Device for recovery of carbon disulfide in viscose fiber production

A carbon disulfide and viscose fiber technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems that the absorption effect is not as good as solvent adsorption, flammability, and slow absorption speed, so as to avoid excessive gas separation, The effect of high degree of automation and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

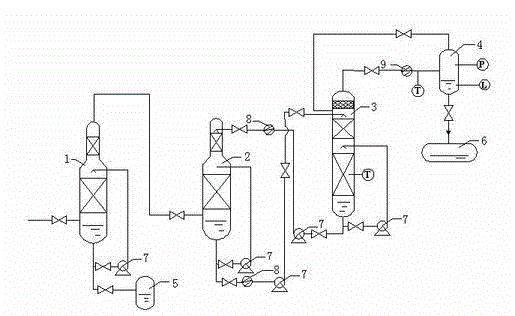

[0039] A recovery device for carbon disulfide in viscose fiber production, comprising an alkali spray tower, an absorption tower, a heat exchanger, an analysis tower, a condenser and a gas-liquid separator, the alkali spray tower is connected to the absorption tower, and the absorption tower is connected to the The heat exchanger and heat exchanger are connected to the desorption tower, the desorption tower is connected to the condenser, and the condenser is connected to the gas-liquid separator; the carbon disulfide waste gas generated in the production of viscose fiber is sprayed with alkali in the alkali spray tower to remove hydrogen sulfide, and then enters the absorption tower, the absorbent in the absorption tower absorbs carbon disulfide in the exhaust gas, the saturated carbon disulfide rich liquid is cooled by a heat exchanger, and is pumped to the analysis tower to obtain carbon disulfide gas and lean liquid, the carbon disulfide gas is condensed by a condenser, and t...

Embodiment 2

[0041] A recovery device for carbon disulfide in viscose fiber production, comprising an alkali spray tower, an absorption tower, a heat exchanger, an analysis tower, a condenser and a gas-liquid separator, the alkali spray tower is connected to the absorption tower, and the absorption tower is connected to the The heat exchanger and heat exchanger are connected to the desorption tower, the desorption tower is connected to the condenser, and the condenser is connected to the gas-liquid separator; the carbon disulfide waste gas generated in the production of viscose fiber is sprayed with alkali in the alkali spray tower to remove hydrogen sulfide, and then enters the absorption tower, the absorbent in the absorption tower absorbs carbon disulfide in the exhaust gas, the saturated carbon disulfide rich liquid is cooled by a heat exchanger, and is pumped to the analysis tower to obtain carbon disulfide gas and lean liquid, the carbon disulfide gas is condensed by a condenser, and t...

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 2, on this basis:

[0047] The absorbent is white oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com