Droplet separator system

A droplet separator and separation technology, which can be applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reducing the separation capacity of droplet separator devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

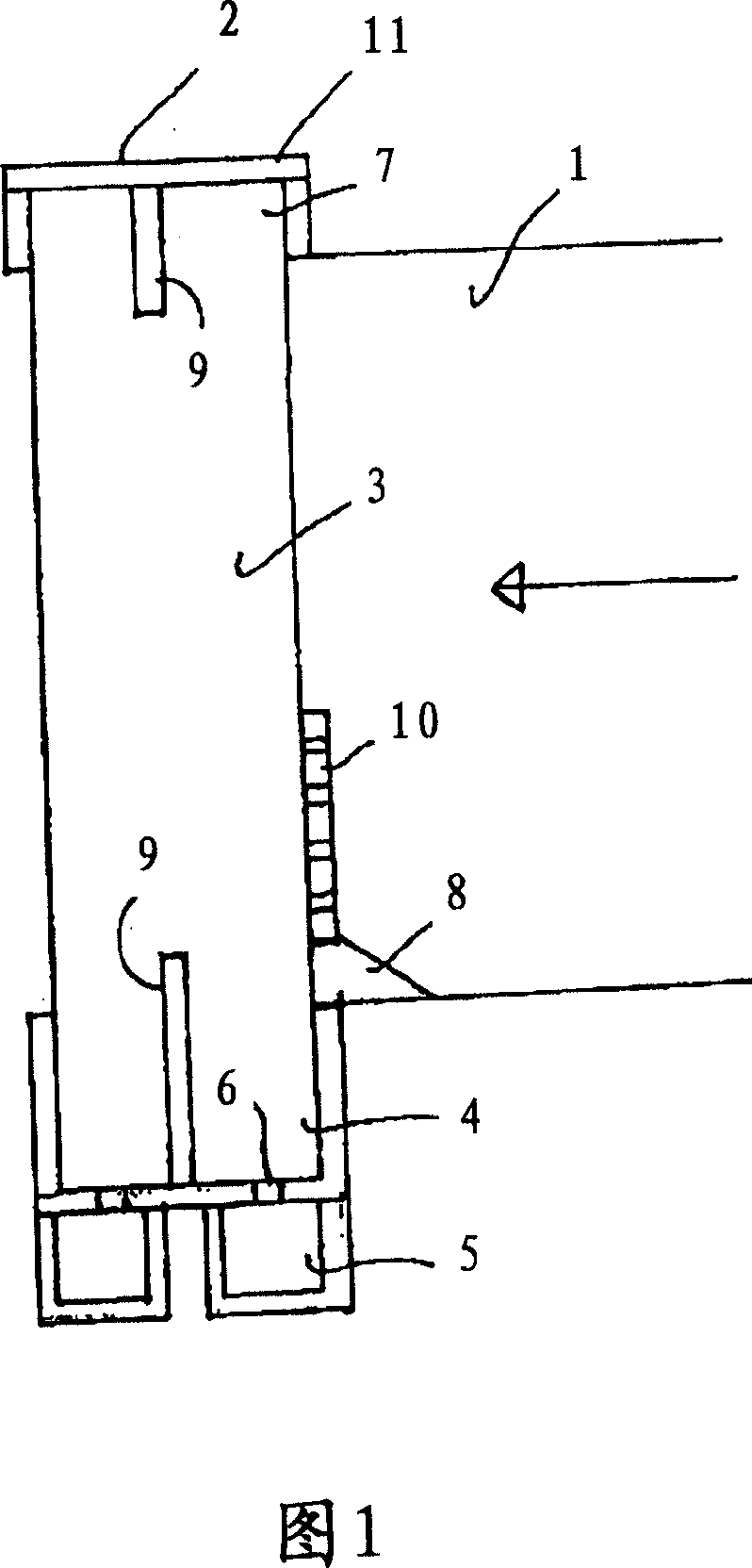

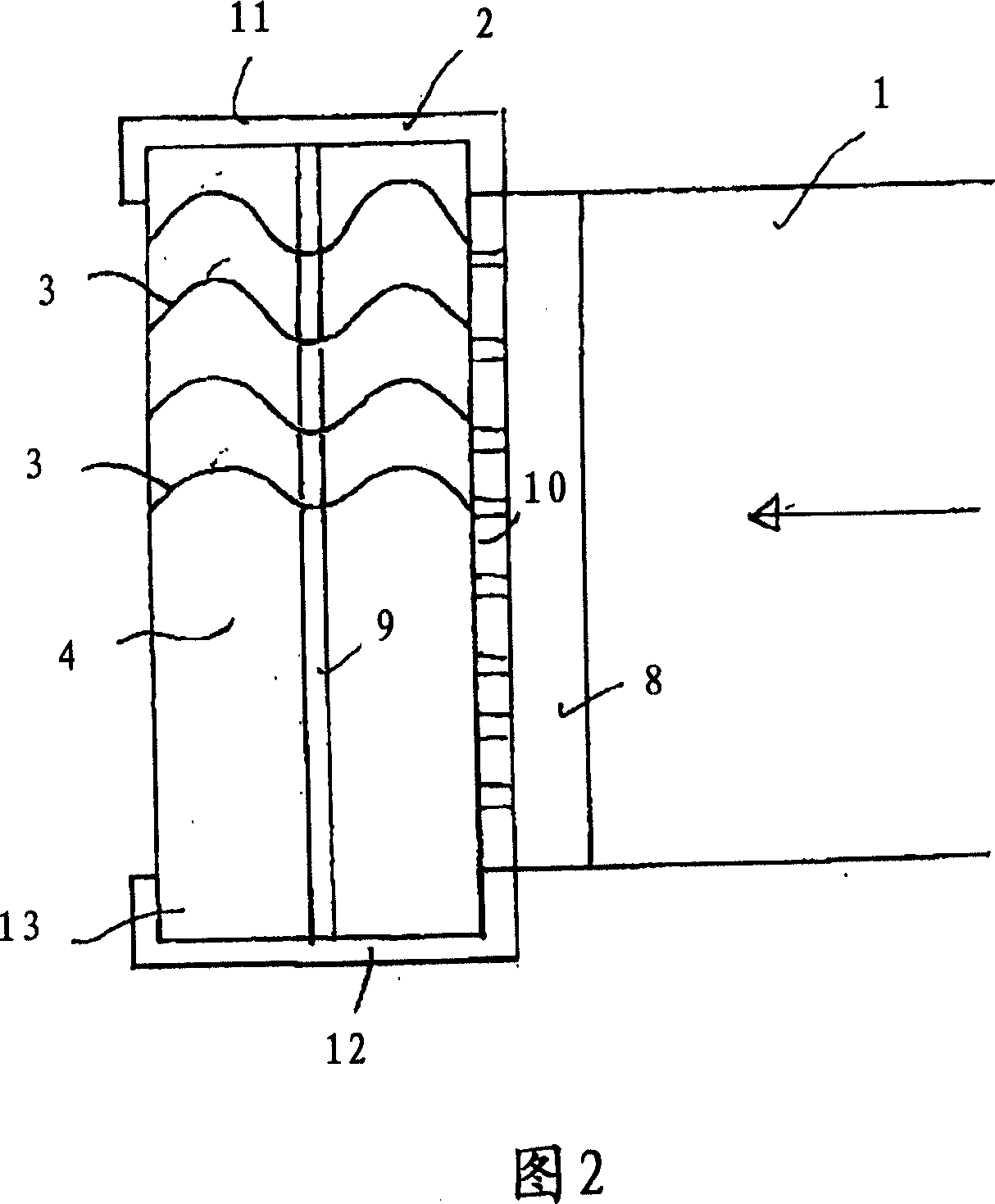

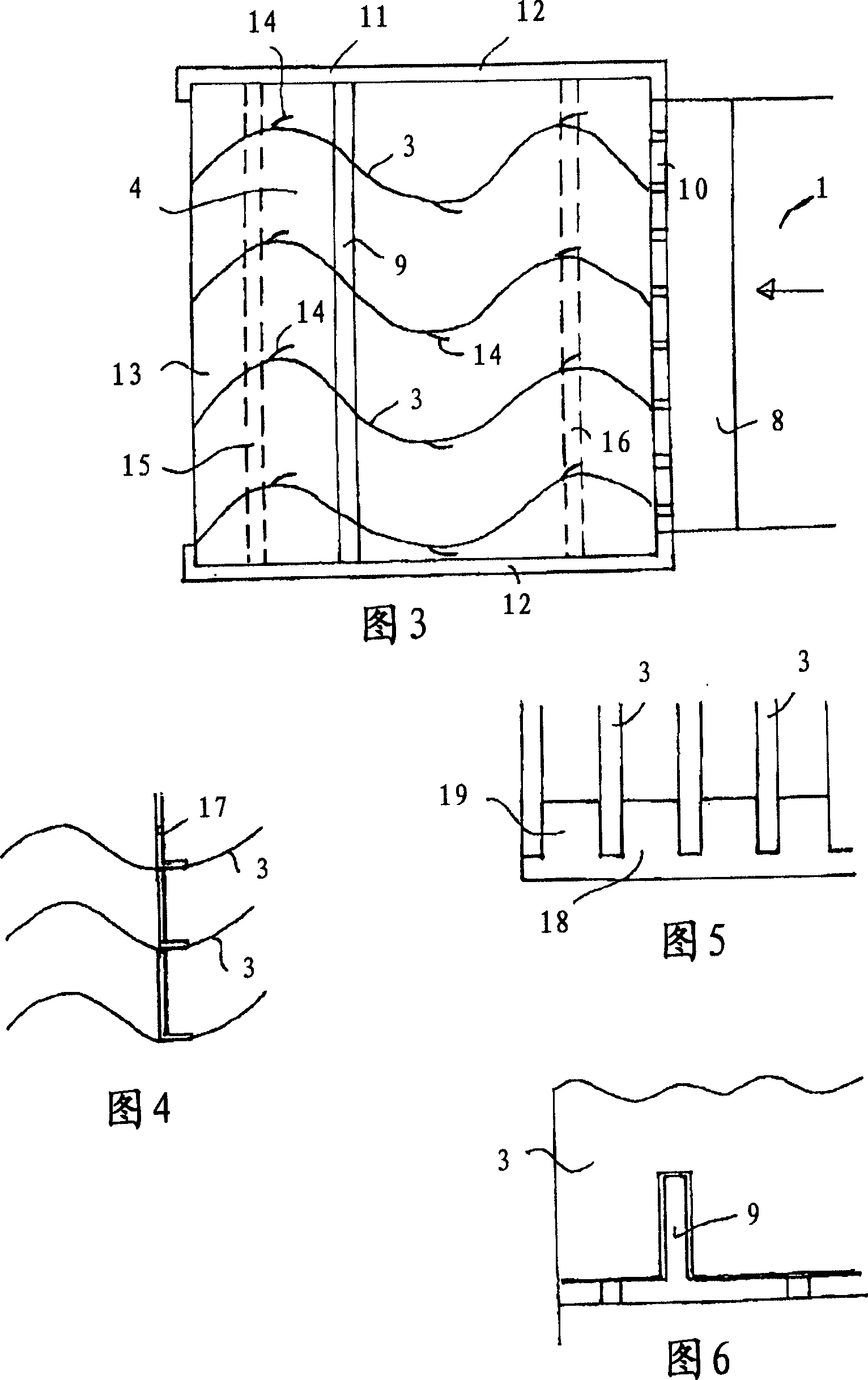

[0039] FIG. 1 shows a section of a flow channel 1 through which a liquid-laden gaseous medium flows. The direction of flow is indicated by the arrows shown. In order to separate the liquid present in the medium, the flow channel 1 leads into a dropper device 2 . The dropper device 2 comprises a frame 11 with two side walls 12 (shown in FIG. 2 ), an upper cover region 7 and a lower trough region 4 . The cover area 7 is located above the flow channel 1 and the groove area 4 is located below the flow channel. Inside the frame 11 are arranged a plurality of vertically arranged drop distributor profiles 3 parallel to one another, this being a laminated drop divider profile of known construction. These drop distributor profiles are not shown in great detail in the figures. Since they are known, no further details have to be stated in this respect. In any case, the flow deflection effected by the foil profile achieves separation of the droplets, which flow down the profile and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com