Automatic dedusting method and system for dust removal pipeline

A technology for automatic ash cleaning and pipeline cleaning. It is applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. It can solve the problems affecting the continuous operation of the system and the heavy maintenance workload, so as to ensure normal operation and reduce pipeline wear and tear. , to avoid the effect of pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

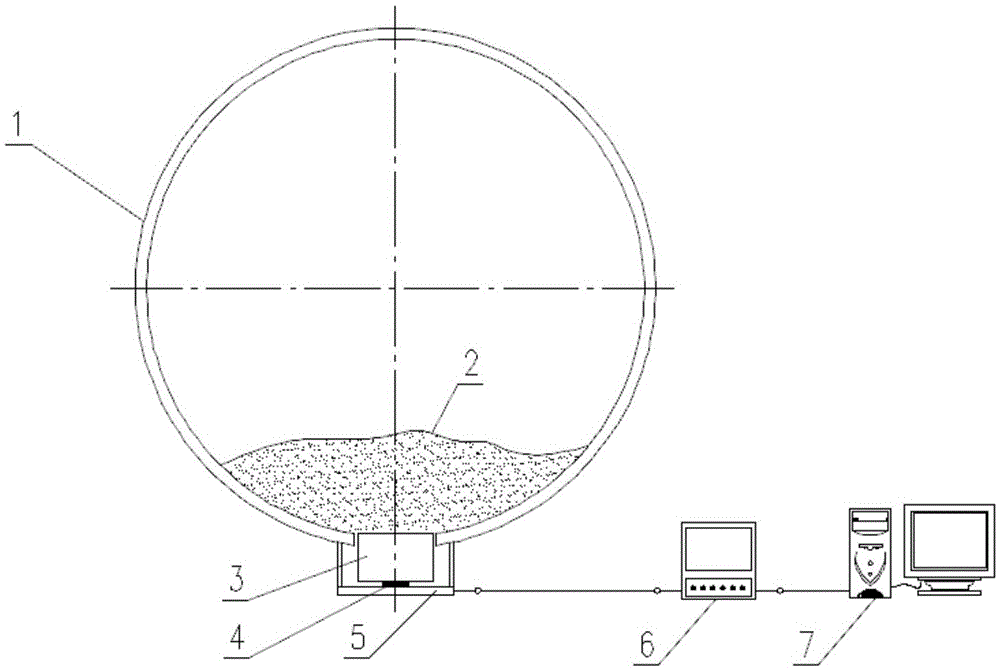

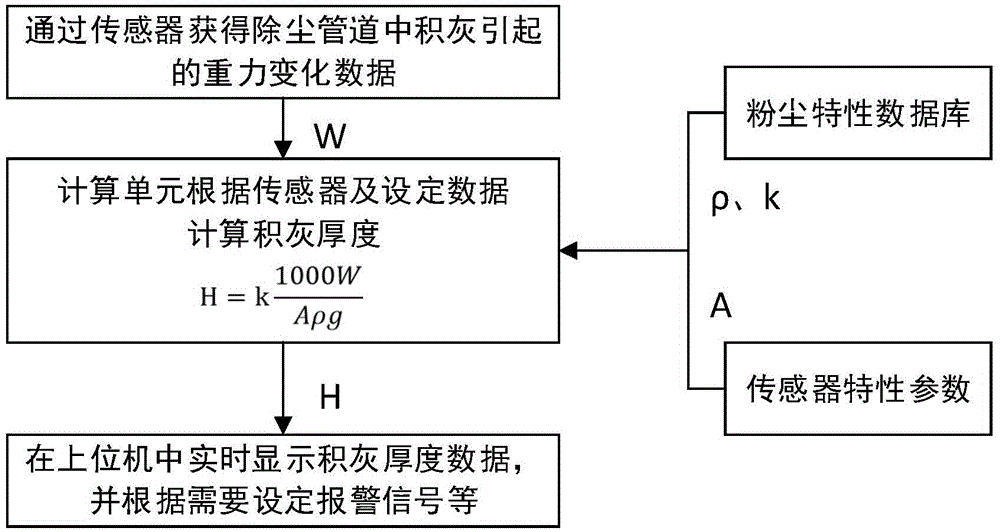

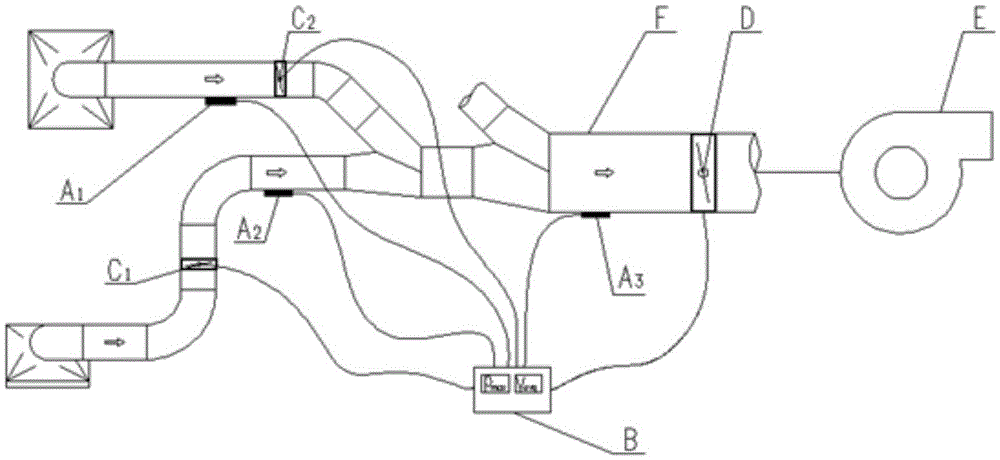

[0073] The invention provides a method and a system for cleaning the dust removal pipe by using a dust removal pipe dust thickness detection device, a calculation and control unit and an adjustable damper. The method and system can make the dust removal system on the premise that the pipe is not blocked , at a lower flow rate than dust removal systems designed according to prior art solutions. When the fan is selected, reducing the opening of the main damper can reduce the energy consumption of the dust removal pipeline system, and the wear degree of the dust removal pipeline is proportional to the cube of the wind speed, so this scheme has good energy saving and wear resistance characteristics.

[0074] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0075] First of all, because the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com