Cooling unit

A cooling unit, coolant technology, applied in cooling/ventilation/heating transformation, electrical components, heating methods, etc., can solve the problems of dangerous operation of electronic equipment or other equipment, can not easily adapt to deal with the surrounding dew point, etc., to avoid The effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

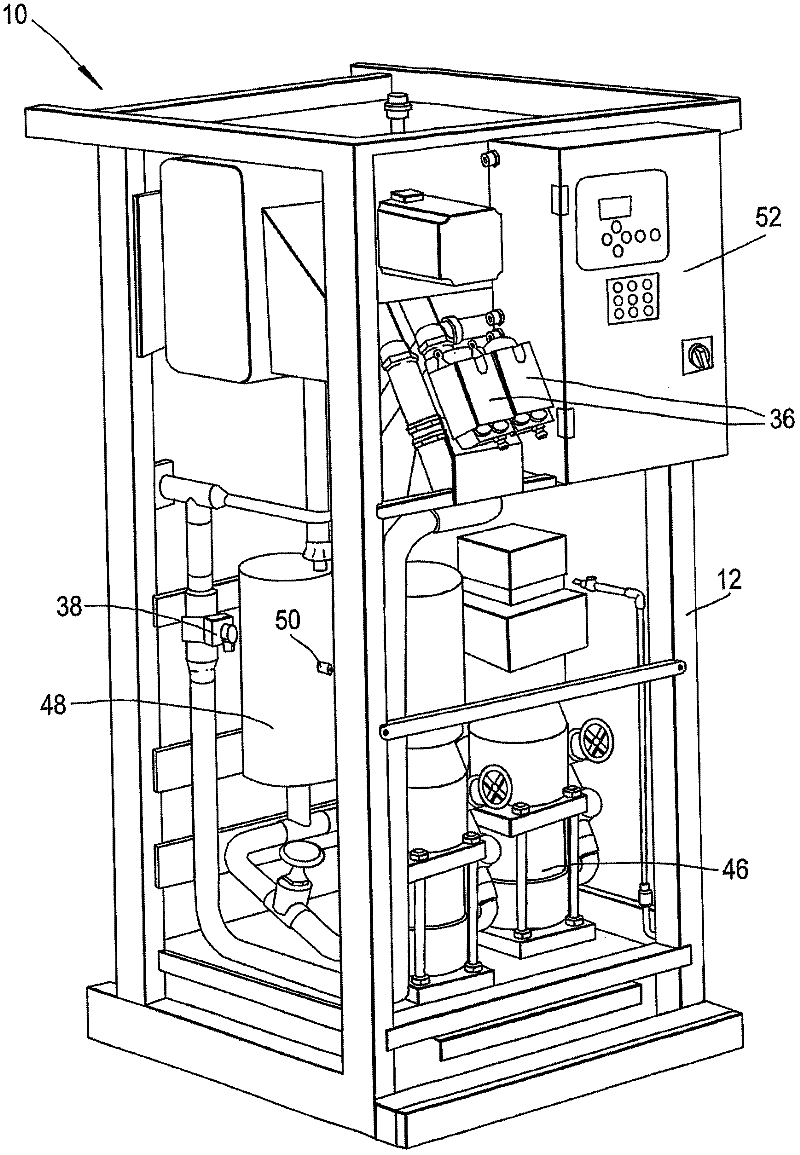

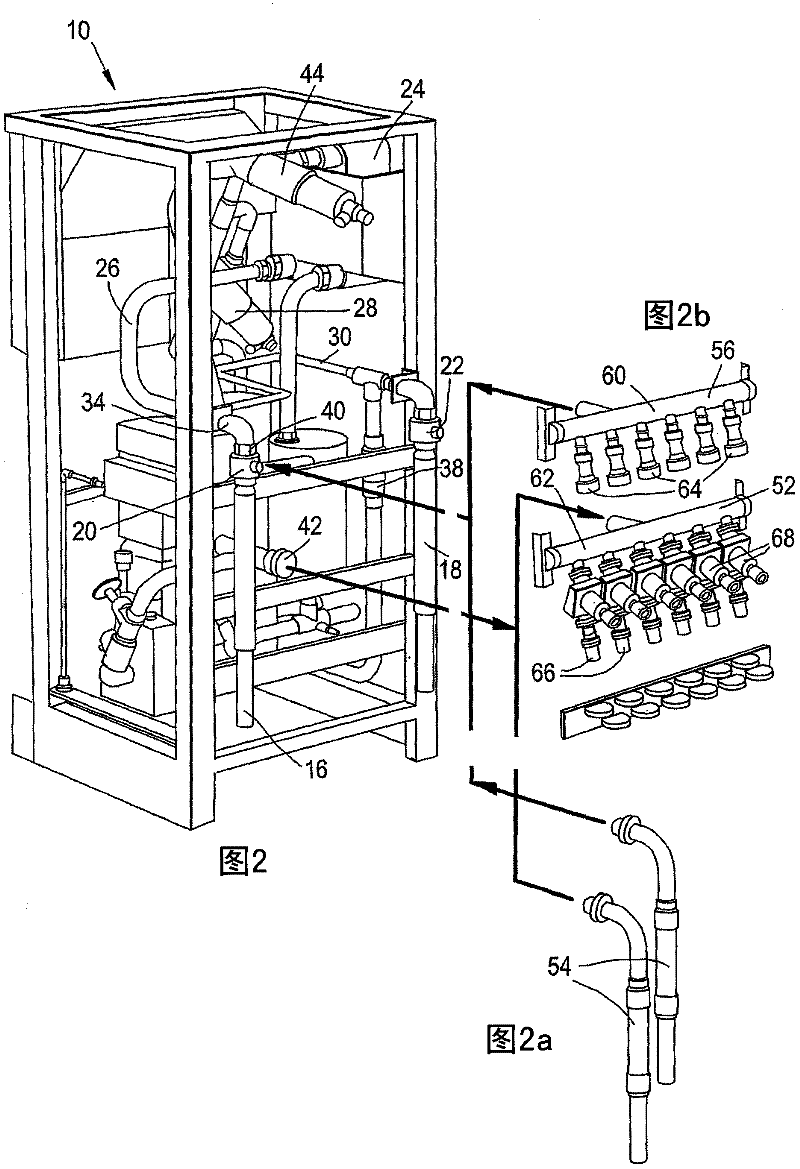

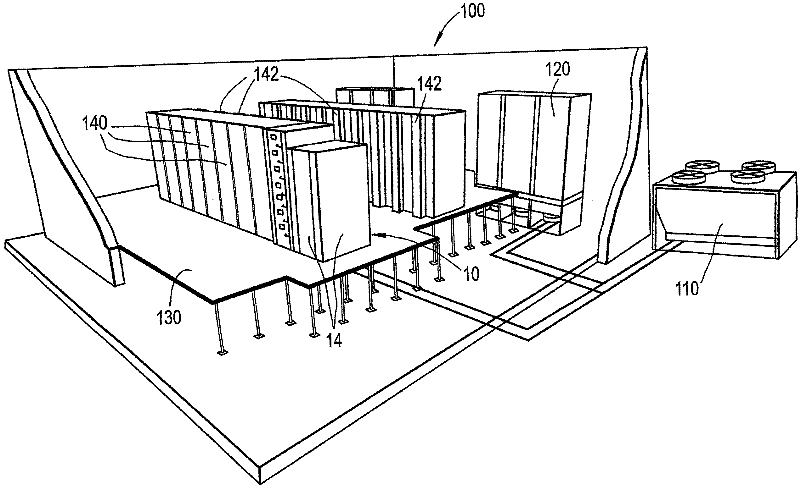

[0027] figure 1 and figure 2 The illustrated cooling distribution unit 10 comprises a plate-shaped metal panel 14 enclosed in a image 3 shown in , but not in figure 1 and figure 2 shown in , so that the components of the unit can be revealed) the metal frame 12 in.

[0028] The frame 12 supports a primary circuit inlet 16 and a primary circuit outlet 18 via respective isolation valves 20 and 22 and via a primary circuit passage 26 (which is in image 3 Shown more clearly) is connected to the plate heat exchanger 24, and the primary circuit channel 26 comprises a part of the heat exchanger 24. The primary circuit inlet 16 is connected to a plate heat exchanger 24 via a filter 28 . A bypass circuit 30 with a shut-off valve 34 interconnects the primary circuit inlet 16 upstream of the isolation valve 20 and the primary circuit outlet 18 downstream of the isolation valve 22 , respectively, to bypass the heat exchanger 24 . The primary circuit outlet 18 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com