Bush assembly capable of adjusting air flow of combustion zone

A technology of air flow and combustion area, which is applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of high flame temperature, nitrogen monoxide emission, and low fuel volume, so as to increase the air volume in the annular area and prevent fuel shortage The effect of flameout, intensified premix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the present invention more clear, the following will describe the exemplary embodiments in detail, and the examples are shown in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

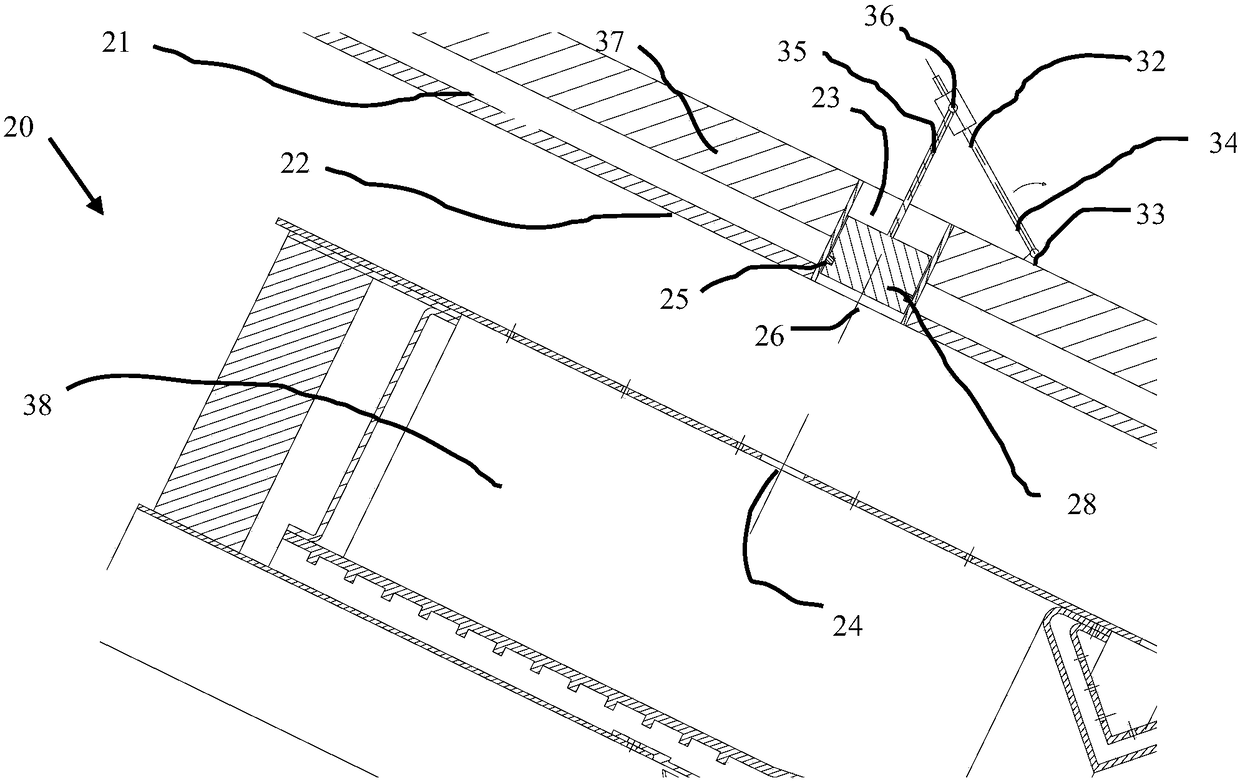

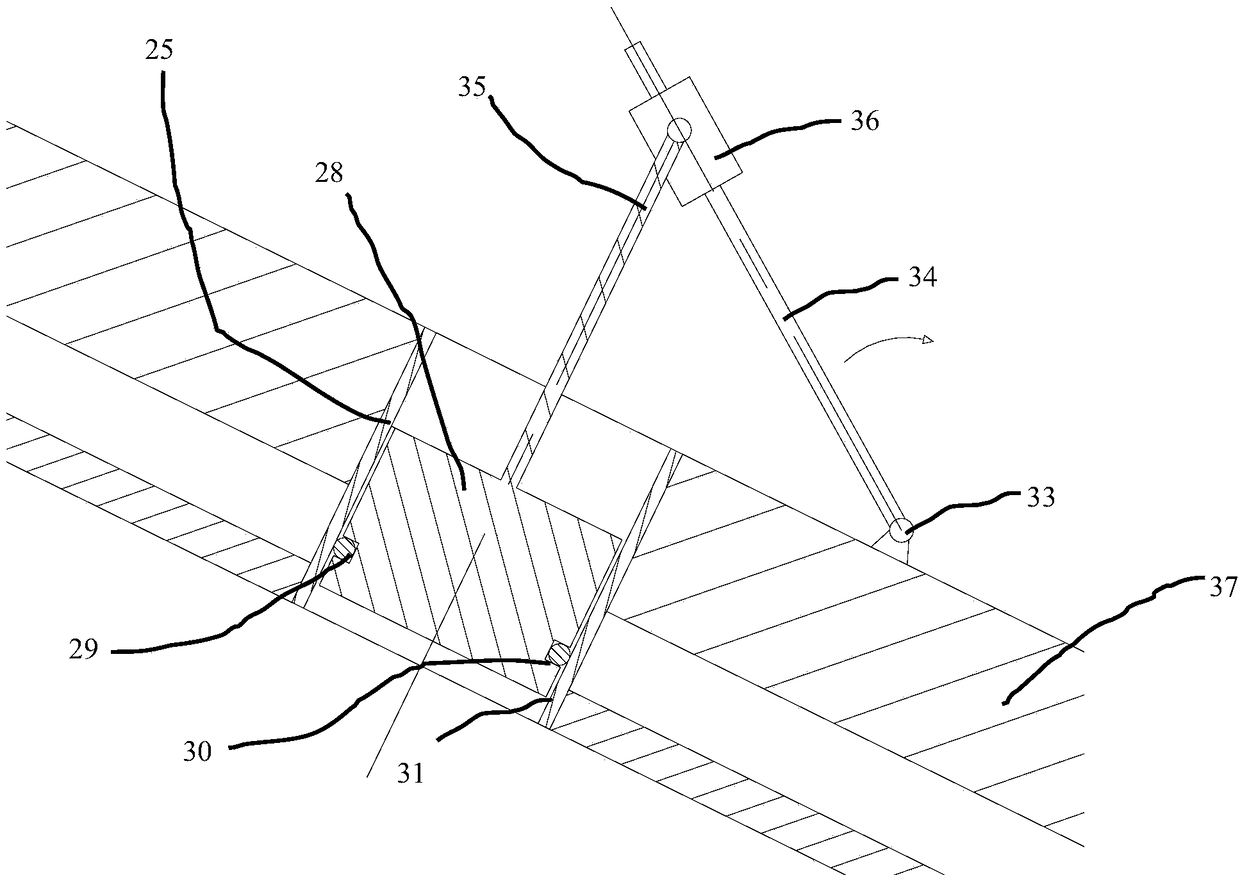

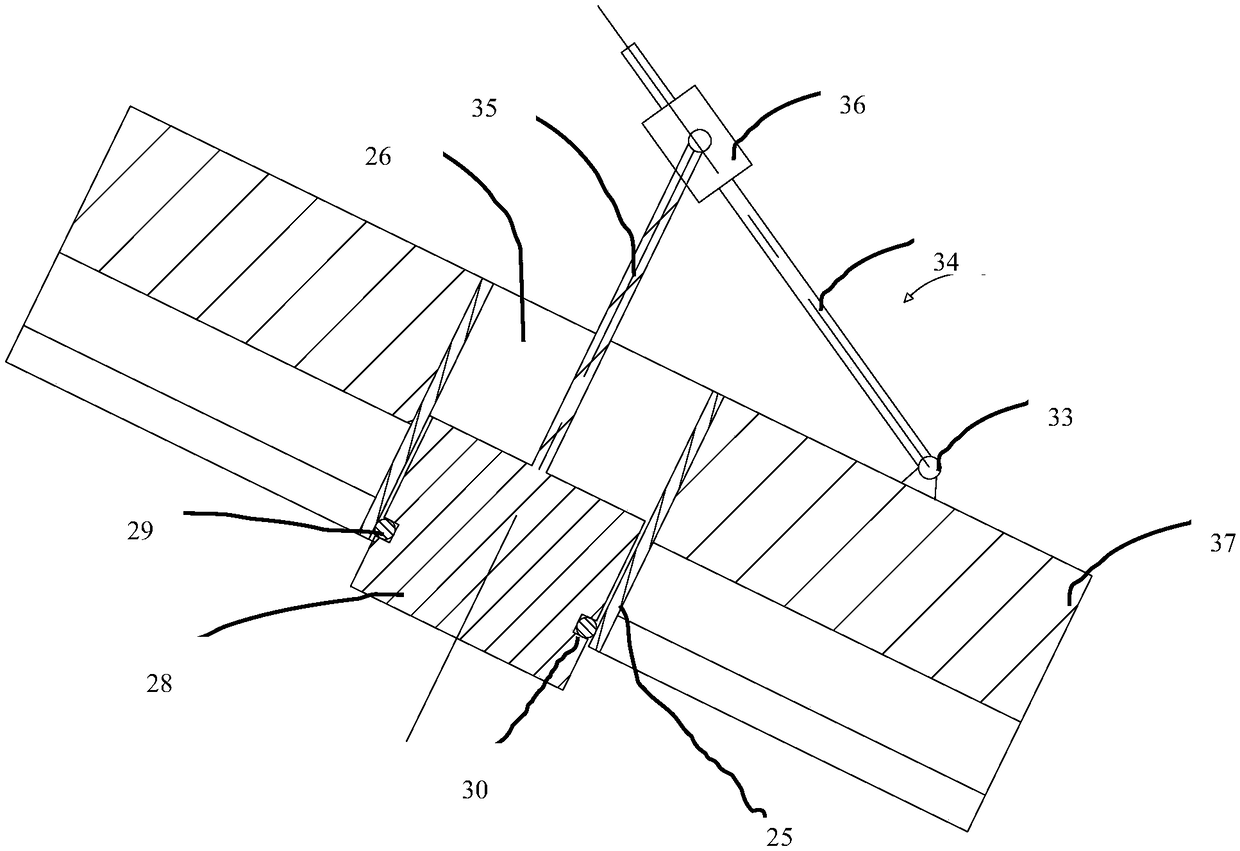

[0025] refer to figure 1 As shown, the liner assembly 21 of the gas turbine combustor 20 that can adjust the air flow in the combustion zone of the embodiment of the present invention is shown. The liner assembly 21 includes a liner outer wall 22 with a thickness of 3 mm and is annular. The upstream side of the liner outer wall 22 has a mounting hole 23, and the position of the mounting hole 23 is aligned with the main combustion hole 24 of the combustion chamber 20 in the axial direction. Adjust the air intake flow of the main combustion hole 24; the sealing sleeve 25, with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com