Spinning process of cellulose fibre and integration apparatus

A cellulose fiber and cellulose technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as uneven force, decreased mechanical properties of fibers, uneven fibers, etc., to achieve uniform strength and elongation long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

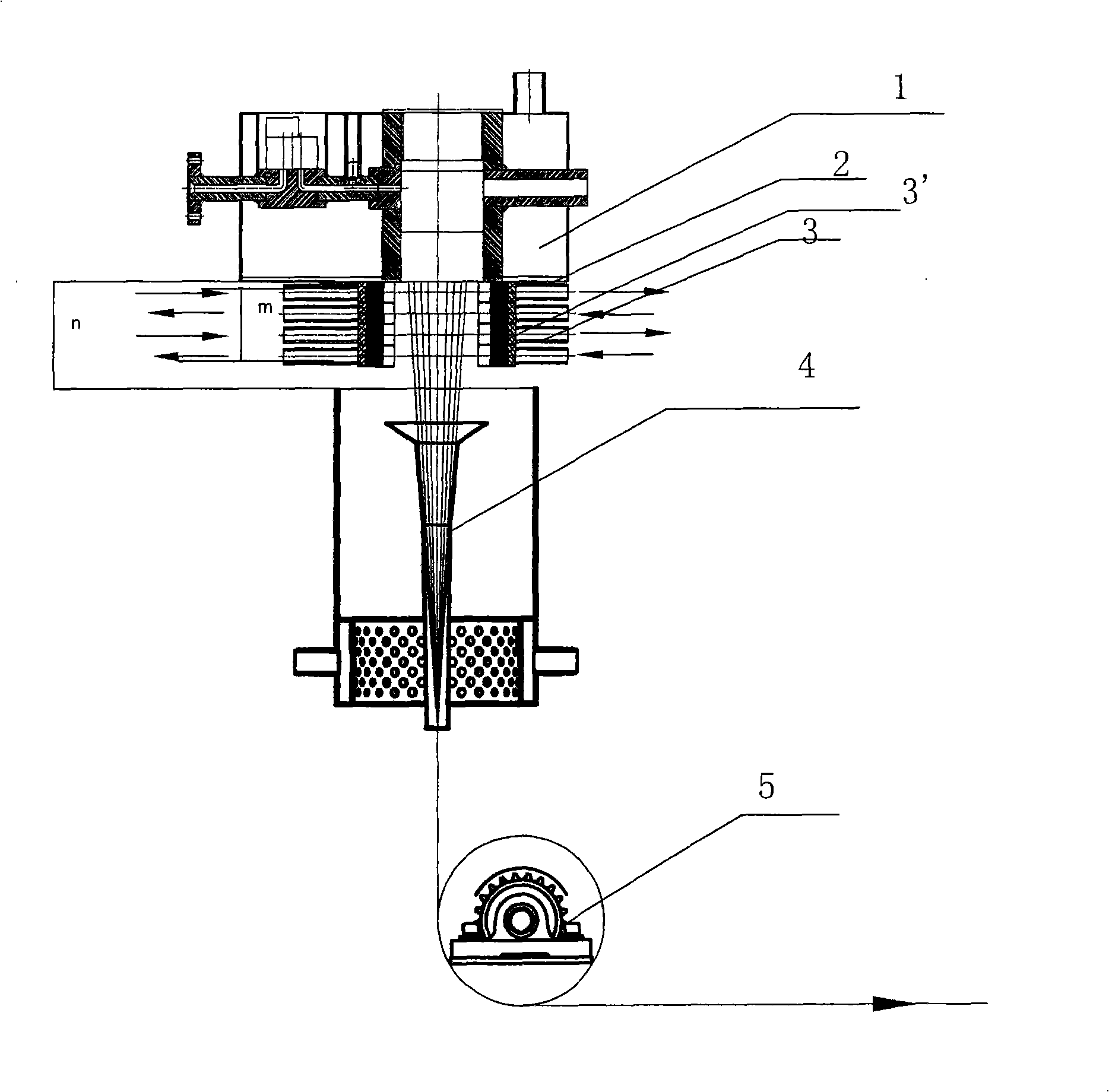

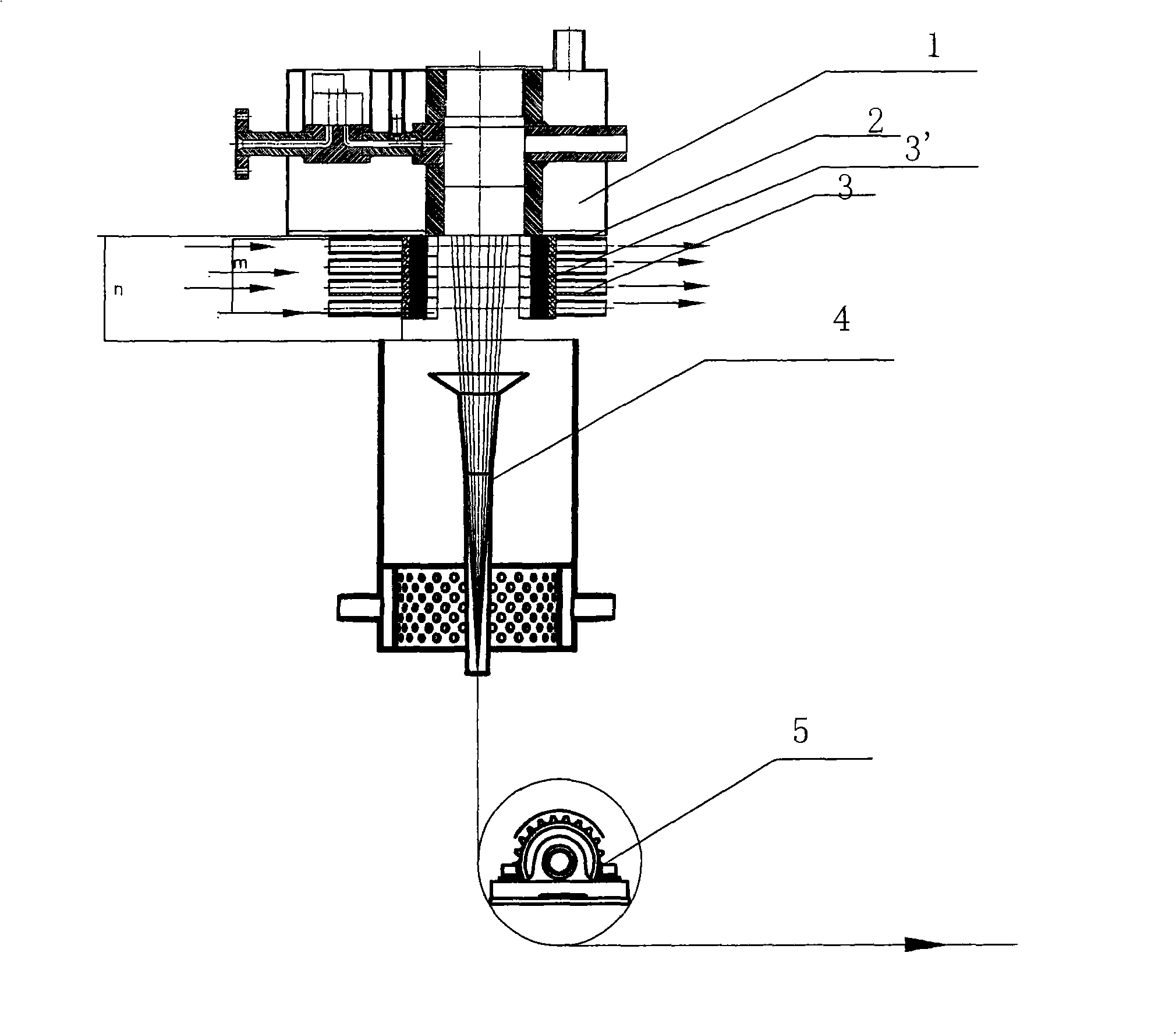

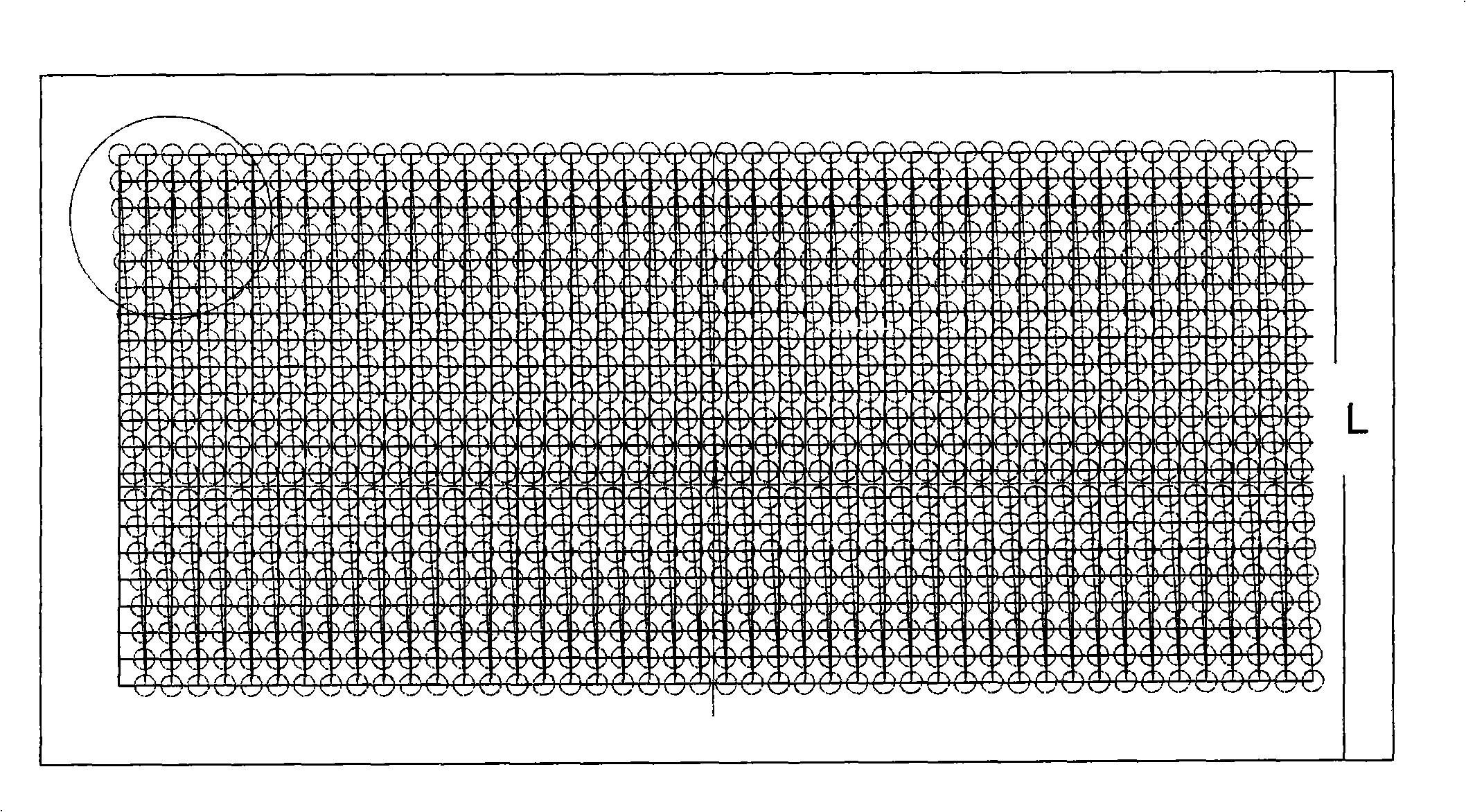

[0037] See attached figure 1, in this method, the spinning stock solution prepared by the continuous spinning stock solution preparation device, wherein the cellulose concentration is 9%, is extruded from the spinneret assembly 1, and passes through the spinneret 2, and the number of holes in the spinneret The number of spinneret holes is 2000, the diameter of the spinneret hole is 0.5mm, the ratio of the length of the spinneret hole to the diameter is 1, all the spinneret holes are arranged on a hole array, and the row of the hole array is parallel to the long side of the spinneret plate. The short side of the column and the spinneret is 0°, that is, parallel to the short side, and then passes through a section of air gap layer, the length n of the air gap layer here is 200mm, in this air gap layer, the cellulose fiber completes its In the stretching process, the cooling air at 20°C is issued from the cooling gas blowing device 3 located below the spinneret, and the tow is bl...

Embodiment 2

[0040] In this method, the spinning stock solution prepared by the continuous spinning stock solution preparation device, wherein the cellulose concentration is 11%, is extruded from the spinning assembly 1, and passes through the spinneret 2, and the number of holes in the spinneret is 2000, the diameter of the spinneret hole is 0.5mm, the ratio of the length to the diameter of the spinneret hole is 1, all the spinneret holes are arranged in a hole array, the row of the hole array is parallel to the long side of the spinneret, and the row It is 35° to the short side of the spinneret, and then passes through an air gap layer, where the length n of the air gap layer is 150mm. In this air gap layer, the cellulose fiber completes its stretching process, where , 10°C cooling nitrogen gas is issued from the cooling gas blowing device 3 located below the spinneret, blowing and sucking the tow in the form of two layers of laminar flow, and the cooling gas generating device includes tw...

Embodiment 3

[0043] In this method, the spinning stock solution prepared by the continuous spinning stock solution preparation device, wherein the cellulose concentration is 13.5%, is extruded from the spinning assembly 1, and passes through the spinneret 2, and the number of holes in the spinneret is 6000, the diameter of the spinneret hole is 0.25mm, the ratio of the length to the diameter of the spinneret hole is 2, all the spinneret holes are arranged in a hole array, the row of the hole array is parallel to the long side of the spinneret, and the row It is 15° to the short side of the spinneret, and then passes through a section of air gap layer, where the length n of the air gap layer is 100mm. In this gas gap section, the cellulose fiber completes its stretching process. Here At 10°C, the cooling air at 10°C is issued from the cooling gas blowing device 3 located below the spinneret. The cooling gas blowing device includes 6 layers of blowing ports and suction ports. The width is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com