Churn screw drill for drilling

A screw drilling tool and drilling technology, applied in the field of drilling tools, can solve the problems of shortening the service life of the drilling tool assembly, affecting the quality of the well body, vibration, etc., achieving the effects of convenient installation and operation, prolonging the life of the drill bit, and increasing the ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

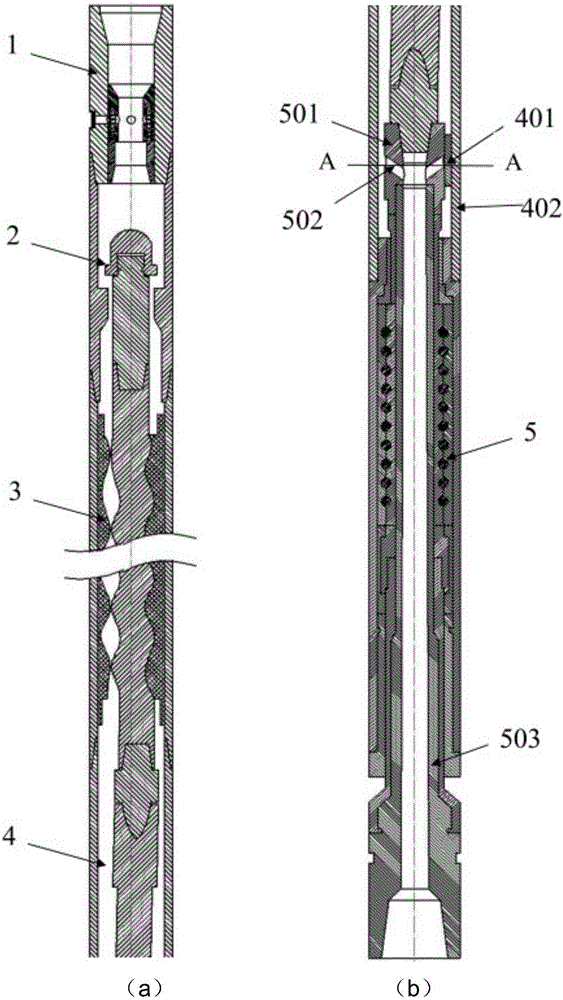

[0021] figure 1 Including the structure diagram a of the upper part of the drilling tool and the structure diagram b of the lower part. Such as Figure 1-2 As shown, the present invention is a rotary punching screw drilling tool for well drilling, which is composed of a bypass valve assembly 1, an anti-drop assembly 2, a motor assembly 3, a cardan shaft assembly 4, and a transmission shaft assembly 5. The cardan shaft in the cardan shaft assembly 4 is connected with the water cap 501 and the power transmission shaft 503 with threads successively. The purpose of using screw connection is to realize detachable connection and simplify installation steps, thereby improving the efficiency of assembly and disassembly.

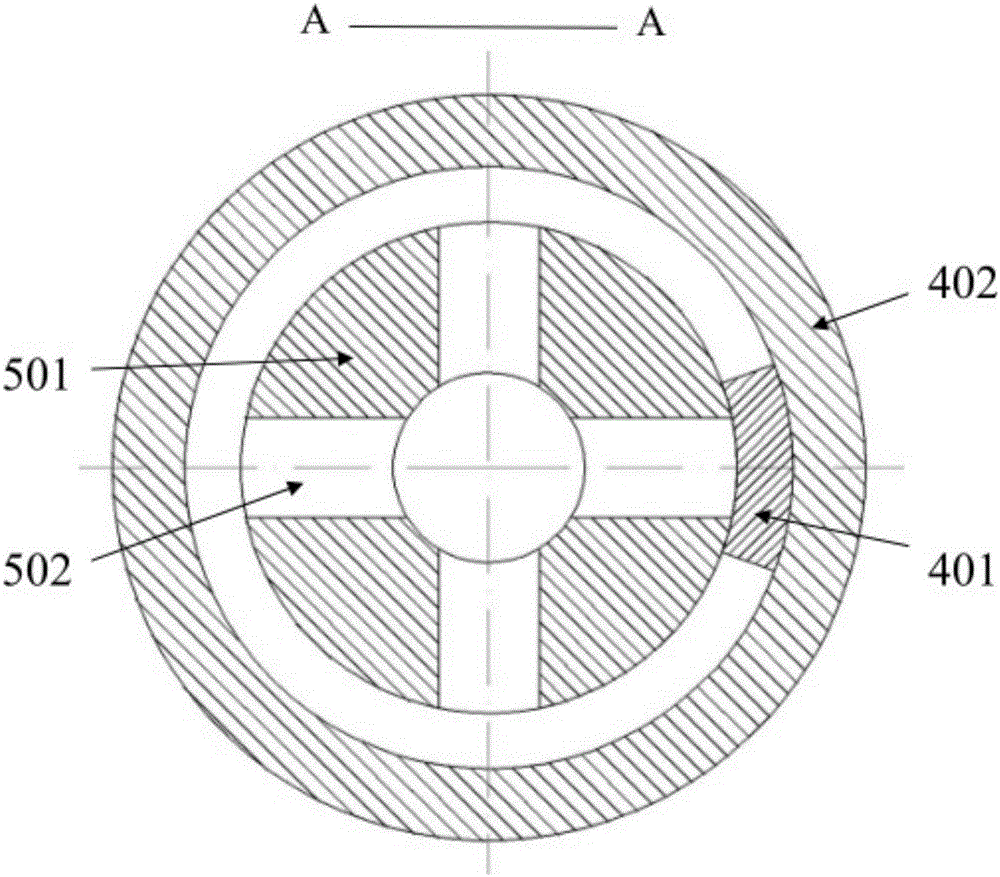

[0022] A blocking baffle 401 is installed inside the cardan shaft assembly housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com