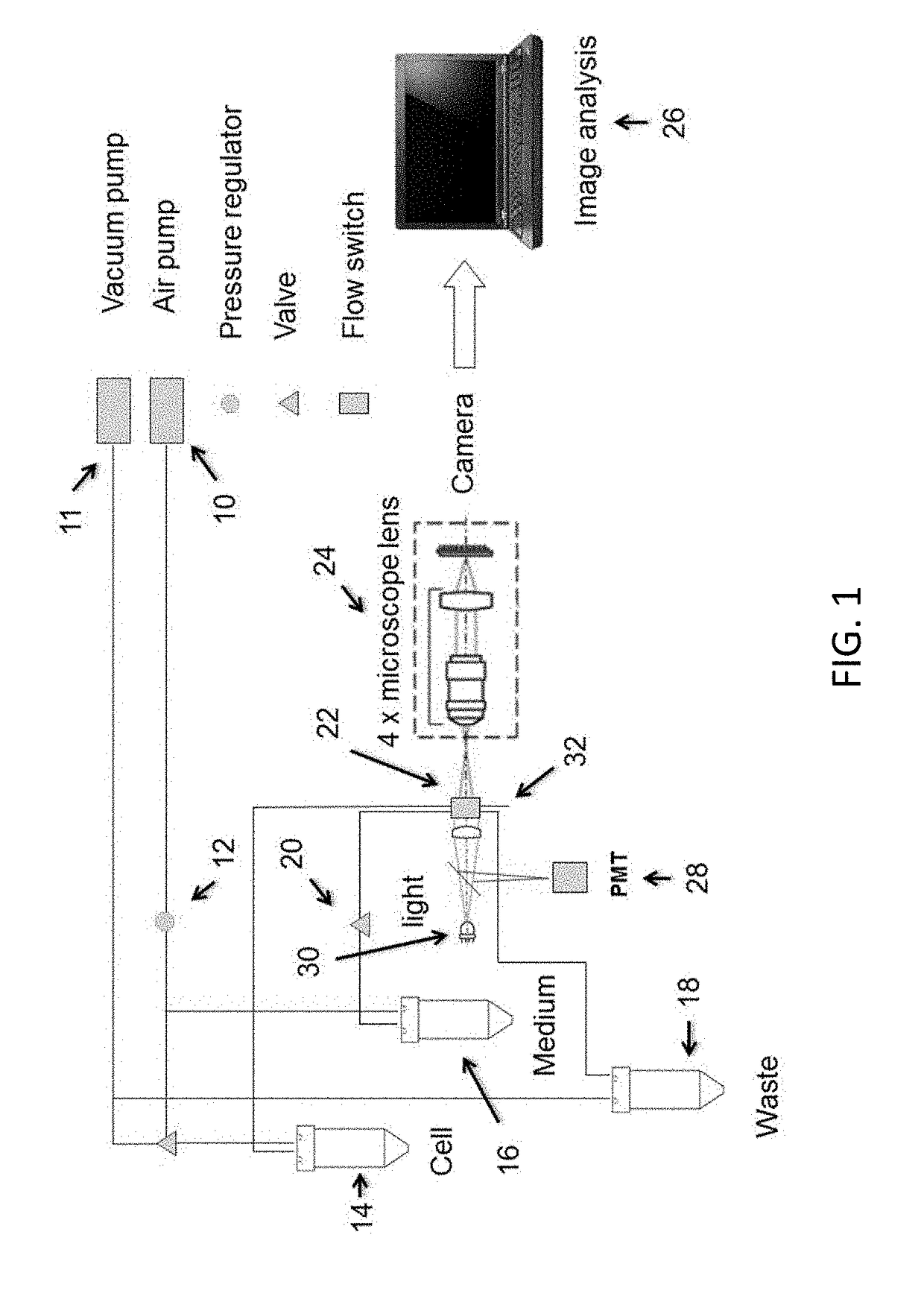

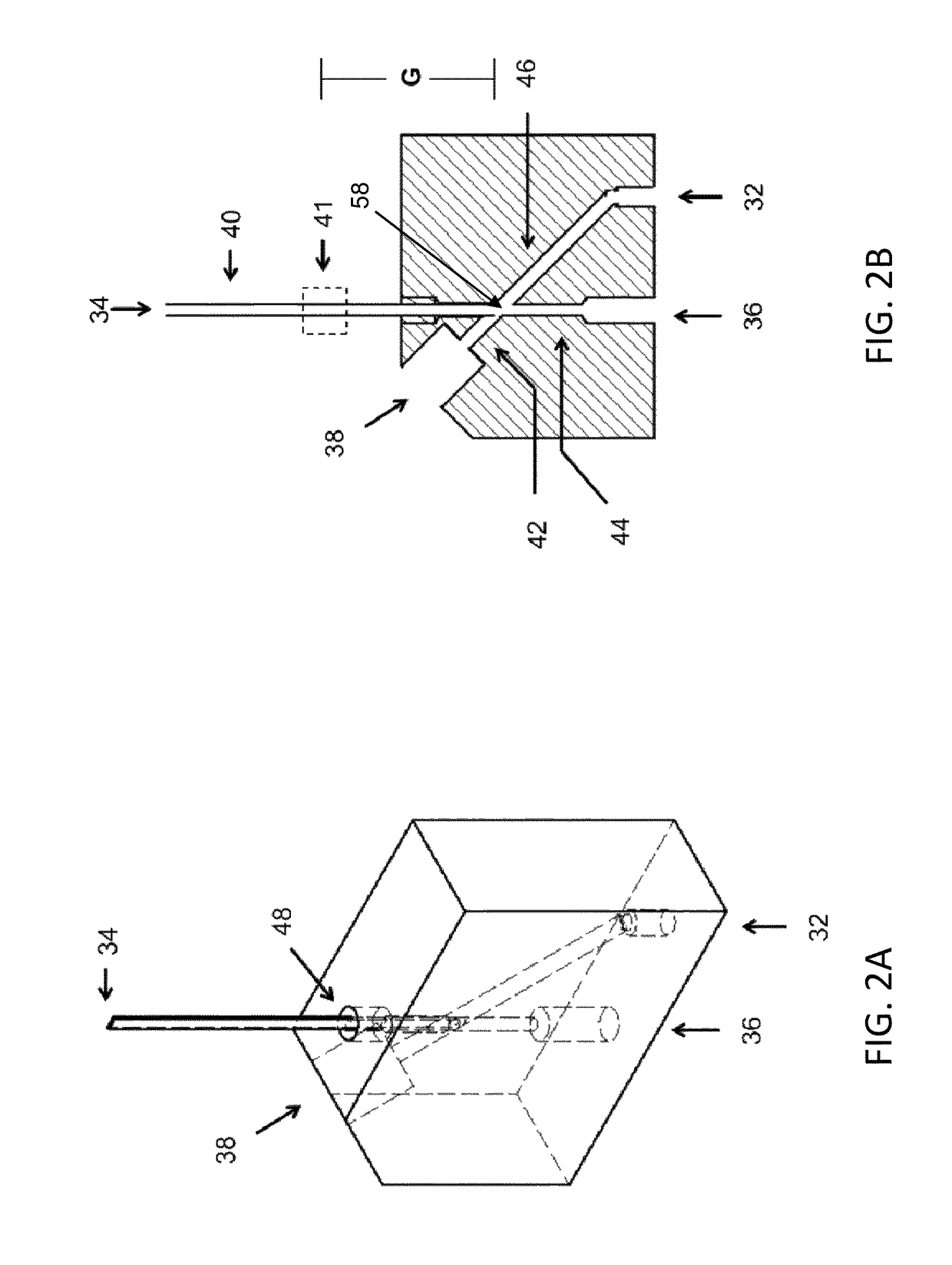

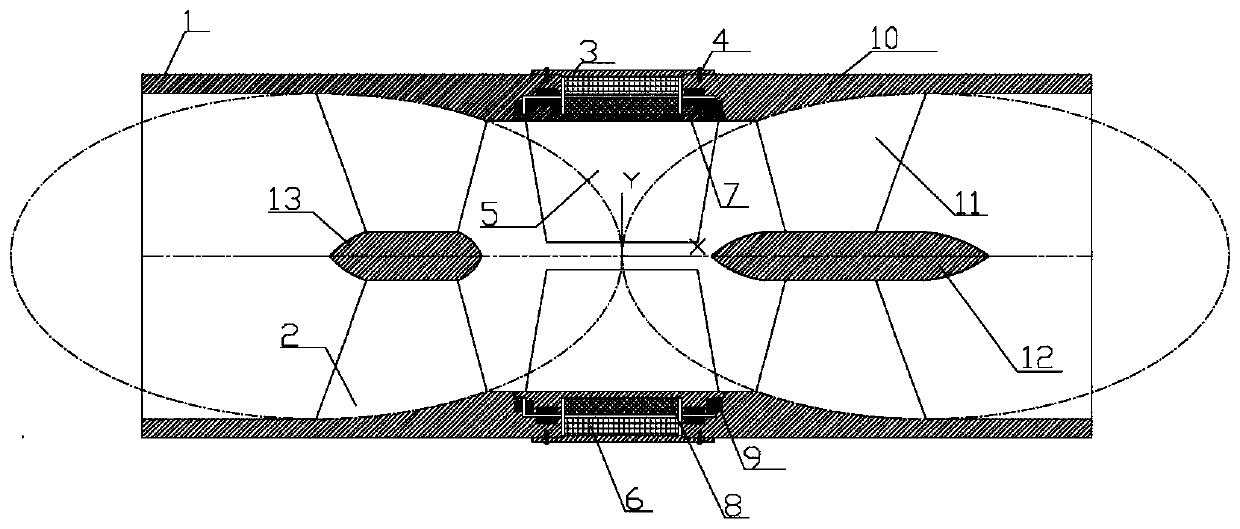

Method and apparatus for particle sorting

ActiveUS8820538B1Effectively and precisely sortingReduce areaAnalysis material containersBiological particle analysisParticle sortingMonoclonal antibody

Apparatus and methods for sorting and dispensing microparticles using a flow switch mechanism wherein changing flow rate into the flow switch changes flow path. The present invention is well-suited for precisely sorting microparticles, such as cells, for applications such as cell line development, monoclonal antibody selection and single cell research, etc.

Owner:NAMOCELL INC

Method and apparatus for bulk microparticle sorting using a microfluidic channel

ActiveUS20170089826A1Avoid disruptionChange flow rateBiological particle analysisLaboratory glasswaresEngineeringMicroparticle

Methods and apparatuses for sorting and isolating individual microparticles (e.g., cells) by bulk sorting groups of microparticles into groups containing one or more microparticle having a desirable characteristic (e.g., a label such as a florescent label, shape, size, etc.), and then sorting the individual microparticles with this desired characteristic individual particles.

Owner:NAMOCELL INC

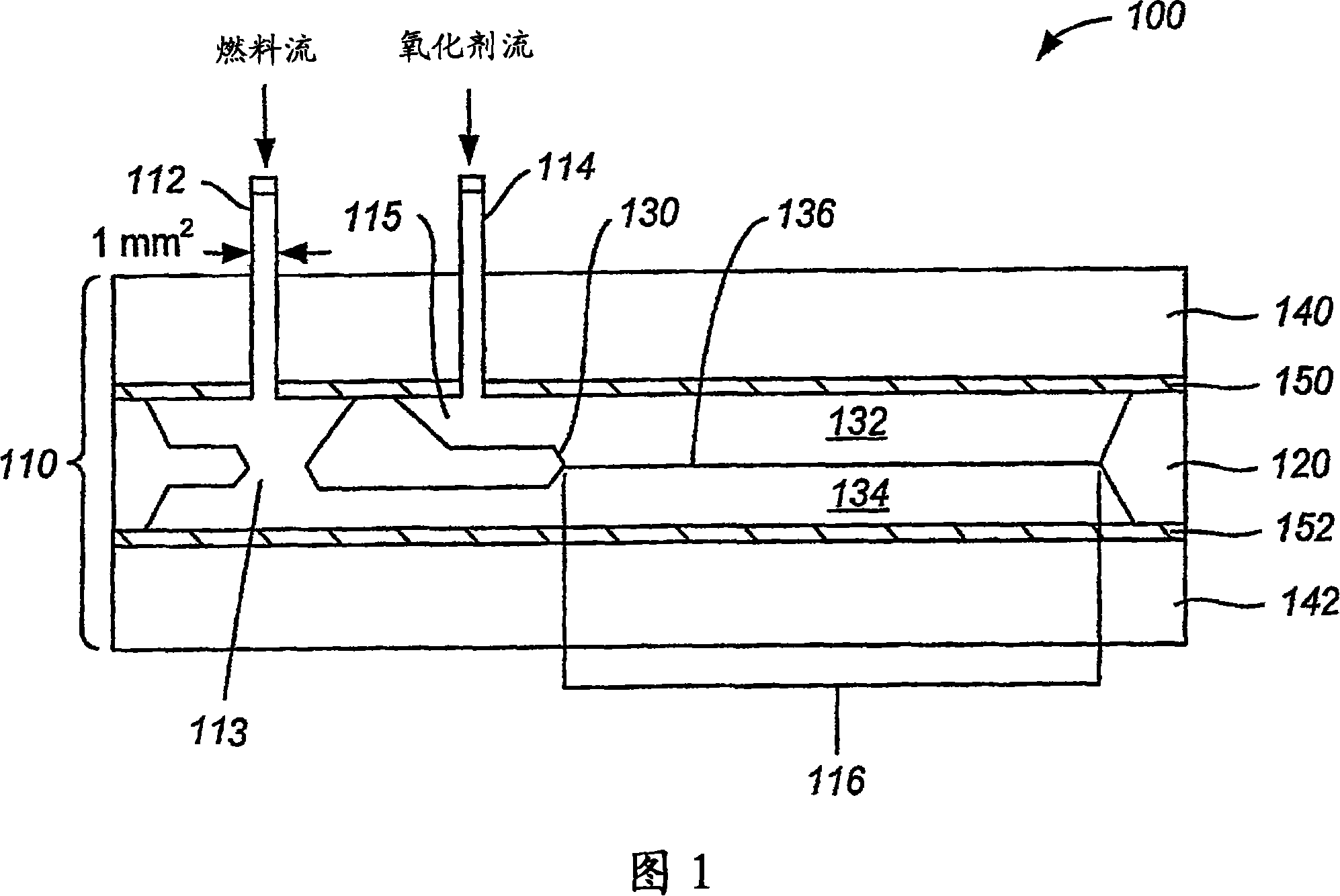

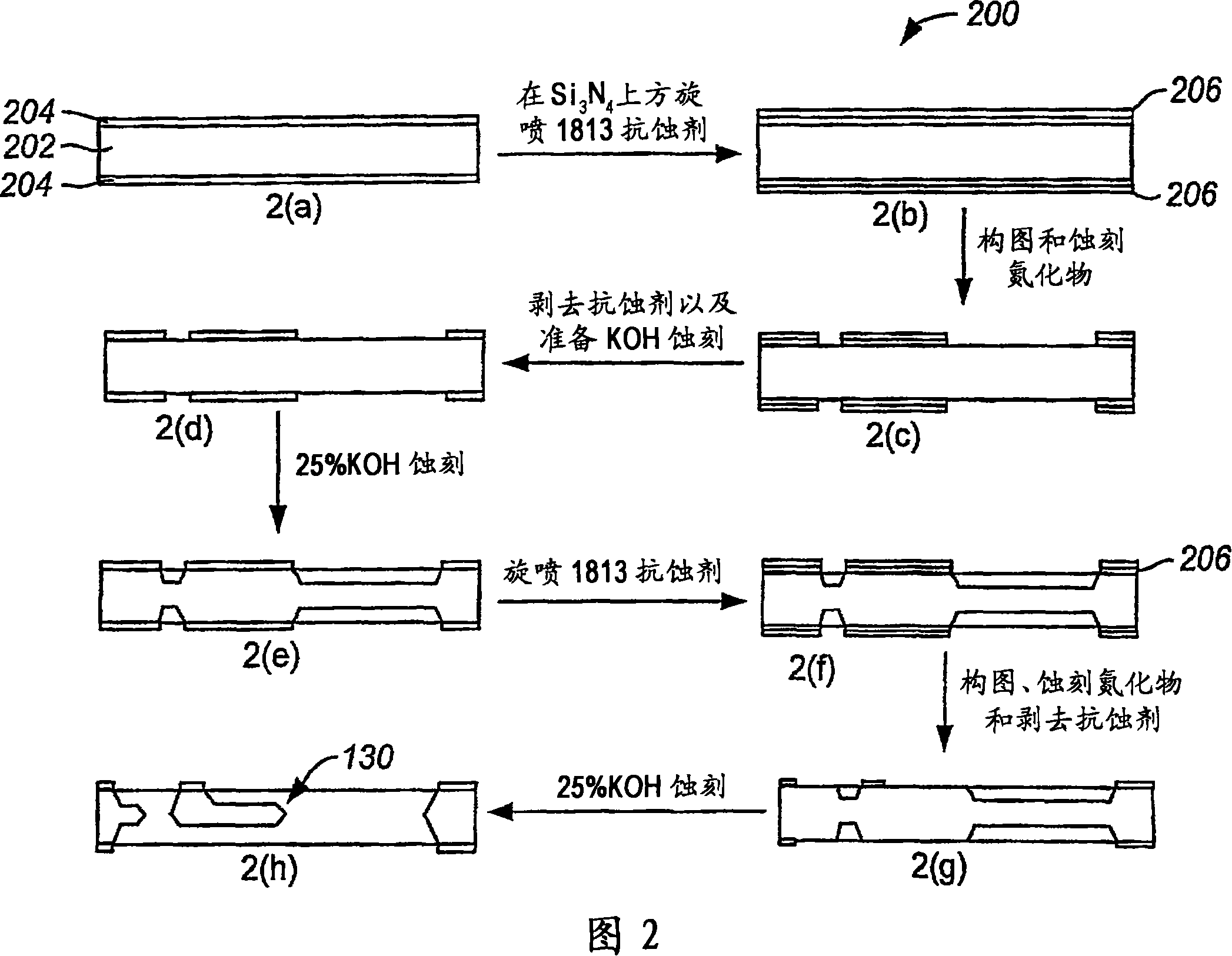

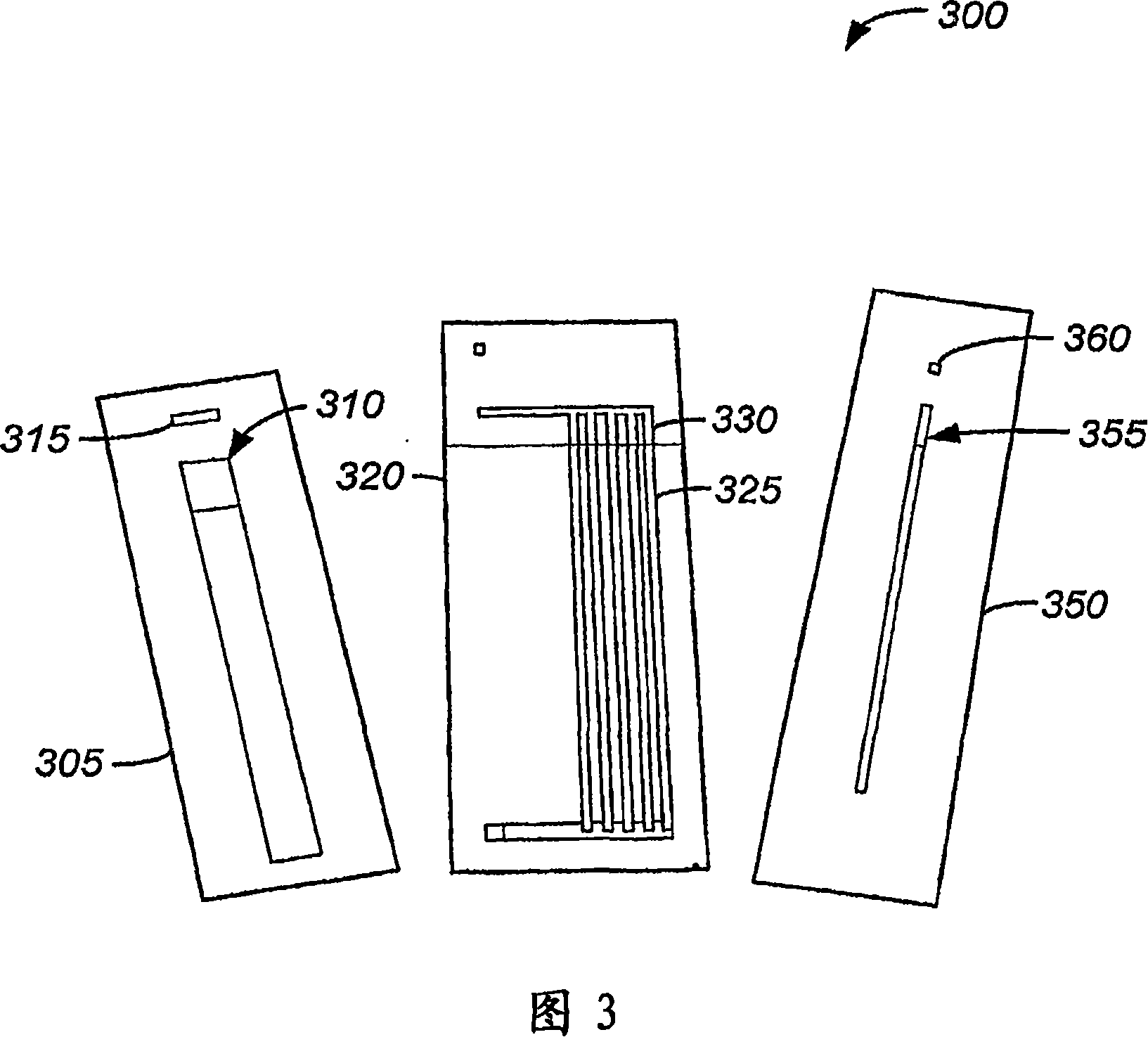

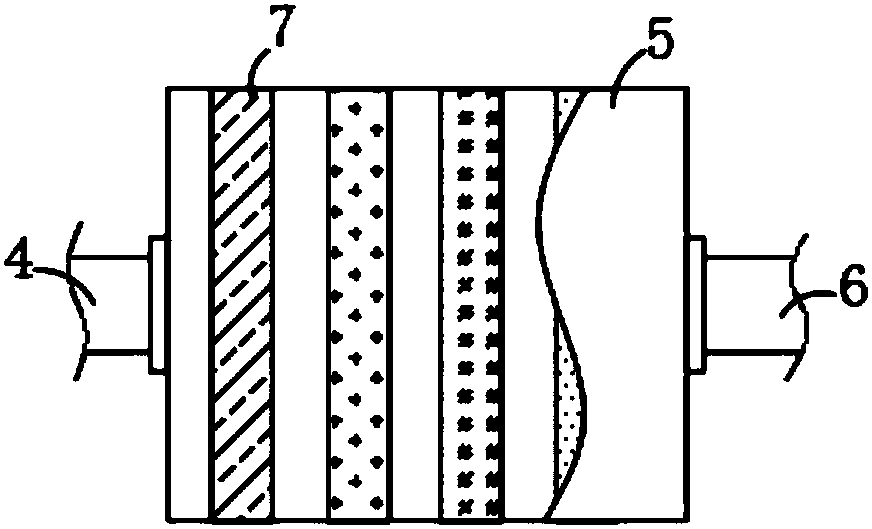

Planar membraneless microchannel fuel cell

InactiveCN101084364AChange thicknessChange flow rateElectrolyte holding meansFuel cell shape/formFlow cellEngineering

A microfluidic membraneless flow cell formed with multiple acidic / alkaline electrolyte solutions. The flow cell can be adapted to provide a dual electrolyte H2 / O2 fuel cell that generates thermodynamic potentials of up to 1.943 V or possibly greater. The selected fuel can be hydrogen dissolved in 0.1 M KOH, and the selected oxidant can be oxygen dissolved in 0.1 M H2SO4. Individual fuel cells can be combined to form fuel cell stacks to generate increased power output. Furthermore, microchannels of varying dimensions may be selected, including thickness variations, and different flow rates of acid / base electrolyte solutions can be applied to satisfy predetermined power generation needs. Some (micro-) fuel cell embodiments can be formed with silicon microchannels or fixed length and variable width and height, and can be used with hydrogen or formic acid as a fuel and oxygen as an oxidant, each dissolved in different acid / base electrolyte solutions. Micro-fuel cells are also provided which can be designed to generate different power levels for various applications including portable electronic devices such as wireless communication handsets and cellular telephones.

Owner:CORNELL RES FOUNDATION INC

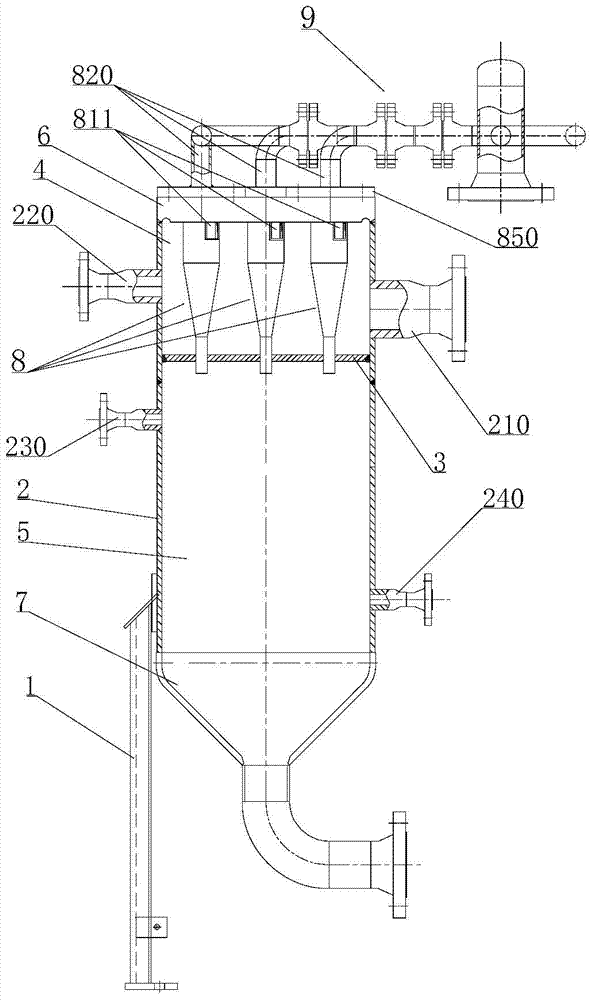

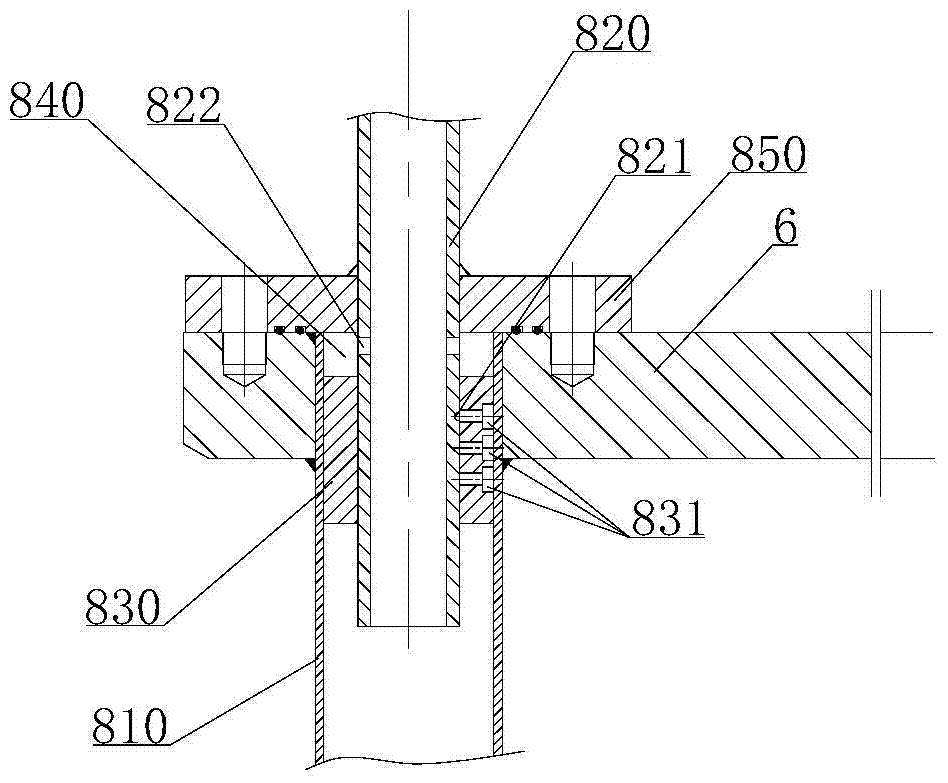

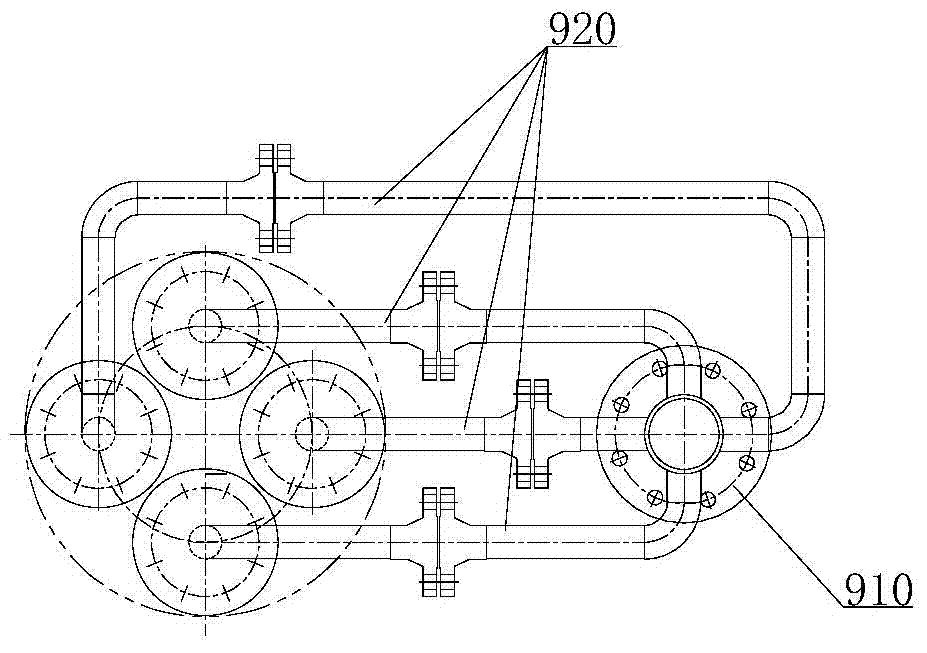

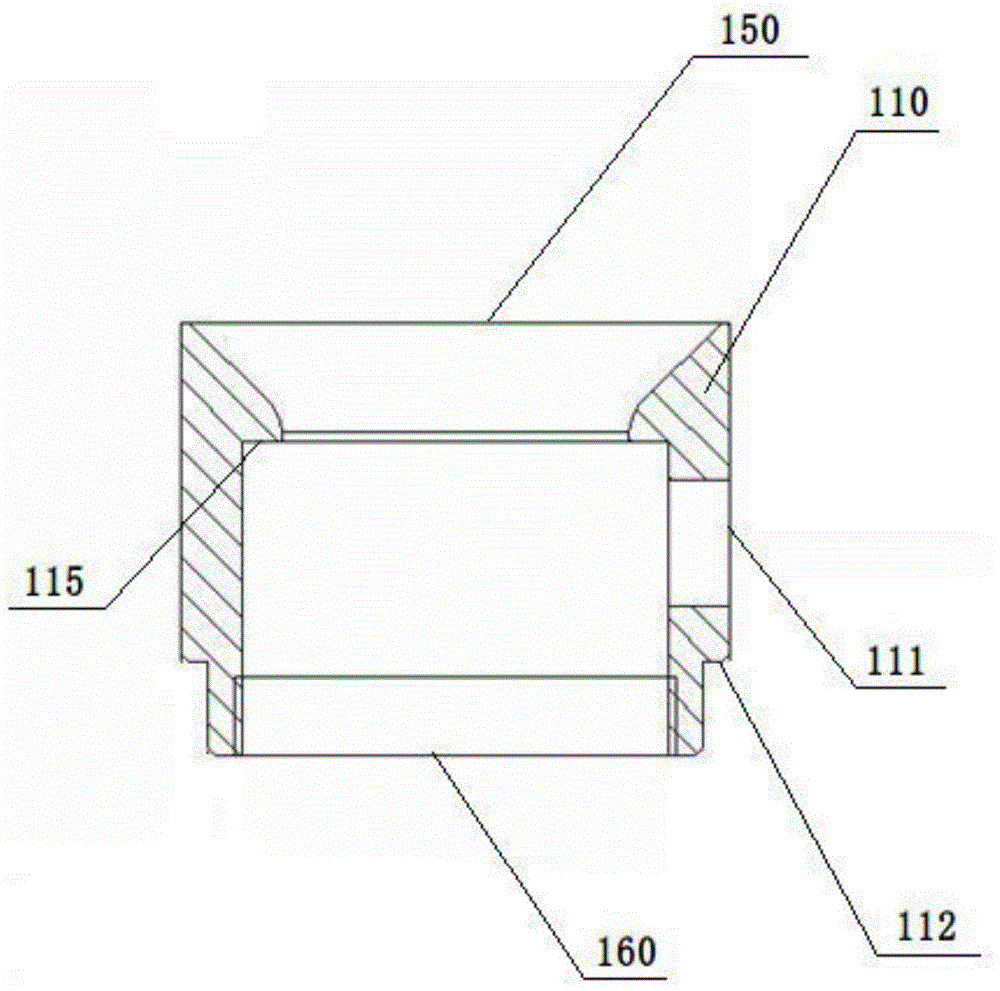

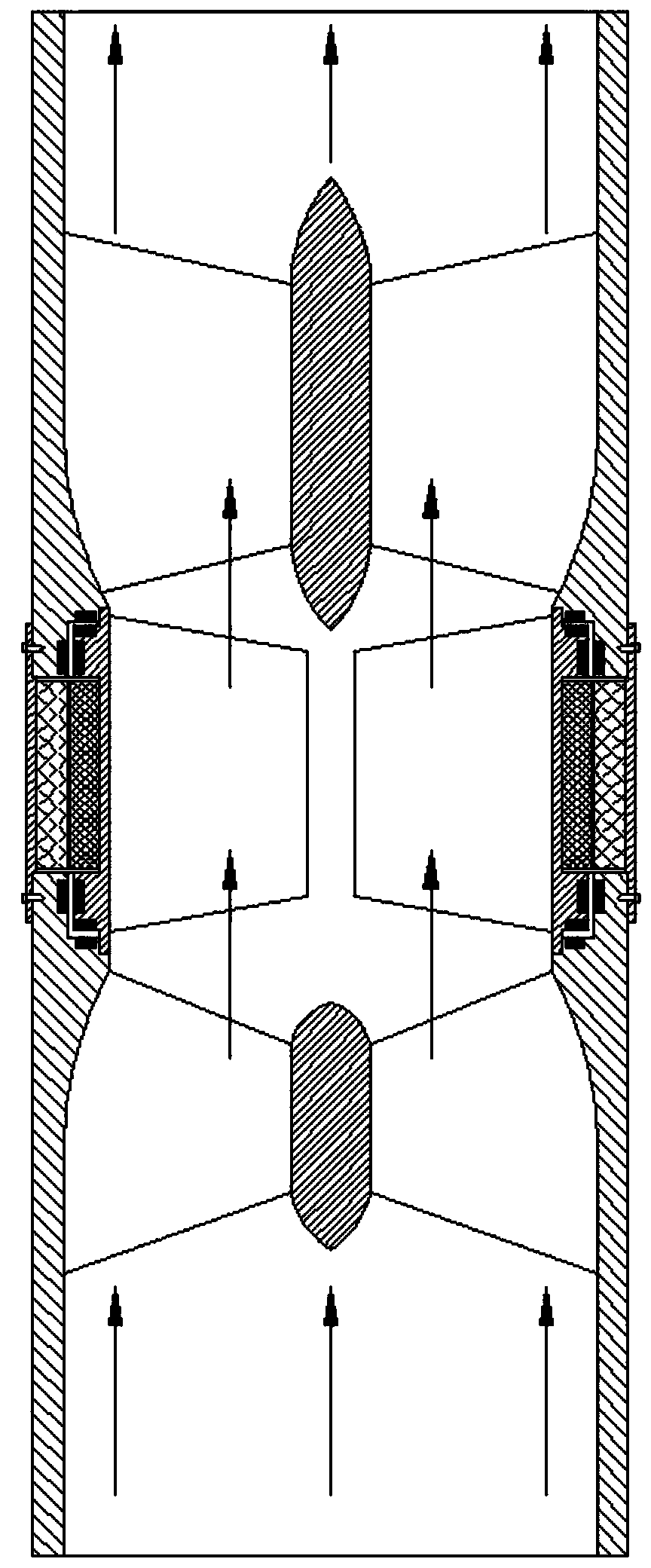

Multistage parallel hydrocyclone capable of regulating flow velocity

InactiveCN104492616AMeet the use requirementsChange up and down positionReversed direction vortexCycloneEngineering

The invention discloses a multistage parallel hydrocyclone capable of regulating flow velocity. The multistage parallel hydrocyclone comprises a rack body and a cyclone cylinder, wherein the inner cavity of the cylinder is divided into a solid-liquid separation cavity provided with a liquid inlet and a solid outlet cavity by virtue of a transverse separator; an upper end cover and a conical joint are respectively arranged at the upper and lower ends of the cyclone cylinder; the hydrocyclone also comprises multiple cyclones consisting of at least one cyclone cylinder provided with a longitudinal cutting seam, an overflow pipe and a packing bushing provided with multiple radial threaded holes; the upper end of the cyclone cylinder is fixedly inserted into the upper end cover, and the lower end of the cyclone cylinder penetrates through the transverse separator; the overflow pipe is inserted into the cyclone cylinder, an annular cavity is formed between the overflow pipe and the cyclone cylinder, a flange plate which is fixedly connected with the upper end cover in a detachable manner is fixedly arranged on the overflow pipe, and a positioning hole is formed in the outer side surface of the flange plate; the packing bushing is arranged in the annular cavity and is fixedly connected with the overflow pipe by virtue of a screw; the hydrocyclone further comprises a manifold structure consisting of a total joint and multiple pipelines. According to the hydrocyclone, different liquid production capacity conditions are met by virtue of the number of the started cyclones, and the flow velocity of the oil-gas mixed solution entering the cyclone cylinder is changed by changing the vertical position of the packing bushing, so that a good solid-liquid separation effect is achieved.

Owner:E TECH ENERGY TECH DEV CORP

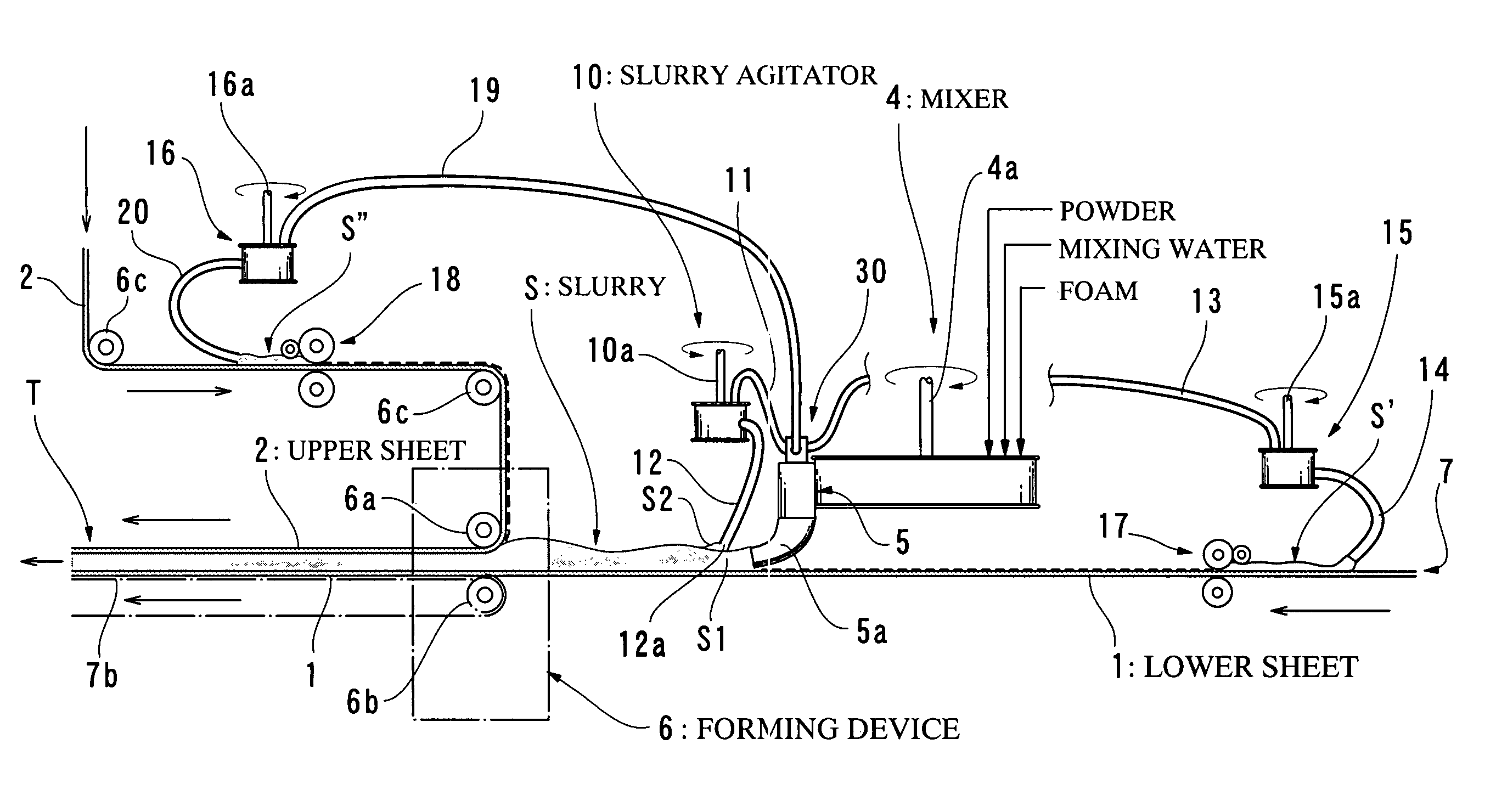

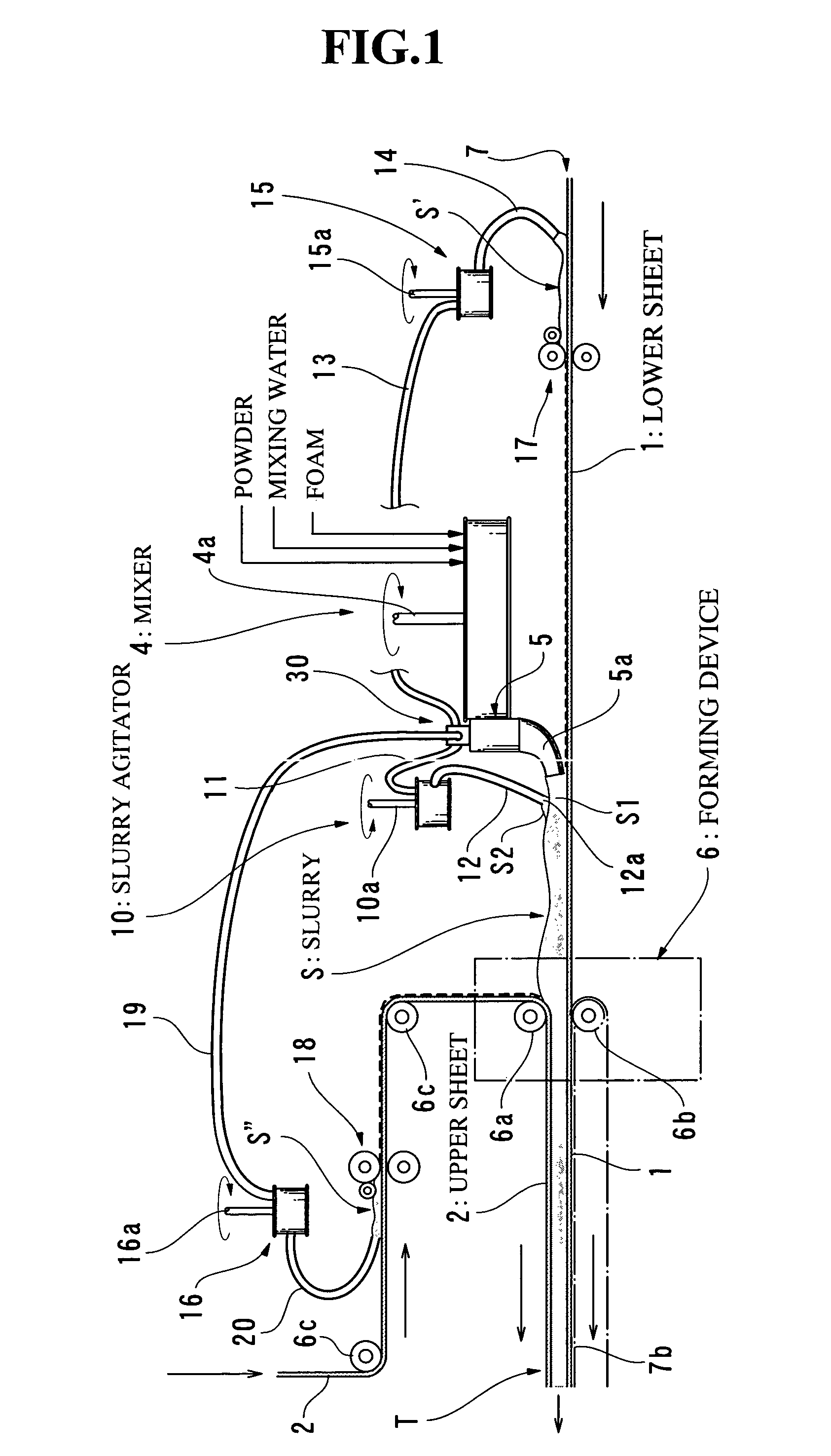

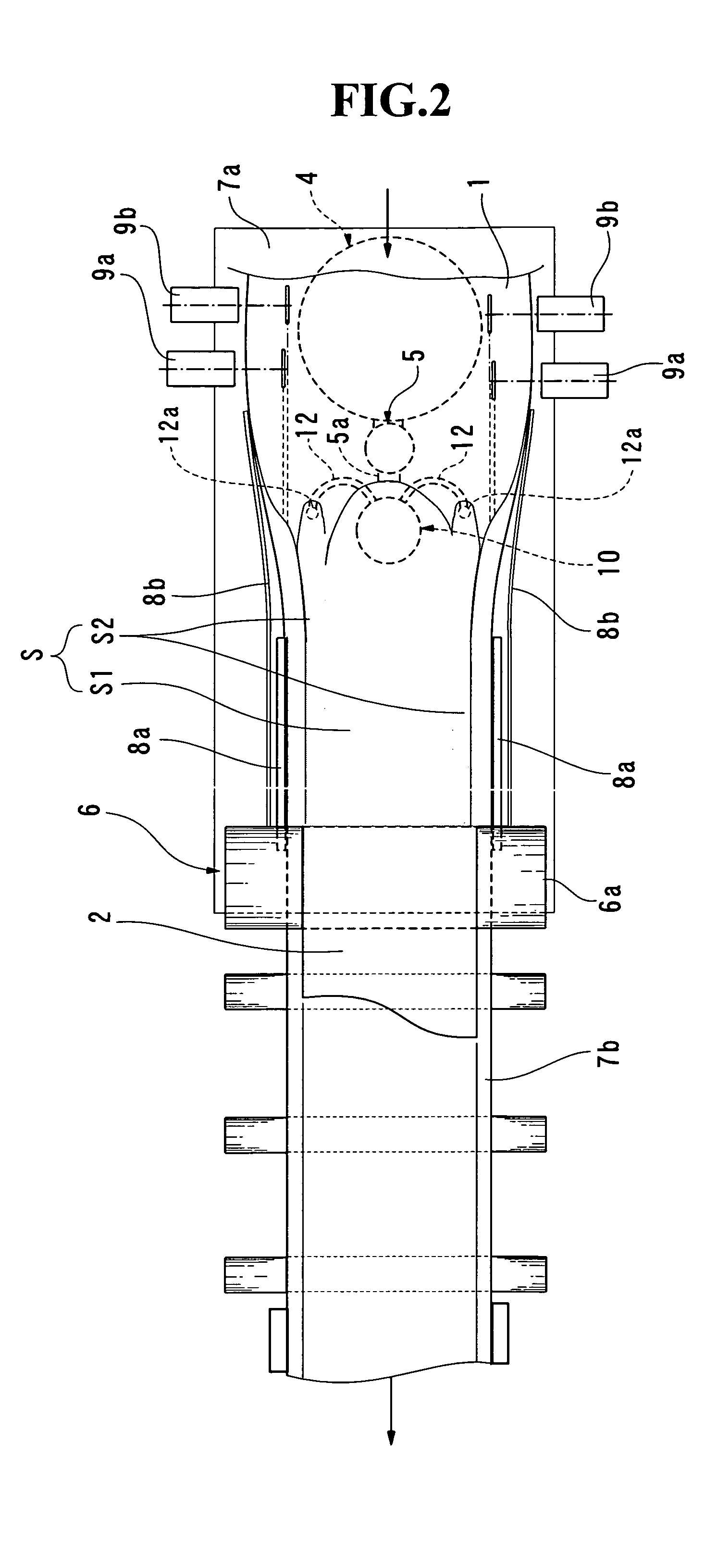

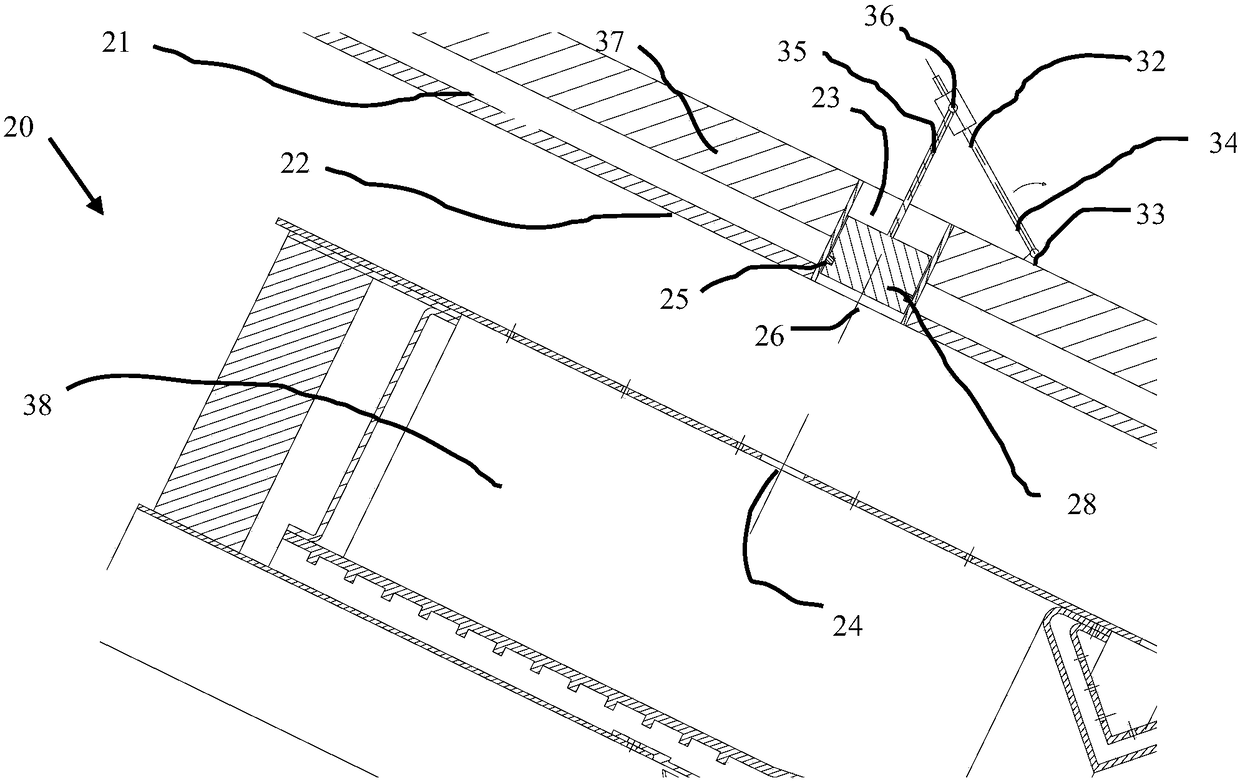

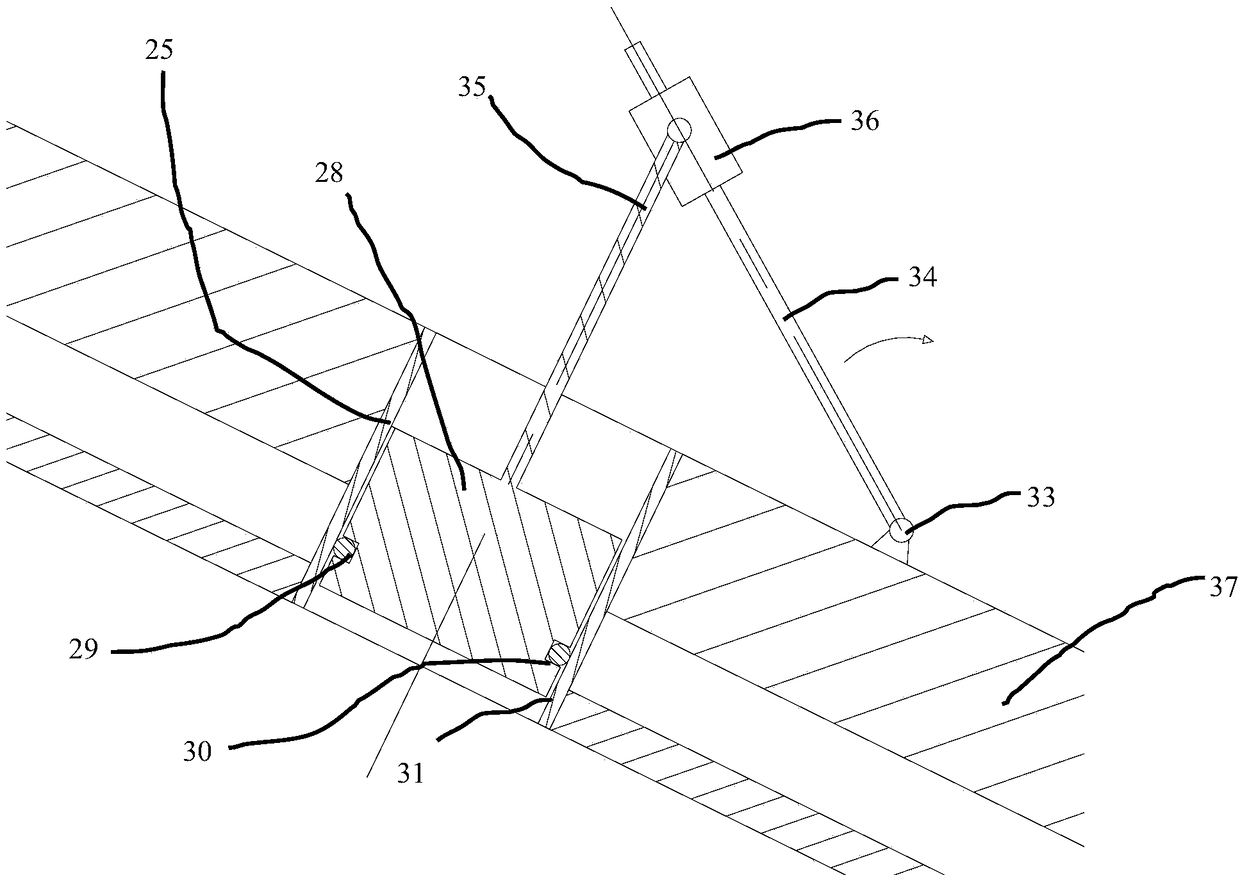

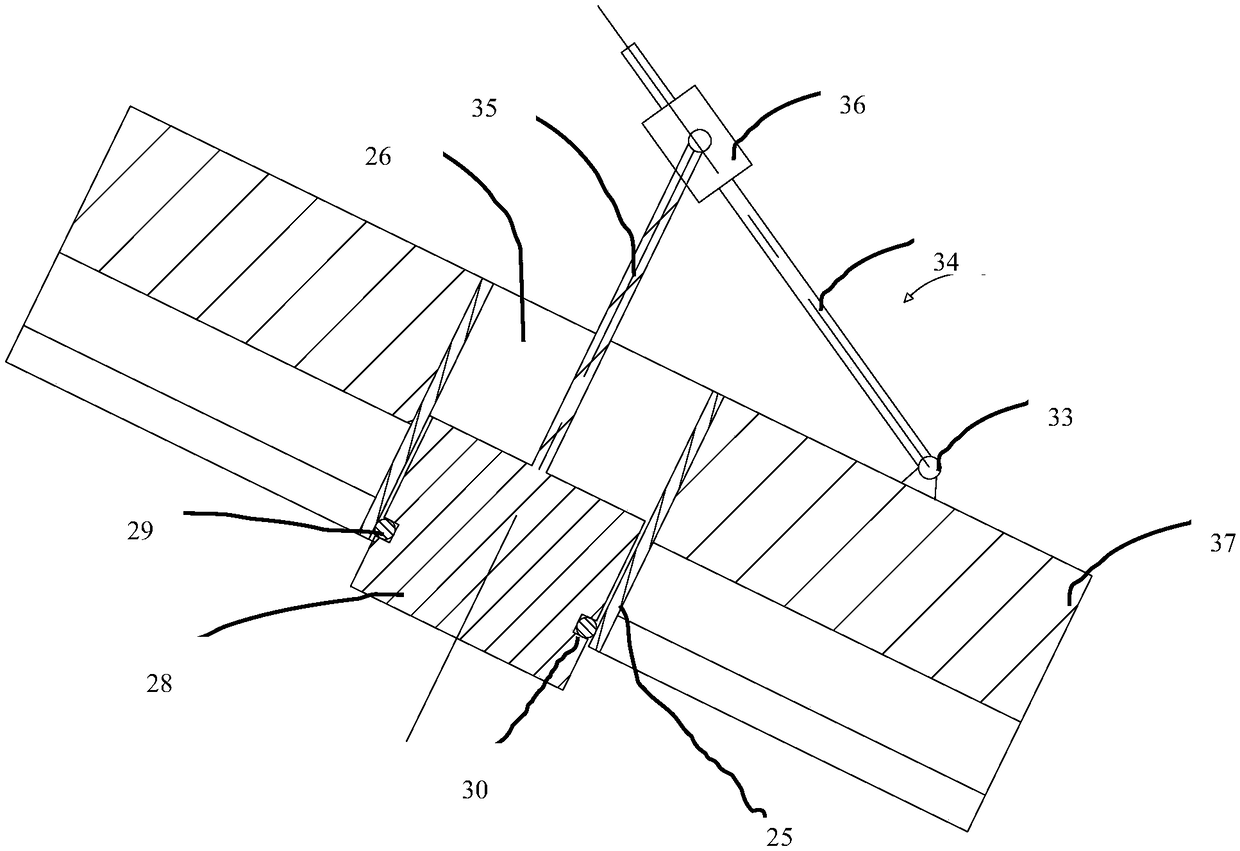

Apparatus and method for fractionating gypsum slurry and method of producing gypsum board

ActiveUS8685188B2Reduce consumptionChange flow rateDischarging apparatusPretreated surfacesFoaming agentFractionation

The present invention provides an apparatus and a method for fractionating gypsum slurry which can surely control the density of the gypsum slurry fractionated from the mixer (fractionated slurry), which can restrict change of the flow rate of the fractionated slurry, and which can reduce the consumption of foam or foaming agent. The fractionation apparatus (30) fractionates the gypsum slurry from a mixer (4) for mixing calcined gypsum and water. The mixer has a hollow connector section (50), which allows the gypsum slurry to flow from a mixing area inside of the mixer into a chute section (5), and the chute section (5) discharging the inflow of gypsum slurry through its slurry discharge port onto a gypsum board liner paper. The fractionation apparatus has a slurry fractionation port (33) opening to the chute section or the hollow connector section, and causes a part of the gypsum slurry in the chute or hollow connector section to be delivered to a slurry delivery conduit (11,13,19).

Owner:YOSHINO GYPSUM CO LTD

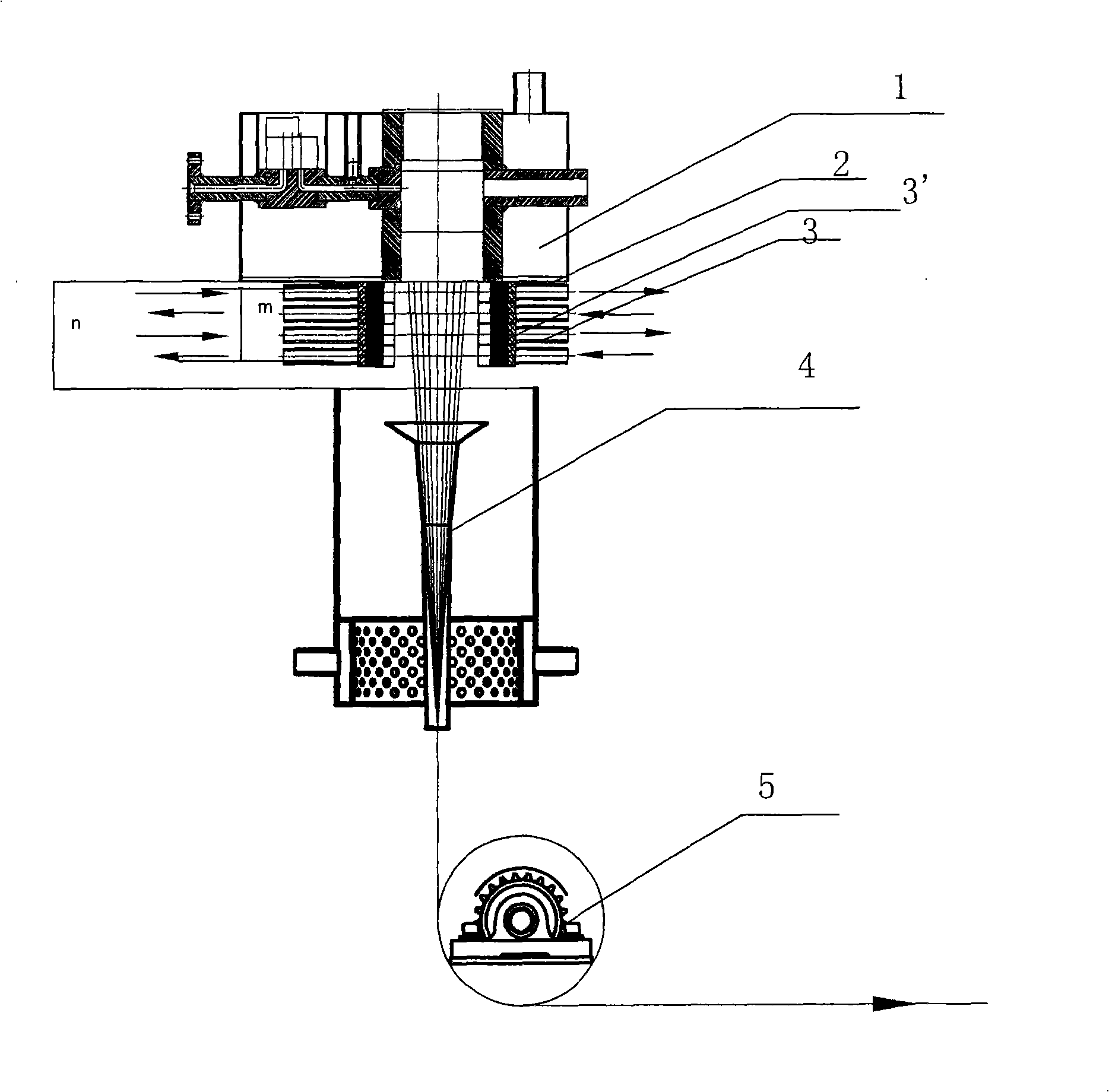

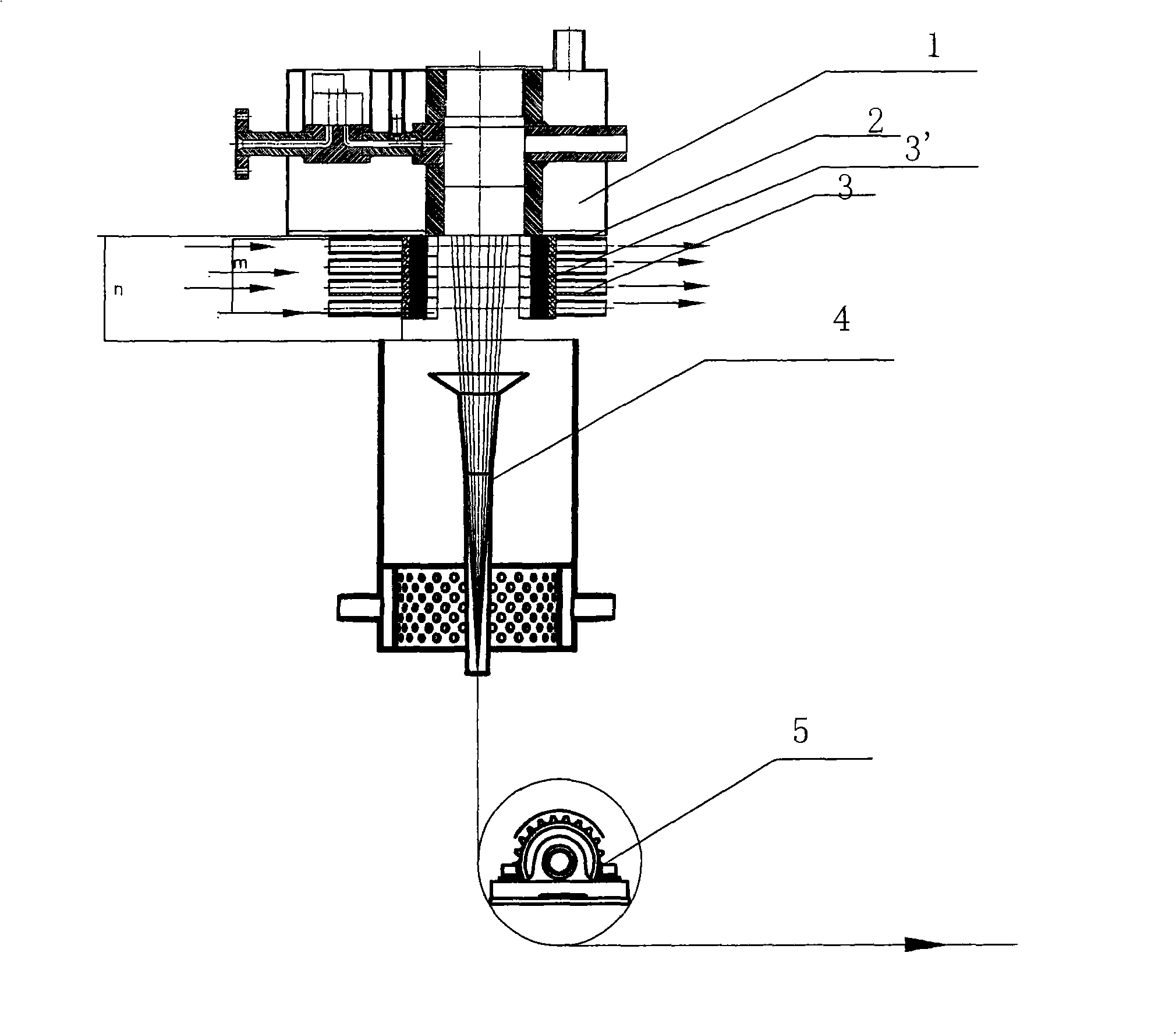

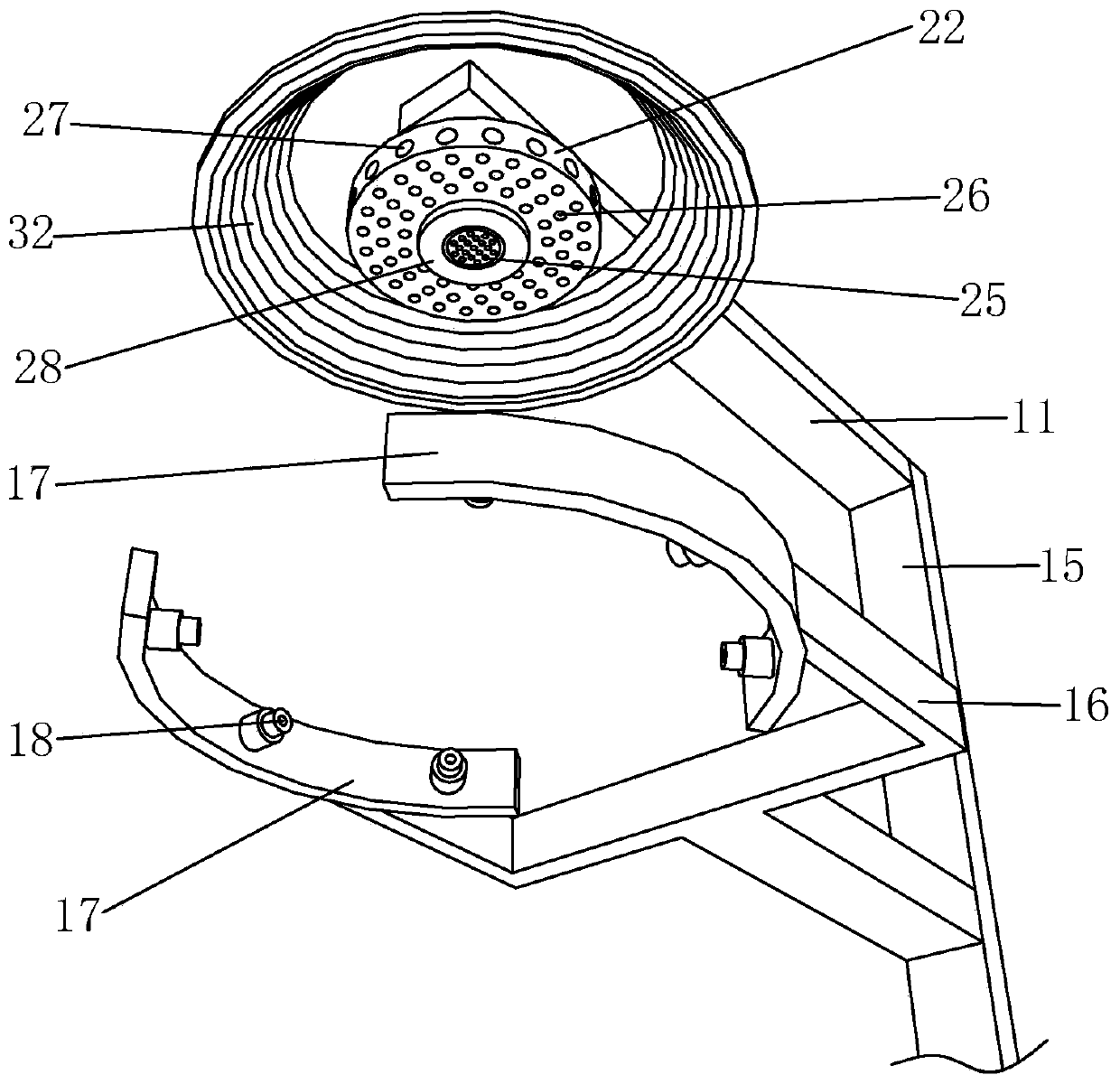

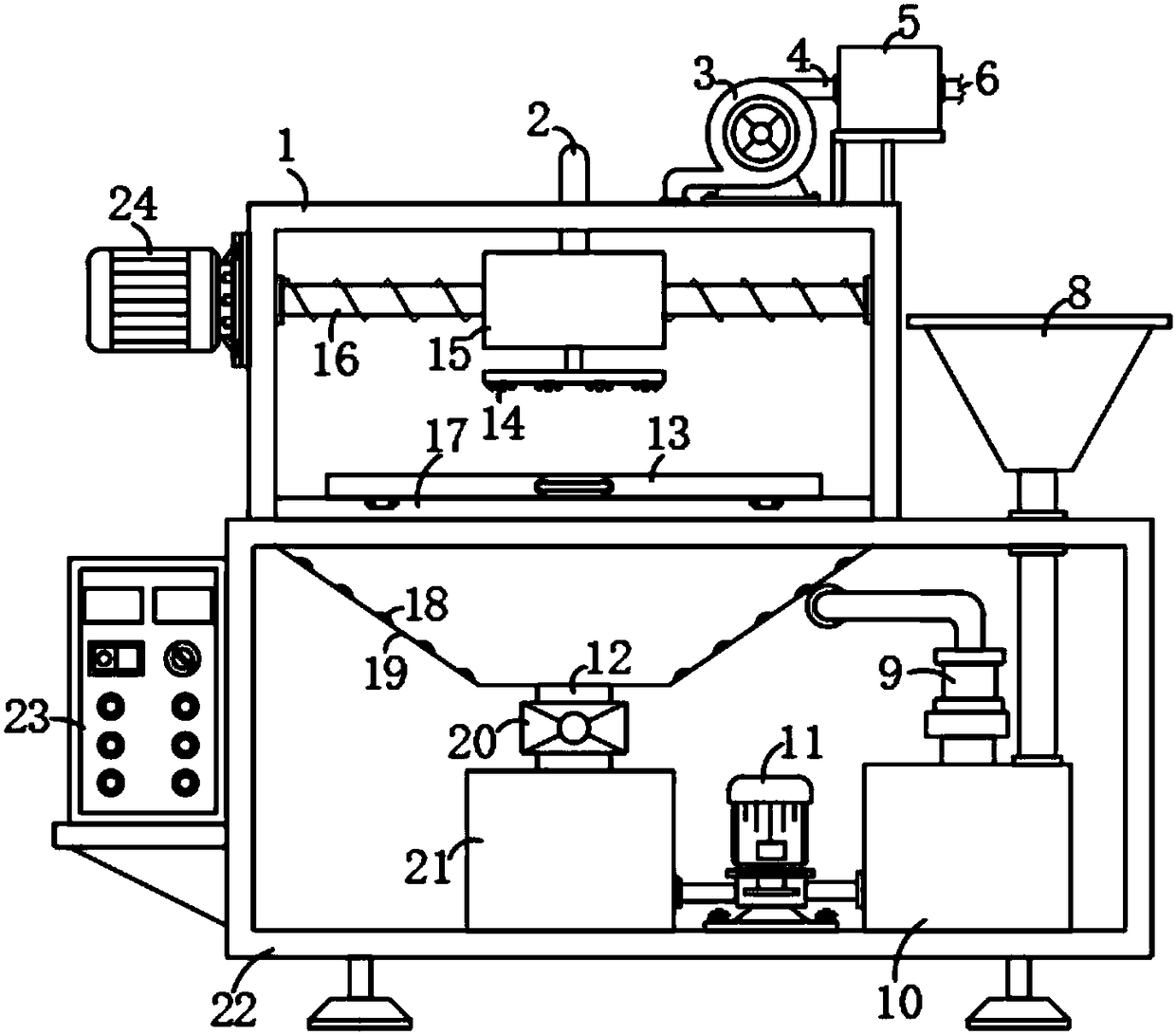

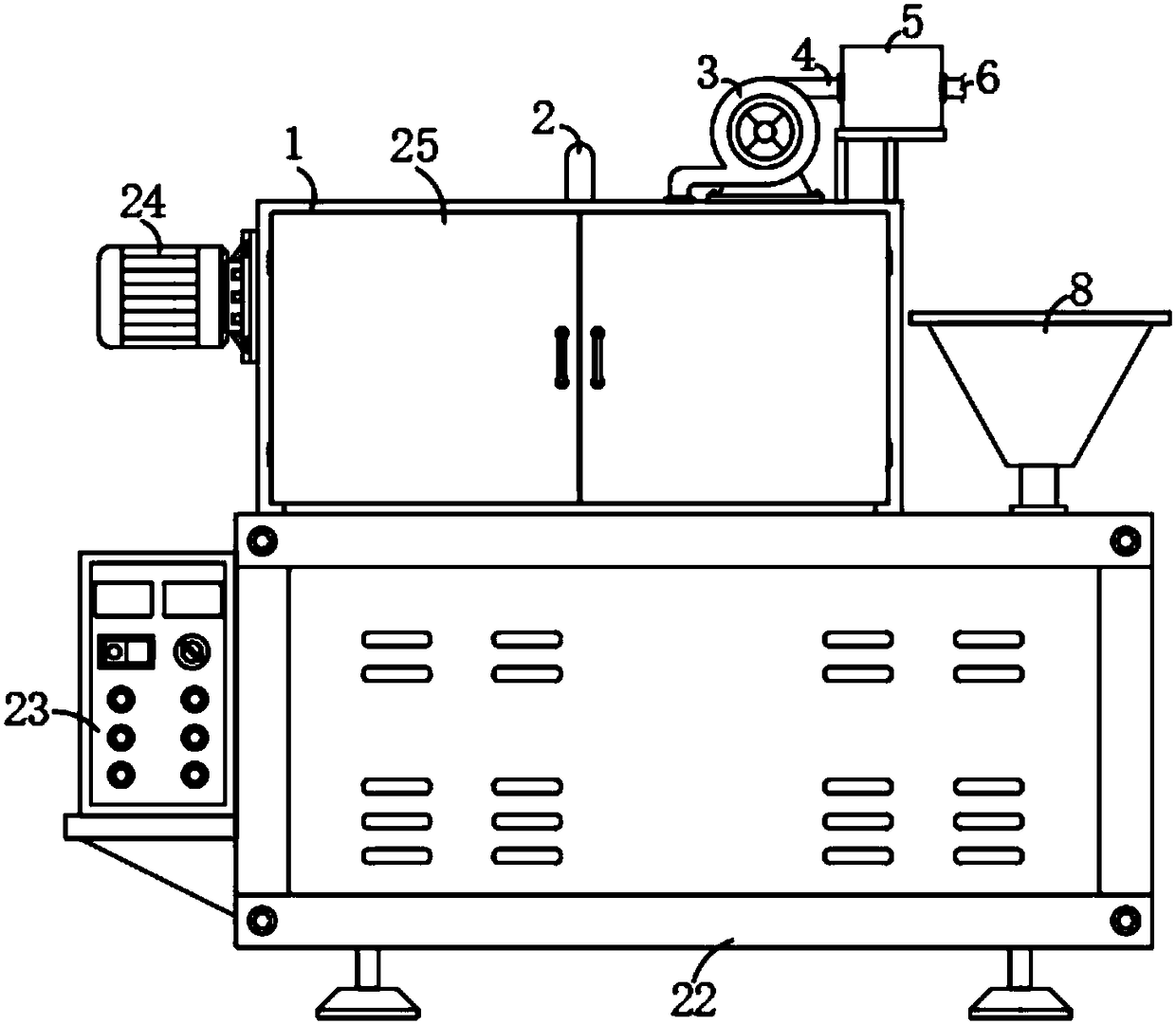

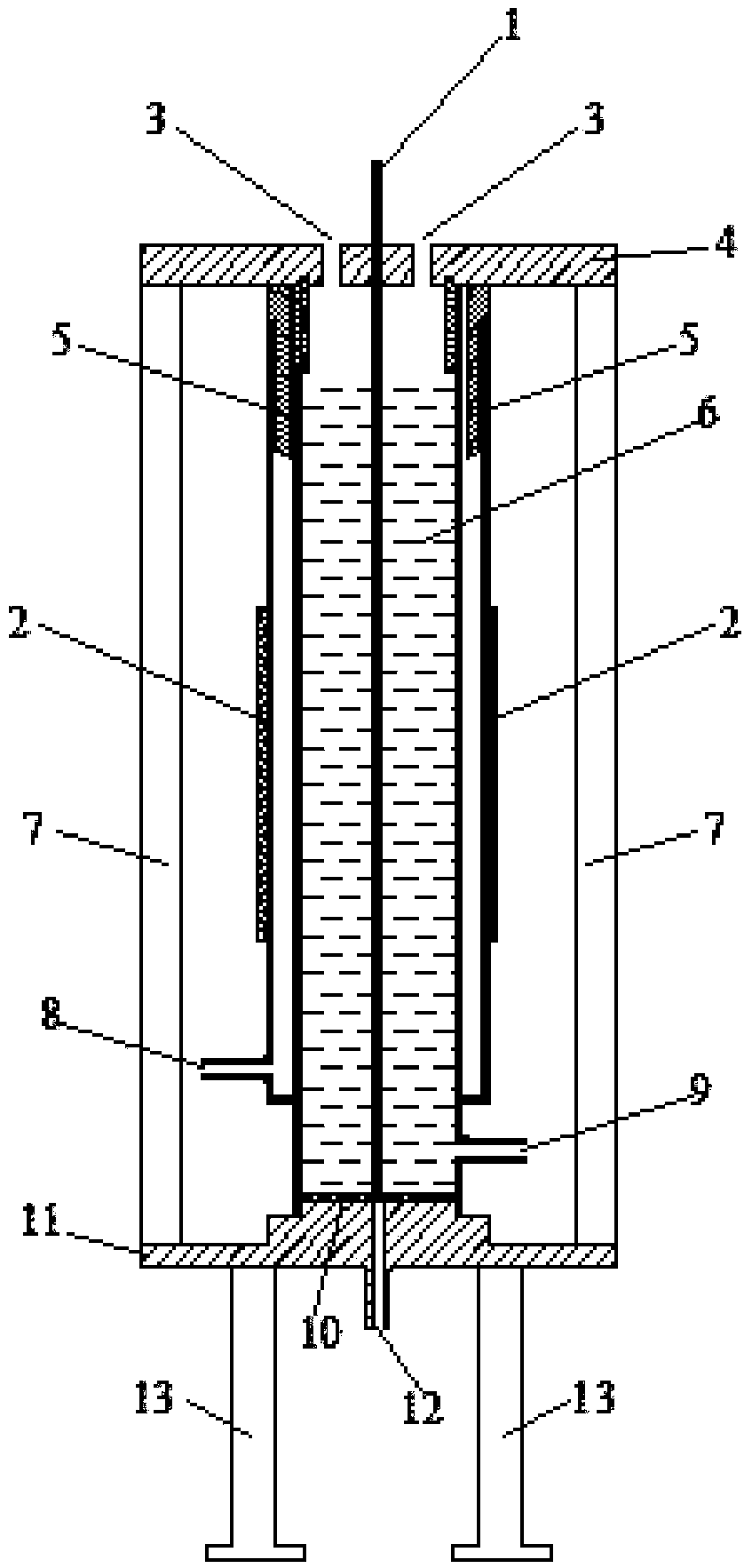

Spinning process of cellulose fibre and integration apparatus

ActiveCN101289762ACool evenlyChange flow rateSpinnerette packsArtificial filament physical treatmentOrganic solventCellulose fiber

The invention relates to a method for spinning cellulose fibers, comprising the following steps that: cellulose and organic solvent are mixed and dissolved, and mixture is obtained; the mixture enters into a section of air gap layer via a spinneret and ejected tows are blown and sucked by cooling air; the tows is brought into a precipitating bath via precipitating solution and led out by a spinning reel under the guidance of hauling equipment, wherein, the tows are blown and sucked by the cooling air by means of multi-layered laminar flow wind and the outlet velocity of the precipitating bath is between 20 and 150 meters per minute. The invention also relates to a device for completing the spinning method. By adoption of the spinning method and the spinning device, cellulose filaments or staple fibers obtained finally have uniform strength and elongation amount and the effect is also suitable for fibers with high or low size as well.

Owner:CHINESE TEXTILE ACAD

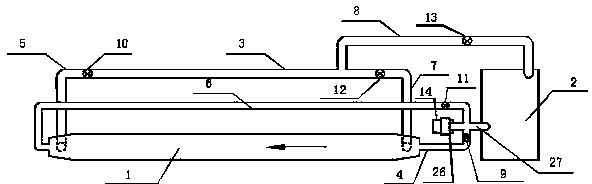

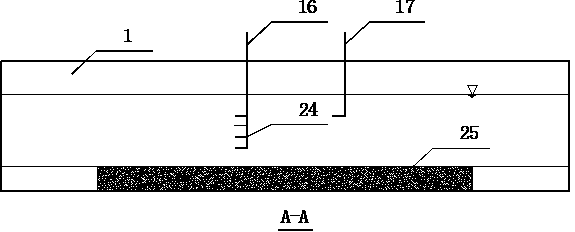

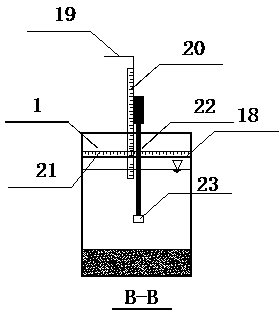

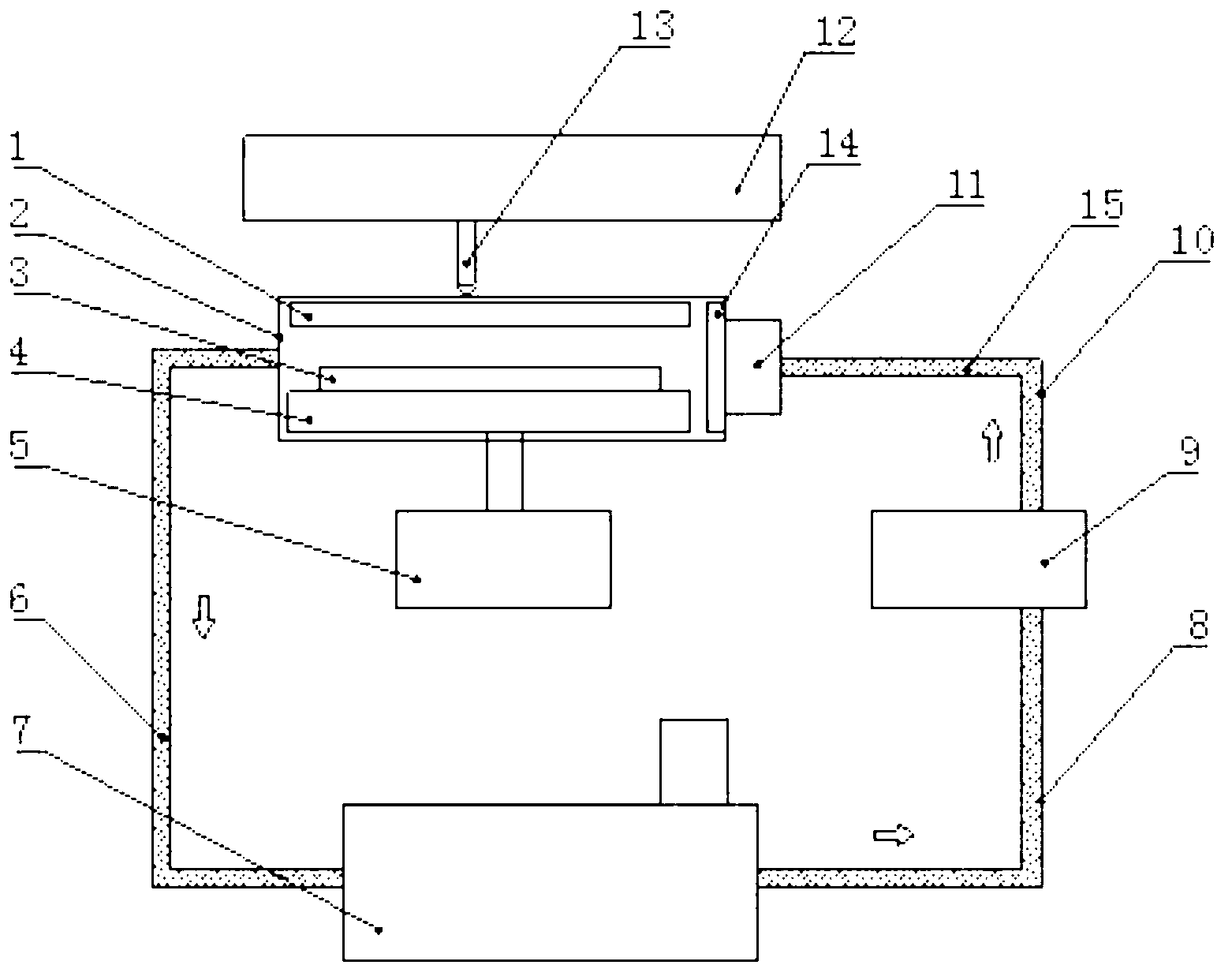

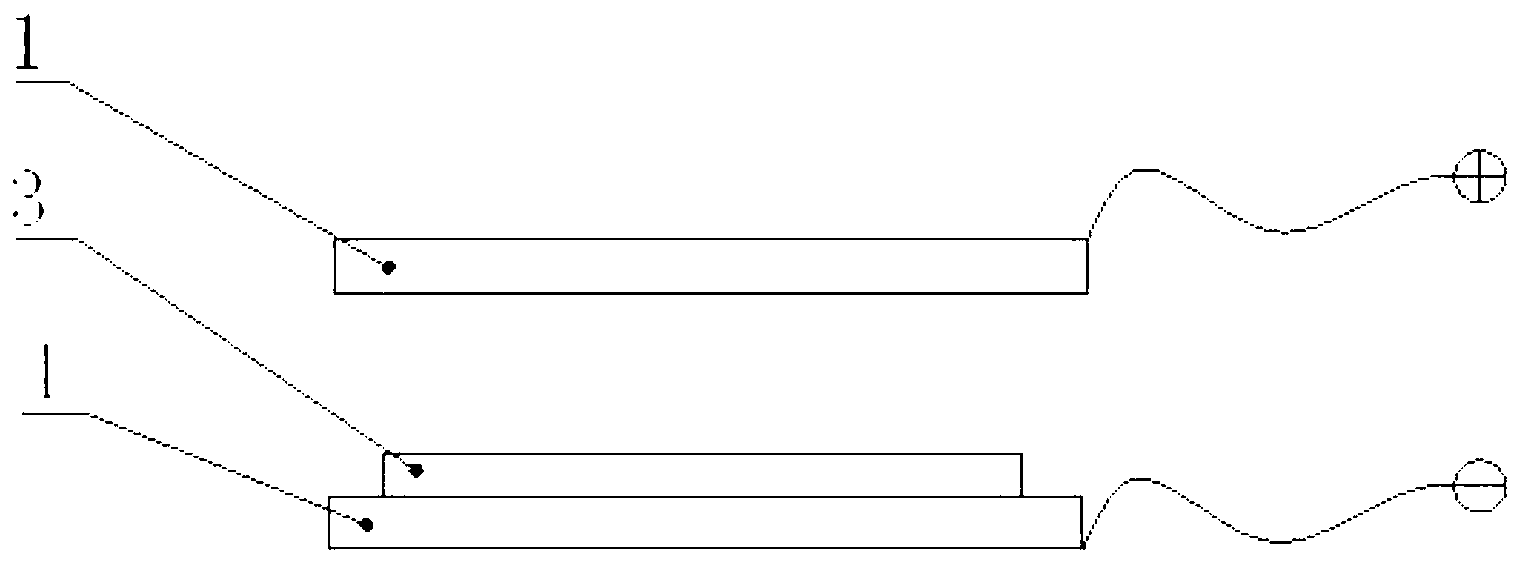

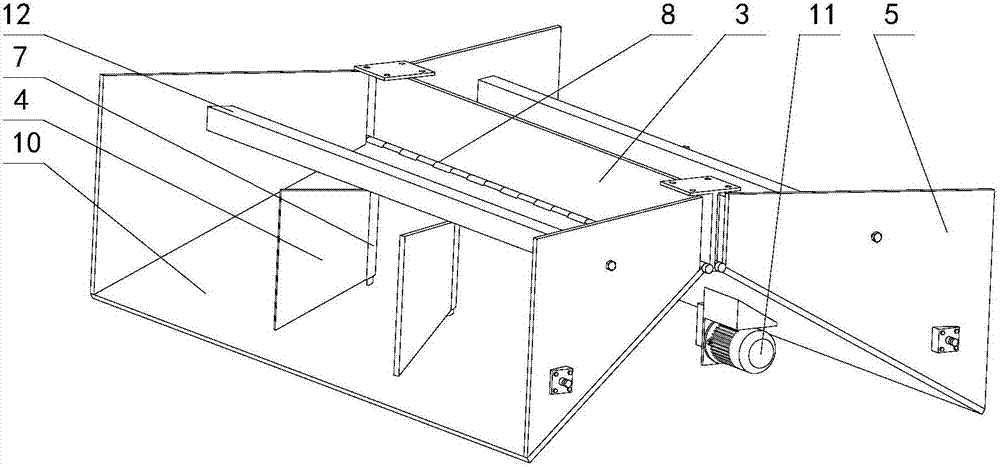

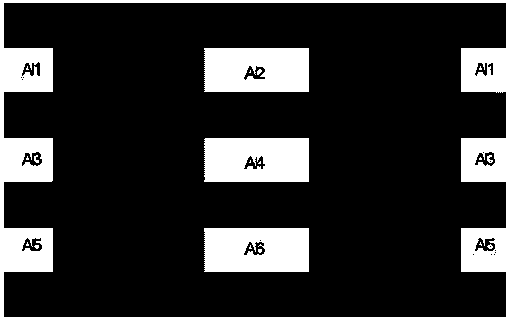

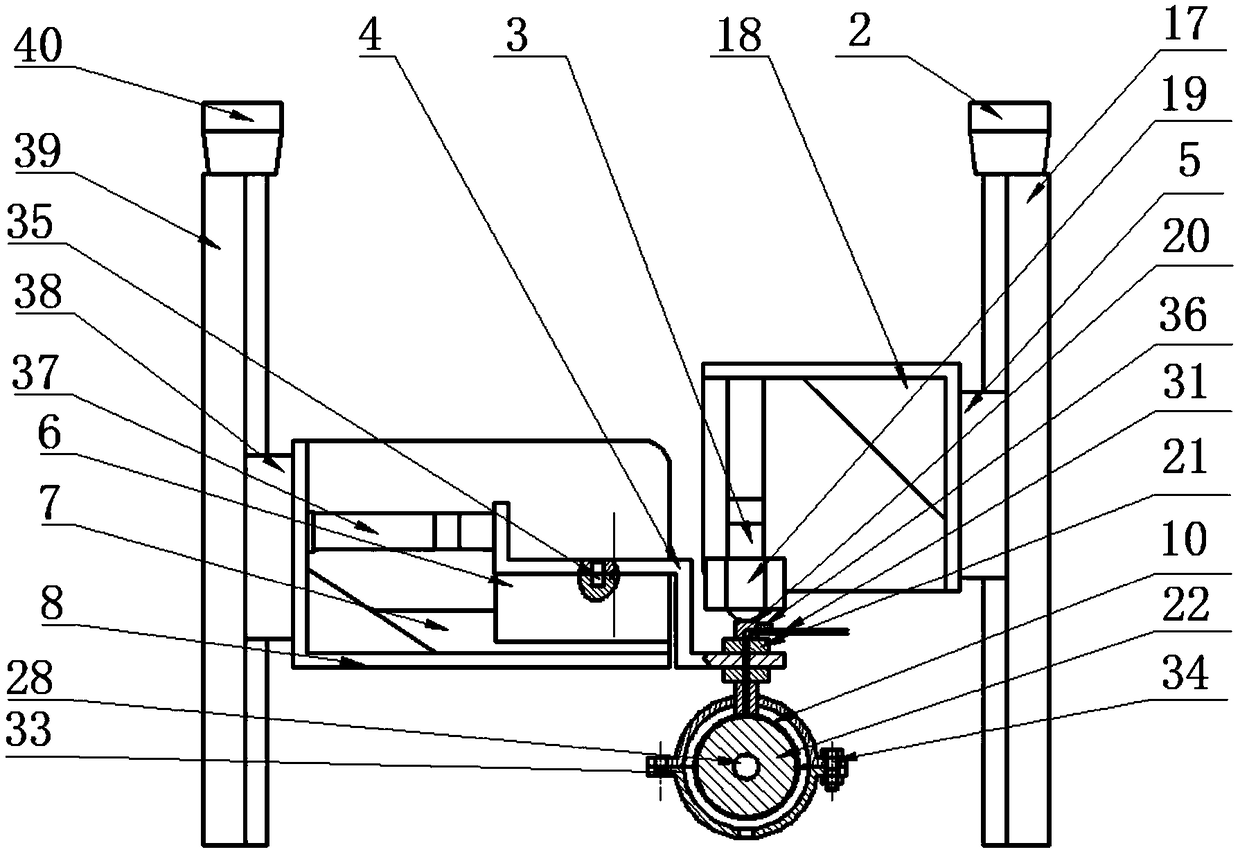

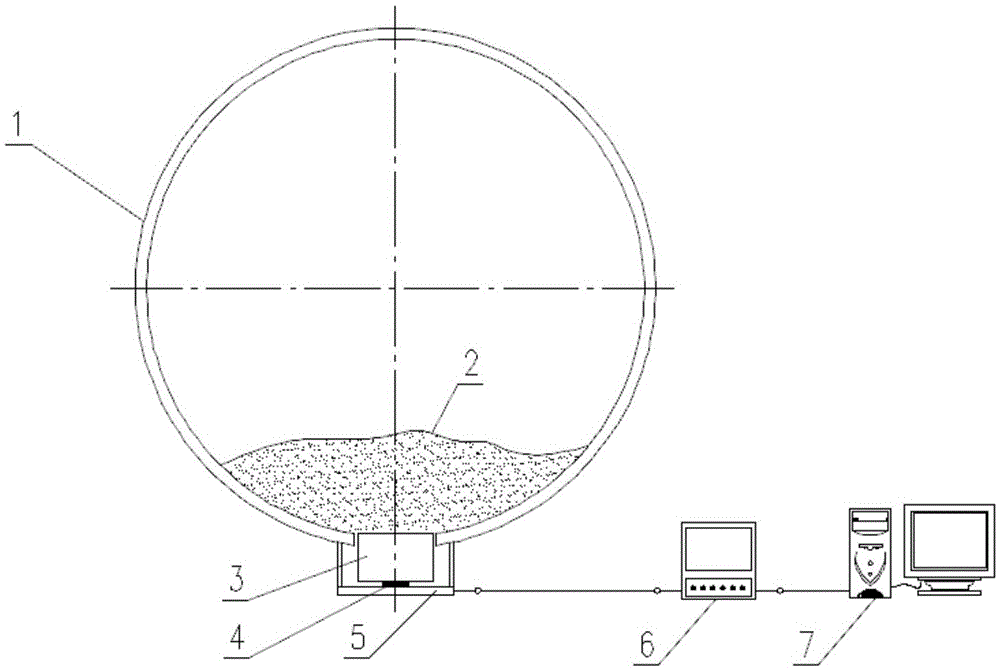

Straight circulation water tank device for simulating resuspension of sediment under action of reversing currents

InactiveCN104075872ASampling is convenientConvenient flow conditionsHydrodynamic testingReverse currentPollutant

The invention relates to a straight circulation water tank device for simulating resuspension of bottom mud sediment under the action of reversing currents. The straight circulation water tank device comprises a long and straight water tank, a bidirectional water supplying and discharging pipeline system, a water current power and control device and a flowing speed measuring and sampling device, wherein the long and straight water tank is connected with the water current power and control device through the bidirectional water supplying and discharging pipeline system, and the flowing speed measuring and sampling device is fixedly installed on the edge of the wall of the long and straight water tank, the water current power and control device provides power for water currents and controls the flowing speed and the flowing direction, the reversing currents are provided for the long and straight water tank through the bidirectional water supplying and discharging pipeline system, and thus resuspension of the sediment is achieved. The straight circulation water tank device has the advantages that the ups and downs and the resuspension of bottom mud under the action of the tide reversing currents in tidal reach can be simulated truly, and water samples at different depths can be collected under a certain hydraulic condition. The straight circulation water tank device is suitable for studying of quantitative relation among water, sediment and pollutants and is an effective device for studying the resuspension release effect of bottom mud pollutants in a river mouth area.

Owner:SHANGHAI UNIV

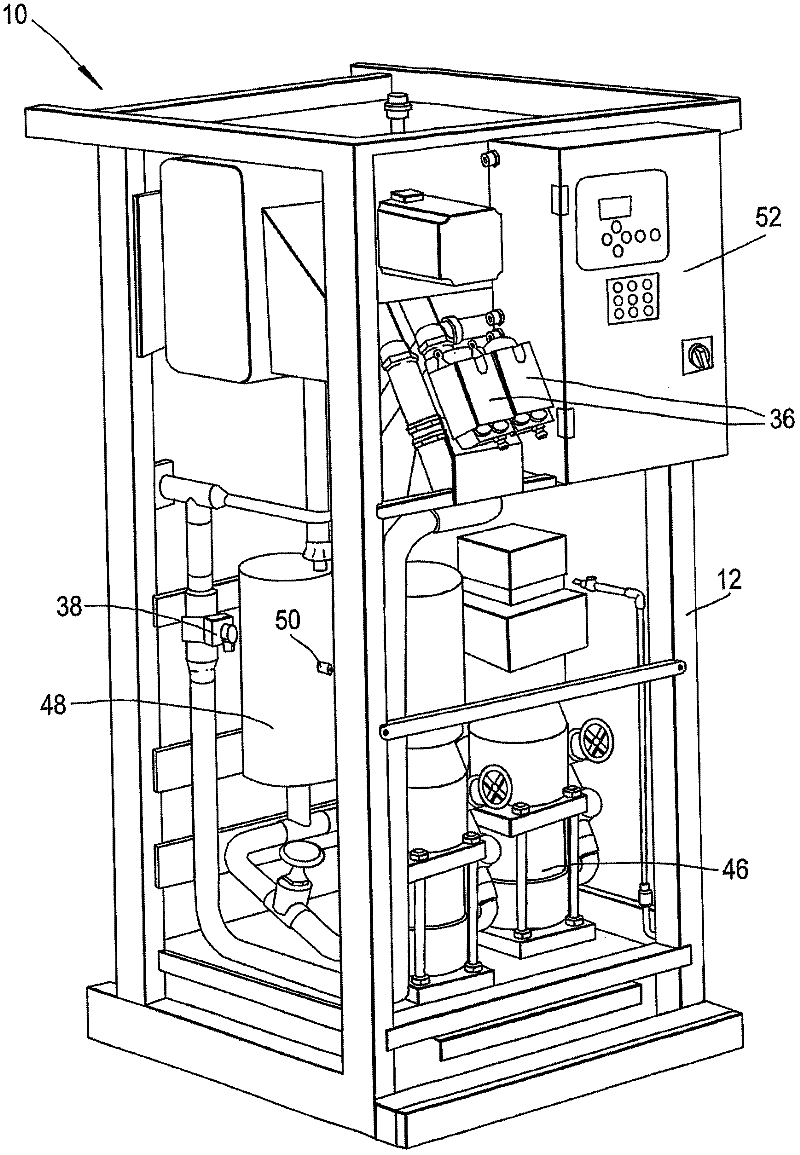

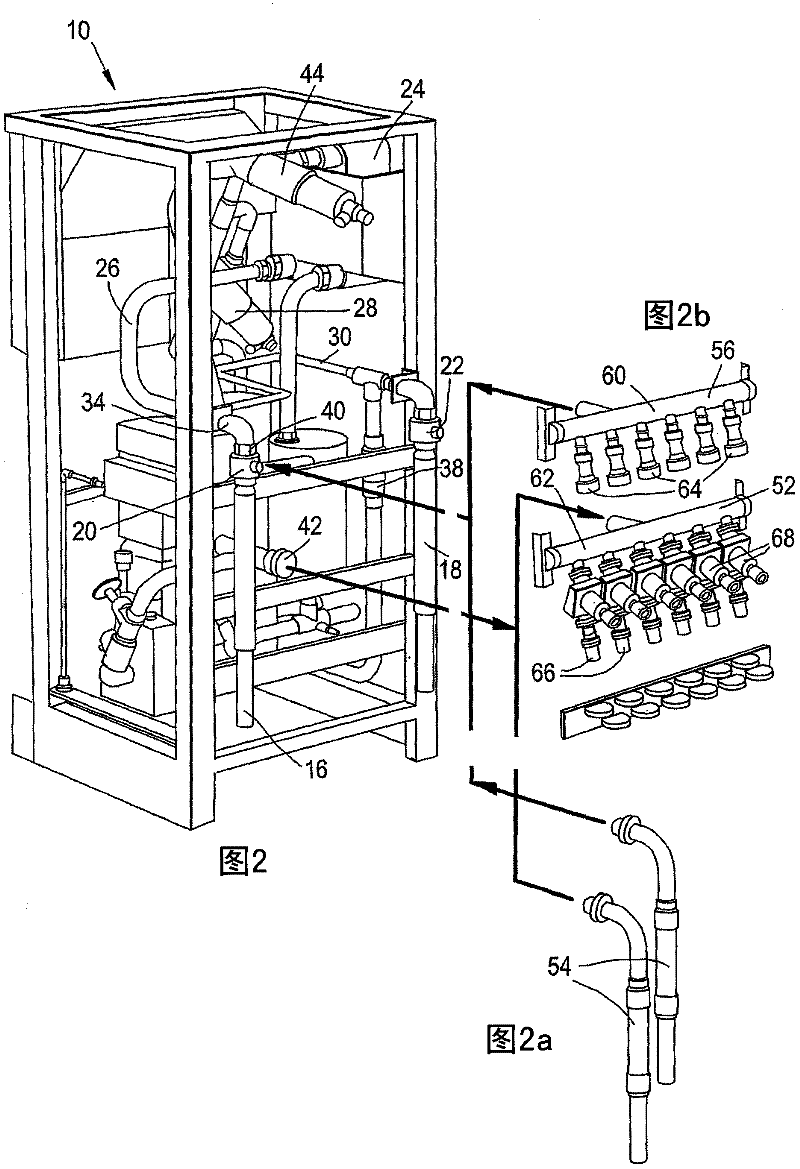

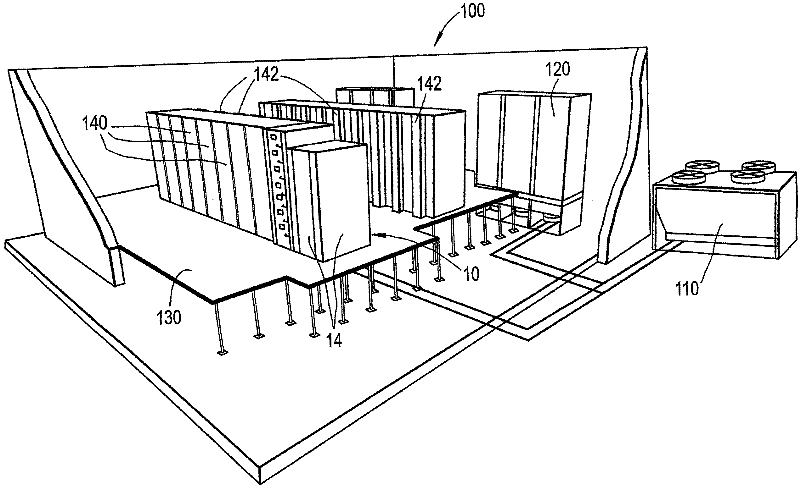

Cooling unit

ActiveCN102449407AControl flow rateReduce the possibility of condensationMechanical apparatusSpace heating and ventilation safety systemsData centerEngineering

A cooling unit (10) comprising a first passageway (26) through which coolant fluid is pumped when the unit is in use, and a second passageway (43) through which coolant fluid is pumped when the unit is in use. Portions of the first and second passageways are thermally coupled to one another so as to constitute a heat exchanger (24). The coolant fluid which passes through the said second passageway (43) when the unit is in use is passed to at least one heat exchanger (142) associated with heat- generating electronic equipment or other equipment which is to be cooled. The unit (10) is provided with a temperature and humidity sensor or sensors (260 and 262) connected to a control processor (52) of the unit (10) and located in the space (100) occupied by such equipment when the unit (10) is in use to enable the control processor (52) to determine the ambient dew point of that space (100). The control processor (52) is connected to control operation of the unit (10) in dependence upon that ambient dew point. The unit (10) further comprises a variable control valve (36) or a variable pump in the said first passageway (26) connected to the control processor (52) to enable the latter to control operation of the unit in dependence upon the said ambient dew point. It does this by adjusting the variable control valve (36) or variable pump in the said first passageway (26) to alter the rate of flow of coolant therein, so as to reduce the likelihood of condensation occurring on or near such electronic equipment or other equipment when the unit is in use. Also, a method of cooling the air in a data centre (100) or other centre, room or space using such a cooling unit (10).

Owner:EATON WILLIAMS GRP

Thin-layer fluid type low-stress polishing device

InactiveCN103317393AHigh polishing precisionEnables low-stress machiningPositive pressureEngineering

The invention discloses a thin-layer fluid type low-stress polishing device and belongs to the field of ultra-precise optical surface machining. The device comprises a sealed working chamber, a rotary table, an anode plate, an anode probe, a cathode platform, a workpiece, a first duct, a booster pump, a lifting platform, a second duct, a moulding nozzle, a liquid collection device and the like. During working, the workpiece is fixed on the rotary table, an electric field is produced between the anode plate or the anode probe and the cathode platform, an electrorheological polishing liquid is mixed uniformly, then is boosted by the booster pump and flows into the liquid collection device through the first duct and the second duct, under the action of pressure, the liquid flows into a thin-layer area through the moulding nozzle, and under the action of the flowing power and the shearing force, surface material removing is achieved. According to the thin-layer fluid type low-stress polishing device, the problem that the workpiece is broken easily by a thin optical component due to the large positive pressure is solved, meanwhile, the phenomena that medium-and-high frequency errors remain easily due to small tool machining are improved, and the device plays an important role in optical component machining which is high in precision, free of subsurface damage and controllable in medium-and-high frequency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

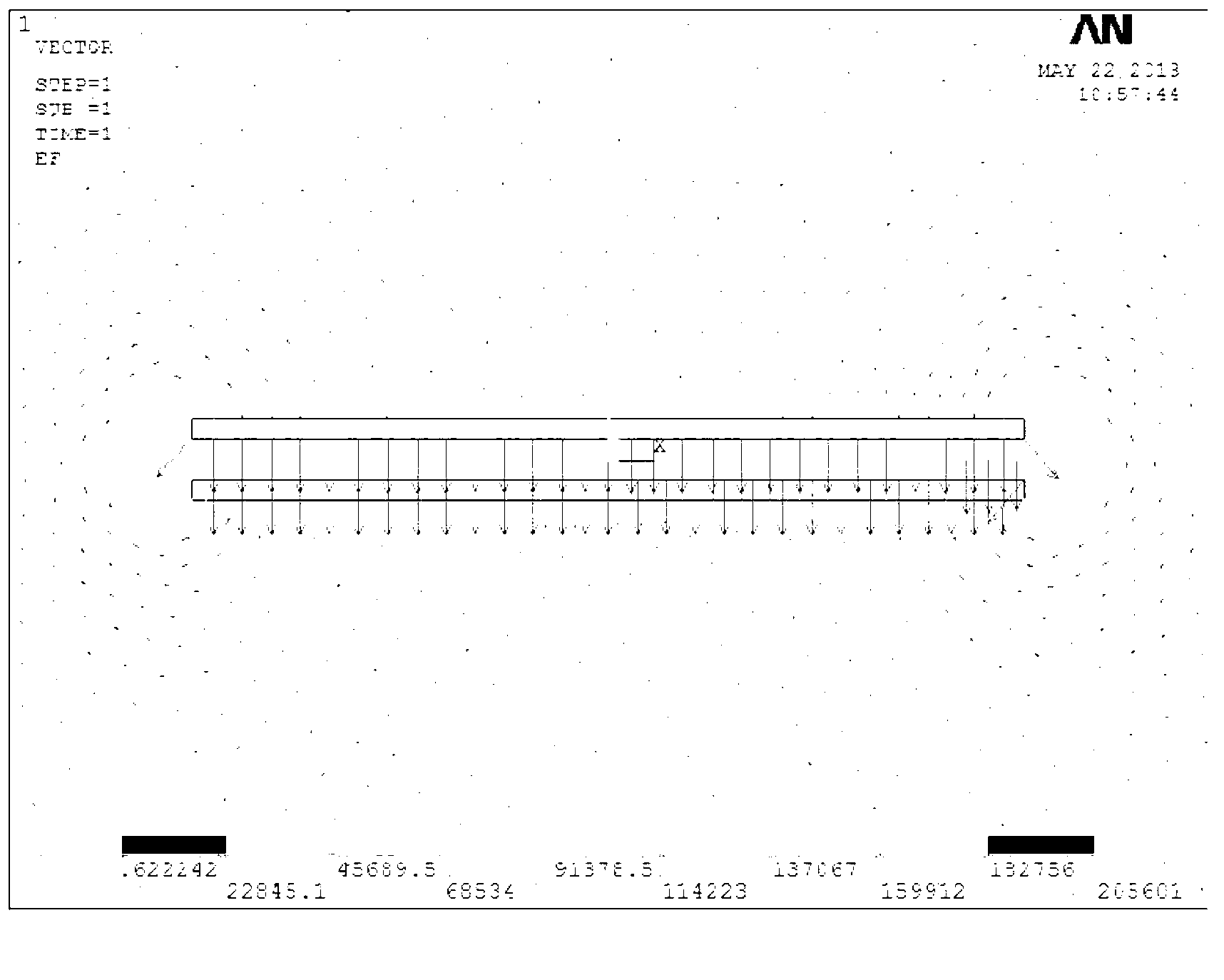

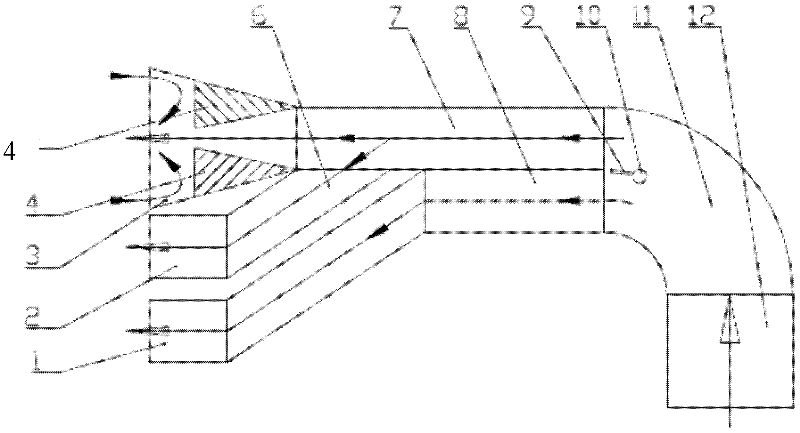

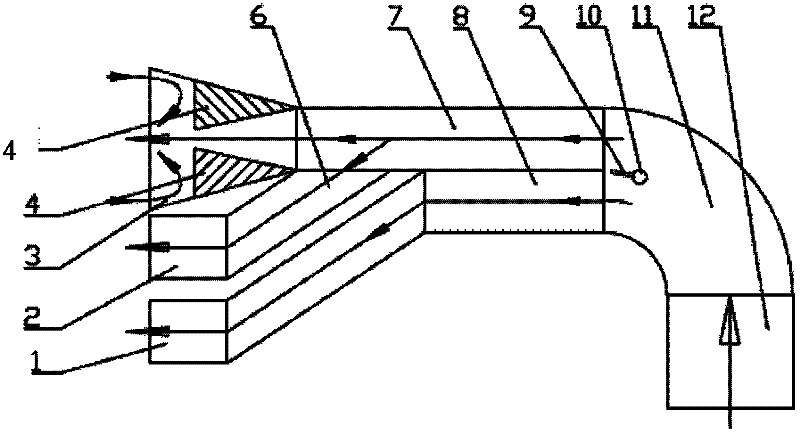

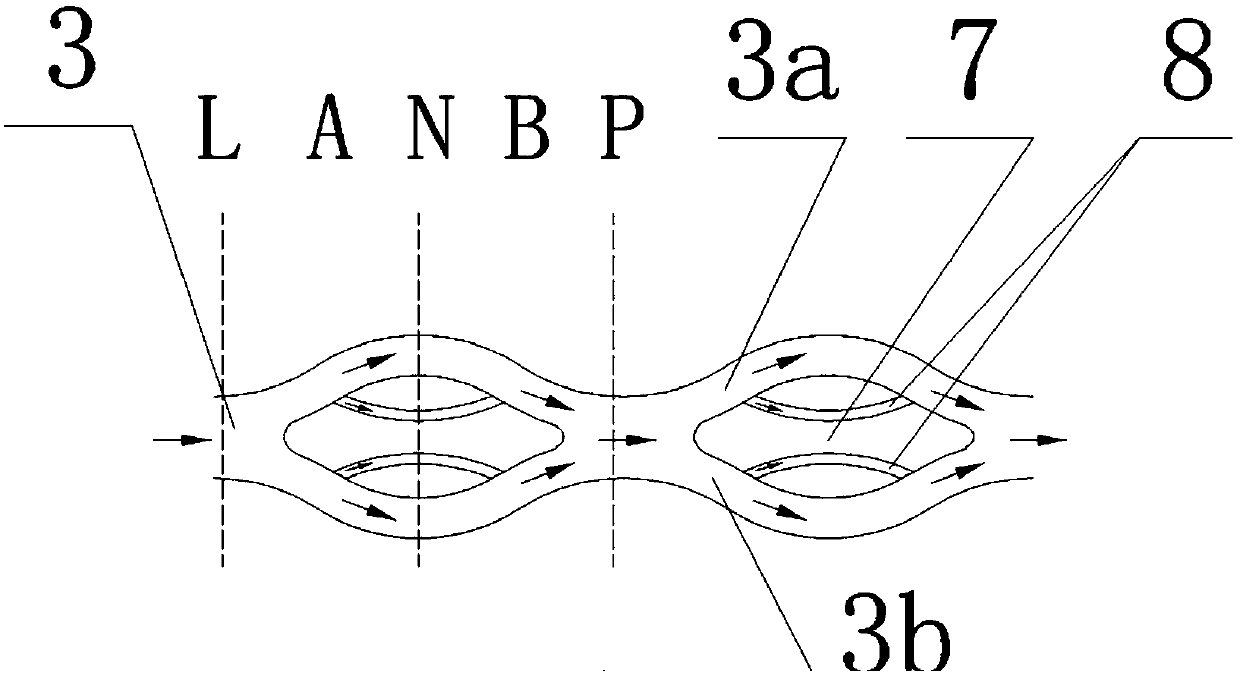

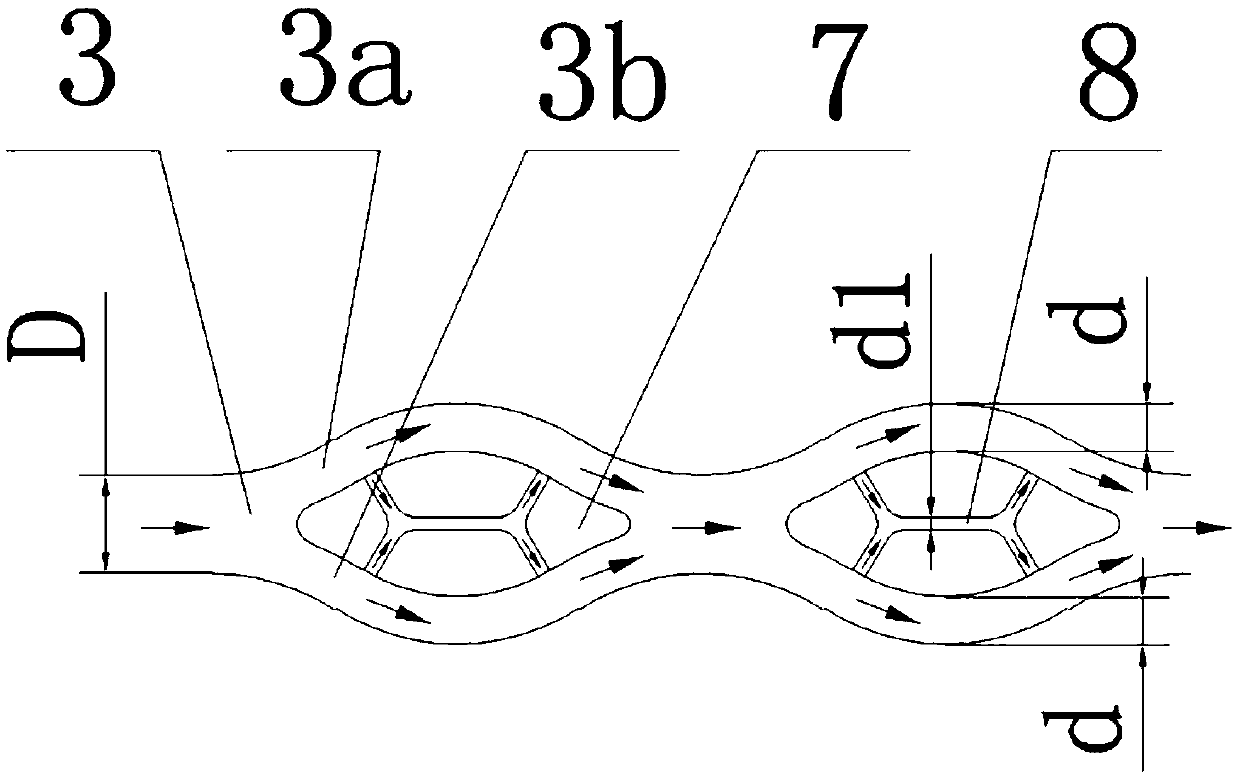

Pulverized coal decoupling combustor and decoupling combustion method thereof

InactiveCN102297425AMeet or exceed concentration efficiencyOver concentration efficiencyPulverulent fuel combustion burnersCombustorGuide tube

The invention relates to a pulverized coal decoupling combustor and a decoupling combustion method thereof. The decoupling combustor comprises a first-stage air duct (12), an inertia separator (11), air current conduits and a spout which are sequentially connected along the air current direction, wherein the air current conduits comprise a dense side air current conduit (7) and a fresh side air current conduit (8); the fresh side air current conduit (8) is communicated with a third-stage spout (1); the dense side air current conduit (7) is connected with a first-stage spout (3); a second-stage spout conduit (6) communicated with the dense side air current conduit (7) is led out of a pipeline between the dense side air current conduit (7) and the first-stage spout (3) on the dense side aircurrent conduit (7); the second-stage spout conduit (6) is communicated with a second-stage spout (2); the first-stage spout (3) is a gradually-increasing spout; a pair of pulverized coal collecting flame stabilizing devices (4) is oppositely arranged at the upper side and the lower side inside the front end of the first-stage spout (3); the cross sections of the pulverized coal collecting flame stabilizing devices (4) along the air current direction is gradually increased; and the area of the cross section of an air current channel is decreased along the air current direction, thus the coupling combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method and apparatus for particle sorting

InactiveUS20170122861A1Effectively and precisely sortingReduce areaLaboratory glasswaresIndividual particle analysisParticle sortingMonoclonal antibody

Apparatus and methods for sorting and dispensing microparticles using a flow switch mechanism wherein changing flow rate into the flow switch changes flow path. The present invention is well-suited for precisely sorting microparticles, such as cells, for applications such as cell line development, monoclonal antibody selection and single cell research, etc.

Owner:NAMOCELL INC

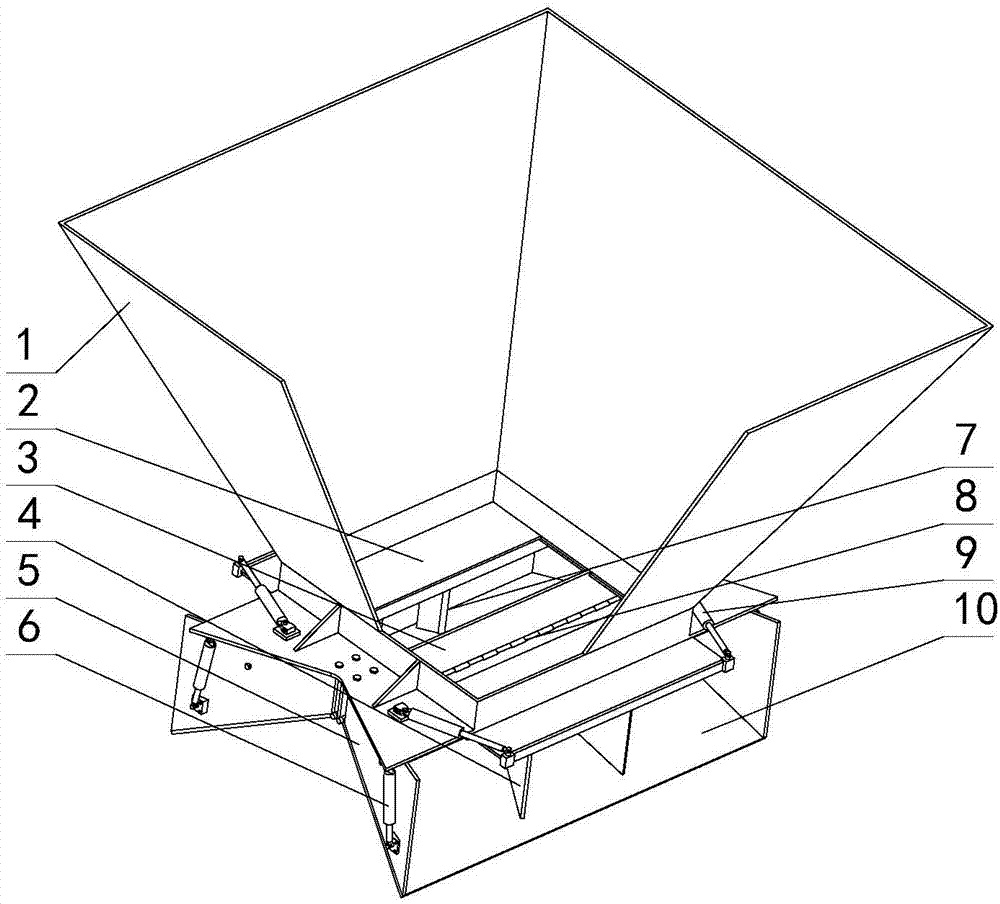

Discharging hopper capable of achieving flat heaping of fallen materials

InactiveCN107380762AImprove work efficiencyReduce manufacturing costConveyorsLarge containersElectrical and Electronics engineeringMaterial flow

The invention discloses an unloading hopper for realizing the flat accumulation of blanking, which is characterized in that it comprises a hopper, a vertically arranged partition is arranged in the middle of the discharge opening at the lower part of the hopper, and material guide grooves are symmetrically arranged on both sides of the partition , the chute is movably connected with the partition plate through the first rotating shaft, the chute is provided with a chute to communicate with the discharge port, and the discharge port is symmetrically arranged on the top of the chute An opening control panel, the opening control panel of the discharge port is slidingly connected with the discharge hopper, and by controlling the opening and closing of the control panel of the discharge port opening, the openings of the material guide ports of the two material guide grooves are realized. Compared with the conventional unloading hopper, the unloading hopper provided by the present invention has added a material guide groove and a material distribution plate, and by adjusting the angle of the material guide groove and the material distribution plate, the direction and flow rate of the material flow can be changed, which can effectively change the flow rate of the material. The stacking state of the material can be realized, so as to realize the uniform and flat accumulation of the material blanking, and there is no need to artificially level the stockpile, thereby improving the operating efficiency and reducing the production cost.

Owner:WUHAN UNIV OF TECH

Multifunctional gas discharging and plasma electric arc detecting device and method

ActiveCN103941167AChange flow rateReduce distractionsTesting dielectric strengthEngineeringElectromagnetic field

The invention relates to a multifunctional gas discharging and plasma electric arc detecting device and method. The multifunctional gas discharging and plasma electric arc detecting device comprises a multifunctional gas discharging unit and a plasma electric arc detecting unit. The multifunctional gas discharging unit comprises a sealing chamber, a test electrode, a heating electrode, a gas charge, discharge and recycling device, an electromagnetic field generator and an electric arc air-blowing module. The plasma electric arc detecting unit comprises a sensor module, a signal conversion module, a central processing unit and an upper computer. By means of the multifunctional gas discharging and plasma electric arc detecting method, gas discharging experiments can be conducted under different experiment condition such as vacuum and pressuring, a kind of gas or mixed gas of various gas, electrodes of different shapes discharging, the normal temperature, the high temperature and different temperatures, static gas discharging, flowing gas discharging and rotary flowing gas discharging with the addition of the electromagnetic field condition according to the experiment requirements, and comprehensive collection and time-share independent collection are conducted on relevant physical quantity of the electric arc performance obtained from the experiments conducted under the different condition.

Owner:SHENYANG POLYTECHNIC UNIV

Method and apparatus for bulk microparticle sorting using a microfluidic channel

ActiveUS9702808B2Avoid disruptionChange flow rateBiological particle analysisLaboratory glasswaresFluorescenceMicroparticle

Methods and apparatuses for sorting and isolating individual microparticles (e.g., cells) by bulk sorting groups of microparticles into groups containing one or more microparticle having a desirable characteristic (e.g., a label such as a florescent label, shape, size, etc.), and then sorting the individual microparticles with this desired characteristic individual particles.

Owner:NAMOCELL INC

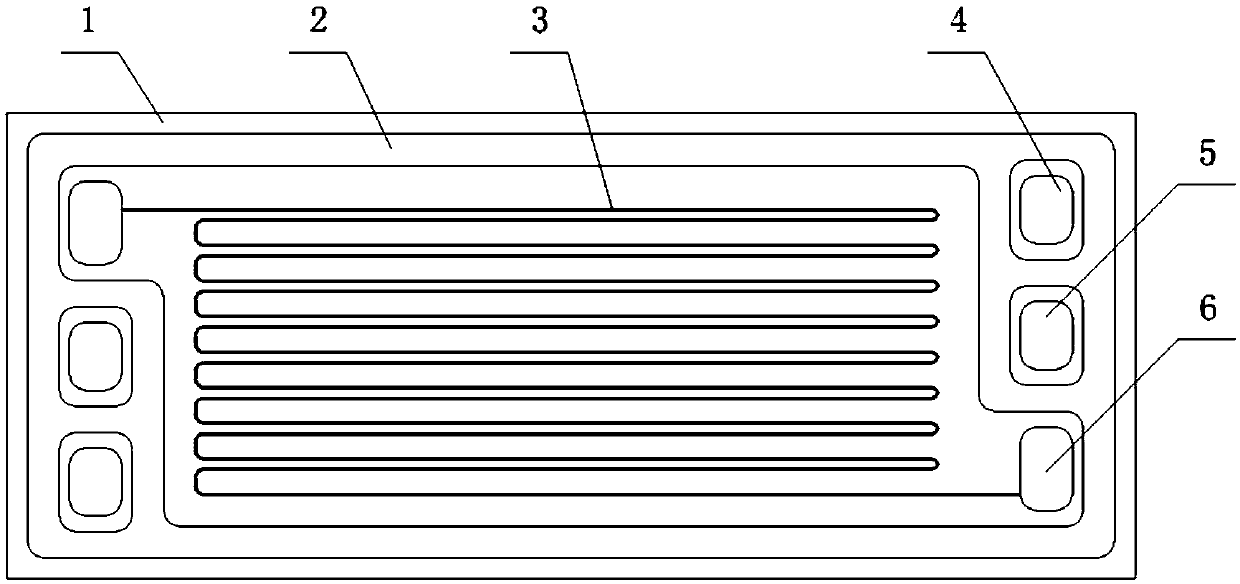

Flow guide plate of fuel cell

Owner:氢鑫沃德(上海)新能源发展有限公司

Air amplifier capable of increasing air flow amount

ActiveCN104826888AIncrease outflow speedImprove the effect of Coanda effectAudio power amplifierIndustrial engineering

The invention provides an air amplifier capable of increasing air flow amount. The air amplifier comprises an outer sleeve, and a lining inserted into the outer sleeve; the outer sleeve is provided with a through hole; a part of the lining corresponding to the though hole shapes like a trumpet, so that a sealed space is formed between the outer sleeve and the lining, and the sealed space is communicated with the though hole, and is used for accommodating outer compressed air; a gap communicated with the sealed space is arranged between an air inlet end of the lining and the outer sleeve, and the gap is communicated with an air channel in the lining; the inner wall of the air inlet end shapes likes a round corner, so that coanda effects of air flows through the through hole, the sealed space, and the gap are induced. The air amplifier is capable of increasing air discharging speed, and realizing real-time adjustment based on working conditions.

Owner:中亿丰金益(苏州)科技有限公司

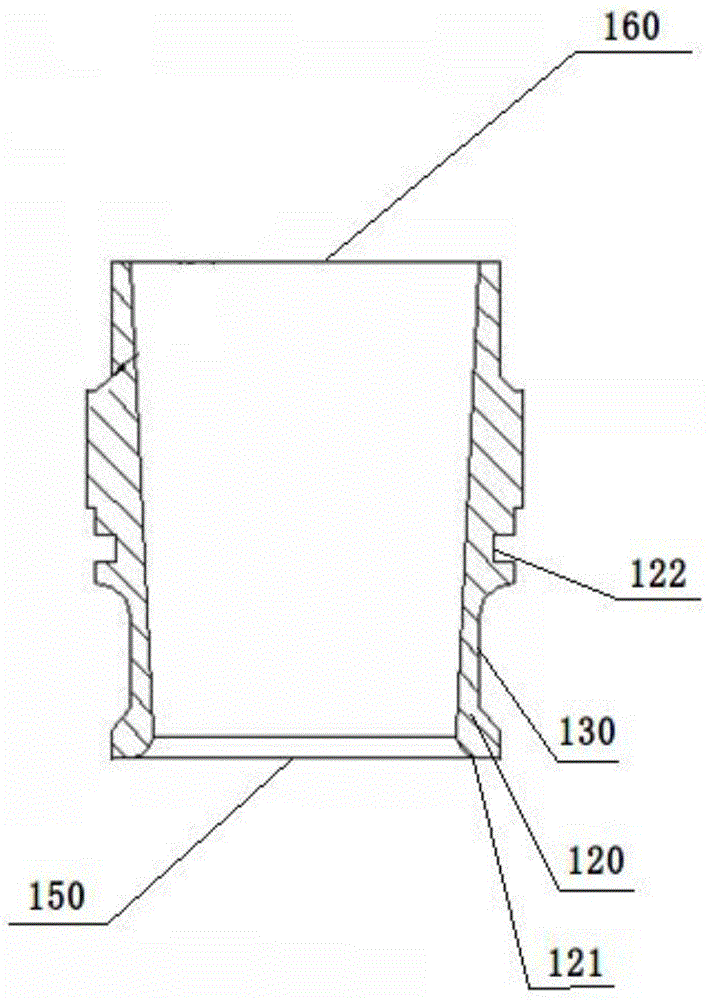

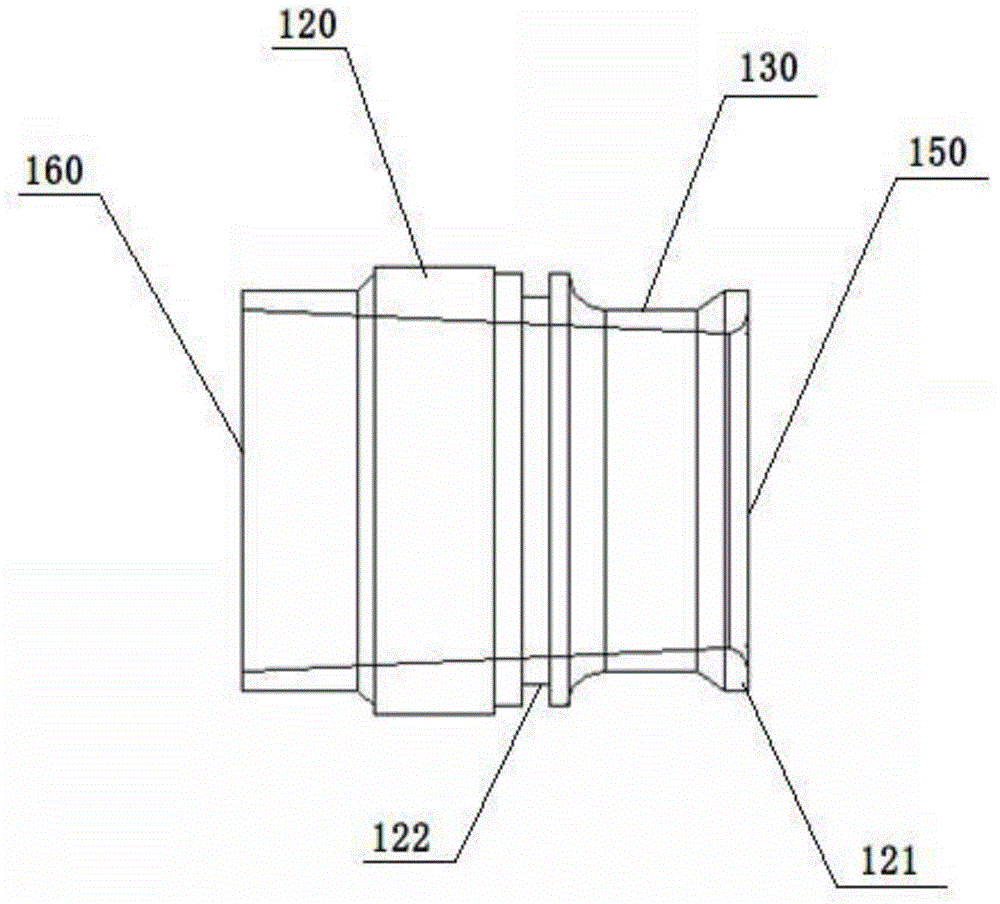

Bush assembly capable of adjusting air flow of combustion zone

ActiveCN108458366AChange flow rateIncrease air volumeContinuous combustion chamberCombustion chamberEngineering

The invention discloses a bush assembly capable of adjusting air flow of a combustion zone so as to solve the problem that lean-oil flameout of idling rating in a currently-occurring condition. The bush assembly comprises an bush out wall, a sealing sleeve, a floating body and a moving mechanism, wherein the bush outer wall is of a annular shape, and an installing hole is formed in an upstream endof the bush outer wall, the sealing sleeve is in a cylindrical shape and is coaxially fixed with the installing hole, and a floating channel is formed inside the sealing sleeve, the floating body isarranged on the inner side of the sealing sleeve in a coaxial mode, and can move up and down inside the floating channel, and the moving mechanism is connected with the floating body and controls thefloating body to move up and down. The bush assembly capable of adjusting air flow of combustion zone has the beneficial effects that the area of an air flow channel is changed by changing the heightof the bush outer wall, and therefore the air flow rate is changed, and the jet angle of an air inlet hole is finally influenced, the effect of adjusting the air flow of an annular region is achieved;the oil-gas ratio of the annular region can be adjusted by adjusting the air flow of the annular region, so that the phenomenon of lean-oil flameout of a combustor in the idling rating is prevented;and meanwhile, when the combustor works in a pre-mixing mode, the air amount of the annular region can be increased, so that the premixed effect of fuel and air is enhanced.

Owner:CAS HEFEI MICRO GAS TURBINE RES INST CO LTD

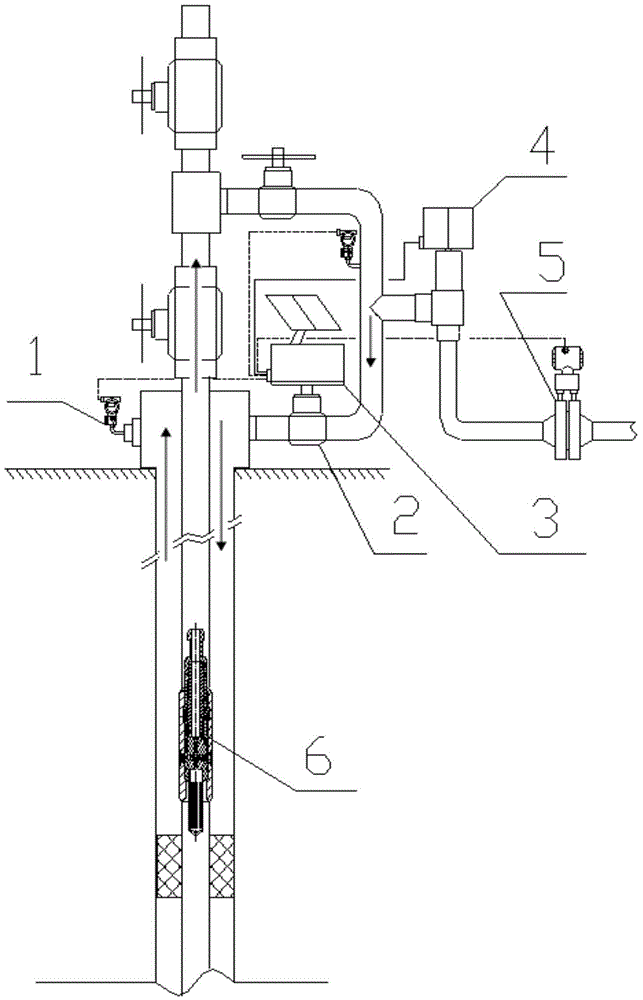

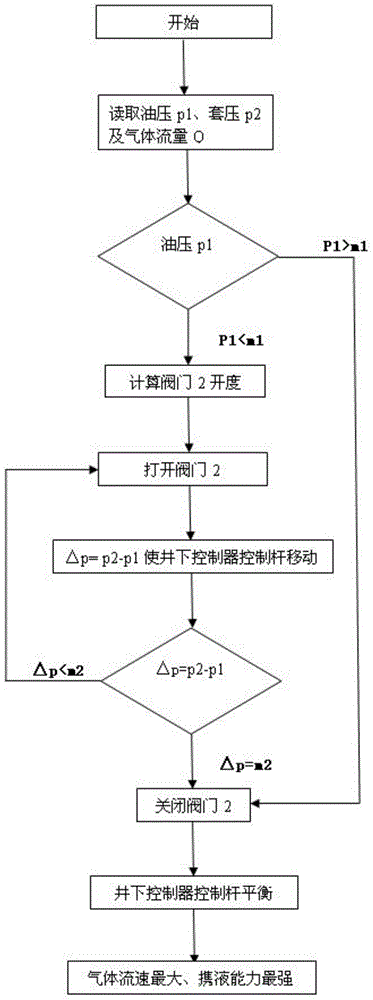

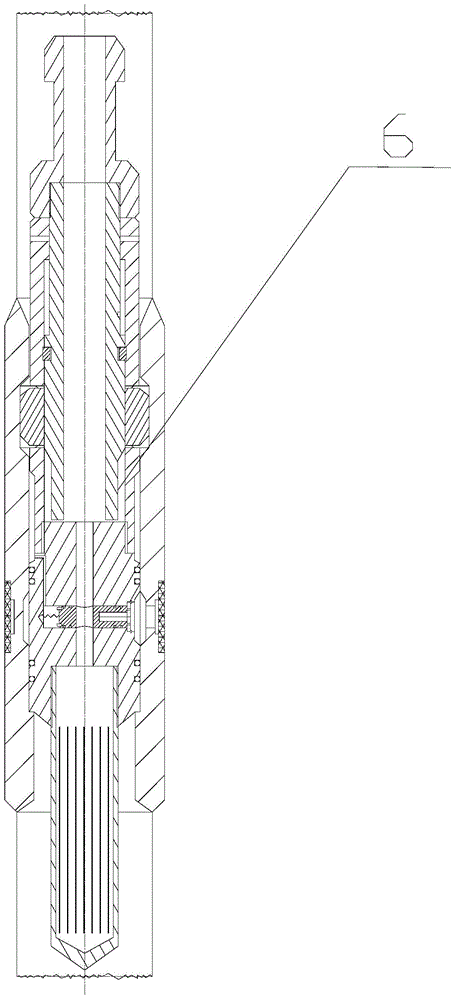

Intelligent production adjusting method and device for gas wells

ActiveCN105089572AChange flow rateGood drainage and gas recoveryFluid removalProduction rateOil pressure

The invention provides an intelligent production adjusting method and device for gas wells and belongs to the technical field of oil field digitization. When oil pressure is higher than a certain pressure value P1, the liquid carrying capability of gas is in a strong state, a control valve is in a circulation-closed state, and at the moment, an underground controller has the maximal opening degree; when the oil pressure is lower than a certain pressure value P2, the liquid carrying capability of gas is poor, or gas cannot carry liquid, and at the moment, the opening degree of the throttling hole of the underground controller is controlled to increase the gas flow rate so as to enhance the liquid carrying capability; and. therefore, the oil pressure value and the casing pressure value of a pressure gauge are read, a reasonable valve opening degree is calculated in combination with the gas production rate, a control box sends a command to the control valve to enable the control valve to reach an appropriate opening degree, a control rod of the underground controller, of which the left face receives a smaller stress than the right face, moves leftwards till a balance is achieved, and the opening degree of the throttling hole is between the maximal opening degree and the minimal opening degree, so that the gas flow rate is the maximal, and the goal of carrying the largest volume of liquid is achieved.

Owner:PETROCHINA CO LTD

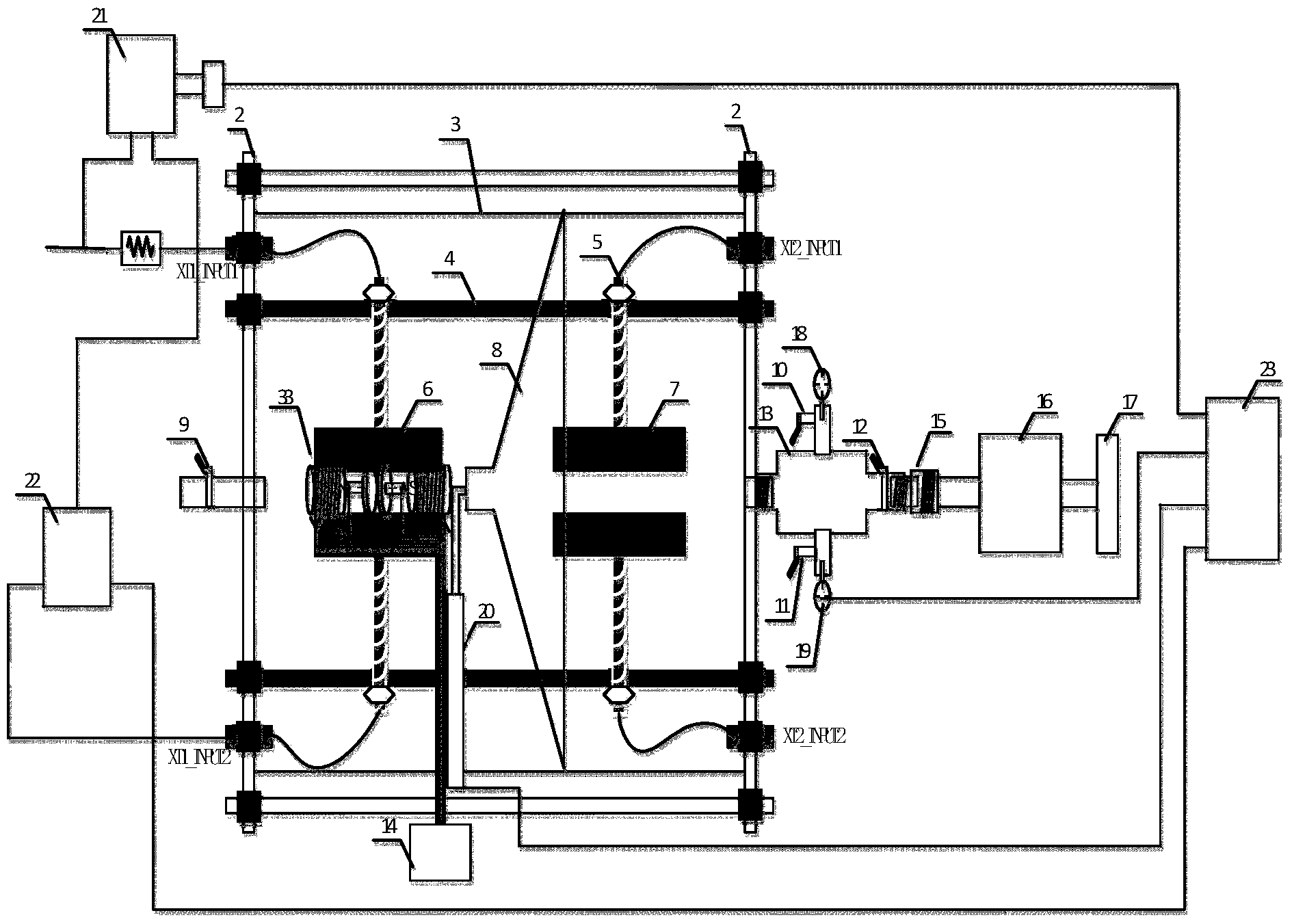

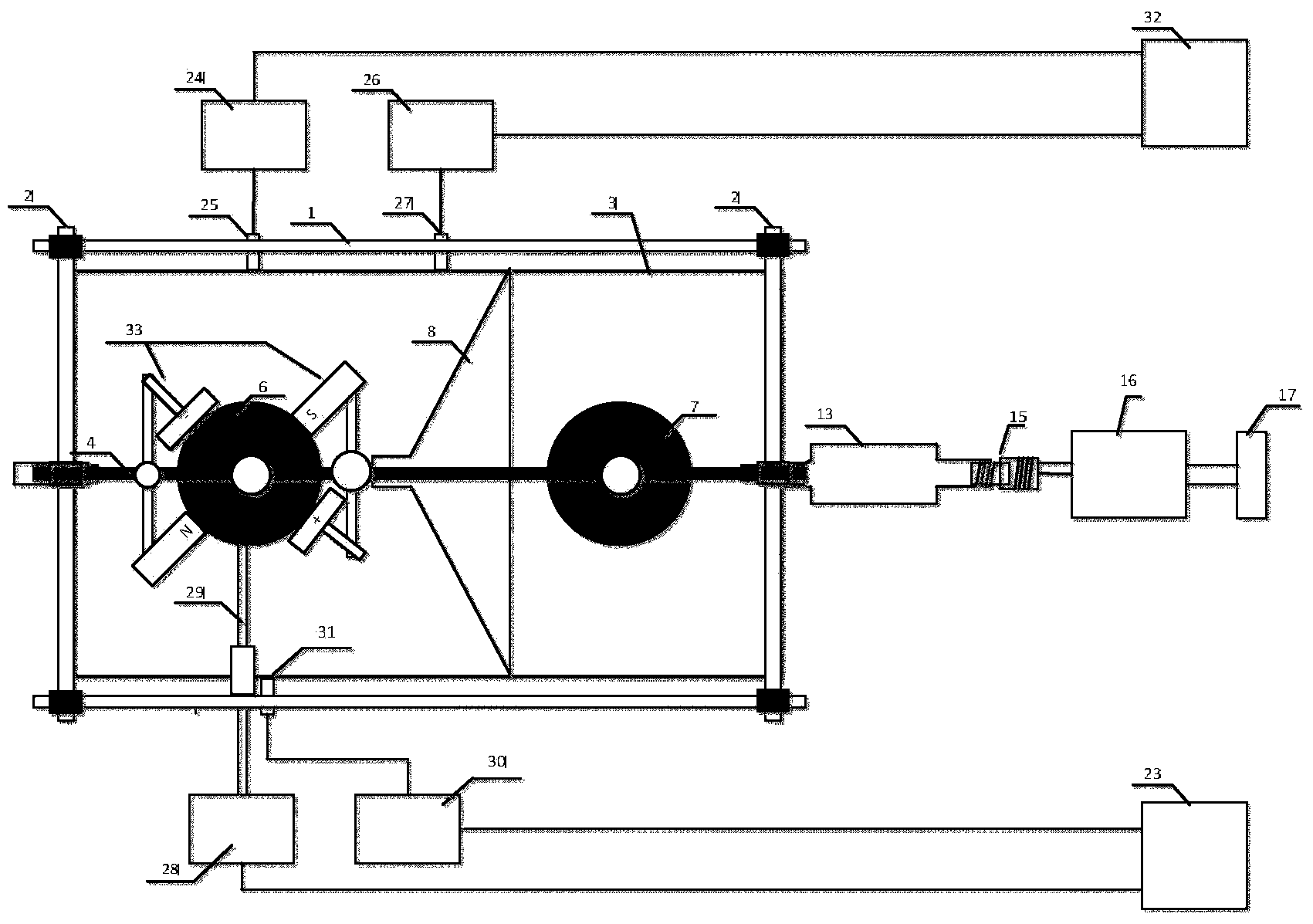

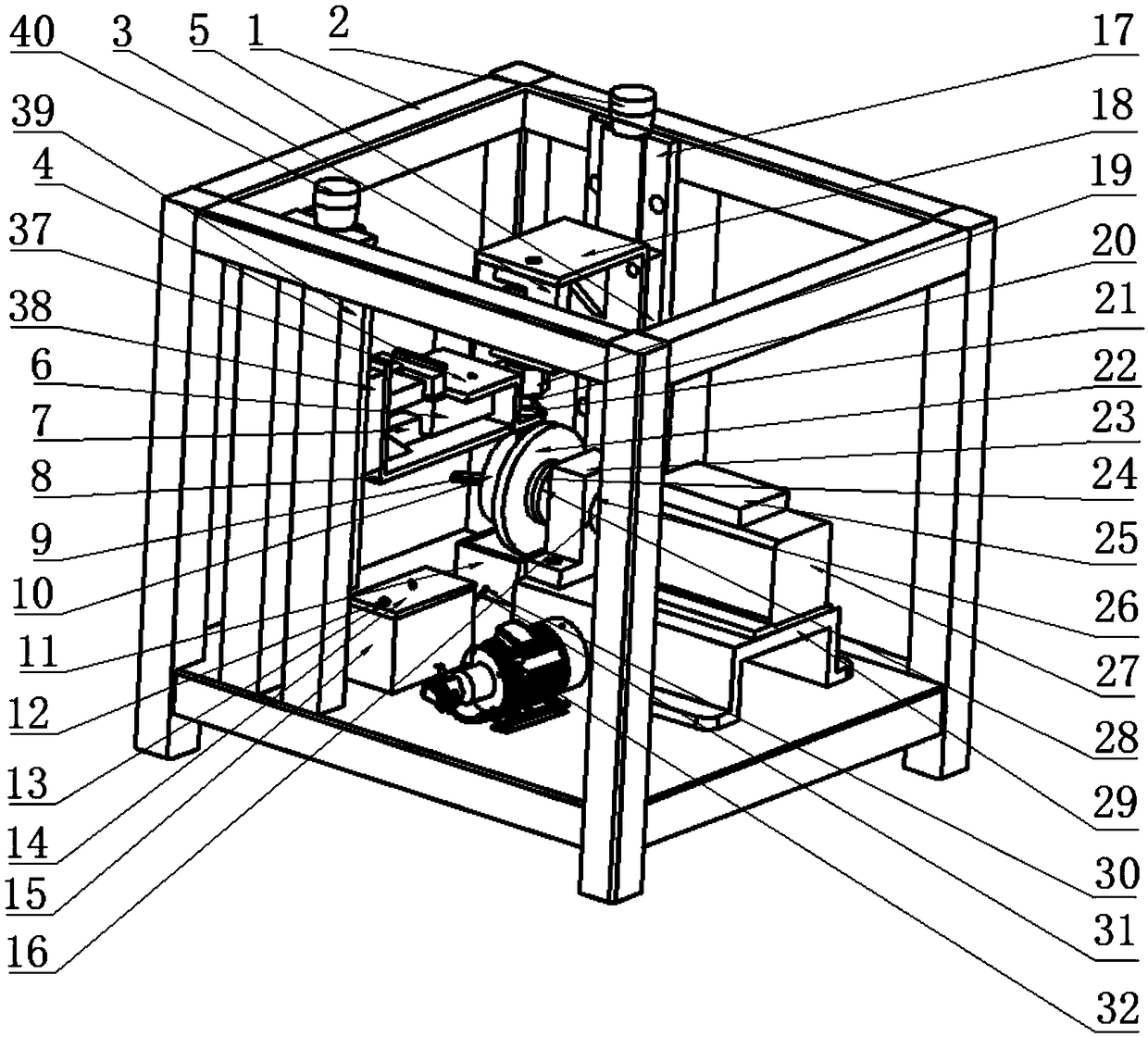

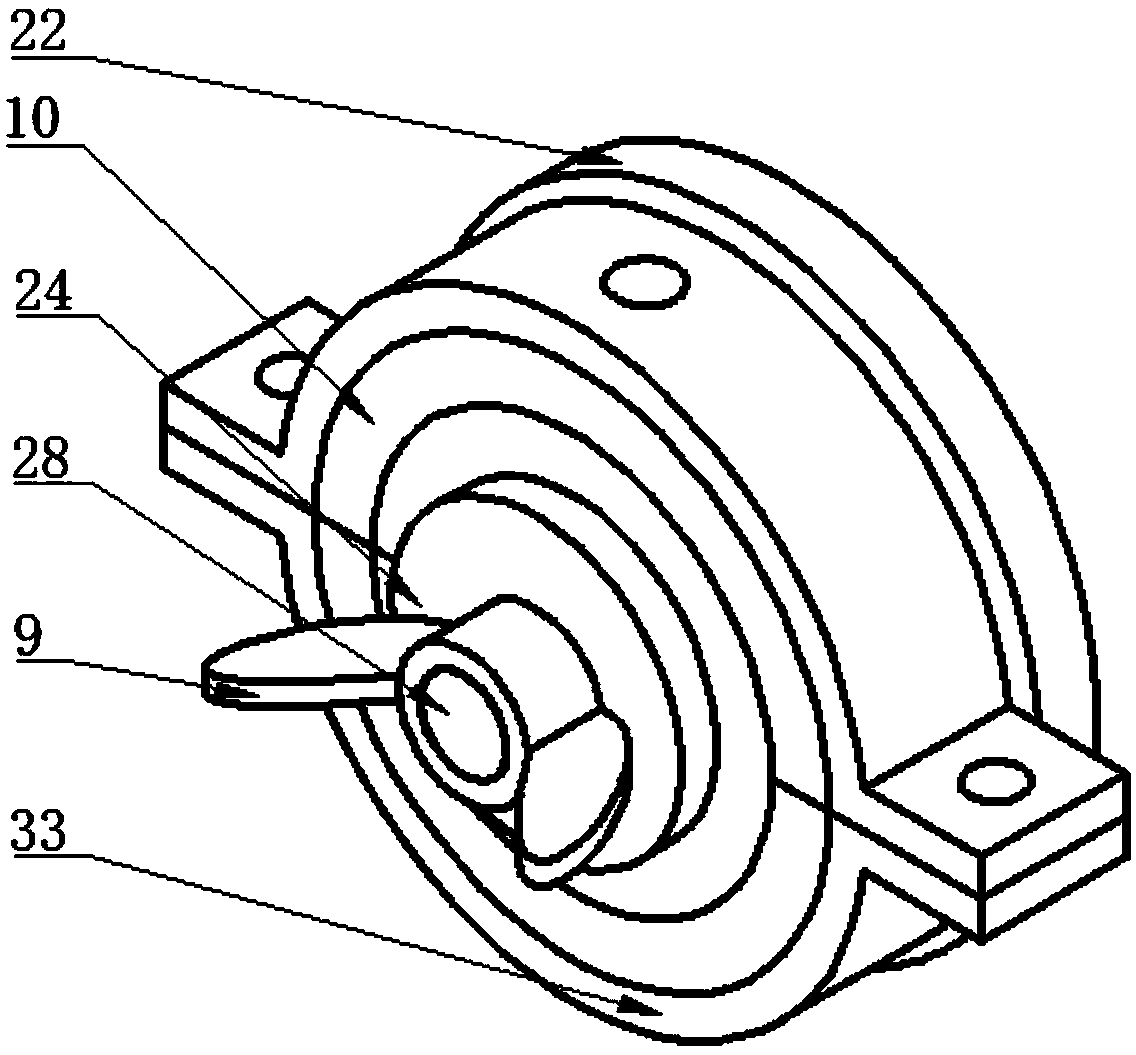

Bearing bush friction wear testing machine and testing method thereof

InactiveCN109342244AStable structureHigh measurement accuracyInvestigating abrasion/wear resistanceEngineeringWear testing

The invention discloses a bearing bush friction wear testing machine and a testing method thereof. The bearing bush friction wear testing machine comprises a bracket, a driving device, a testing device, a loading device, a measuring device and a lubricating oil circulation supply device, wherein the driving device, the testing device, the loading device, the measuring device and the lubricating oil circulation supply device are mounted in the bracket. The bearing bush friction wear testing machine disclosed by the invention has the advantages that the bearing bush friction wear testing machinecan simulate actual working conditions, effectively control loads and accelerate friction wear test; and meanwhile, by using relative rotation of a bearing bush in the friction process, the frictionforce bore on the bearing bush is accurately measured by using a guide rail type force sensor.

Owner:JIANGSU UNIV OF SCI & TECH

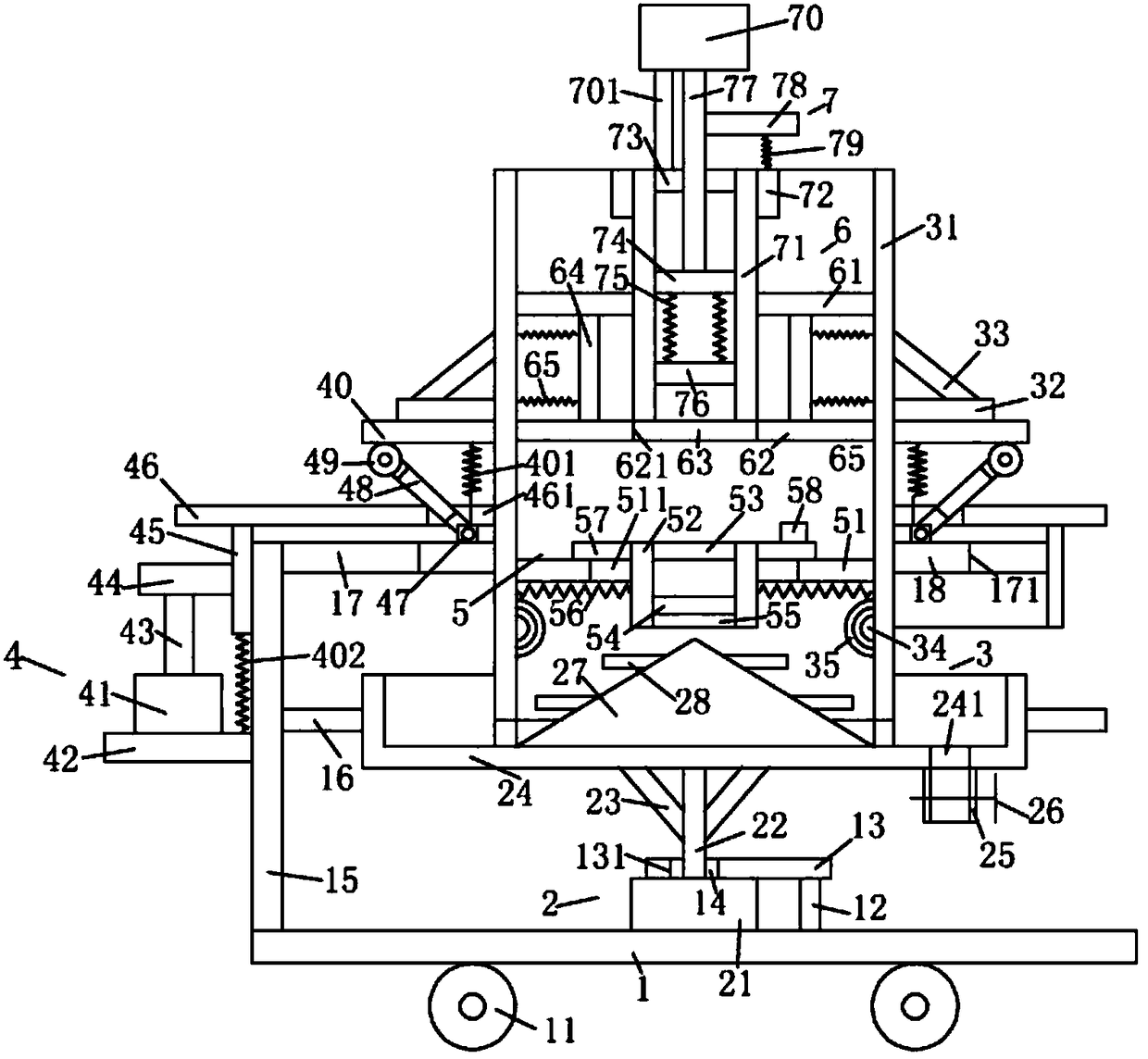

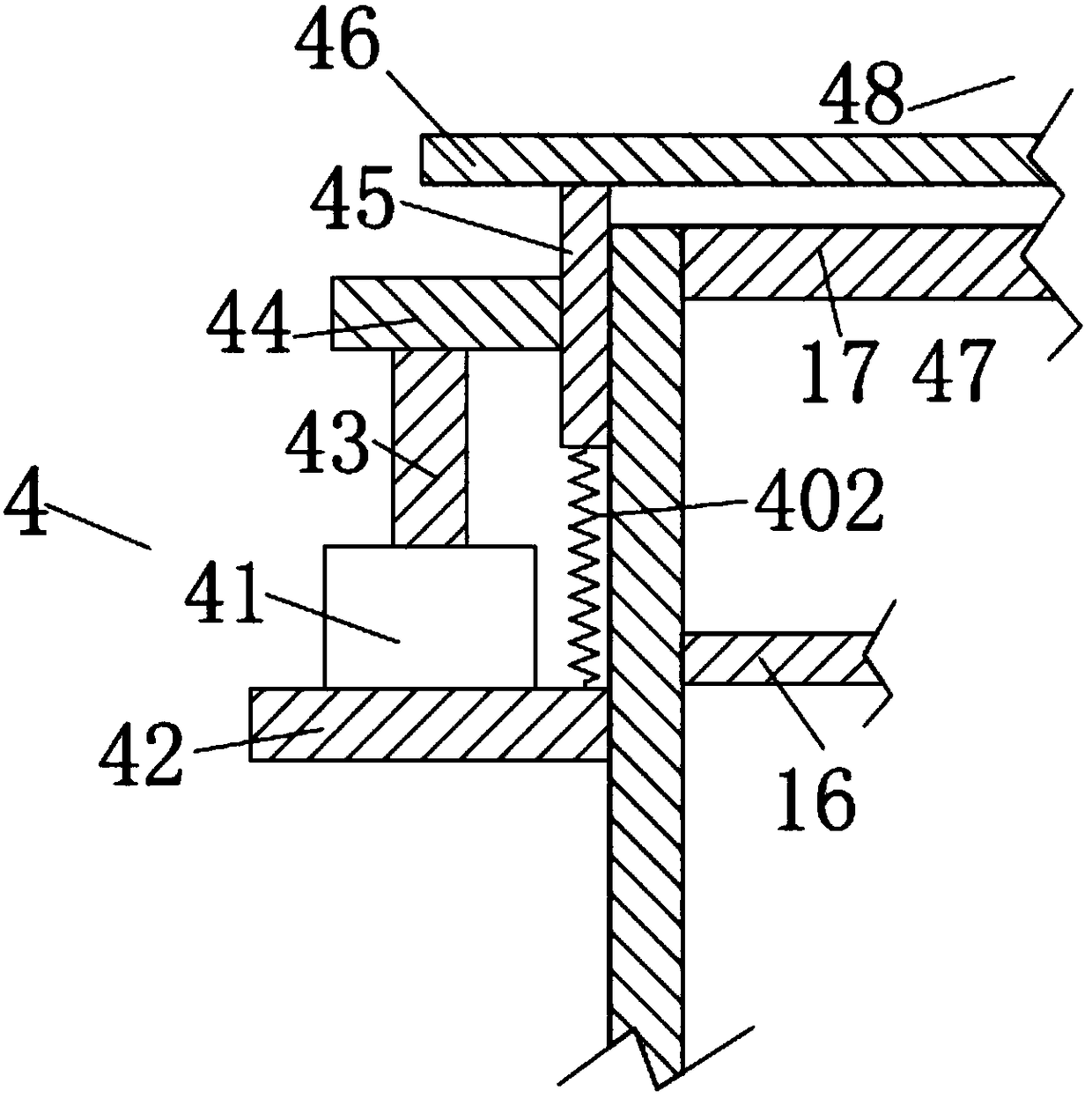

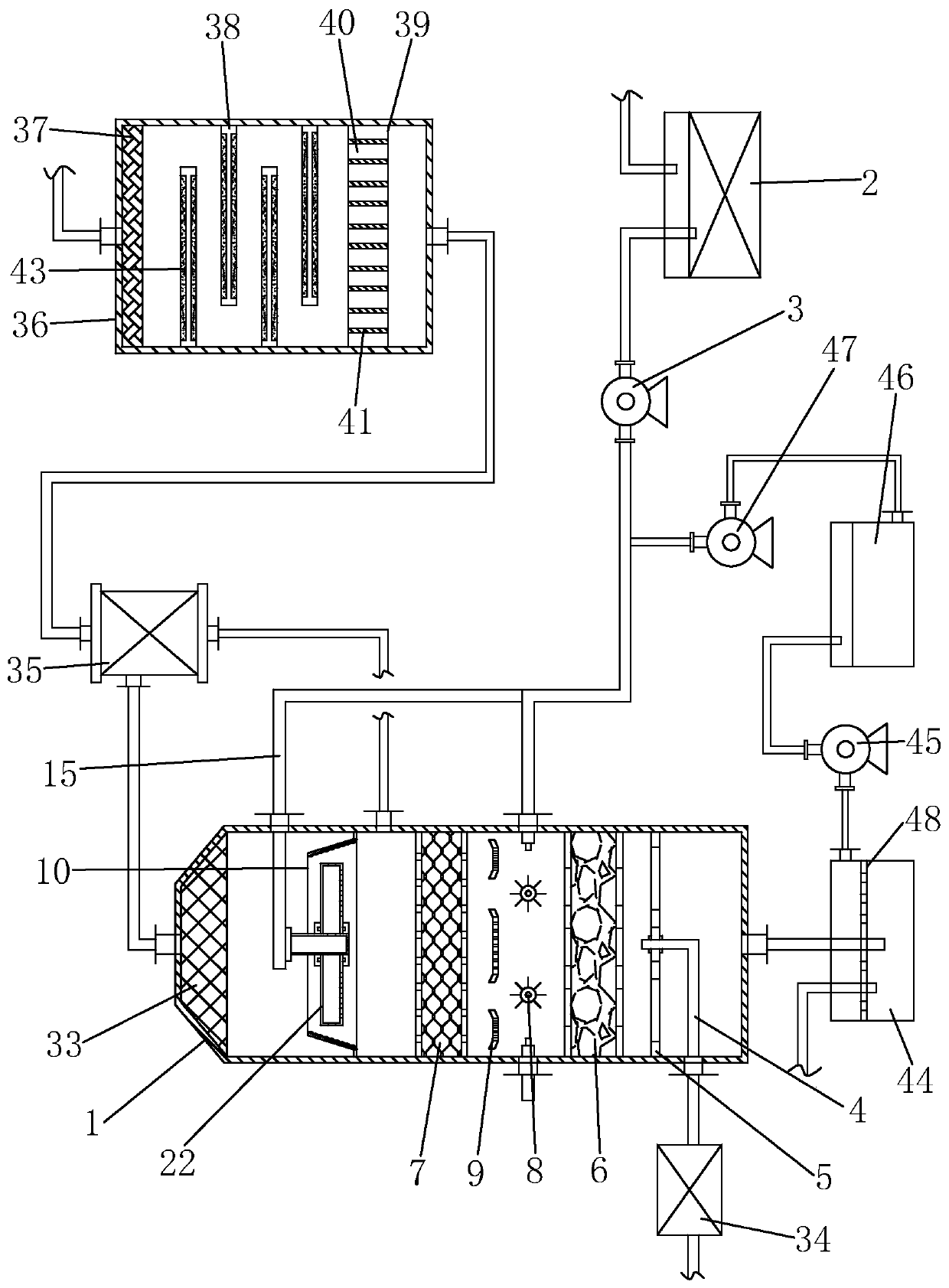

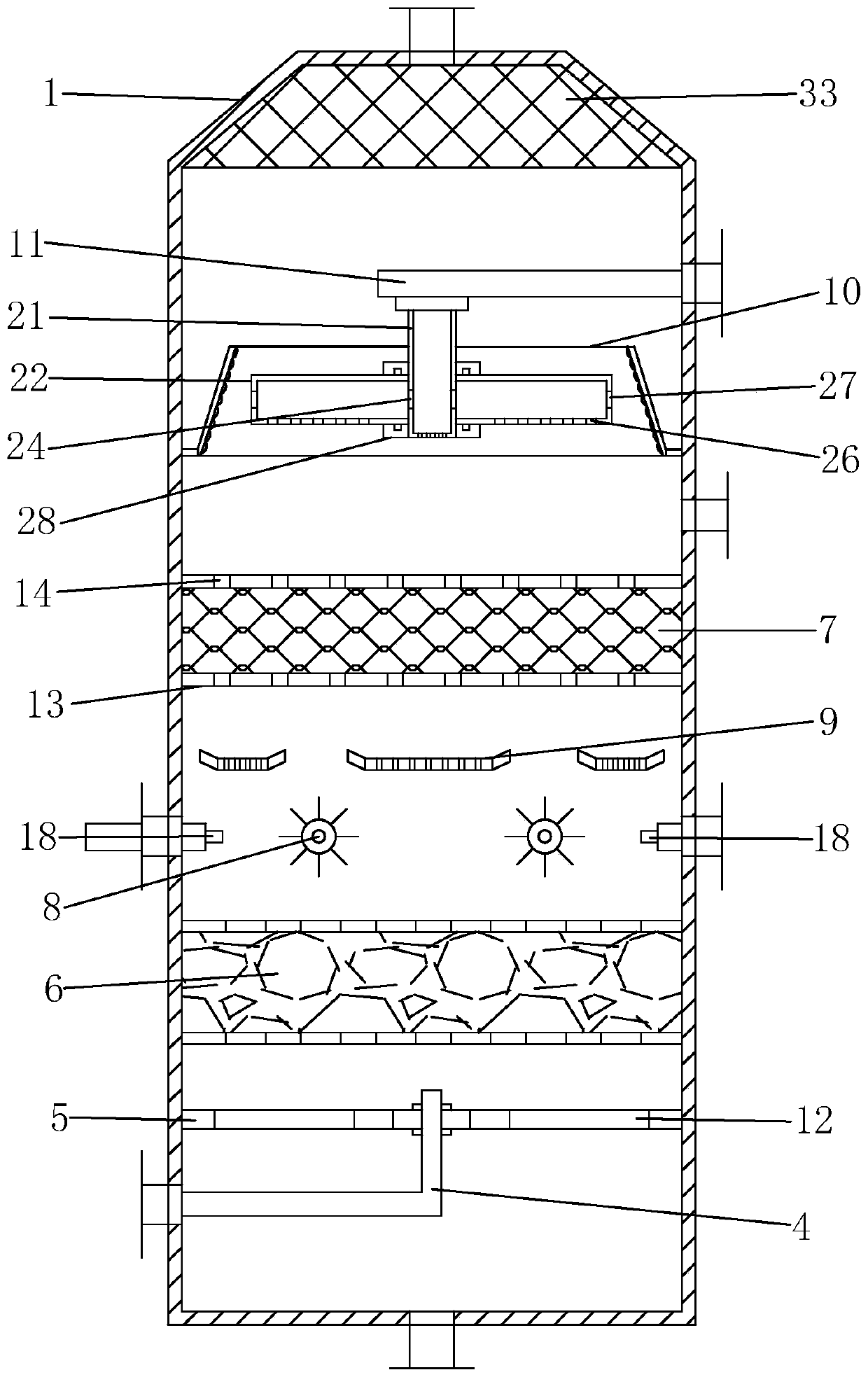

Multifunctional rainwater collection, purification and recycling apparatus for buildings

InactiveCN108585311AChange flow rateGuaranteed sterilization effectWater/sewage treatment by irradiationGeneral water supply conservationSewage treatmentStormwater

The invention relates to multifunctional rainwater collection, purification and recycling apparatus for buildings. The apparatus comprises a bottom plate, a rotary stirring device positioned on the bottom plate, a frame device arranged on the rotary stirring device, an electric cylinder device positioned above the bottom plate, a purifying device arranged in the frame device, a filtering device positioned above the purifying device, and a piston device arranged on the filtering device. According to the invention, a piston continuously moves up and down, and then the flow rate of rainwater canbe effectively changed, so that impurities are effectively prevented from blocking filter holes, and the smooth purification is ensured; in addition, water periodically flows into the inner part, so that the sewage treatment effect can be improved; and the rainwater can be driven to fully flow when the rainwater is disinfected, so that the sterilization and disinfection effect on the rainwater isensured, the further treatment of the rainwater in a lager period is facilitated, and the rainwater purification effect is ensured.

Owner:秦晟博

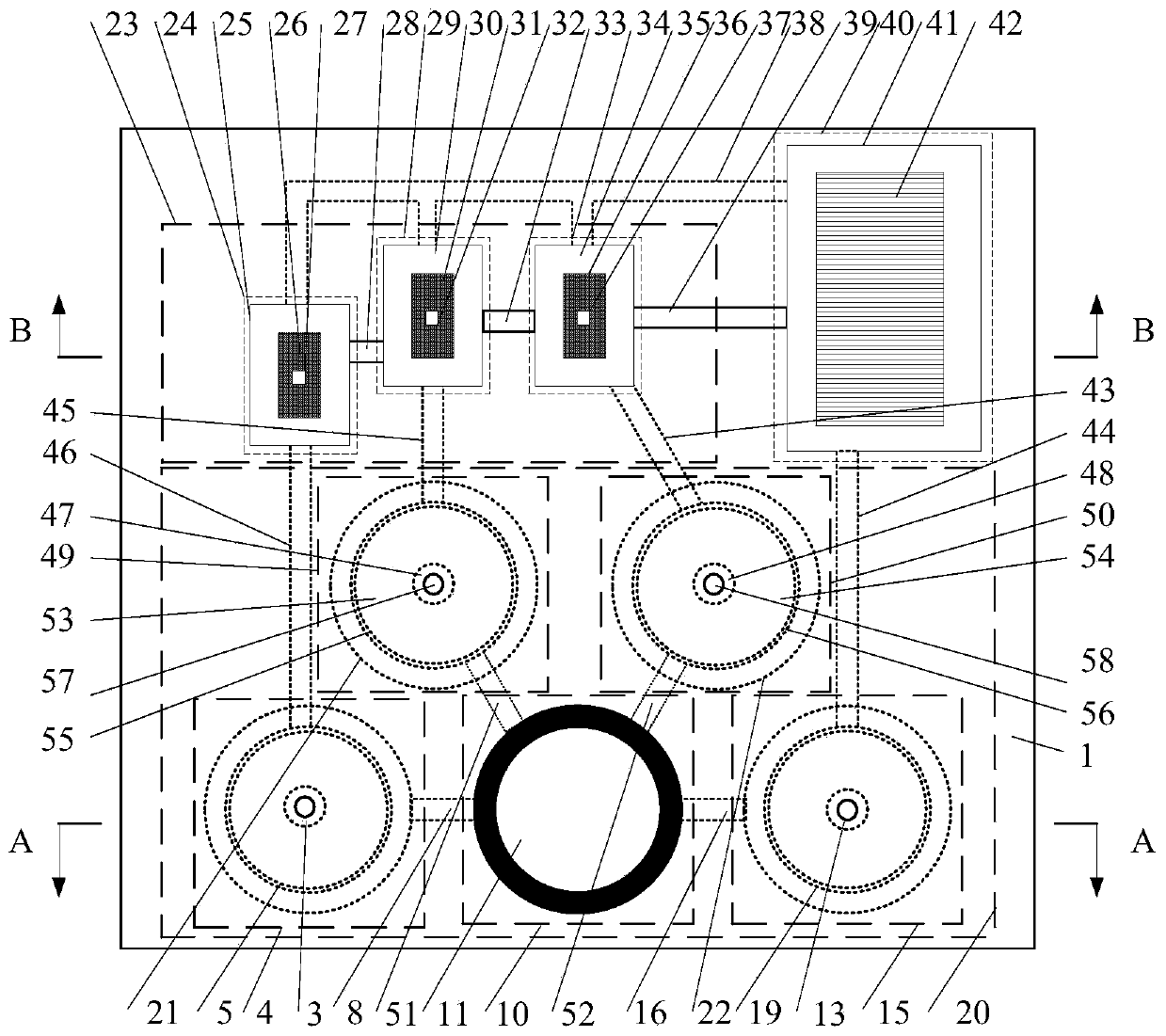

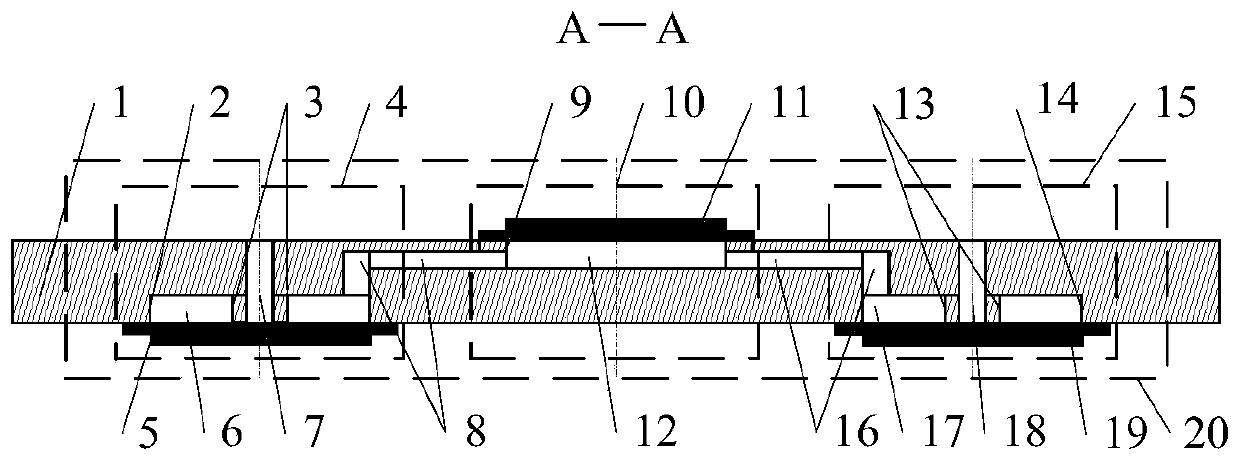

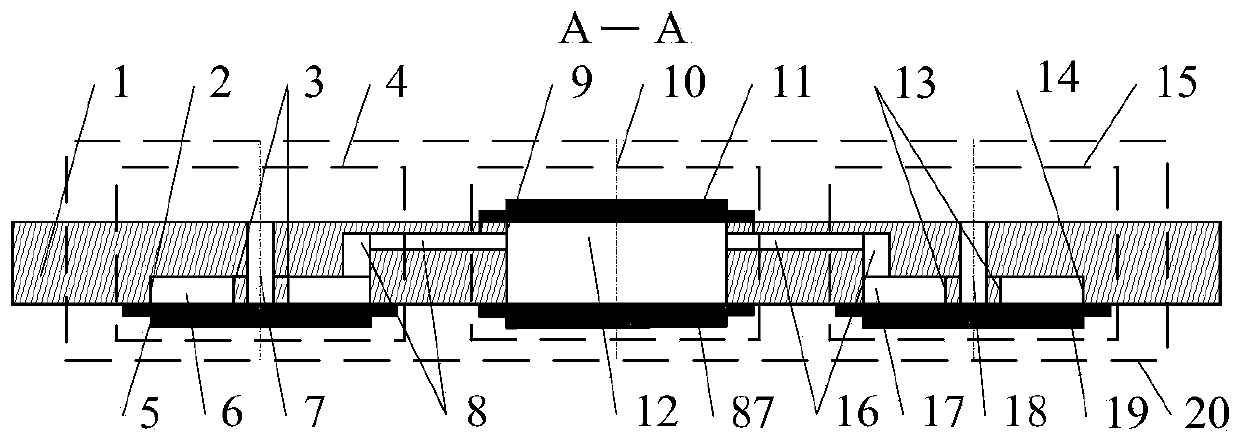

Controllable multi-point active fluid heat dissipation system integrated on PCB

ActiveCN110809359AHigh level of integrationFlexible structureSemiconductor/solid-state device detailsSolid-state devicesFluid controlHeat management

The invention discloses a controllable multi-point active fluid heat dissipation system integrated on a PCB. The active fluid heat dissipation system is composed of an active fluid control device, a heat dissipation device and a fluid cooling device. All the devices are integrated on a PCB. The active fluid control device is mainly composed of a plurality of active control piezoelectric fluid valves and piezoelectric fluid pumps, wherein the active control piezoelectric fluid valves and the piezoelectric fluid pumps are integrated on a PCB and provided with annular surface boundaries. The heatdissipation device is mainly composed of a plurality of micro-channel heat sinks, electronic devices subjected to heat dissipation are placed above the micro-channel heat sinks respectively, and heatflow sensors are placed above the electronic devices respectively. The liquid cooling device is mainly composed of a liquid storage pool and heat dissipation fins or refrigeration pieces. The systemis suitable for being integrated on the PCB, can efficiently and continuously dissipate heat of a plurality of electronic components at different positions and in different areas on the PCB, and has the function of precisely controlling the flow rate, the flow velocity and the flow direction of fluid so as to achieve the purpose of realizing heat management of high-power and high-heat-flux electronic components.

Owner:CHONGQING UNIV

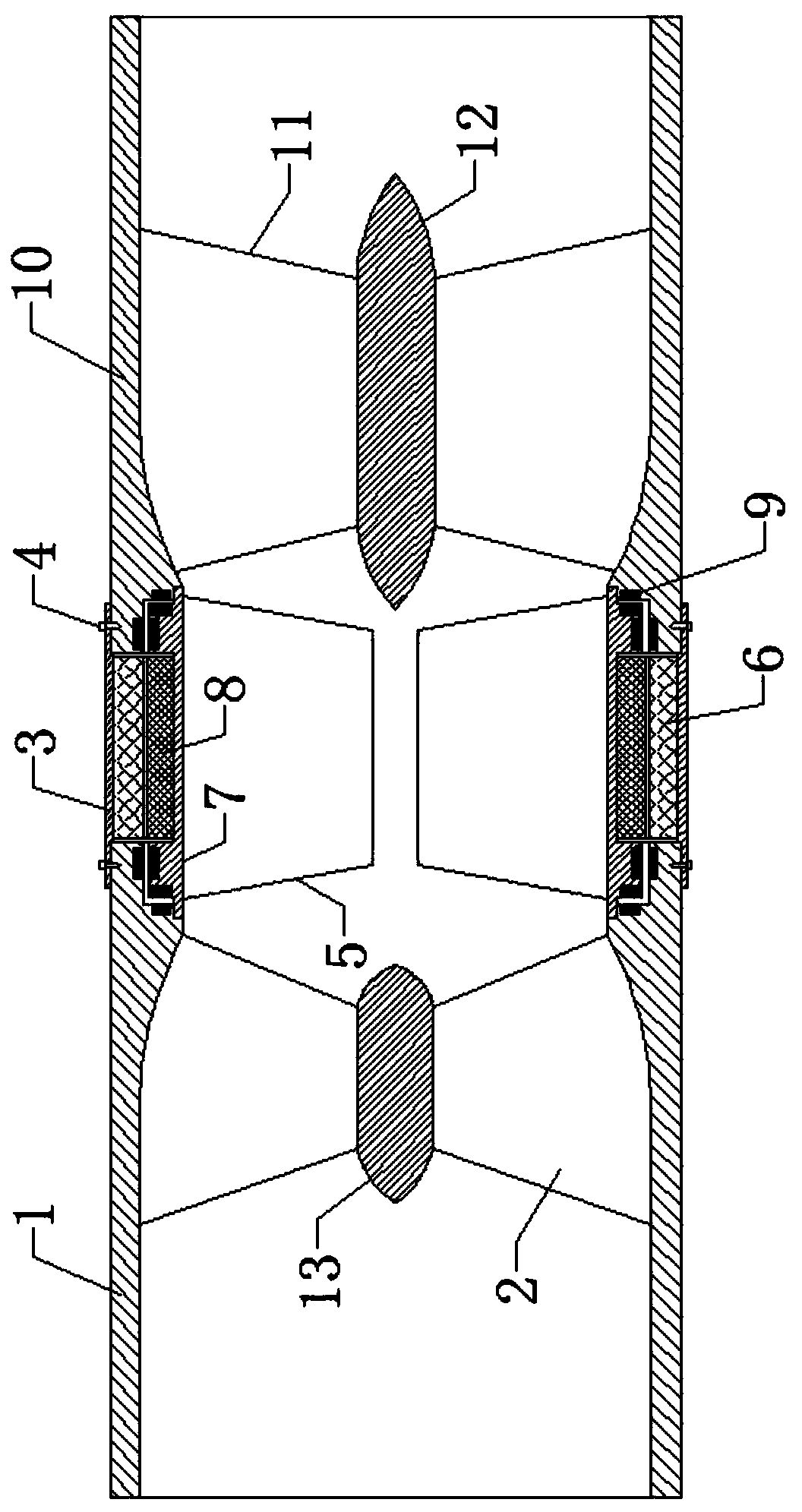

Implantable shaftless heart pump based on gradual change of flow passage

The invention relates to an implantable shaftless heart pump based on the gradual change of a flow passage. The implantable shaftless heart pump is characterized by comprising a flow passage inlet shell, a stator and a flow passage outlet shell, wherein the flow passage inlet shell, the stator and the flow passage outlet shell are sequentially and axially fixedly connected. The inner wall parts ofshell cavities of the flow passage inlet shell and the flow passage outlet shell are respectively provided with straight-through sections.The inner ports of the straight-through sections are respectively in transition connection with the outer ports of contraction sections, and the inner ports of the contraction sections are respectively arranged at the outer ports of the stator.Profile lines ofthe inner wall parts of the shell cavities of the flow passage inlet shell and the flow passage outlet shell are elliptical. The contraction sections of the inner diameters of the flow passage inlet shell and the flow passage outlet shell are arranged near one side of the stator. The inner wall of the stator is fixedly provided with a stator coil, the middle part of the stator coil is provided with an impeller rotor, and the impeller rotor is fixed through permanent magnetic suspension bearing shafts at two ends.The implantable shaftless heart pumphas the advantages of small volume, large flowand small heat productivity, and can effectively reduce the probability of thrombus formation.

Owner:HOHAI UNIV +1

Novel electrophoresis waste gas treatment process and multi-stage efficient degreasing spraying tower thereof

PendingCN110465157AIncrease contact areaEasy to recycleCombination devicesChemical industrySpray tower

The invention discloses a novel electrophoresis waste gas treatment process and a multi-stage efficient degreasing spraying tower thereof. The waste gas treatment process comprises: (a) preliminary impurity removal; and (b) spraying absorption. The spraying tower comprises a tower body and a liquid storage box, wherein an L-shaped gas conduction pipe, a fixed plate, an active carbon filler layer,a chemical industry filler layer, a hairbrush roller, a flow baffle, a liquid collecting hood, a distribution pipe and a liquid distributor are respectively arranged in the tower body. According to the present invention, the waste gas treatment process has characteristics of reliable operation, high treatment efficiency and good treatment effect, and can effectively remove harmful substances fromwaste gas and reduce the harmfulness of waste gas, such that the waste gas can achieve the industrial emission standards; and the spraying tower has characteristics of novel structure, large sprayingrange and complete spraying, and can increase the contact area between the absorption liquid and the waste gas and improve the absorption effect of the absorption liquid.

Owner:上海萧川机械设备有限公司嵊州分公司

Anti-blocking environment-friendly printing and dyeing equipment

InactiveCN108396494AReduce labor intensityImprove work efficiencyGas treatmentDispersed particle separationWorking environmentEngineering

The invention discloses anti-blocking environment-friendly printing and dyeing equipment. The equipment comprises a machine box body, a printing and dyeing bin is fixed to one side of the upper surface of the machine box body, and a collecting tank is arranged on the top in the machine box body; one side of the upper surface of the printing and dyeing bin is provided with an induced draft fan, andthe side, close to the induced draft fan, of the upper surface of the printing and dyeing bin is fixedly provided with a filtering box through an F-shaped support; the air inlet end of the induced draft fan is connected with the printing and dyeing bin through a pipeline, and an air delivery pipe is connected between the air outlet end of the induced draft fan and the filtering box; a plurality of flow guiding convex blocks are arranged on the two sides of the inner wall of the collecting tank at equal intervals. The induced draft fan and the filtering box are arranged, so that air purification is achieved, harmful gas is prevented from being discharged and polluting the environment, and a health and comfortable working environment is formed; the flow guiding convex blocks are arranged, so that the flow state and the flow speed of a dye are changed, flowing of the dye is promoted, the dye is prevented from being condensed, rapid backflow of the dye is achieved, and printing and dyeingof the equipment are more efficient.

Owner:长兴超特纺织有限公司

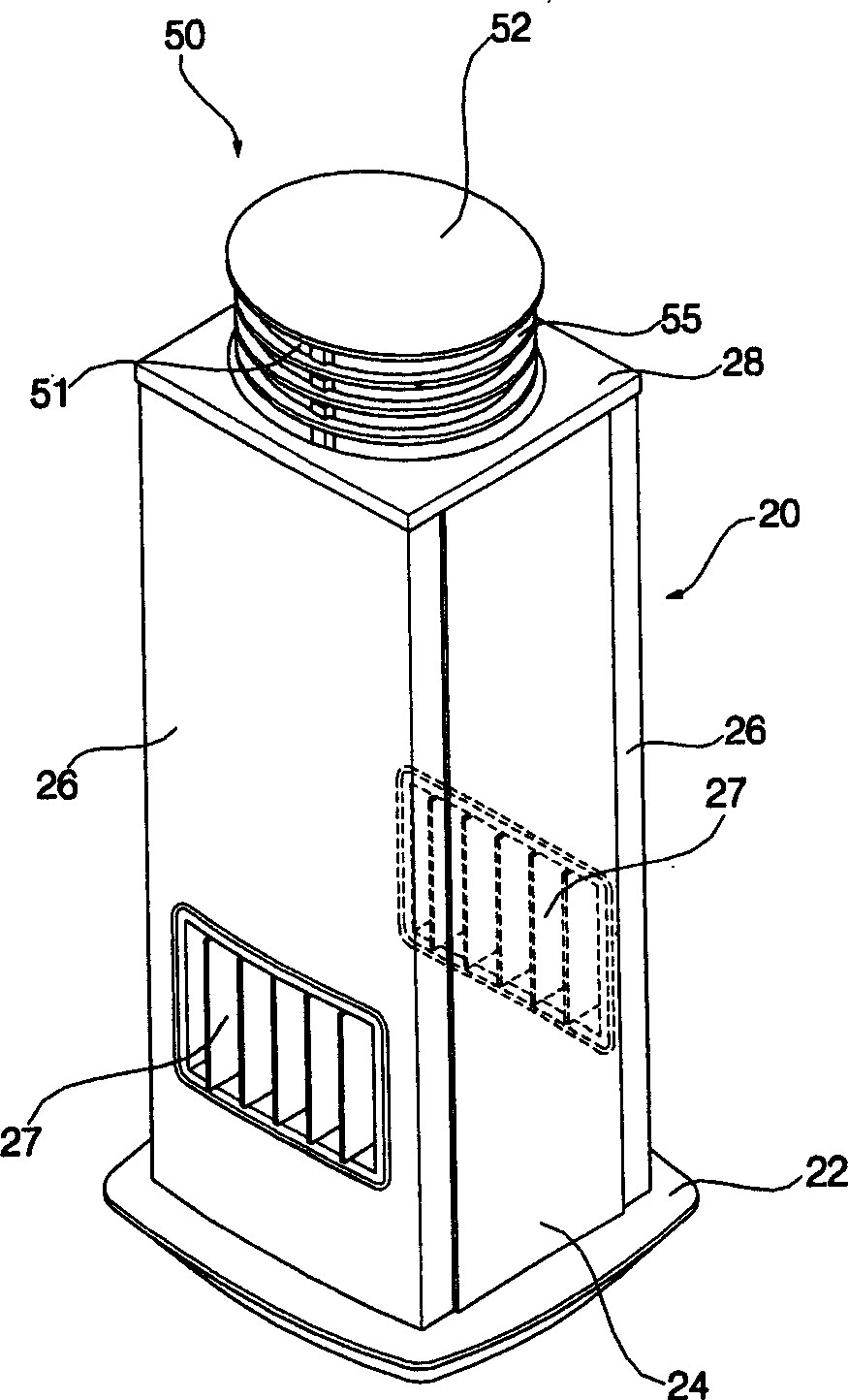

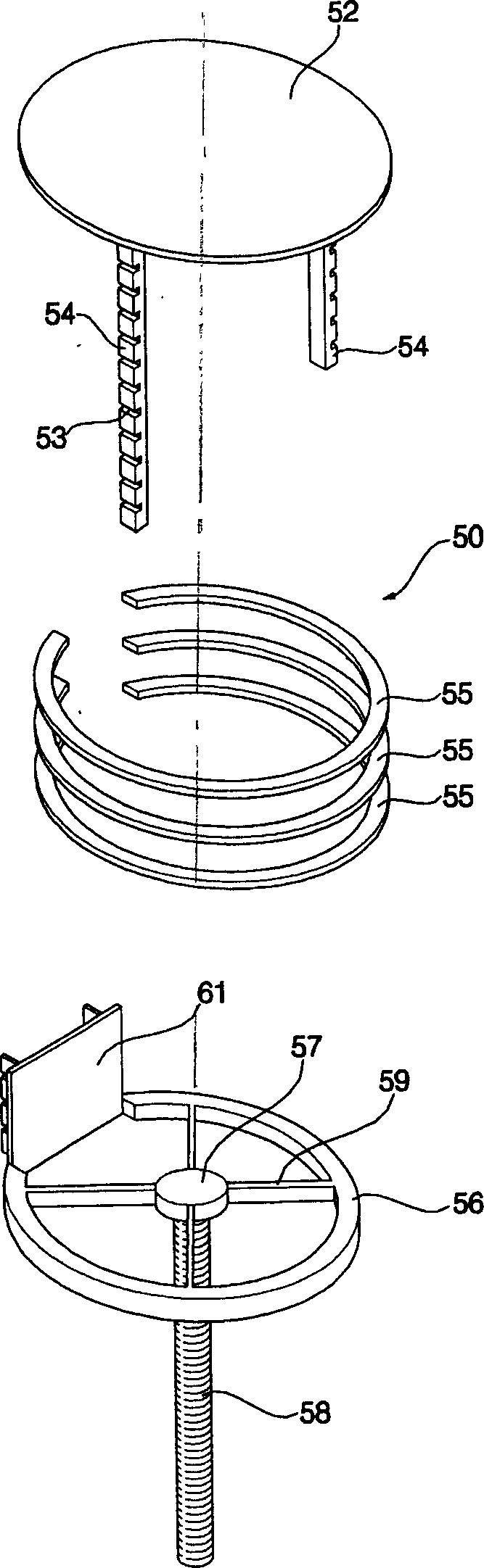

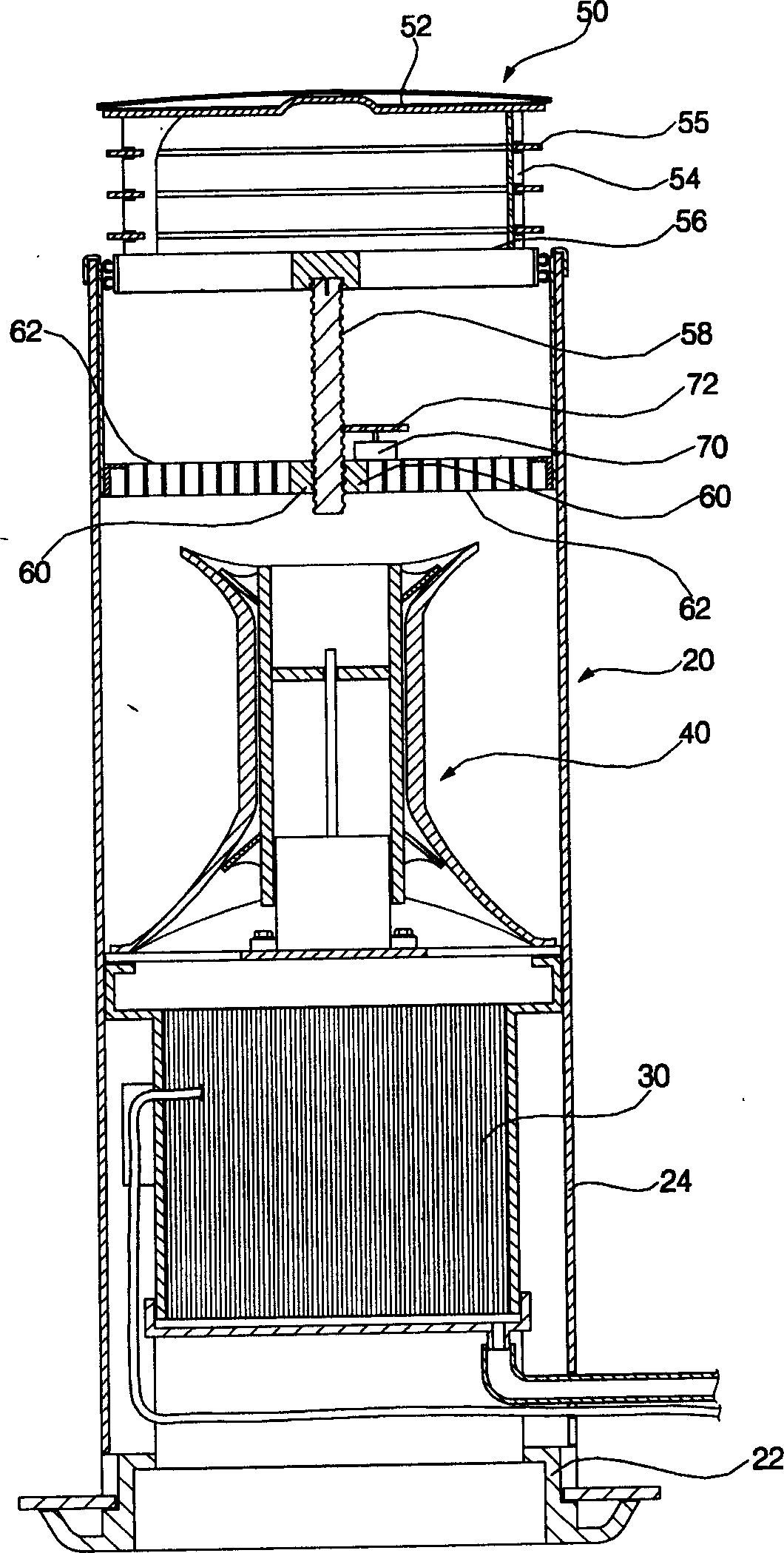

Indoor unit for air conditioner

InactiveCN1752603ASimple structureChange flow rateDucting arrangementsLighting and heating apparatusAir conditioningWaste management

The indoor machine of air conditioner includes external shell whose upper portion has an opening; discharge outlet component which can be lifted and fallen along the inner side of external shell and formed into discharge outlet; screw bolt formed on the lower side of discharge outlet component for lifting and falling the discharge outlet component; fixing component on which a nut portion engaged with screw bolt is formed and moving device for vertically moving screw bolt.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

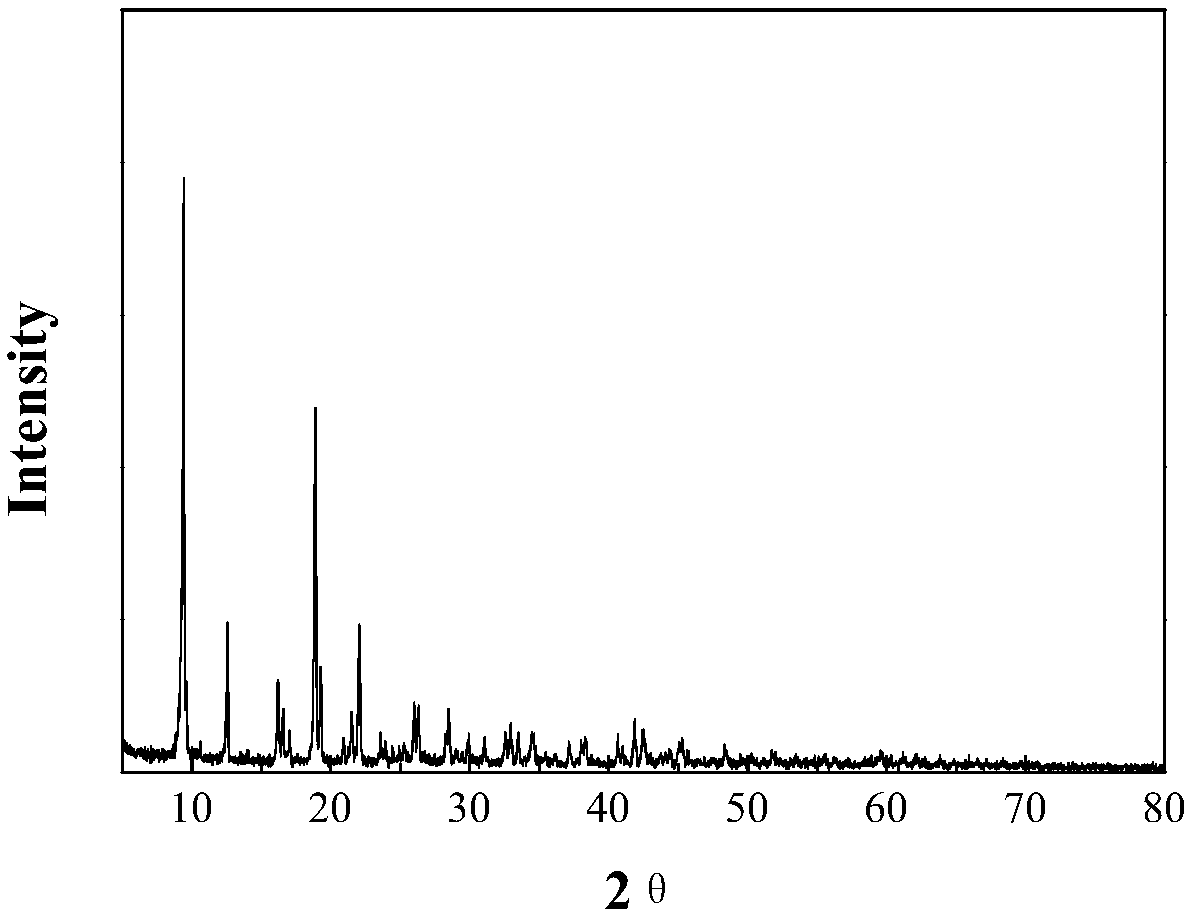

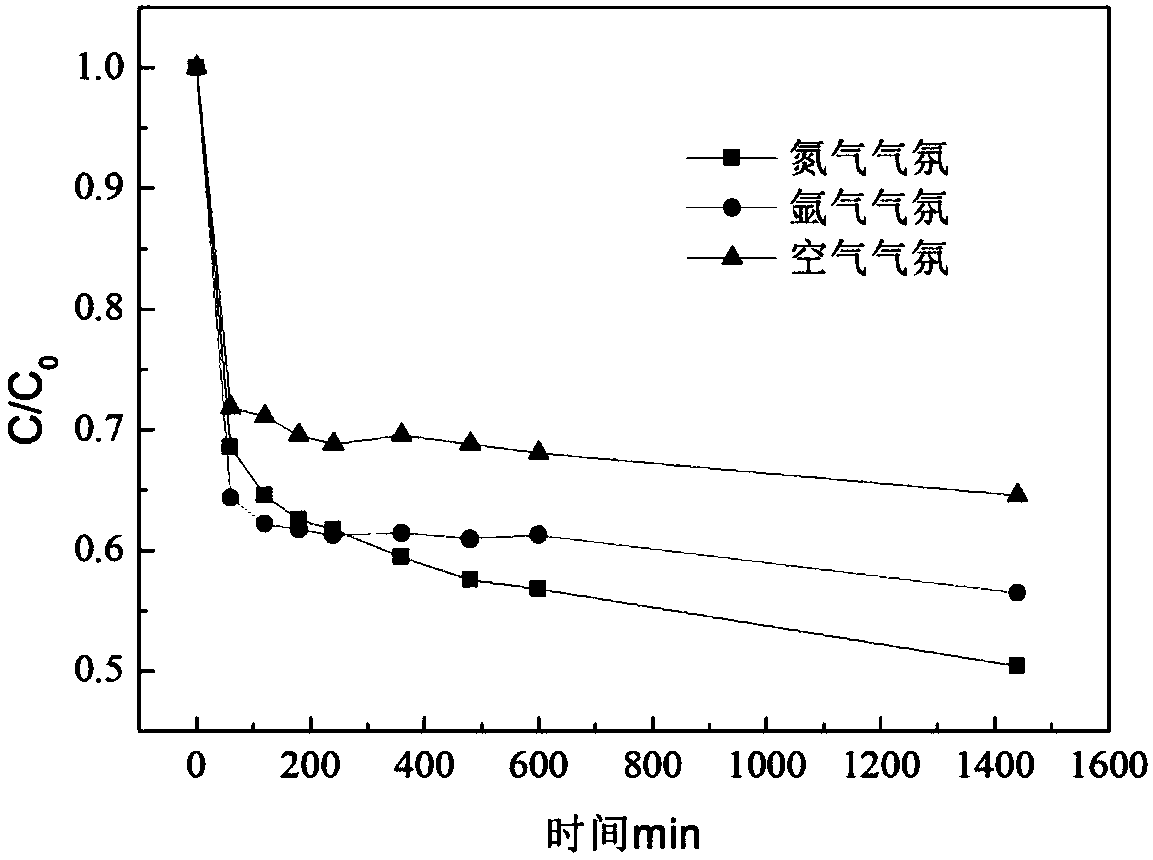

Method for preparing metal organic framework material from dielectric barrier discharge plasma

The invention discloses a method for preparing a metal organic framework material from a dielectric barrier discharge plasma. A metal salt and an organic ligand are added into a solvent, the metal salt, the organic ligand and the solvent are mixed and stirred evenly, and dissolved to obtain a reaction solution, the reaction solution is pumped into an inner tube of a dielectric barrier discharge plasma reactor, overflows from the edge of the inner tube lower than an outer tube, forms an even wall-hanging liquid film between the inner tube and the outer tube, and flows downwards slowly; and meanwhile, a working gas is introduced into the inner tube. Driven by a high-frequency high-voltage power supply, the plasma produced because of the discharge between a liquid electrode and a high-voltageelectrode of the outer tube acts on the liquid film flowing between the inner tube and the outer tube, so that the reaction solution reacts for a certain period of time under the action of the plasma, and the metal organic framework material is prepared. The method has the advantages of high synthesis speed, stable and efficient performance, strong adjustability, strong practicality, no secondarypollution and the like, and has a better application prospect.

Owner:QINGDAO UNIV OF SCI & TECH

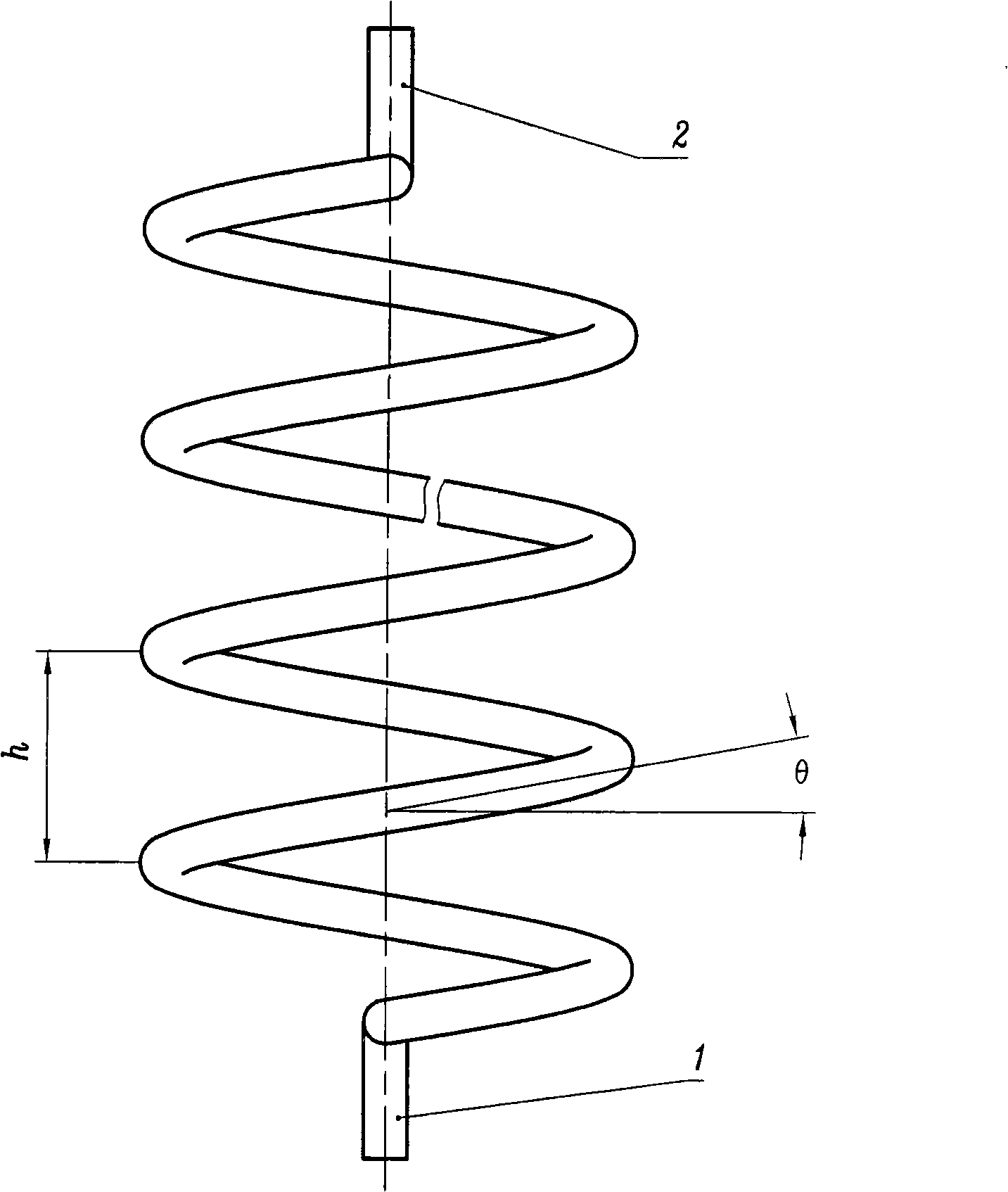

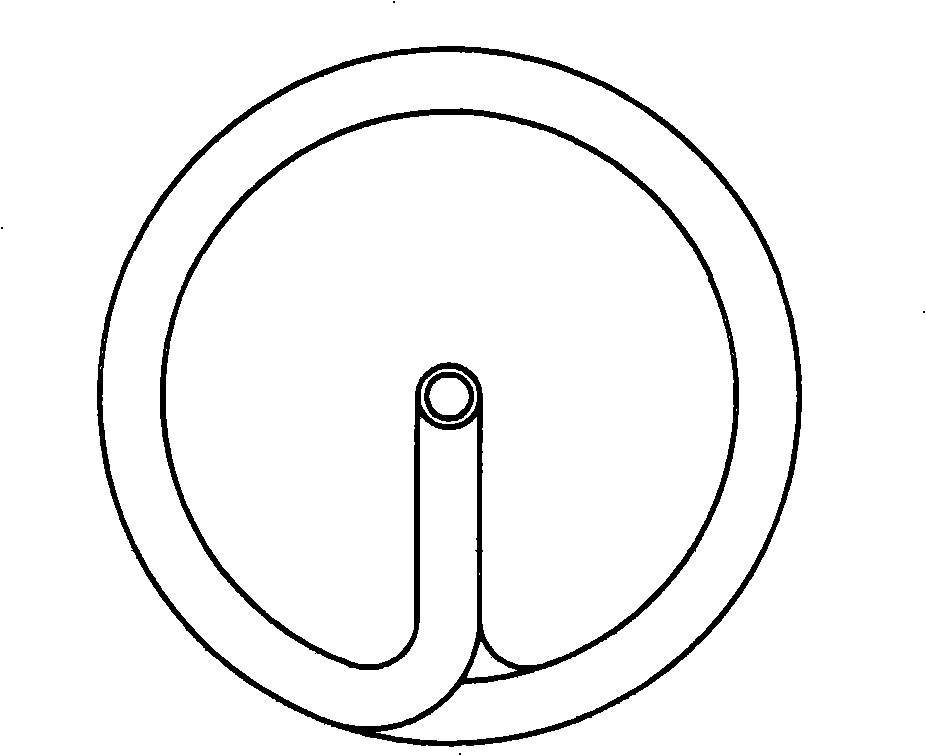

Spiral heat exchange tube

InactiveCN101514880AAvoid corrosionImprove heat transfer performanceHeat exchanger casingsHeat transfer modificationHeat transmissionStraight tube

The present invention provides a spiral heat exchange tube of which the cross section is annular, wherein, the helix angle of part with the heat exchange function is 10 DEG to 30 DEG. The thread pitch is 3-6 times of the outer diameter of the heat exchange tube. The inlet end 1 and outlet end 2 of heat exchange medium, which fix two ends of heat exchange tube to the heat exchanger, are equally one segment of straight tube. When the spiral heat exchange tube is installed into the heat exchanger, the pressure and flow velocity of medium (hot water, etc.) flowing through the heat exchanger tube can be continuously changed with a microseism mode. Compared with the prior heat exchange tube, the spiral heat exchanger according to the invention not only has high heat transmission efficiency, but also has strong self-cleaning and anti-scaling capability. The space can be effectively used and the capability of large heat transmission in small space is realized. The integrated energy-saving plan provided by the invention has the advantages of simple structure and low system cost. Relative to the prior self-cleaning heat exchange tube, the spiral heat exchange tube of the invention further has the advantages of smaller resistance, simpler structure, low cost, and suitability for quickly generalized and applied in practice.

Owner:CHONGQING UNIV

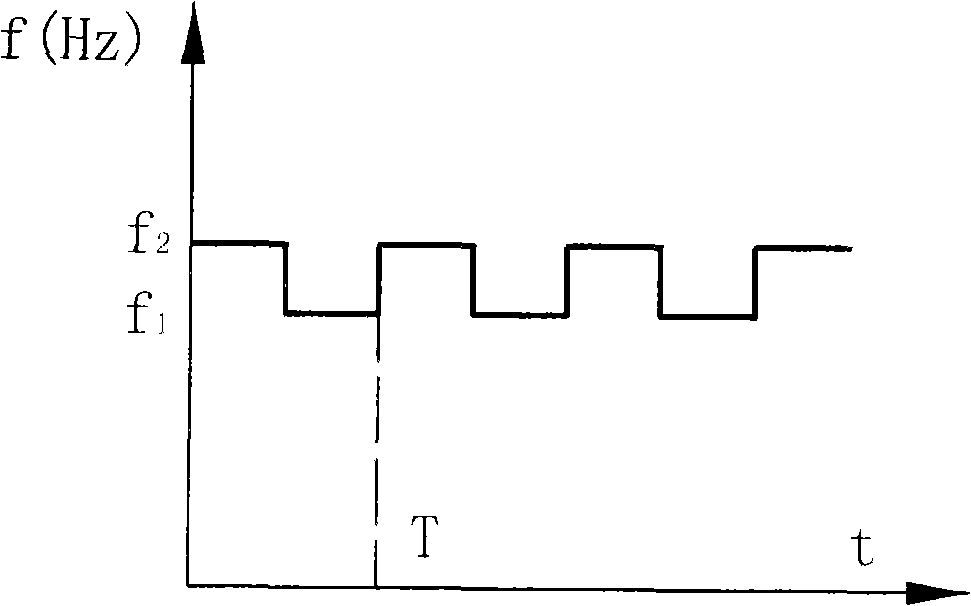

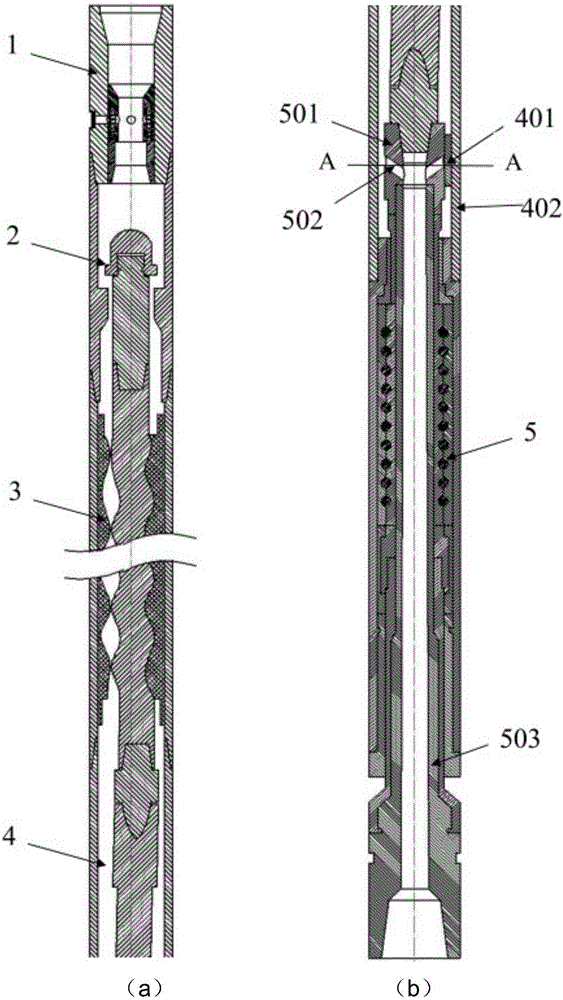

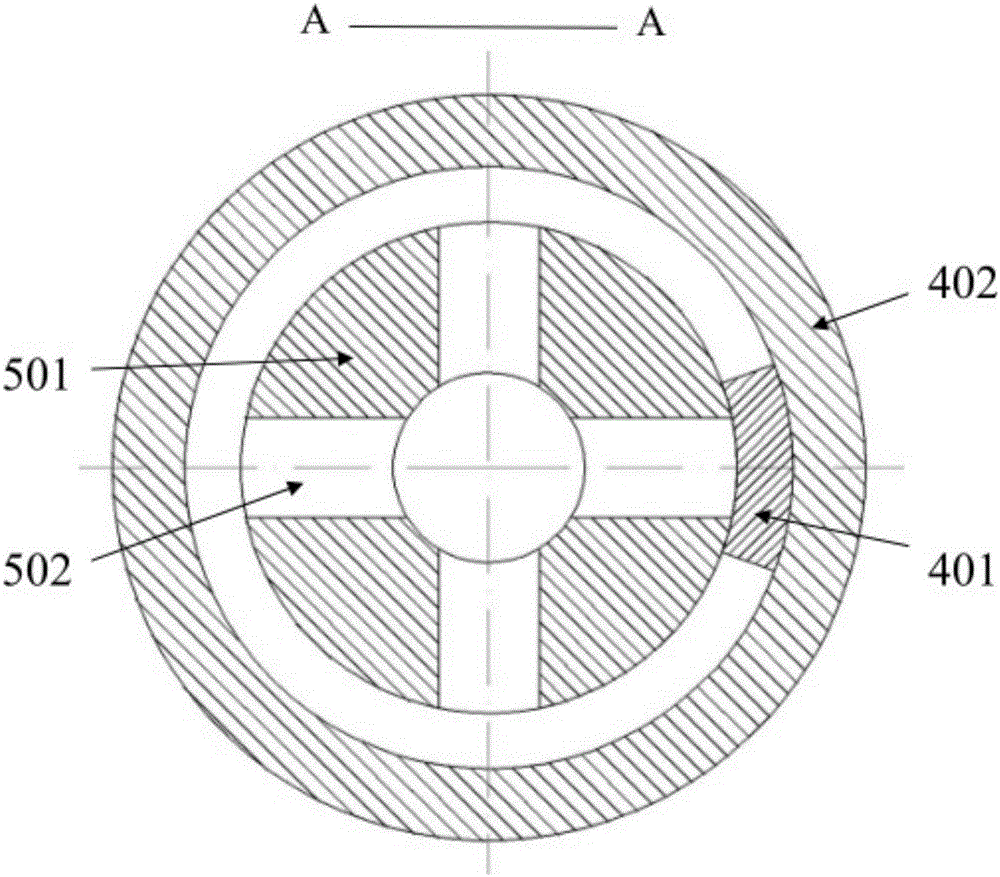

Churn screw drill for drilling

InactiveCN106522829AReduce "stuck-slip" phenomenonExtend your lifeDrilling drivesWell drillingDrive shaft

The invention provides a churn screw drill for drilling. The churn screw drill for drilling comprises a bypass valve assembly, an anti-falling assembly, a motor assembly, a universal shaft assembly and a transmission shaft assembly, wherein the universal shaft assembly comprises a universal shaft assembly housing and a universal shaft; the transmission shaft assembly comprises a water cap and a transmission shaft; the universal shaft, the water cap and the transmission shaft are sequentially connected through screw threads; a main liquid delivery hole is formed in the center of the water cap; a plurality of water cap liquid inflow holes which are evenly distributed in a circular array mode and communicate with the main liquid delivery hole are formed in the side face of the water cap; a liquid delivery channel communicating with the lower end of the main liquid delivery hole is arranged in the center of the transmission shaft; a stop baffle is installed on the inner side of the universal shaft assembly housing; and the water cap liquid inflow holes are covered with the stop baffle when rotated to the stop baffle, so that the total liquid inflow area of the water cap is decreased. The churn screw drill for drilling has the beneficial effects that through the design, torsion and rotation speed of the motor assembly can be periodically changed, thus, a motor can generate continuous torsion while high-frequency low-amplitude torsion impact shock is transferred to a drill bit, and accordingly the jamming and slippage phenomena of the drill bit are avoided.

Owner:天津市高原瑞丰工贸有限公司

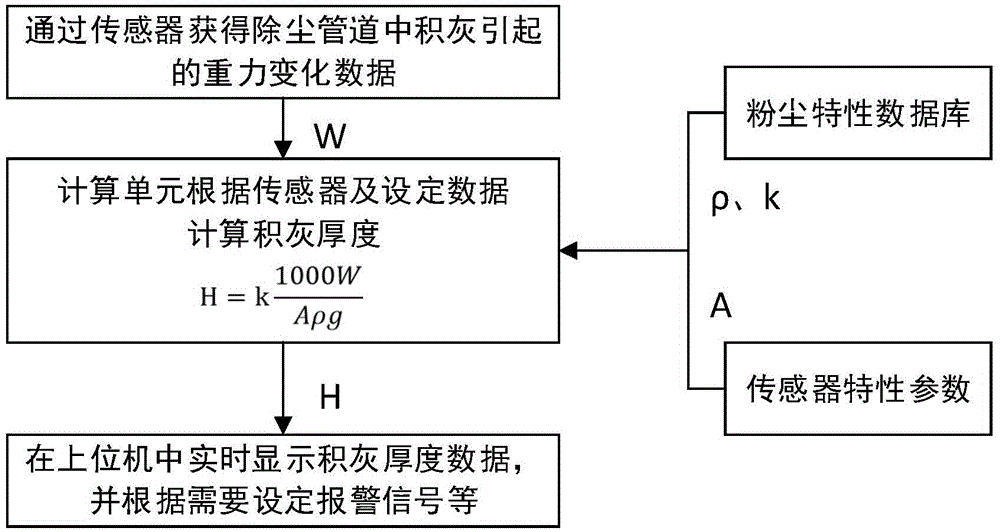

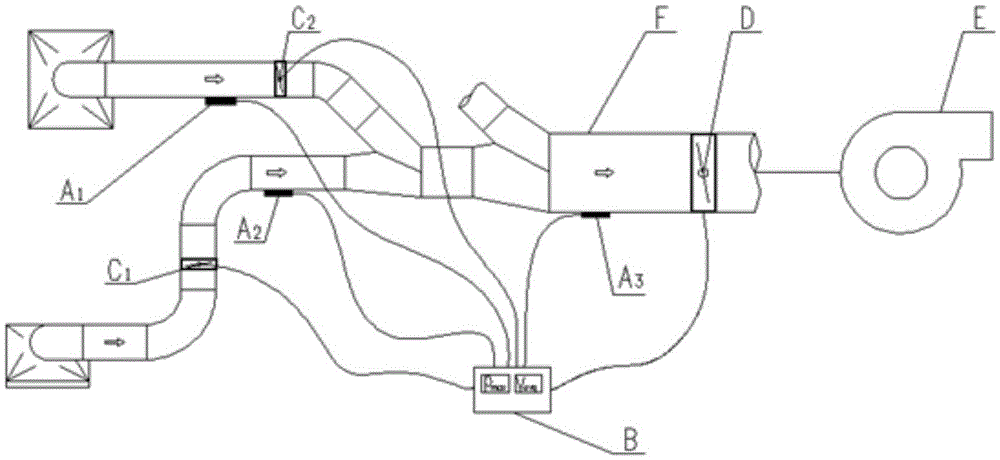

Automatic dedusting method and system for dust removal pipeline

The invention discloses an automatic dedusting method and system for a dust removal pipeline. The automatic dedusting method comprises the steps that dust deposition weight data of each detection point in the dust removal pipeline are obtained; the dust deposition thickness of each detection point is calculated according to the dust deposition weight data; the pipeline blockage degree P and the dust deposition rate V of each detection point are calculated according to the dust deposition thickness, and the average dust deposition rate V<avg> of all the detection points is calculated according to the dust deposition rates V; when the pipeline blockage degree P of a certain detection point reaches the set value, dedusting is conducted by increasing the air door open degree of a pipeline body where the detection point is located; and when the average dust deposition rate V<avg> reaches the set value, the dust deposition rate is decreased by increasing the air door open degree of a main pipeline body. According to the automatic dedusting method and system for the dust removal pipeline, energy consumption of a dust removal system can be significantly reduced; pipeline abrasion is effectively relieved; long-term stable operation of the dust removal system is ensured; and in addition, the method adopts an automatic feedback closed-loop control mode, so that manual operation is not needed, and the operation and maintenance workload is small.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com