Air amplifier capable of increasing air flow amount

An air amplifier and air flow technology, which is applied in the field of cooling devices, can solve the problems of insufficient wind strength and non-concentrated wind force, and achieve the effect of increasing the outflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

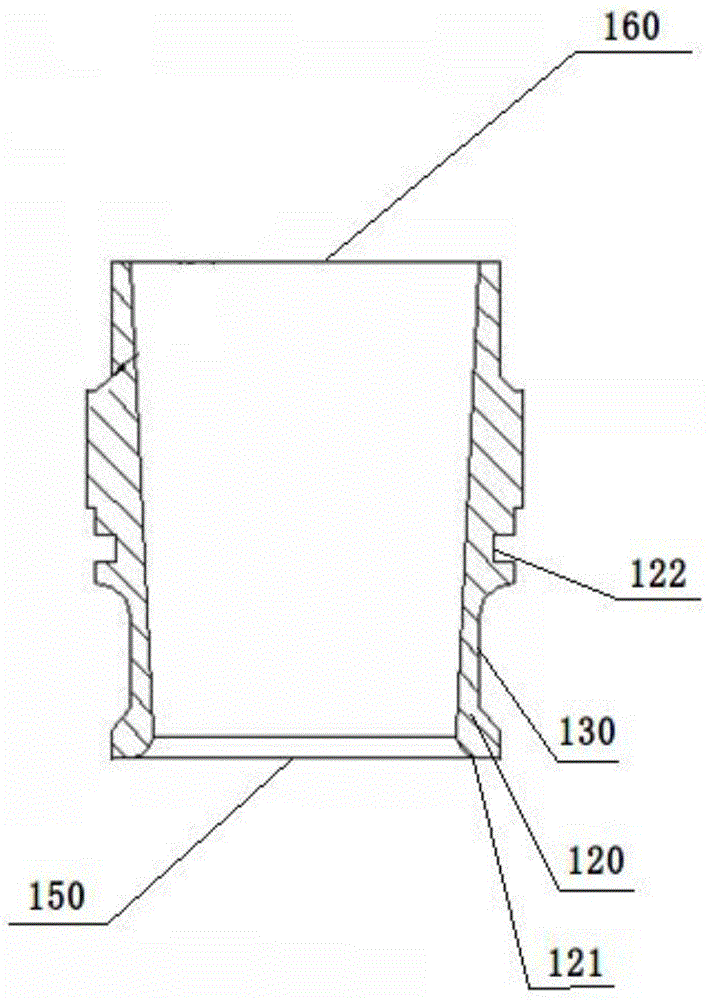

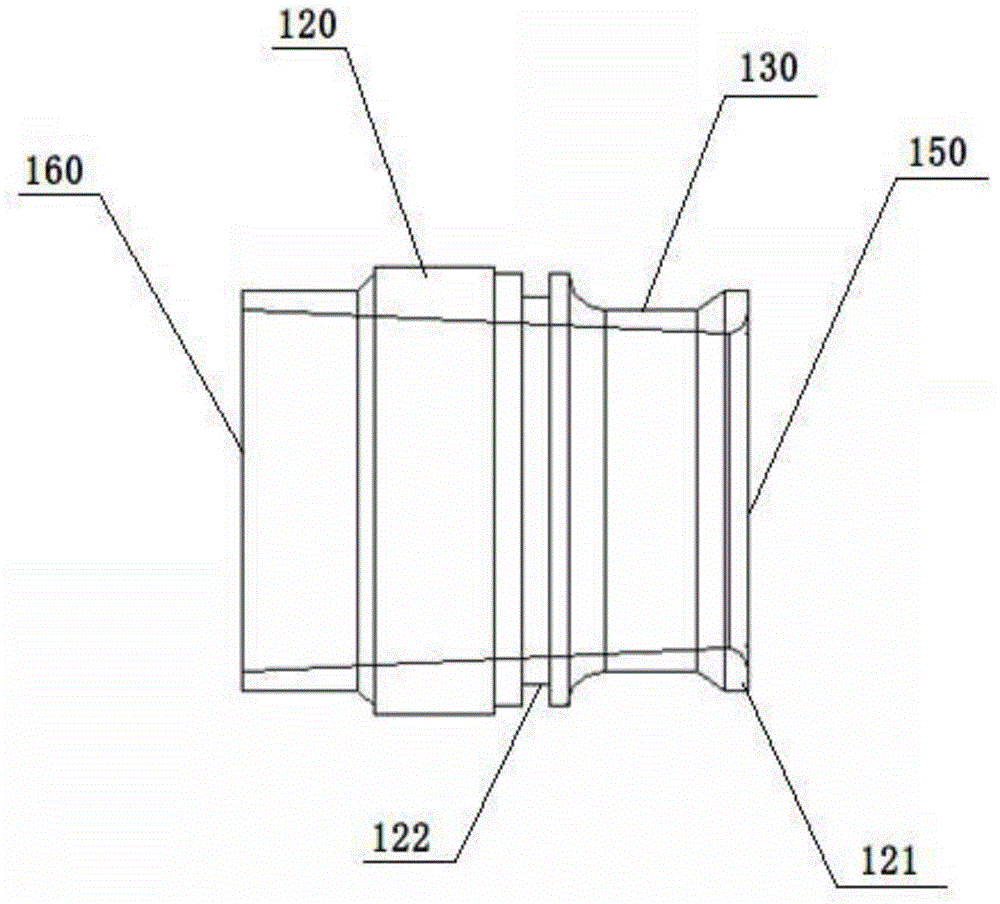

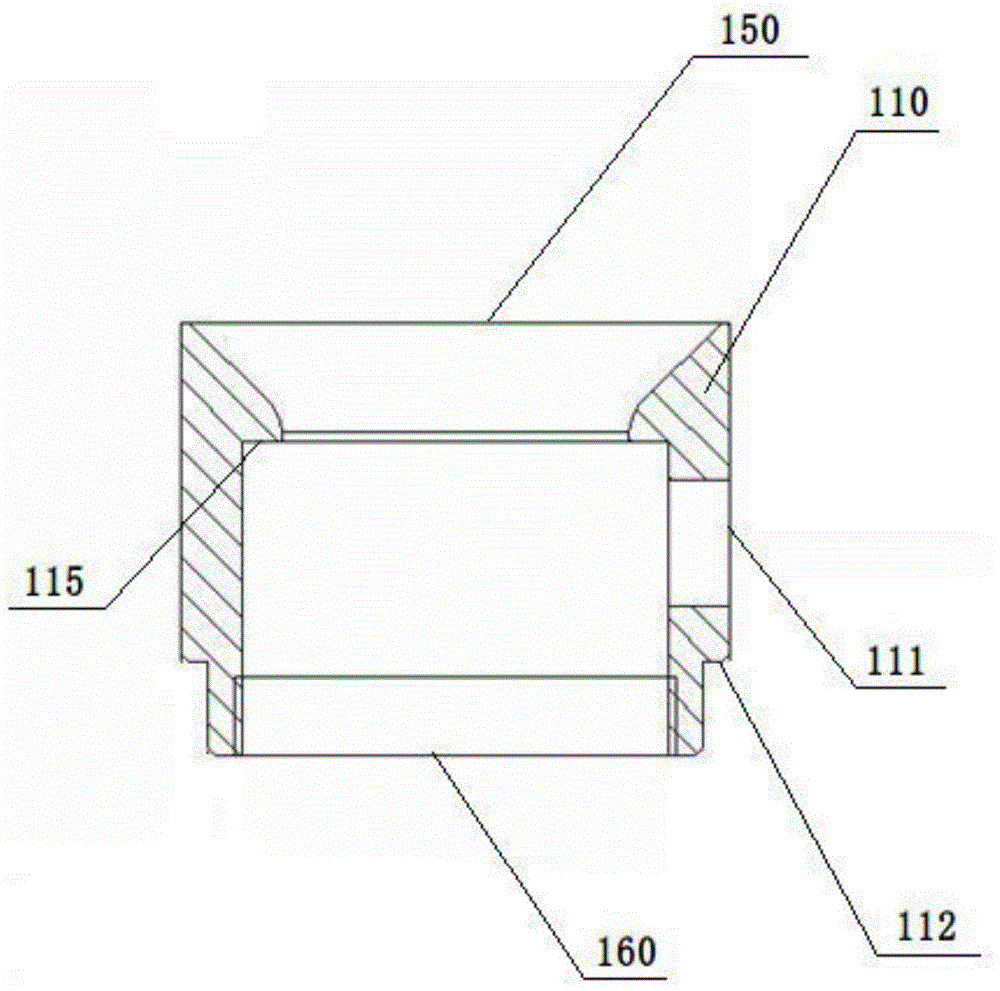

[0030] combine Figure 1 to Figure 6 , is a schematic structural view of the combination of the inner lining 120 and the outer jacket 110 of the air amplifier 100 of the present invention. In the present invention, the air amplifier 100 includes a casing 110 and an inner liner 120 , and the inner liner 120 is inserted into the outer casing 110 to form the air amplifier 100 . In order to provide external compressed air to the air amplifier 100, the overcoat 110 is provided with a through hole 111, the through hole 111 communicates with the external compressed air source and the inside of the overcoat 110, corresponding to the through hole 111, the inner lining opposite the air outlet end inside the overcoat 110 The part of 120 is folded, that is, part of the liner 120 is folded inward to form a structure similar to a bell mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com