Controllable multi-point active fluid heat dissipation system integrated on PCB

A heat dissipation system and active technology, applied in the direction of circuit fluid transportation, electric solid devices, circuit heat devices, etc., can solve the problems of low integration, limited pump cavity compression ratio, weak control ability of fluid heat dissipation system, etc., to achieve flexible structure, The effect of changing the form and improving the degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

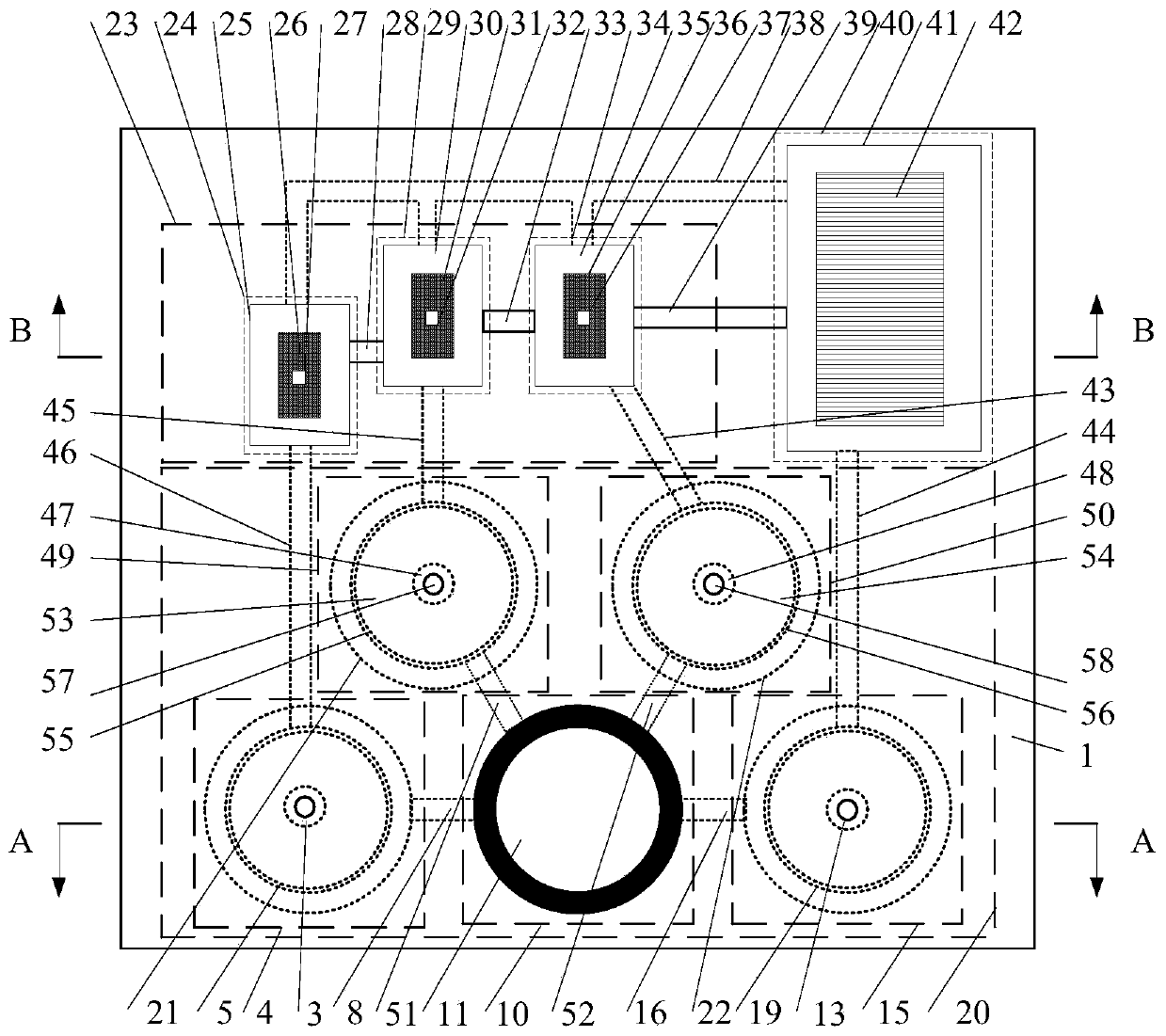

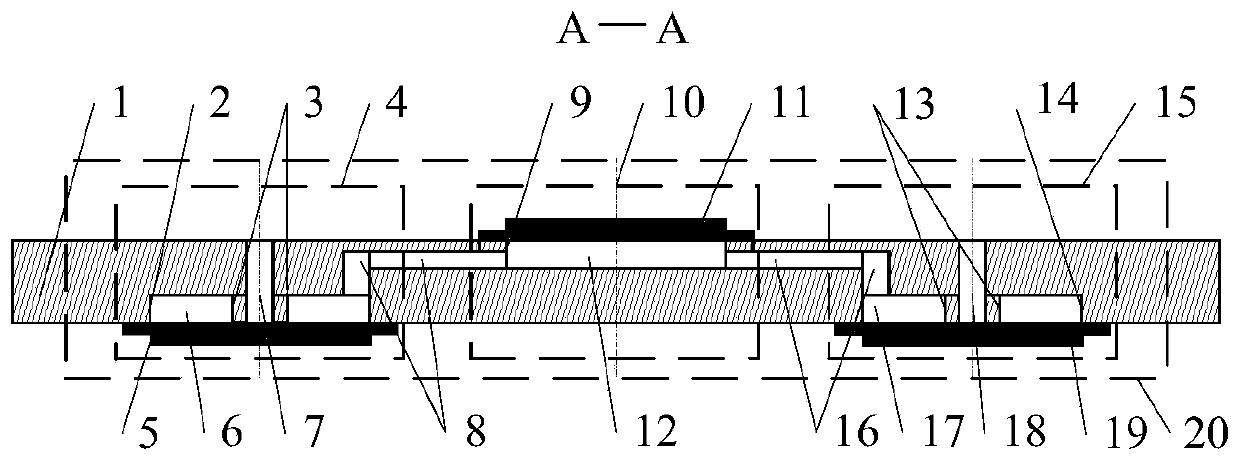

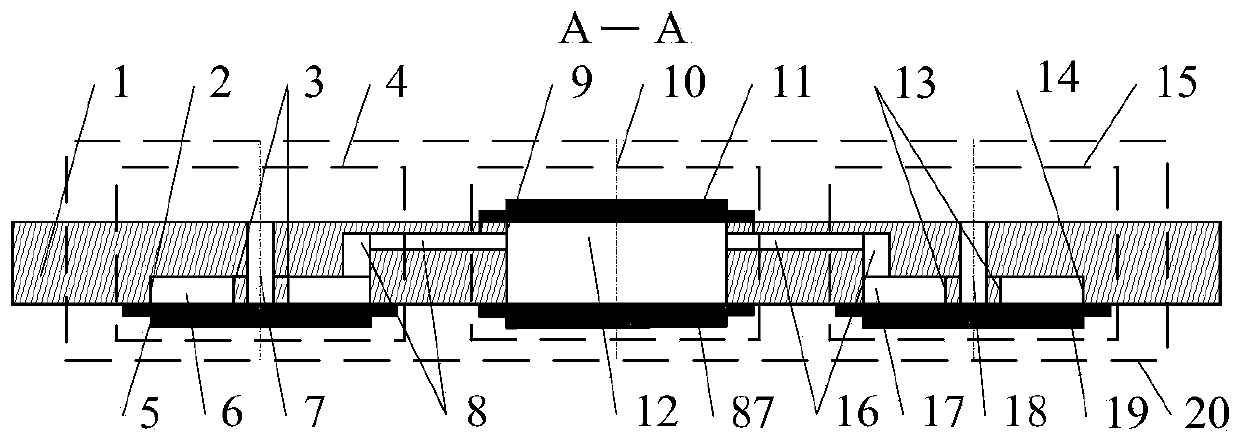

[0053] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0054] figure 1 It is a schematic diagram of the structure and principle of the controllable active fluid cooling system integrated on the PCB of this embodiment. The controllable active fluid cooling system integrated on the PCB is composed of an active fluid control device 20 , a cooling device 23 and a fluid cooling device 40 welded on the PCB substrate 1 . Wherein the active fluid control device 20 is mainly composed of a piezoelectric actuated fluid pump consisting of a cylindrical pump action unit 10 and a plurality of piezoelectric actuated fluid pumps with torus boundaries 3, 13, 47, 48. Fluid valves 4, 15, 49, 50 constitute, and the cylindrical pump action unit 10 communicates with a plurality of piezo-actuated fluid valves 4, 15, 49, 50 with torus boundaries through flow channels 8, 16, 51, 52 connect. Among them, the cylindrical pump action unit 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com