Method for preparing metal organic framework material from dielectric barrier discharge plasma

A technology of dielectric barrier discharge and metal-organic framework, which is applied in the field of plasma preparation, can solve the problems of difficult control of product morphology and stability, difficulty of plasma establishment, and complicated process flow, so as to achieve easy control of product morphology and stability , control the effect of perfect crystal growth and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

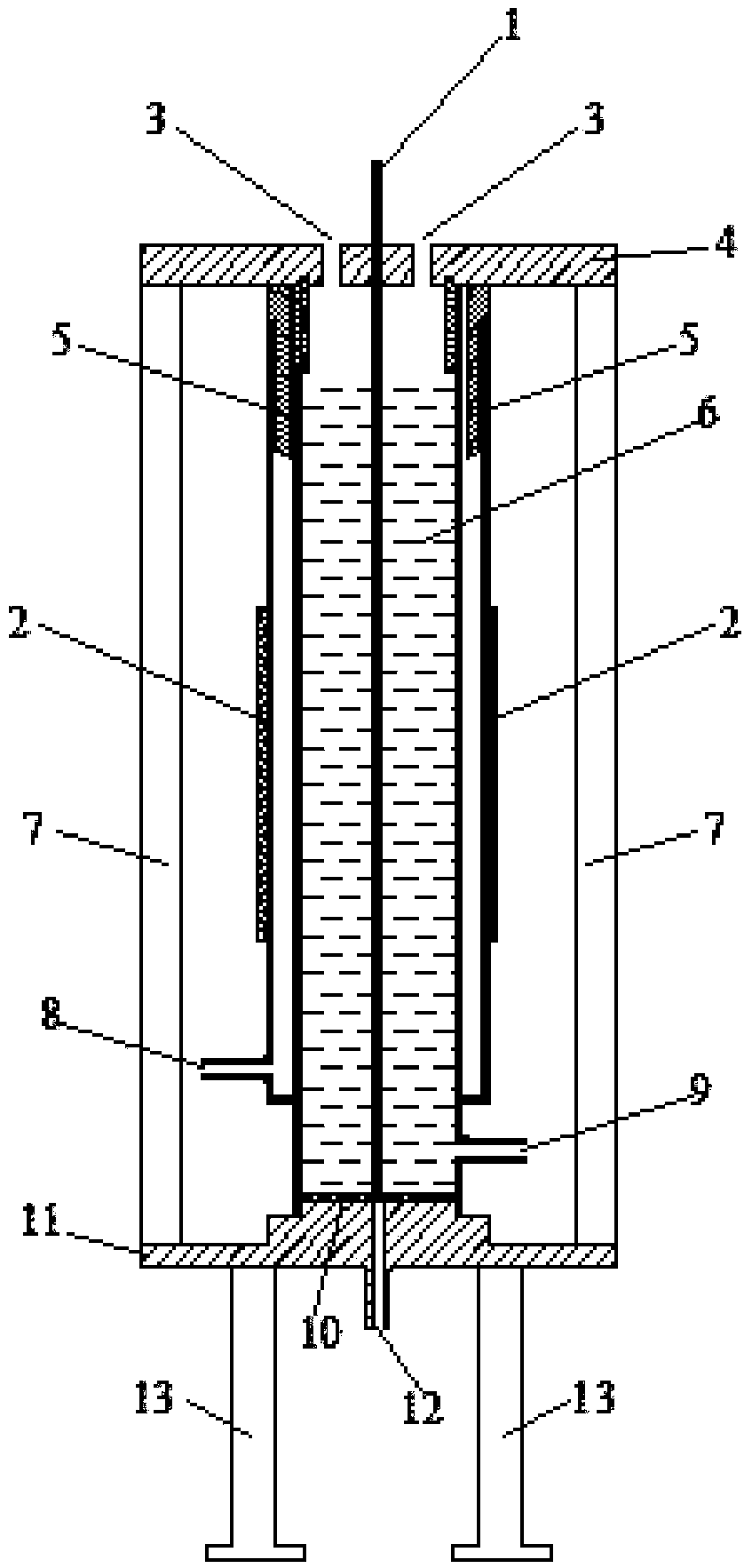

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of iron metal organic framework material

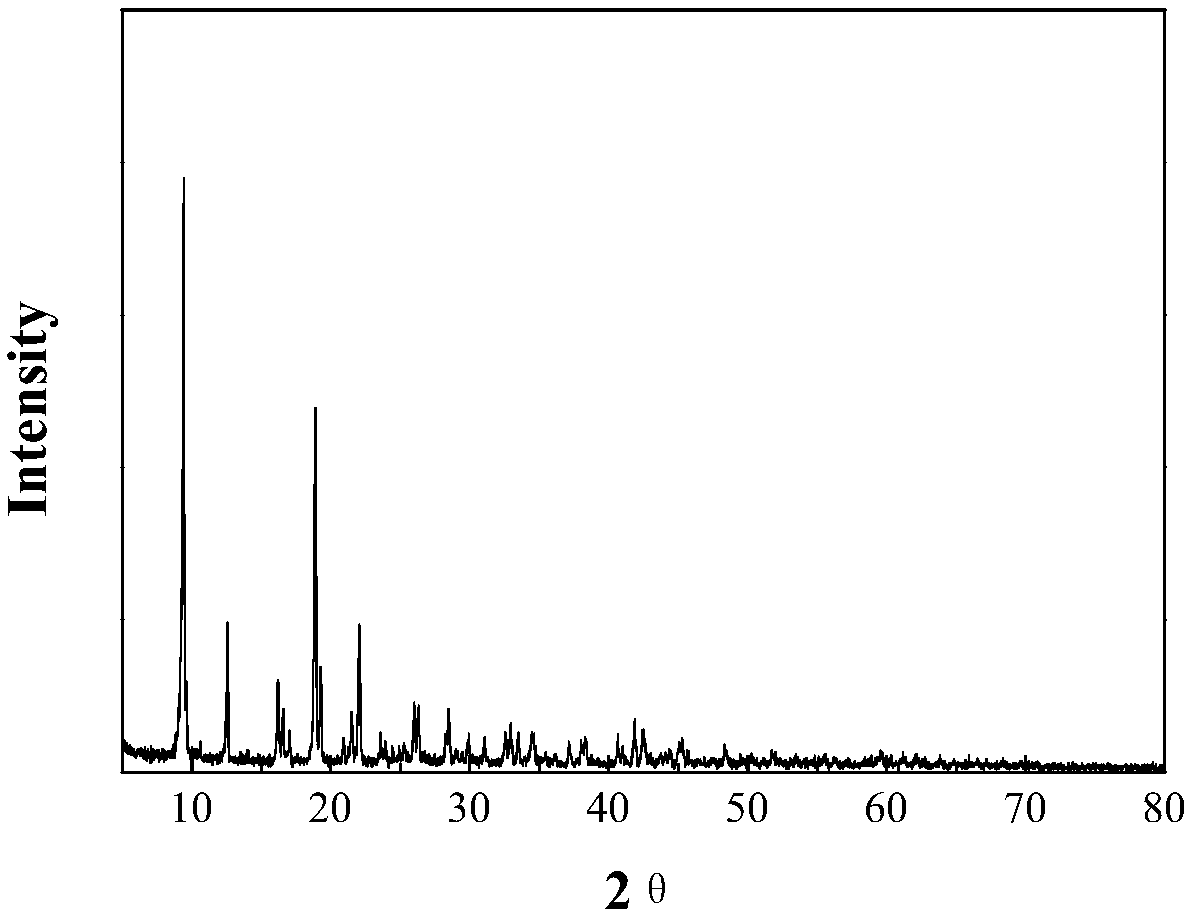

[0043] Weigh 0.8gFeCl 3 ·6H 2 O and 1.6g terephthalic acid, dissolved in 150mL DMF, stirred for 10min until uniformly dissolved, added 150mL absolute ethanol and mixed, then poured into a beaker, pumped into the plasma reactor with a peristaltic pump, at a discharge voltage of 60V, a current of 1.5A Under the condition of reaction 19min. Let it stand still and centrifuge the reaction solution containing the precipitate. After cleaning, put it in a drying oven and dry it at 160°C for 4 hours. The precipitate is tested by X-ray diffraction (XRD). For details, see the attached figure 2 ,exist figure 2 Among them, the main diffraction peaks are at 2θ=9.7, 12.6, 19 and 22, and the relative diffraction intensity of the crystal is the same as that of the MOF-235 standard, which proves that the crystal material is MOF-235.

Embodiment 2

[0044] Example 2: Preparation of iron metal organic framework materials by argon discharge

[0045] Weigh 0.8gFeCl 3 ·6H 2 O and 1.6g terephthalic acid were dissolved in 150mL DMF, stirred for 10min until uniformly dissolved, then poured into a beaker after adding 150mL absolute ethanol to mix, and pumped into the plasma reactor with a peristaltic pump. The reaction was carried out for 19 minutes under the condition of blowing argon gas. Let it stand still and centrifuge the reaction solution containing the precipitate. After cleaning, put it into a drying oven and dry it at 160° C. for 4 hours.

Embodiment 3

[0046] Example 3: Preparation of iron metal organic framework materials by nitrogen discharge

[0047] Weigh 0.8gFeCl 3 ·6H 2 O and 1.6g terephthalic acid were dissolved in 150mL DMF, stirred for 10min until uniformly dissolved, then poured into a beaker after adding 150mL absolute ethanol to mix, and pumped into the plasma reactor with a peristaltic pump. The reaction was carried out for 19 minutes under the condition of blowing nitrogen gas. Let it stand still and centrifuge the reaction solution containing the precipitate. After cleaning, put it into a drying oven and dry it at 160° C. for 4 hours.

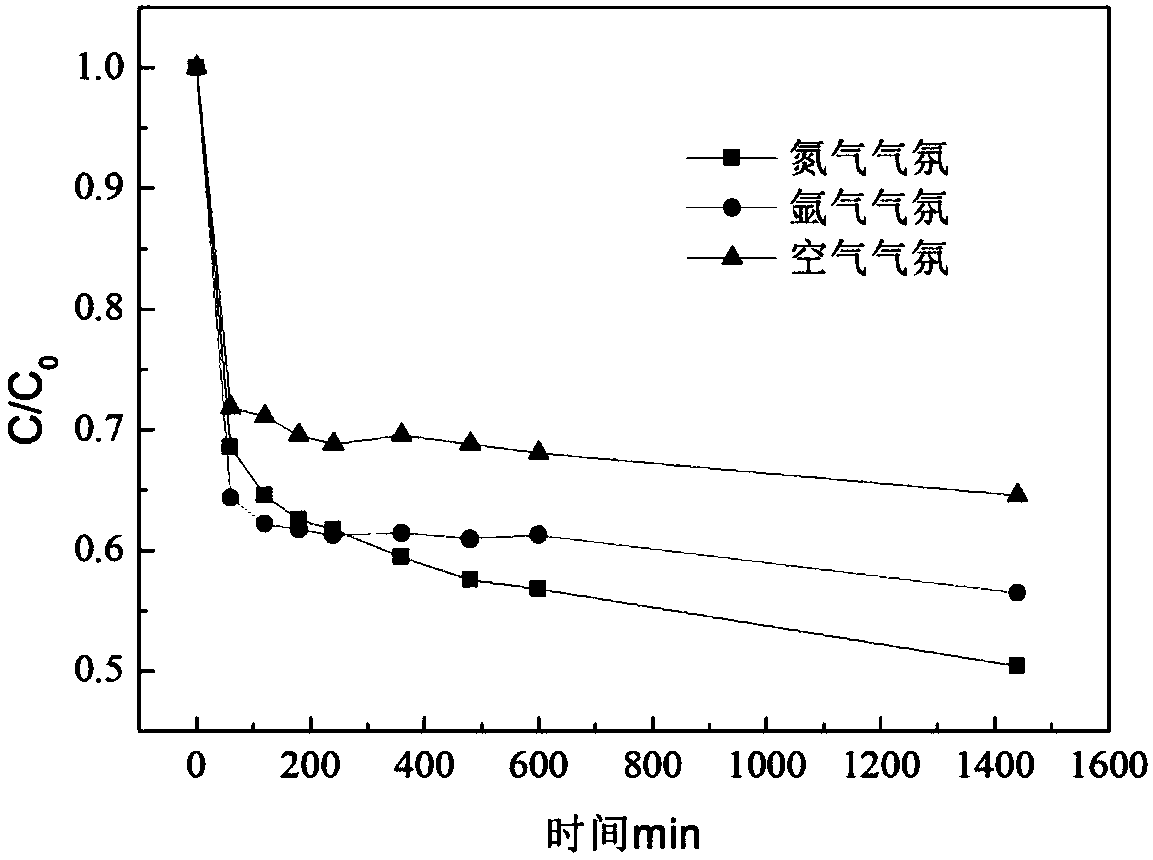

[0048] The iron metal organic framework material in 10mg embodiment 1-3 is used to adsorb the methyl orange solution of 100mL100mg / L, and the change curve of methyl orange concentration with time is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com