Method and equipment for purifying tail gas generated by burnning garbage

A technology of waste incineration and tail gas, which is applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of large floor space, high investment and operating costs, inability to effectively remove fine dioxin particles, etc. Small area, low cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

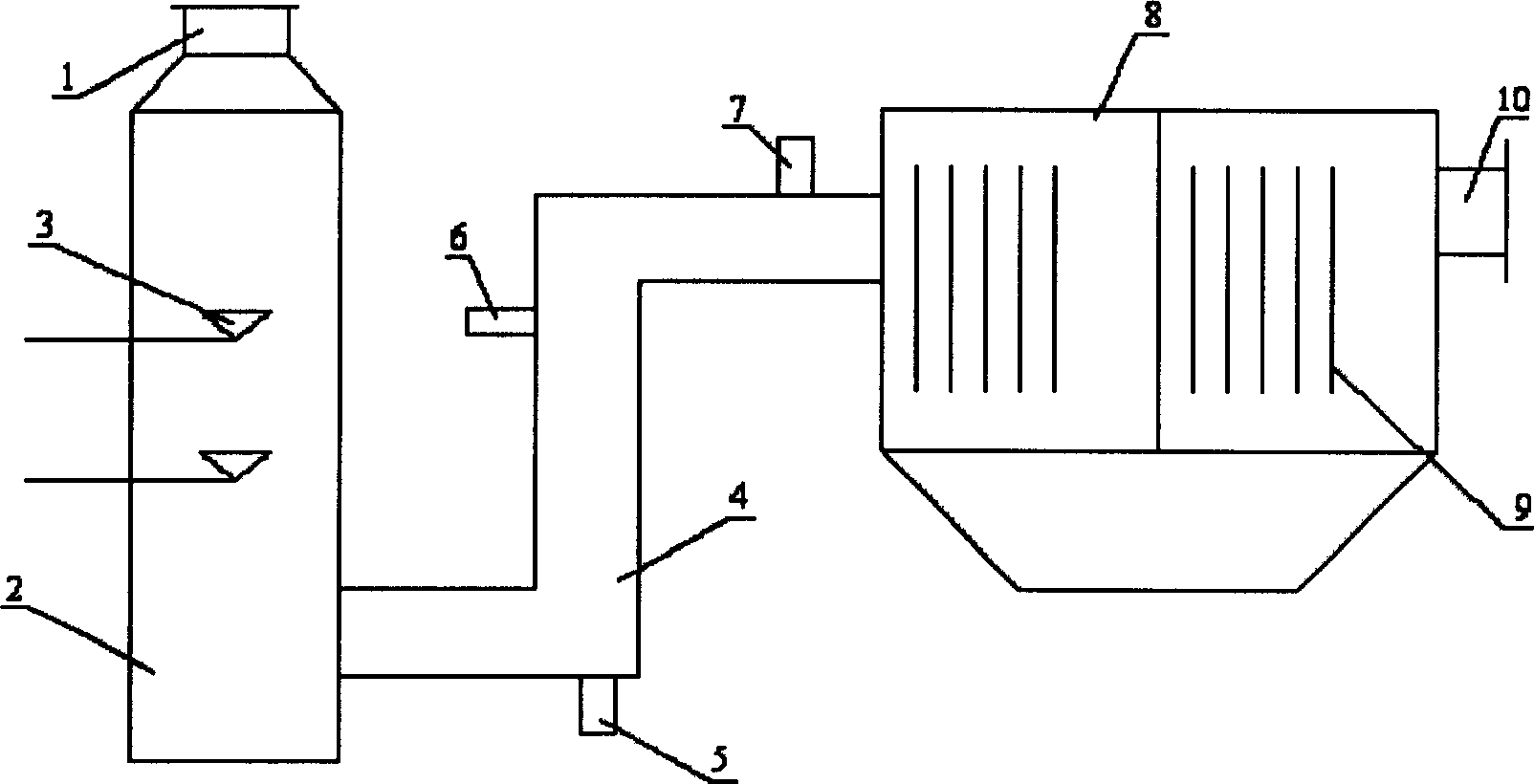

[0024] Referring to the accompanying drawings, the device of the present invention includes a cooling tower 2 and a bag filter 8 . The flue gas inlet 1 of the cooling tower 2 is placed on the top of the cooling tower 2, and the cooling tower 2 is provided with two groups of water spray nozzles 3 opposite to the flow of the flue gas. connection Type flue 4. The bottom section of the type flue 4 is provided with a lime powder inlet 5, The middle section of the type flue 4 is provided with an iron fly ash inlet 6, The upper section of the type flue 4 is provided with an activated carbon inlet 7. A filter material layer 9 using film-coated filter material is placed in the bag filter 8 , and a purified gas outlet 10 is placed above the side of the bag filter 8 .

[0025] During device operation of the present invention, its step is:

[0026] 1) The flue gas discharged from the waste incinerator enters the cooling tower 2 from the flue gas inlet 1 at the upper end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com