Multi-hole stopper rod for continuous casting

A technology of hole plug and stopper rod, which is applied in the direction of casting equipment, casting molten material container, metal processing equipment, etc., can solve the problems of partial flow of molten steel, the inability of stopper rod to accurately control the flow rate of molten steel, and the inability to clean up impurities, so as to achieve accurate Improve the flow rate of molten steel, improve the overall efficiency and reduce the effect of drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

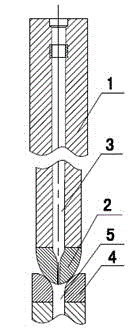

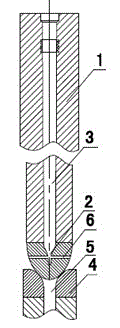

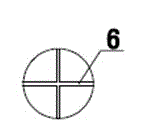

[0014] The invention discloses a porous stopper rod for continuous casting, such as figure 2 , image 3 As shown, it includes a stopper rod body 1 and a stopper rod head 2 connected to the bottom of the stopper rod body 1 , an argon gas passage 3 is opened inside the stopper rod body 1 , and the argon gas passage 3 extends to the inside of the stopper rod head 2 . The stopper tip 2 is horizontally provided with an air guide hole 6, which is perpendicular to the axis of the argon channel 3, and the air guide hole 6 is arranged above the contact surface between the nozzle 4 and the stopper tip 2 and connected to the argon channel 3. Unicom. to combine image 3 , Figure 4 As shown, the air guide holes 6 can be set as required, and there are two or more holes, which are evenly distributed in the stopper tip 2 . The number and size of the argon gas bubbles blown into the nozzle are controlled by adjusting the number and size of the inner holes of the horizontal air guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com