Washing machine

A technology of washing machine and washing machine shell, applied in the field of washing machine, to achieve the effect of increasing washing capacity and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

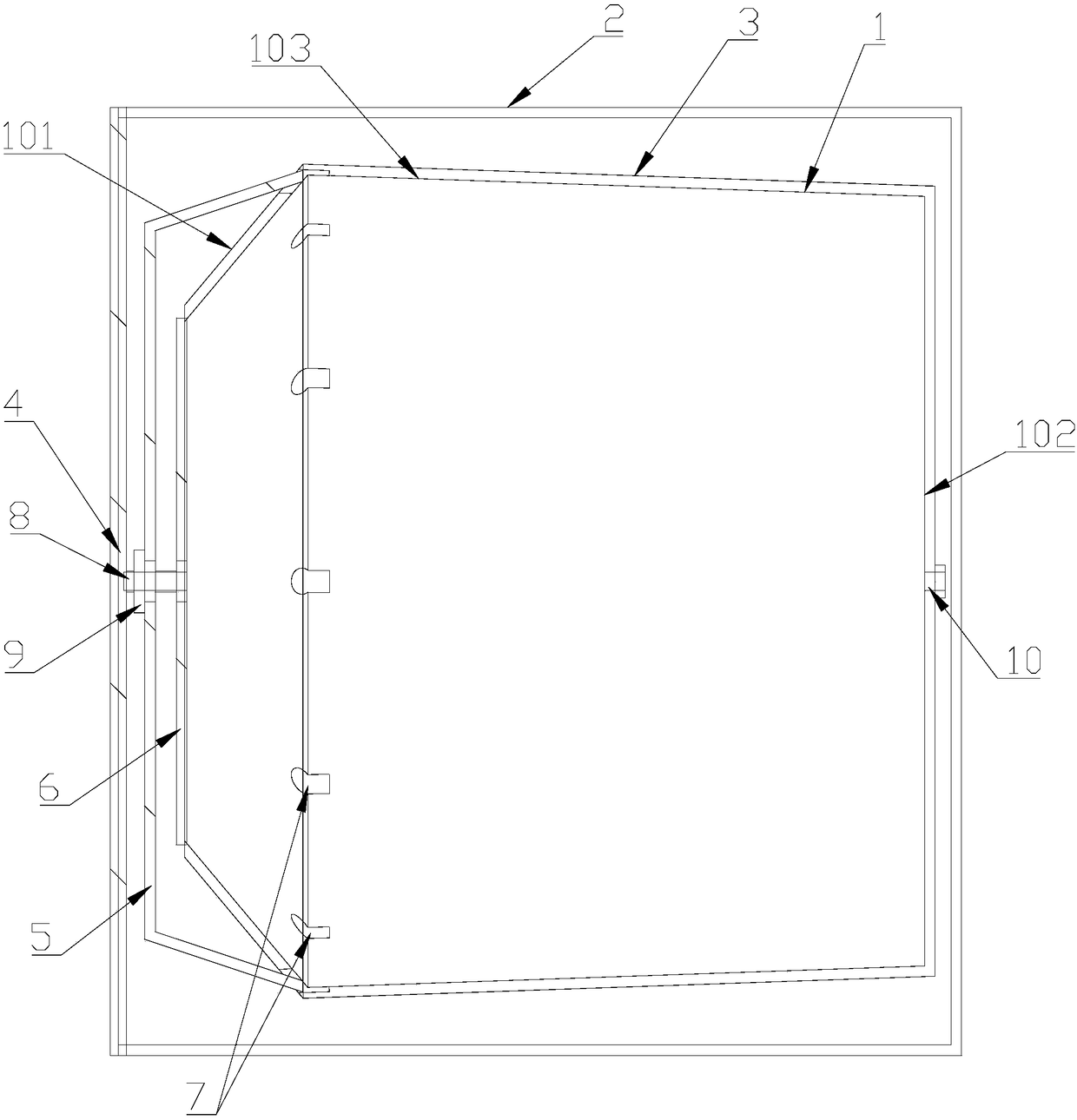

[0038] Such as Figure 1 to Figure 4 As shown, in this embodiment, a washing machine is introduced. The washing machine includes a housing 2 in which an inner tub 1 is arranged. The axis of the inner tub 1 extends horizontally or is gradually inclined downward from front to back. The front end of the inner tub 1 is The opening 101 of the inner cylinder and the rear end are the inner cylinder bottom 102 which is sealed; the wall of the inner cylinder 1 is not provided with a through hole, so that the inner cylinder 1 constitutes a sealed container with only the front part of the clothing inlet. At the same time, a door cover 4 that can be opened outwards is installed at the front end of the washing machine housing 2 to close the inner tube opening 101 after the door cover 4 is closed. After opening the door cover 4, the laundry opening provided on the inner tube opening 101 is inward. The purpose of putting clothes in the tube 1. The rear end of the inner tub 1 is installed in ...

Embodiment 2

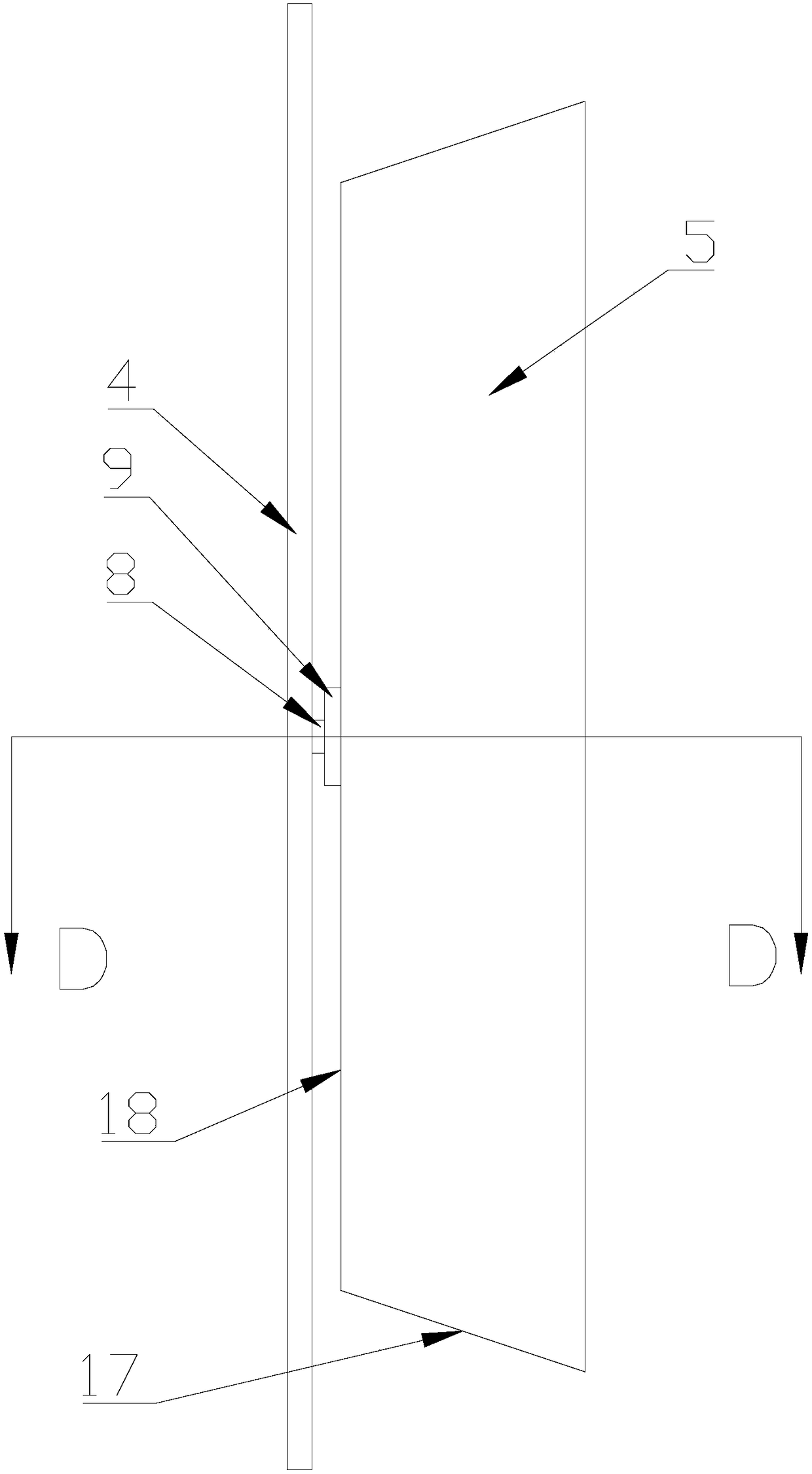

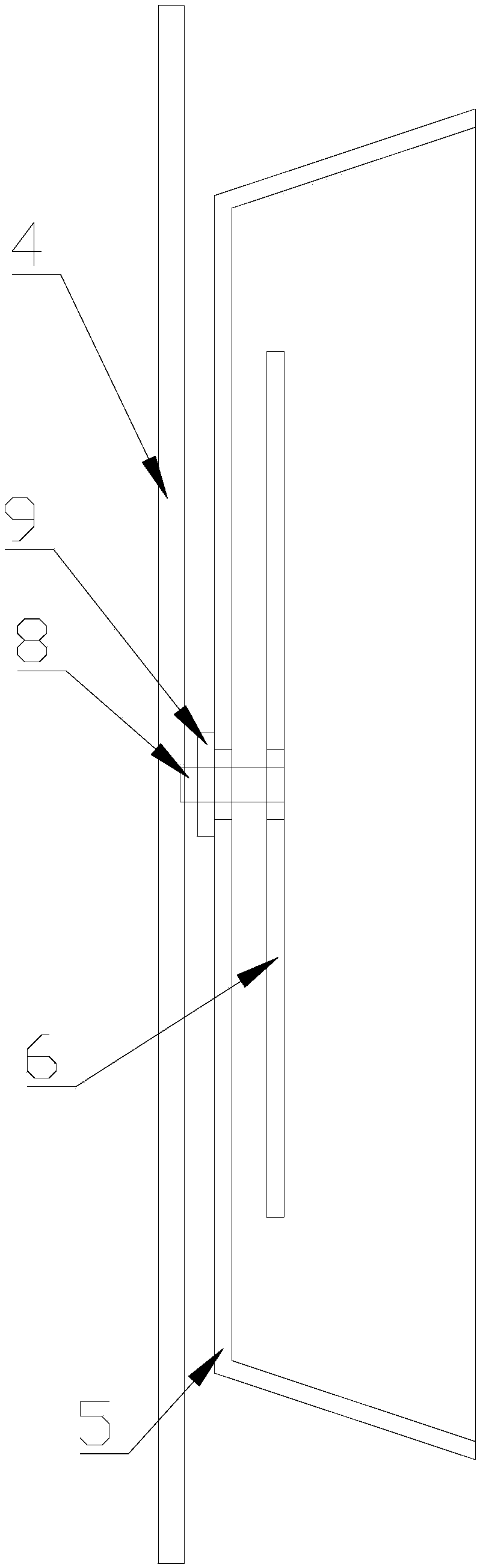

[0052] Such as figure 1 As shown, in this embodiment, the door cover 4 is also provided with an inner cylinder inner cover 6. The inner cylinder inner cover 6 is connected to the door cover 4 by an elastic mechanism, so that the elastic mechanism aligns with the inner cylinder after the door cover 4 is closed. The inner cover 6 exerts an elastic force to drive the inner cover 6 of the inner cylinder to be buckled at the clothing insertion opening of the inner cylinder mouth 101, so that the clothing insertion opening of the inner cylinder mouth 101 is sealed and buckled by the inner cylinder inner cover 6, thereby realizing the internal sealing of the inner cylinder , To supply water to hold, and drive the inner cylinder to rotate and use the water to wash clothes.

[0053] In this embodiment, the outer cover 5 of the inner cylinder and the inner cover 6 of the inner cylinder are sequentially installed on the inside of the door cover 4 via the rotating shaft 8. One end of the rota...

Embodiment 3

[0056] Such as figure 1 with Figure 4 As shown, in this embodiment, the center of the inner cylinder bottom 102 is mounted on the inner cylinder support 3 via the rotating shaft 10, so that the inner cylinder 1 can rotate around the axis of the inner cylinder 1 under the action of the drive motor installed at the end of the rotating shaft 10; The rotating shaft 10 is hollow. One end of the hollow part is connected to the washing machine inner tub 1 and the other end is connected to the washing machine water inlet pipe. The hollow part of the rotating shaft 10 is used to inject water into the washing machine inner tub 1.

[0057] In this embodiment, the rotating shaft 10 is composed of three layers of sleeves sleeved in sequence from the inside to the outside. The inner sleeve 11 forms a water inlet 14 communicating with the washing machine water inlet pipe and forms the inner cylinder. The inner sleeve 11 The flow passage between the middle sleeve 12 and the middle sleeve 12 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com