Spiral heat exchange tube

A technology of heat exchange tube and helical shape, which is applied in the field of heat exchange tubes with enhanced heat exchange structure, can solve the problems of difficulty, limited flow heat transfer coefficient, excessive helix angle, etc., achieve high economy and prolong service life , the effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

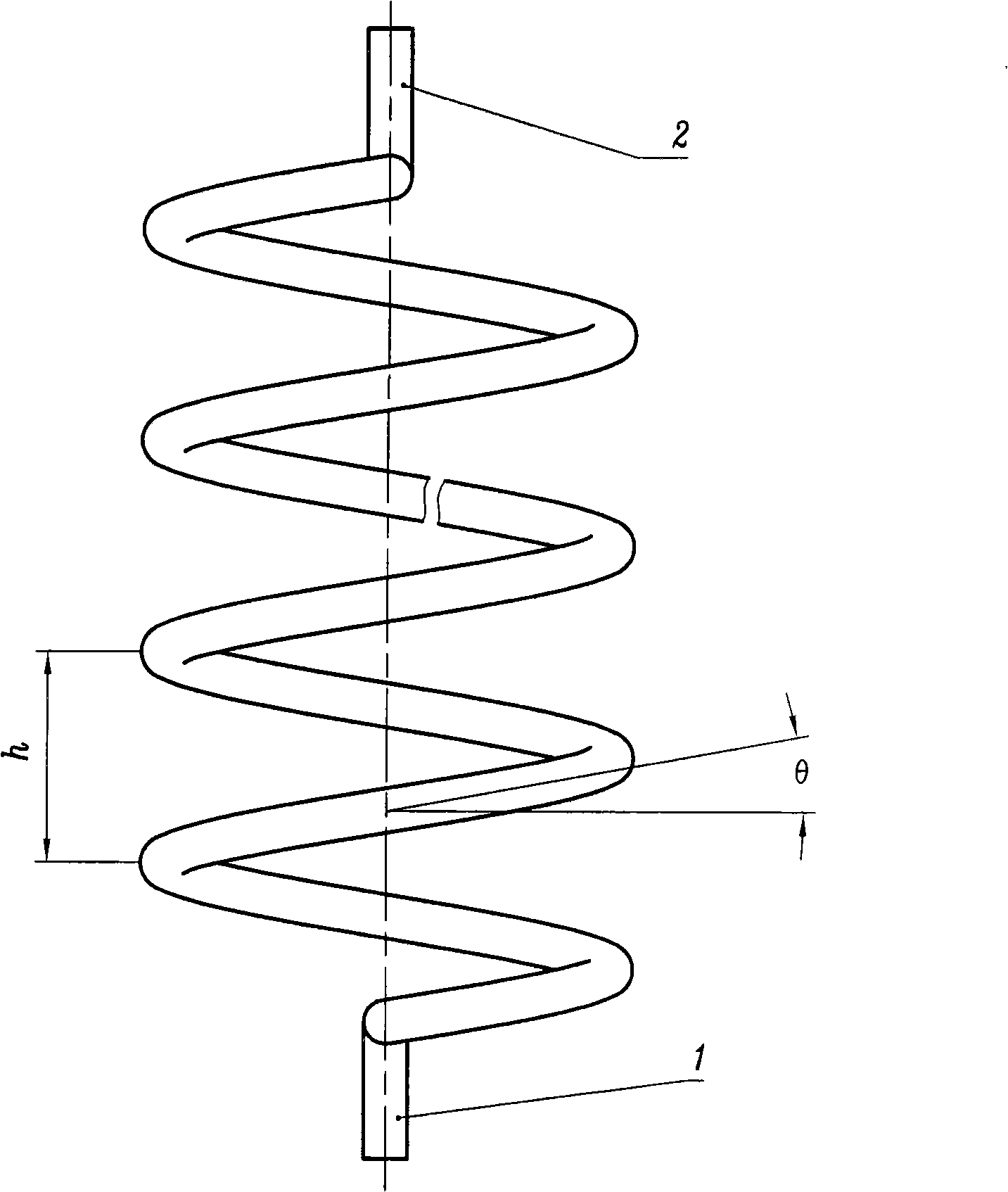

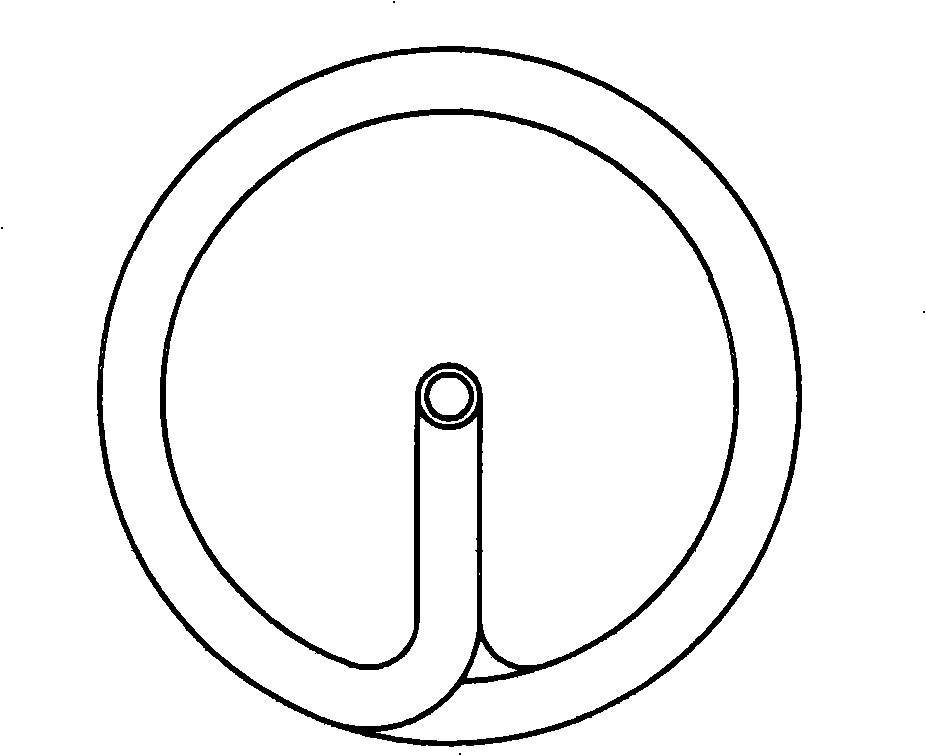

[0019] A helical heat exchange tube, the part that performs heat exchange is helical (refer to figure 1 , 2 ). In the present invention, the cross-section of the heat exchange tube is circular, the helix angle θ of the heat exchange part is 10° to 30°, and the pitch h is 3 to 6 times the outer diameter of the heat exchange tube; The two ends of the heat exchange tube are fixed (usually welded) on the heat exchanger, the inlet end 1 and the outlet end 2 of the heat exchange medium are the same as the prior art, and they are all straight pipes (obviously, they are only a small section) ). According to the actual installation situation, this short section of straight pipe at the inlet end 1 or outlet end 2 can be directly extended or bent with the two ends of the spiral pipe section, or can be bent to the axis of them or one of them and the spiral pipe section. A state where the axes overlap (due to the obviousness, the accompanying drawing only draws the structure in which th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com