Patents

Literature

124results about How to "Increase washing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

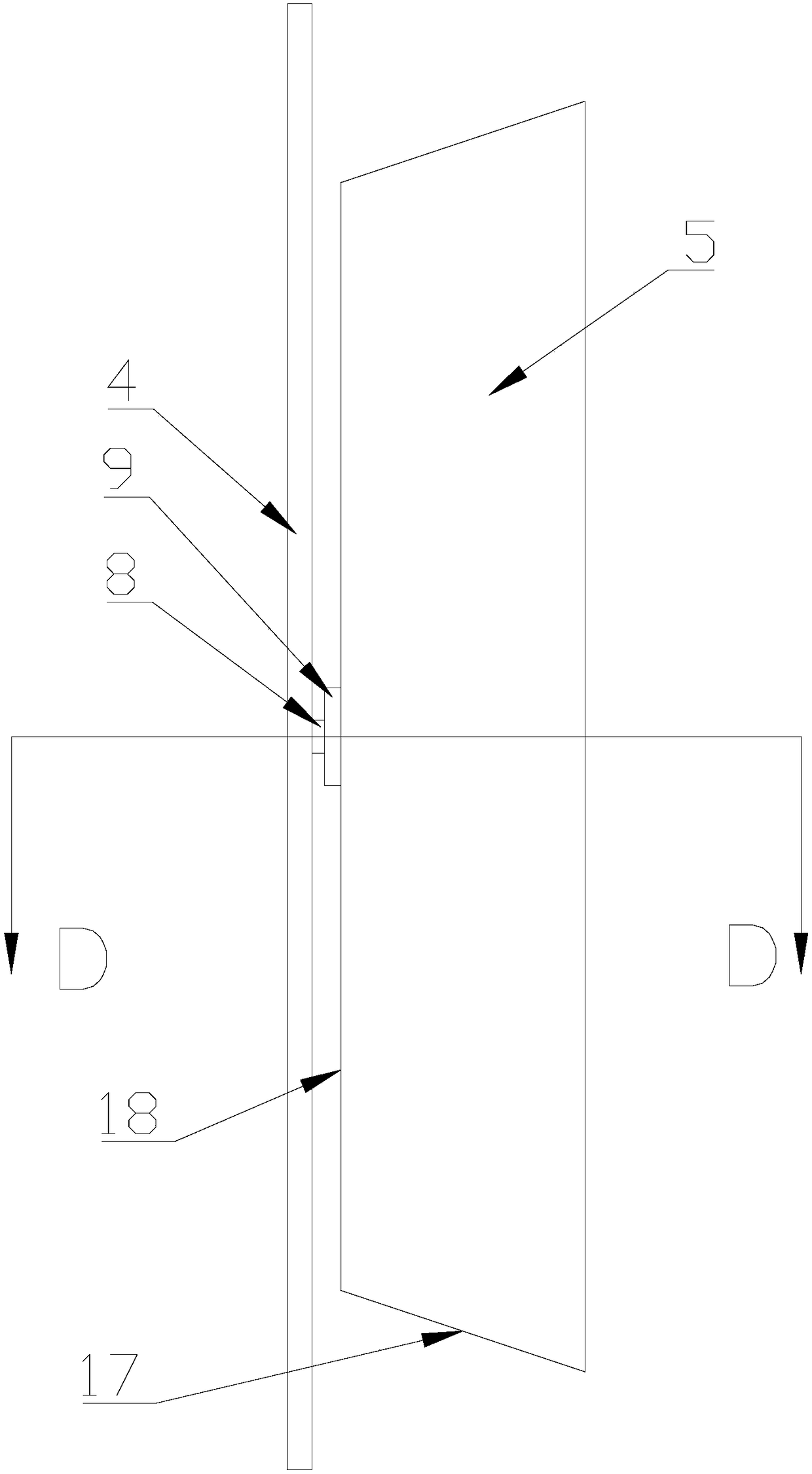

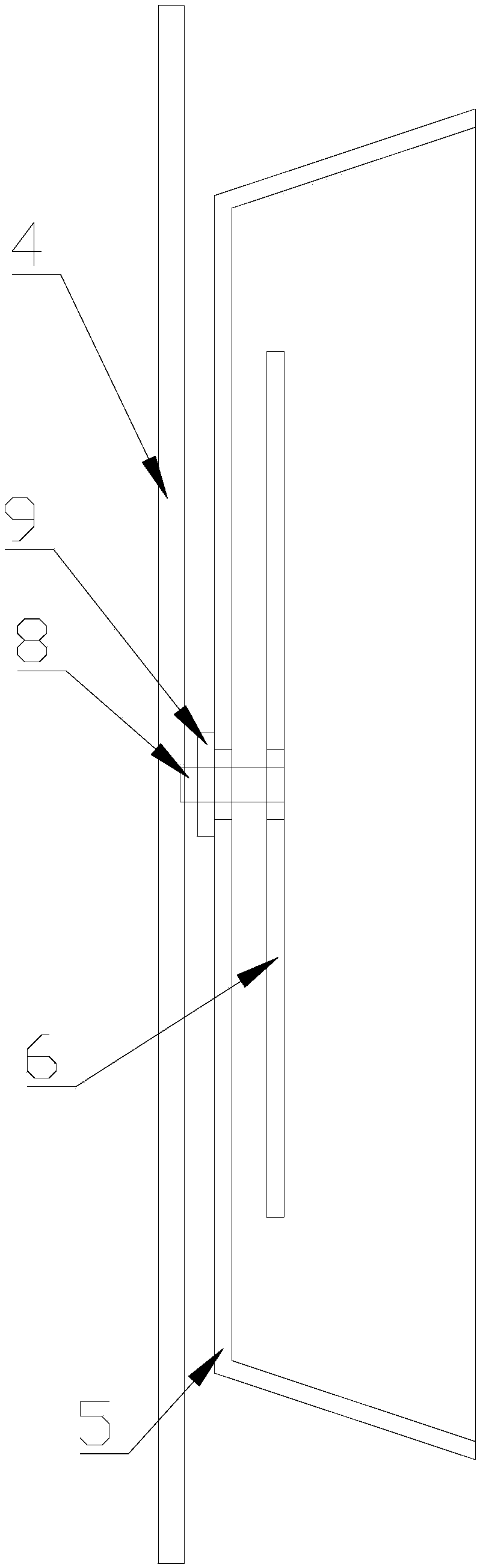

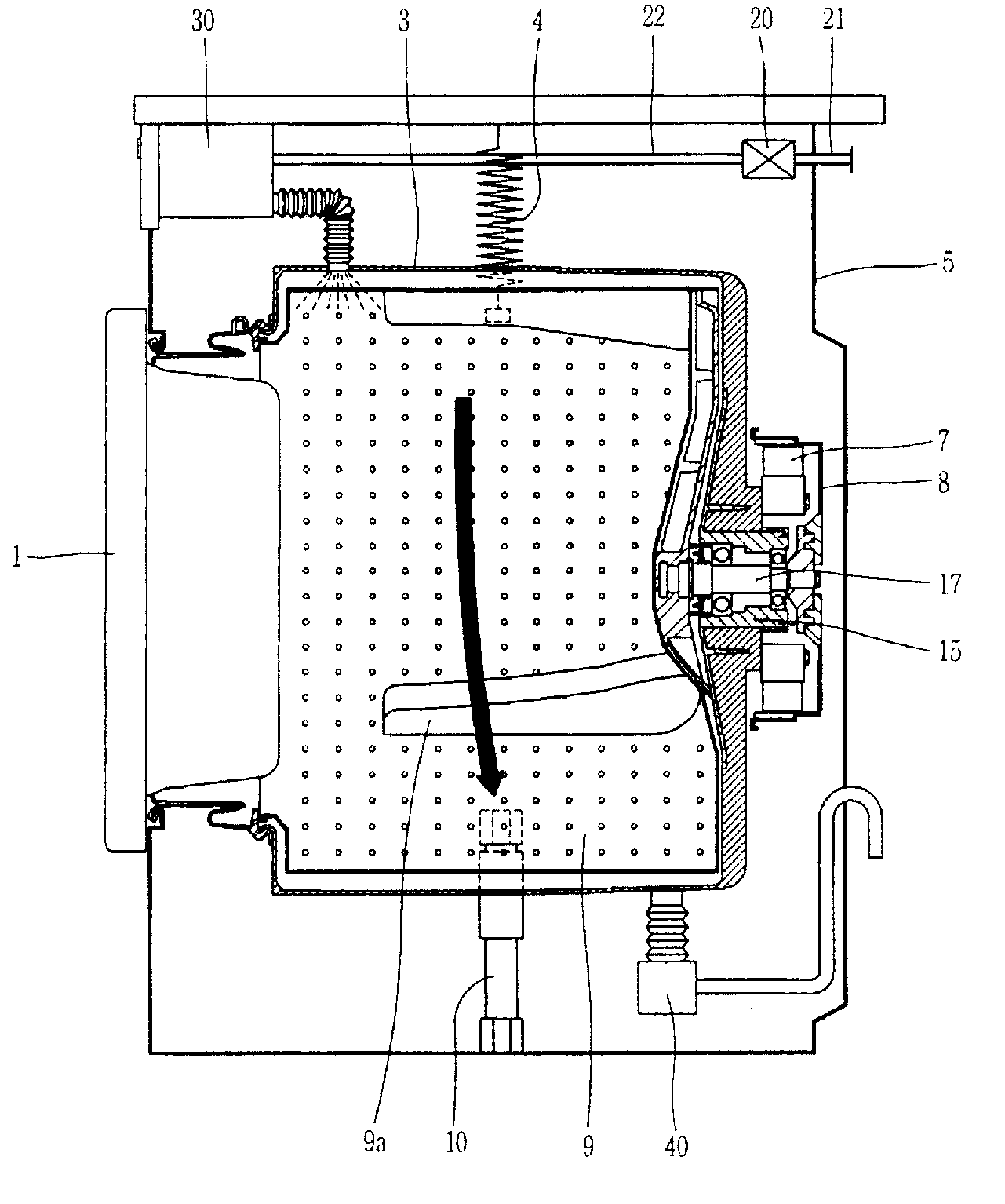

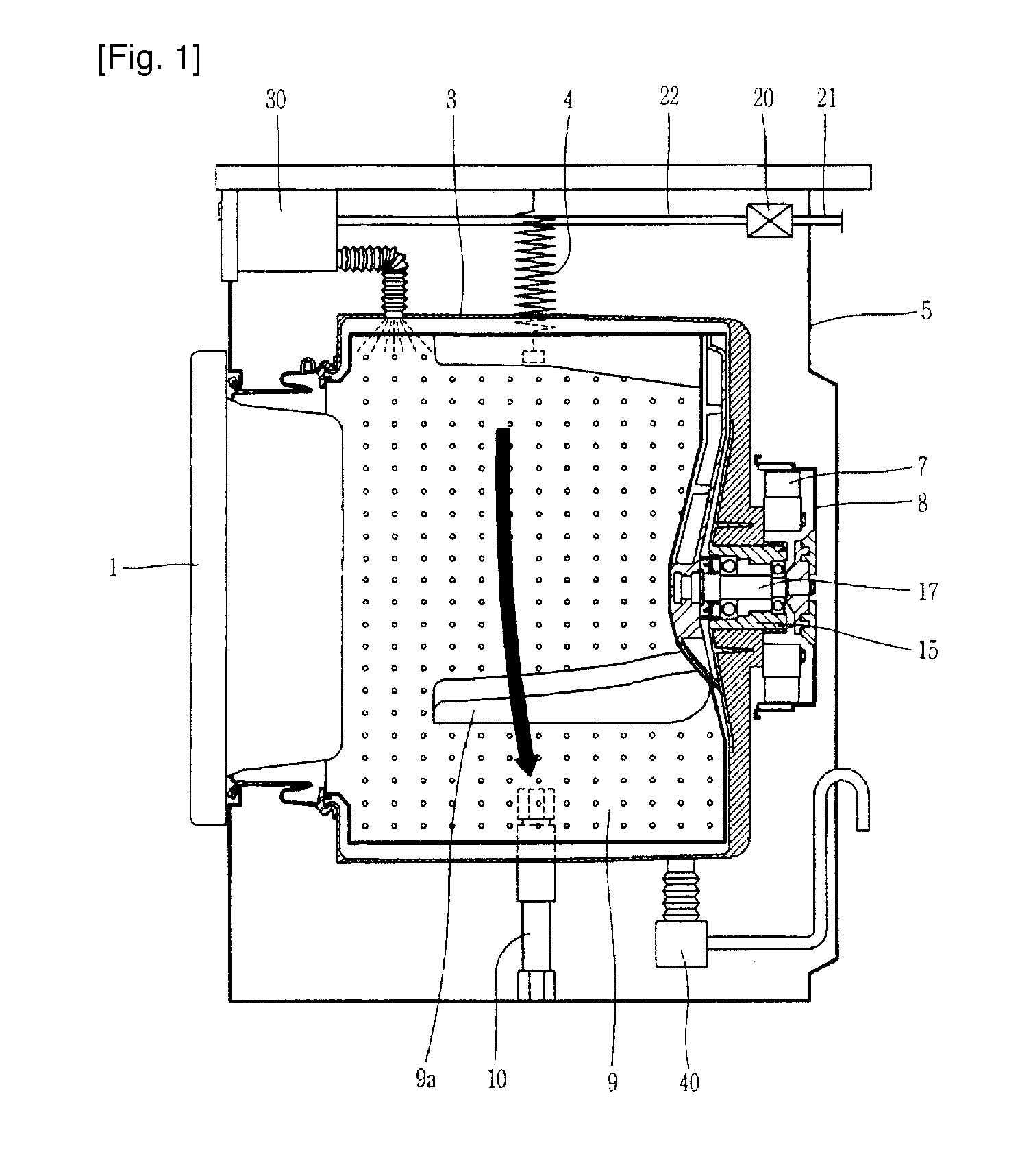

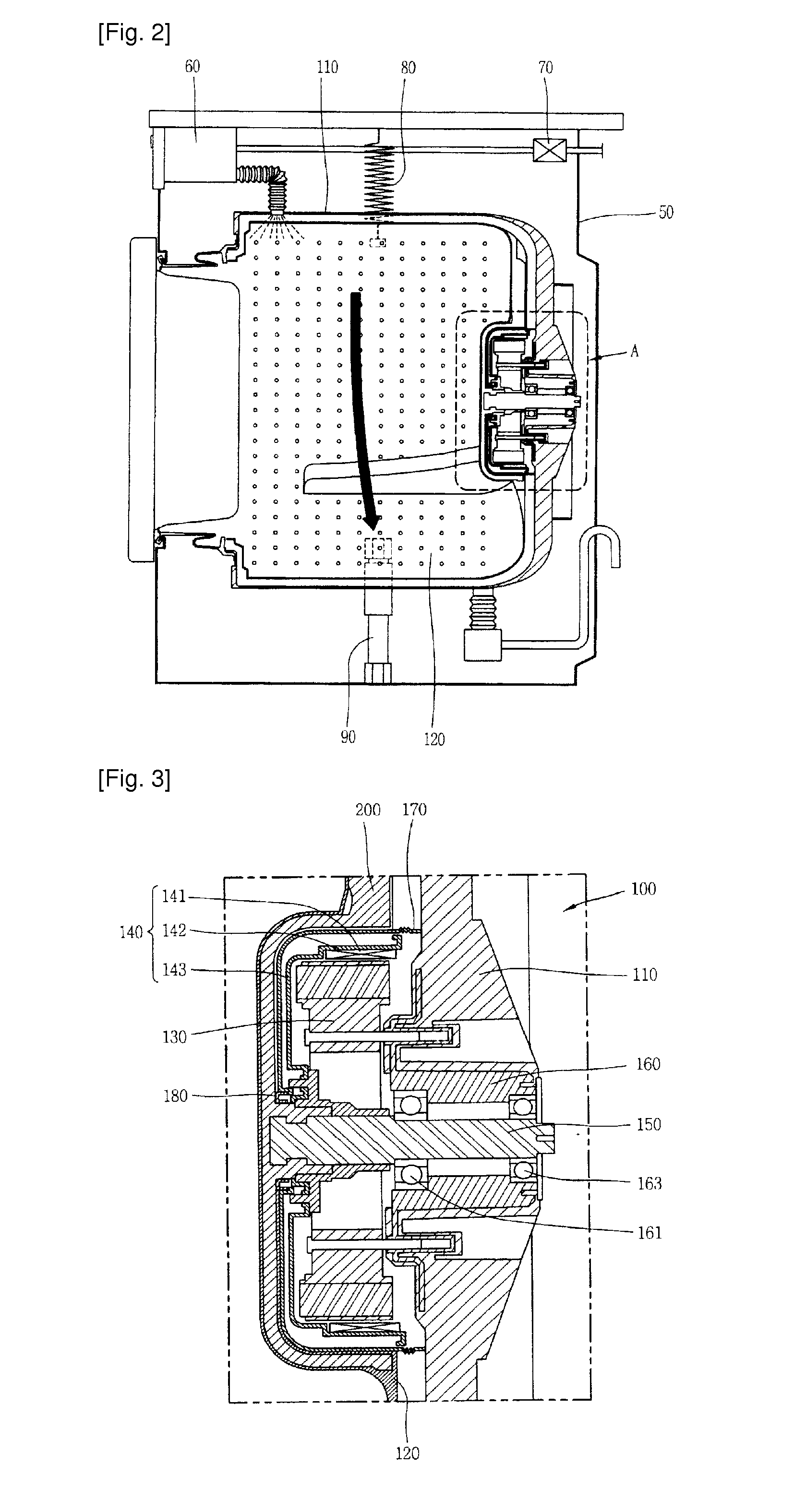

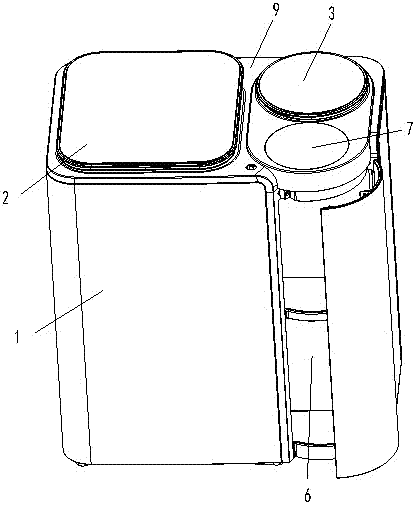

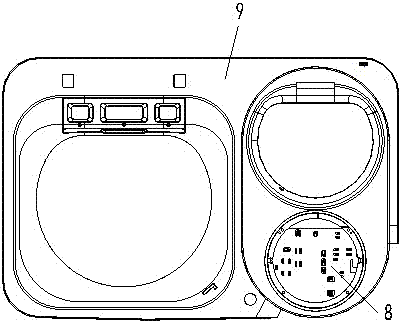

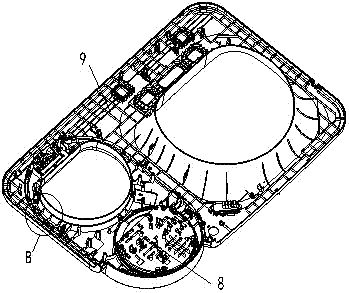

Auxiliary washing machine and clothes treatment apparatus using the same

ActiveCN104321481AIncrease the installation locationSimple structureOther washing machinesTextiles and paperWash waterEngineering

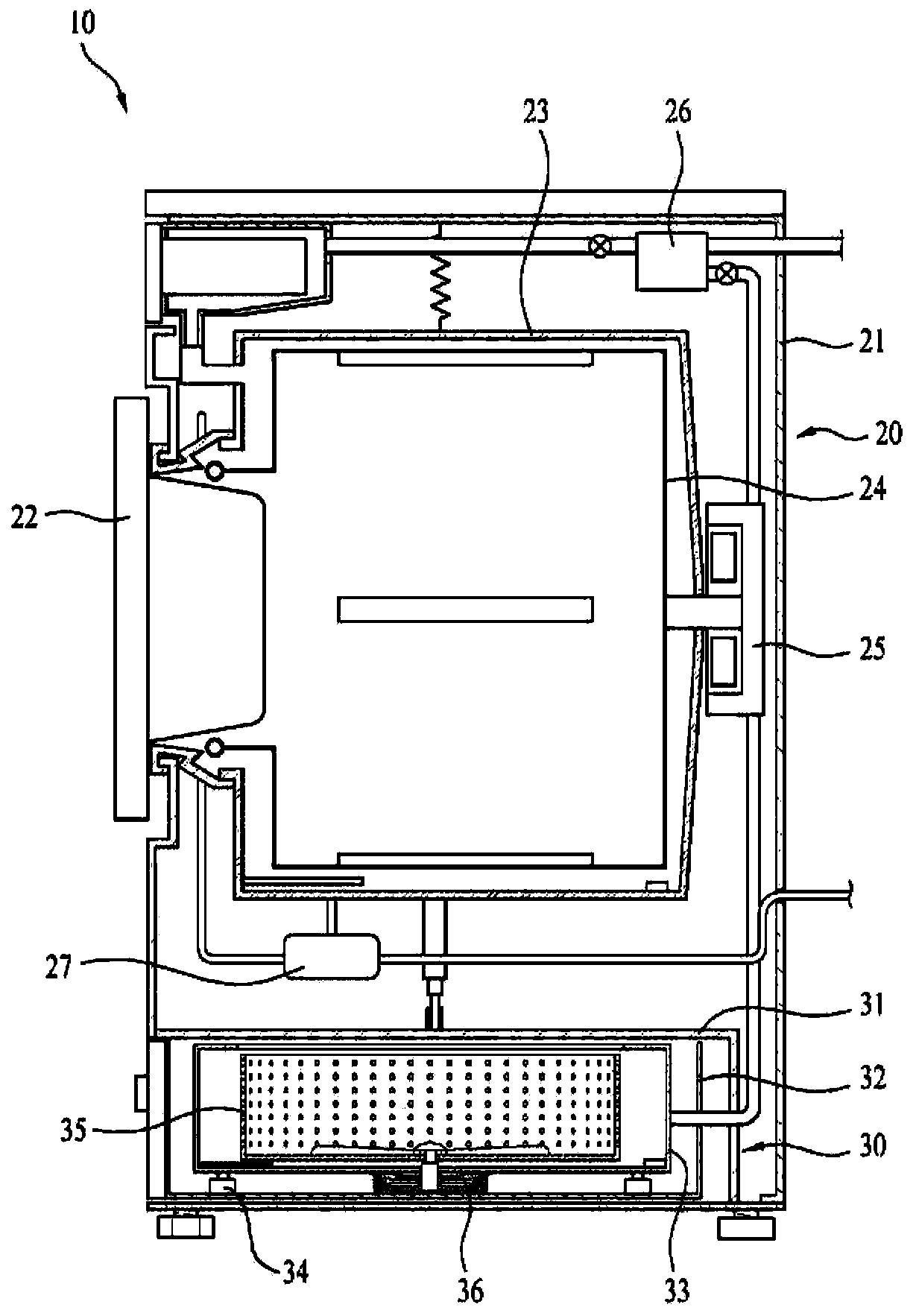

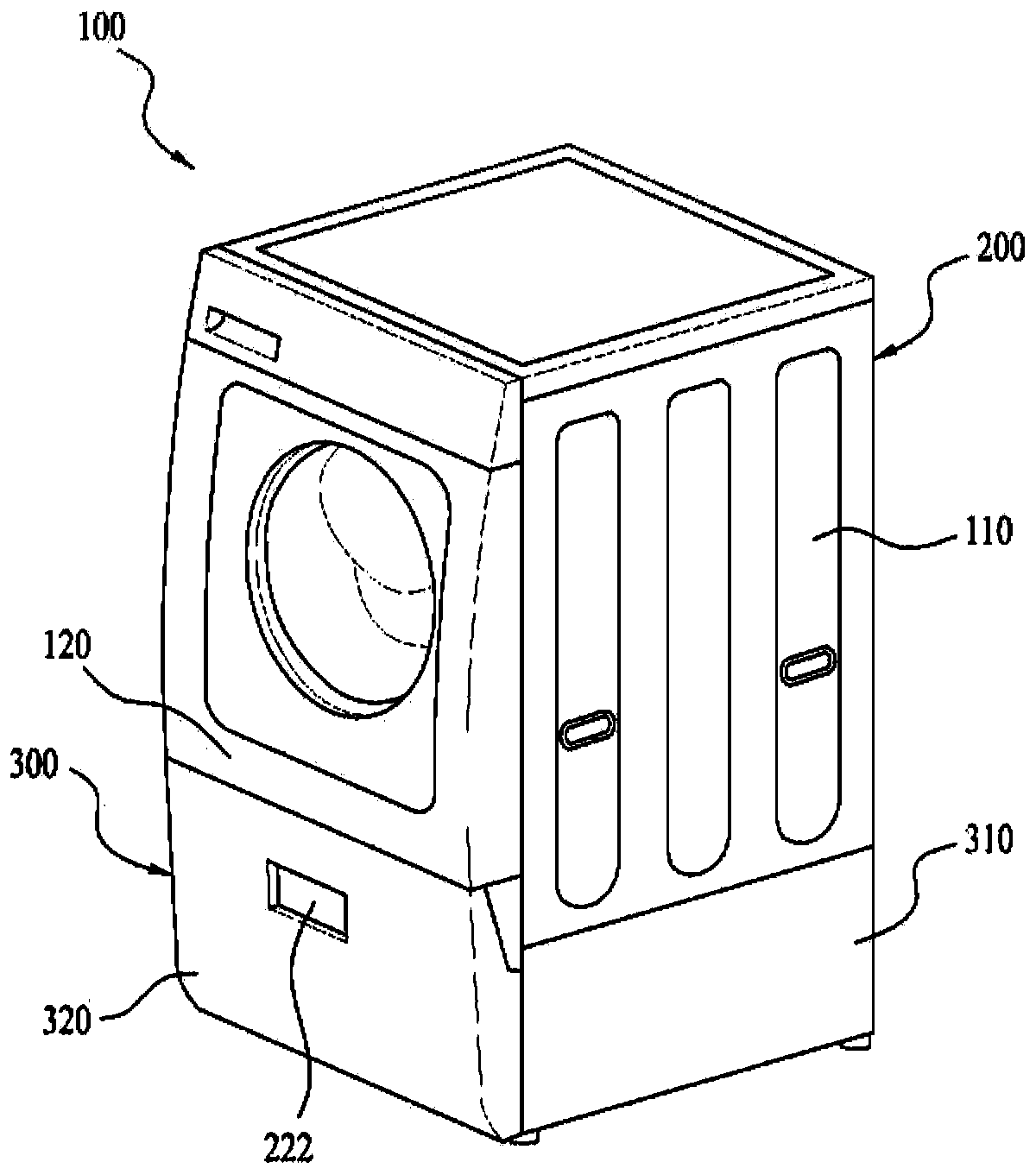

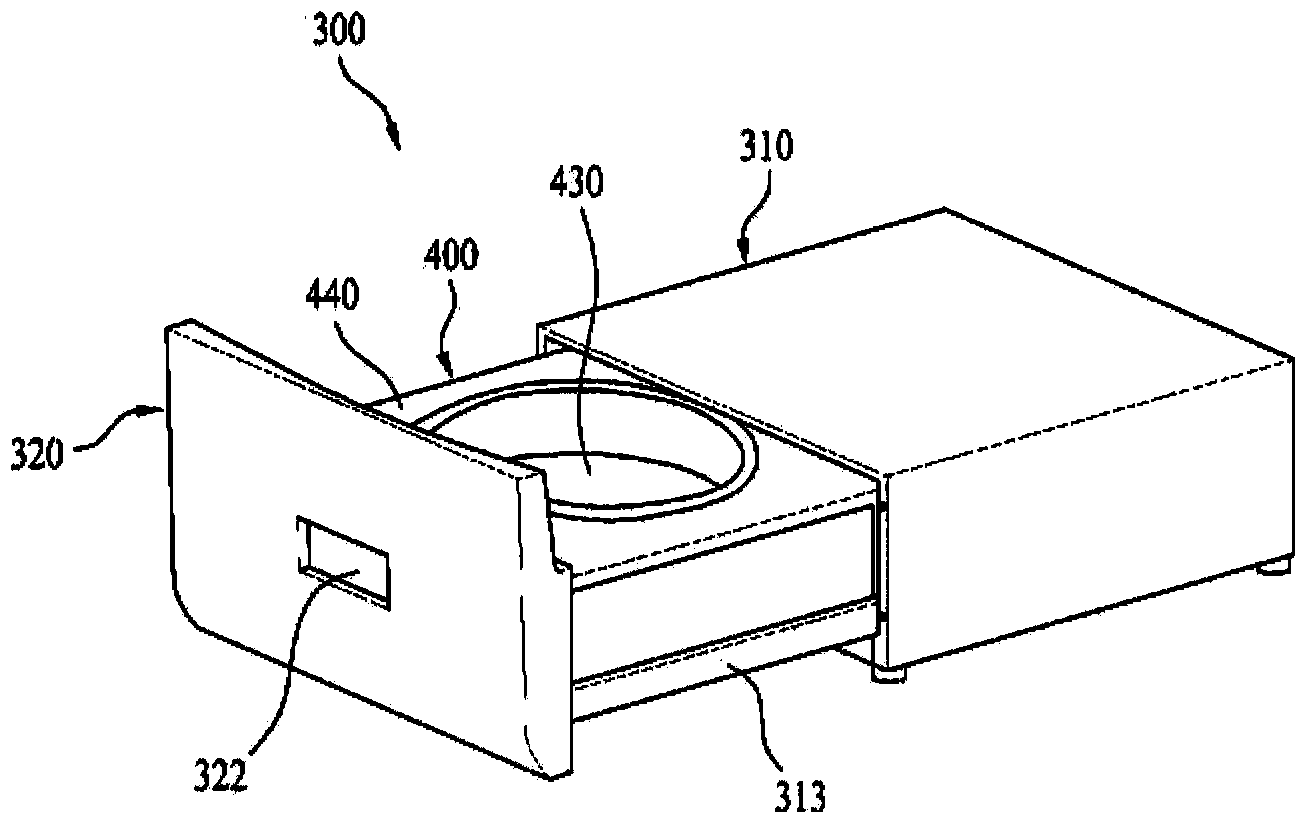

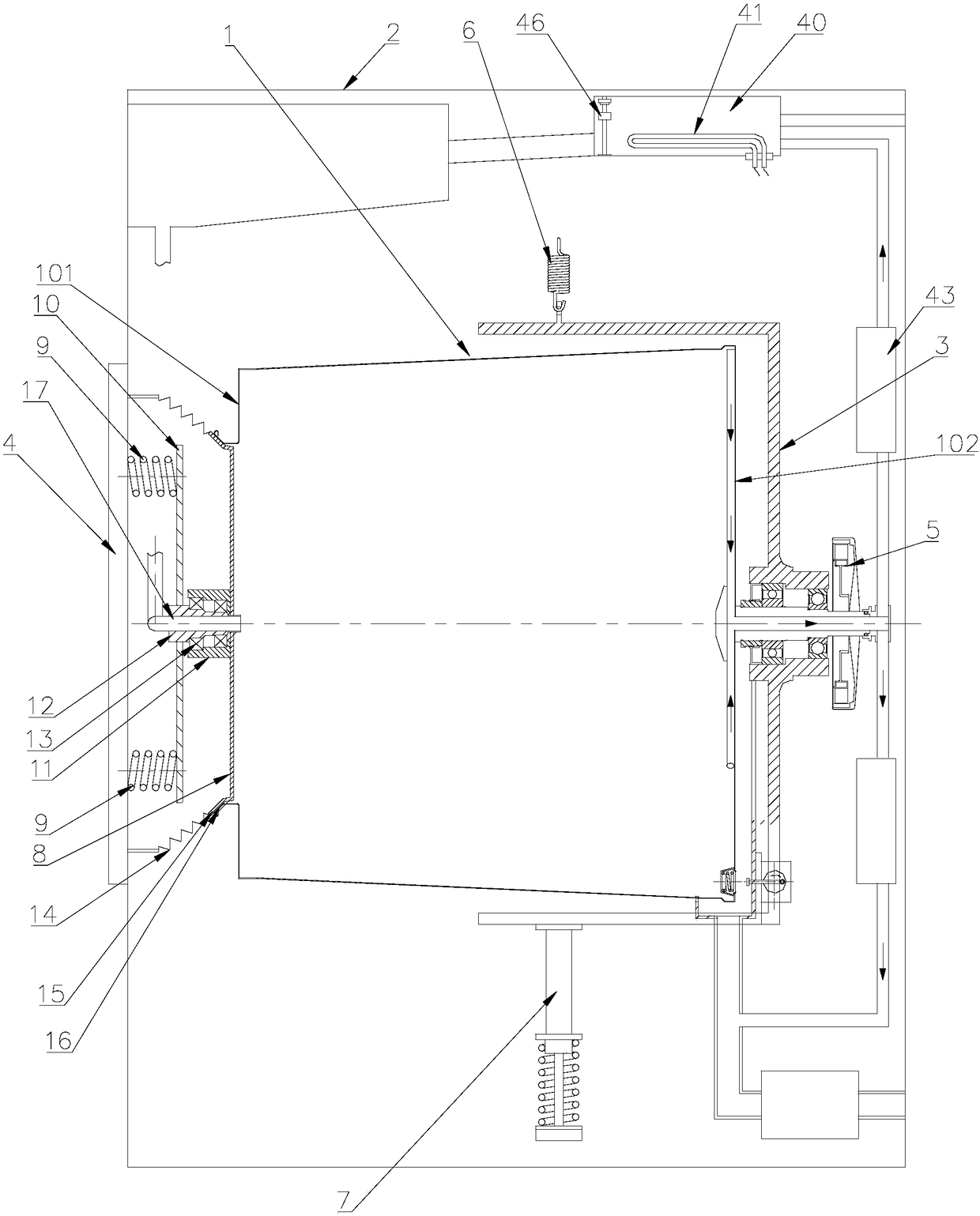

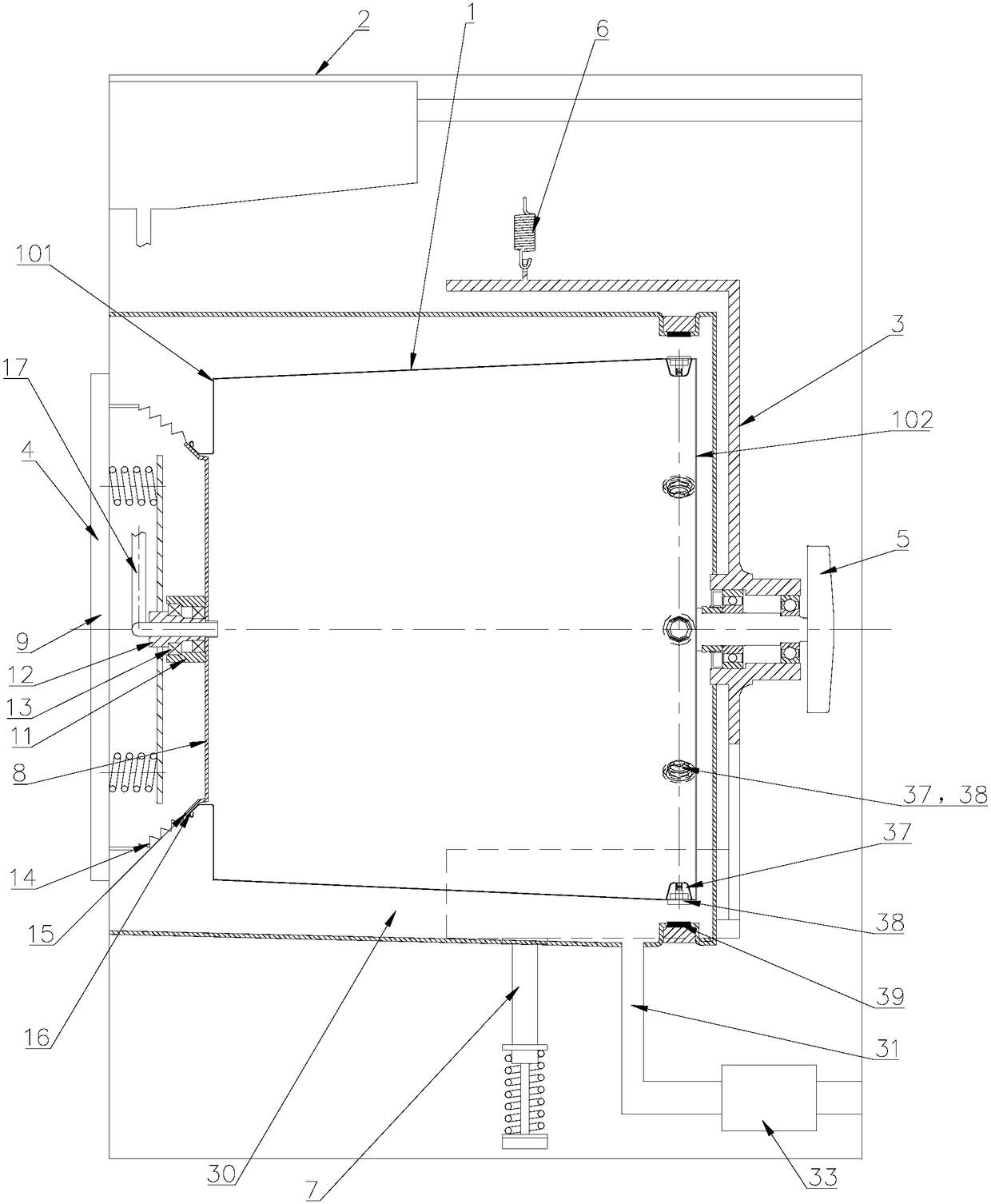

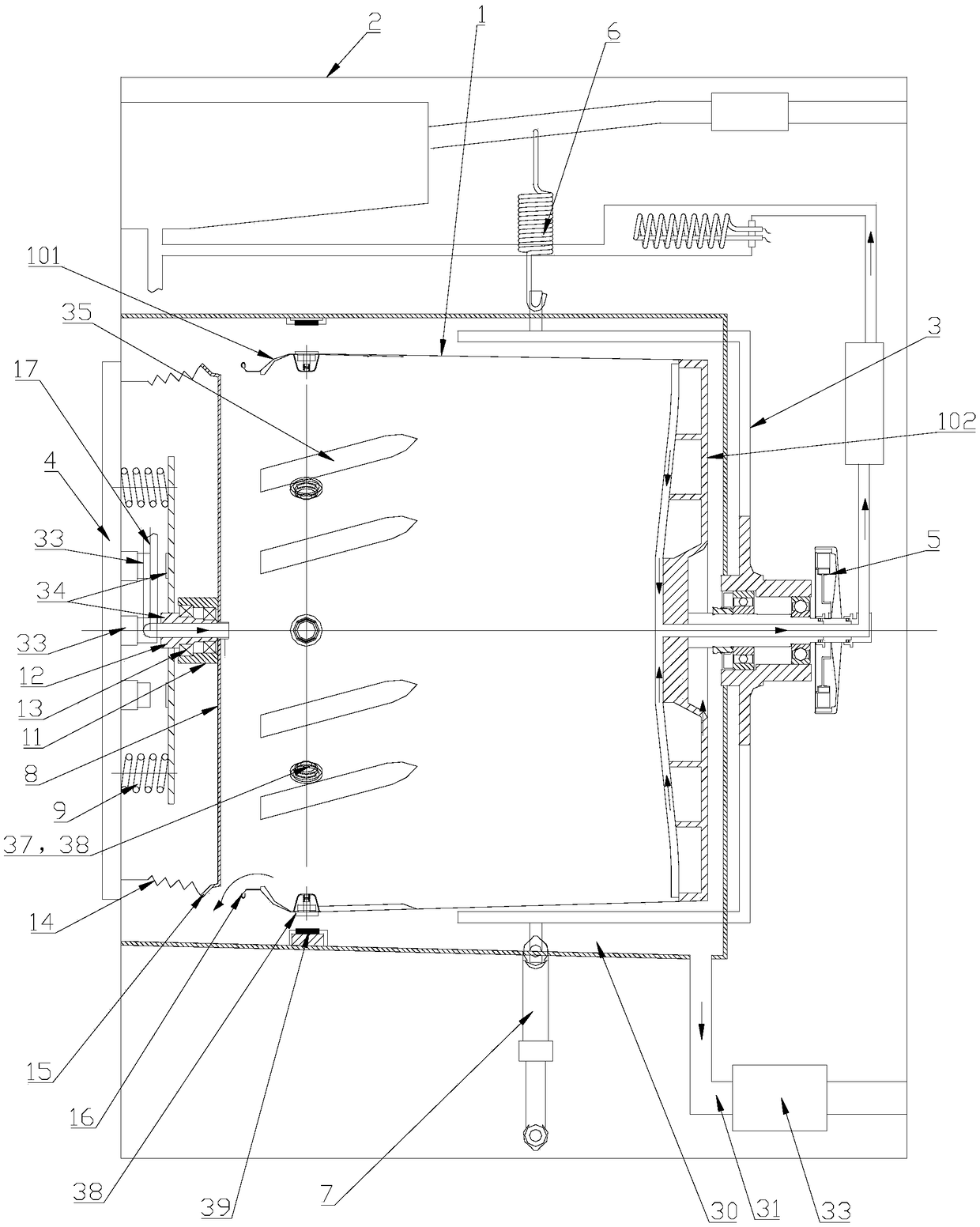

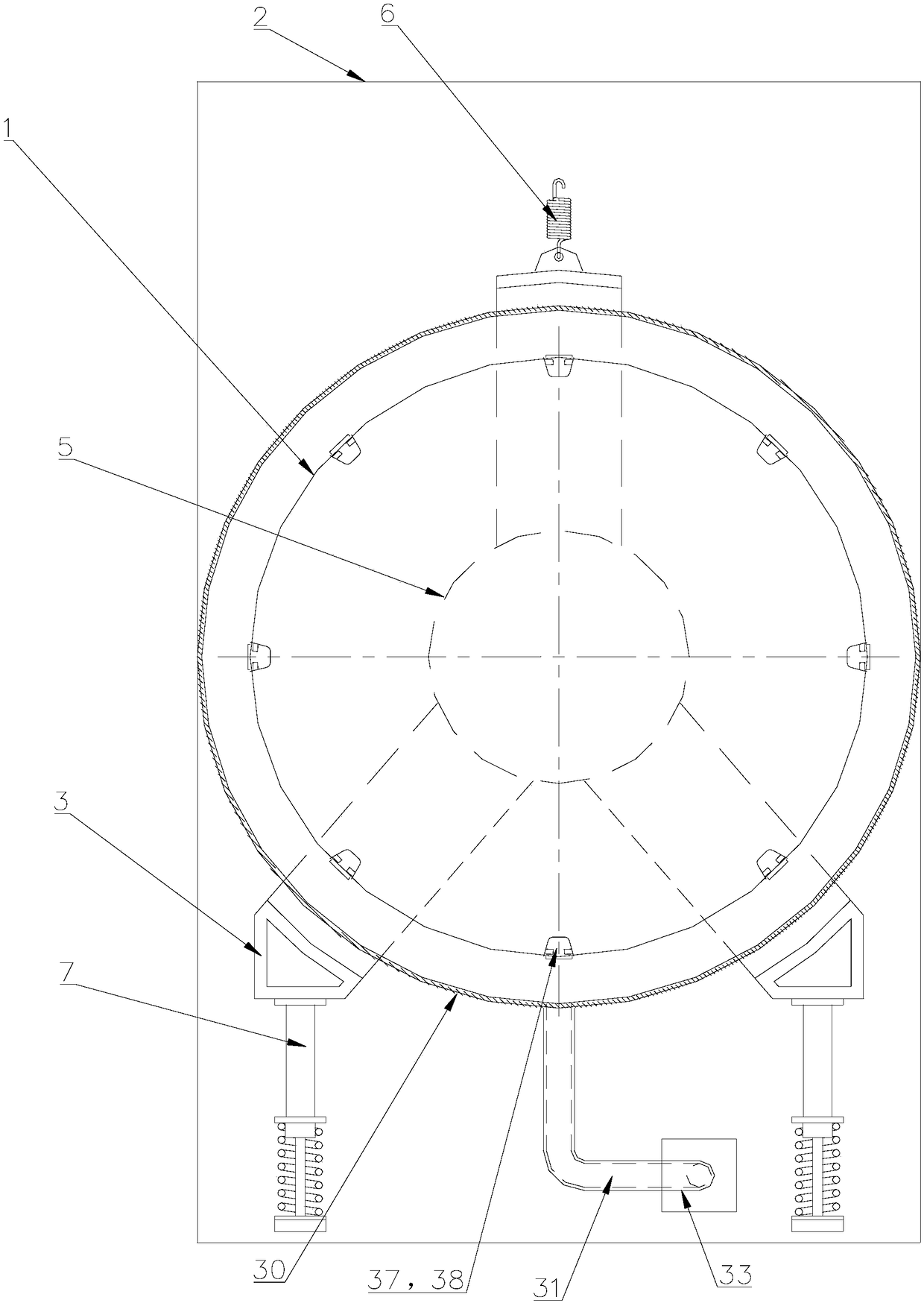

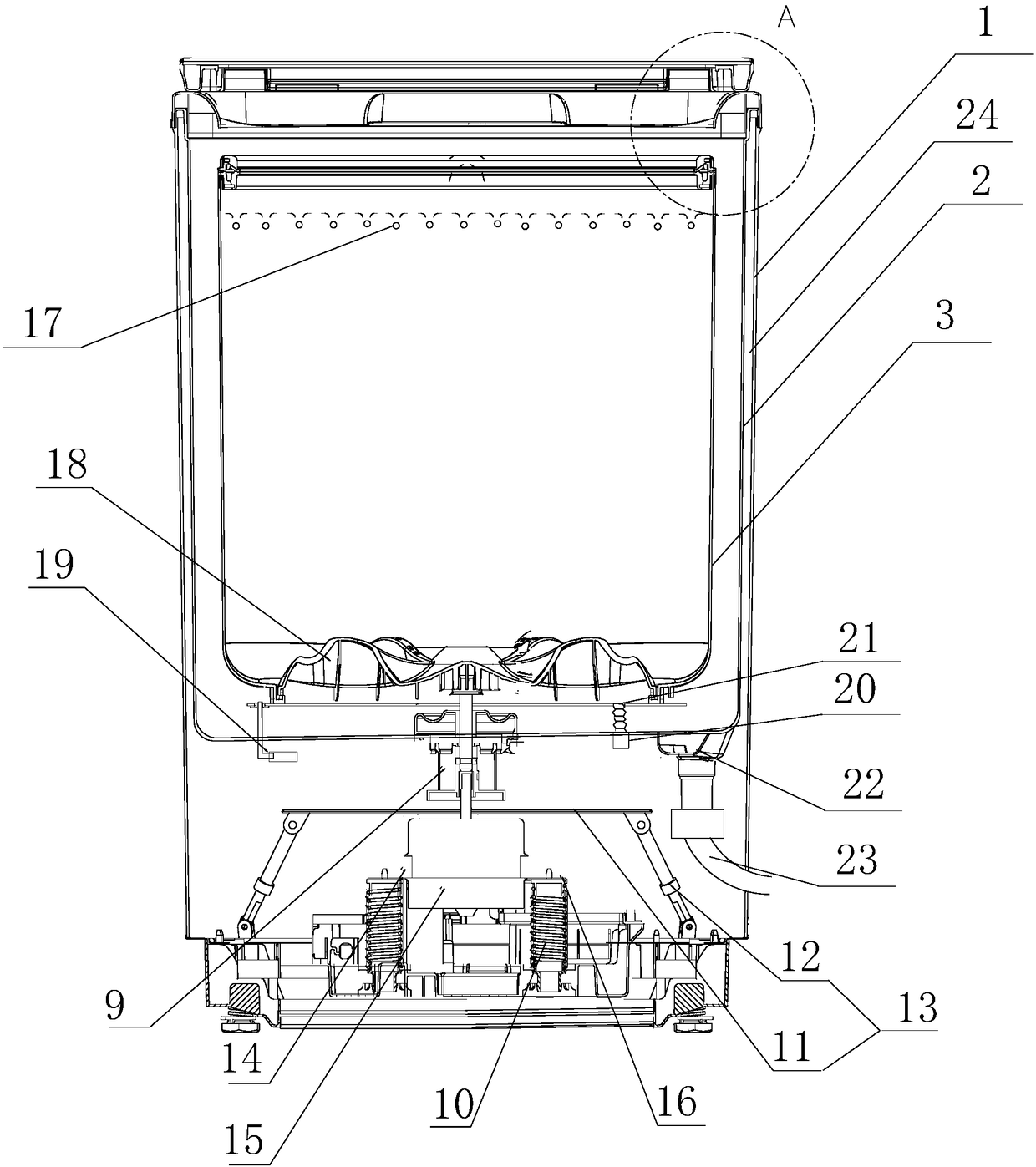

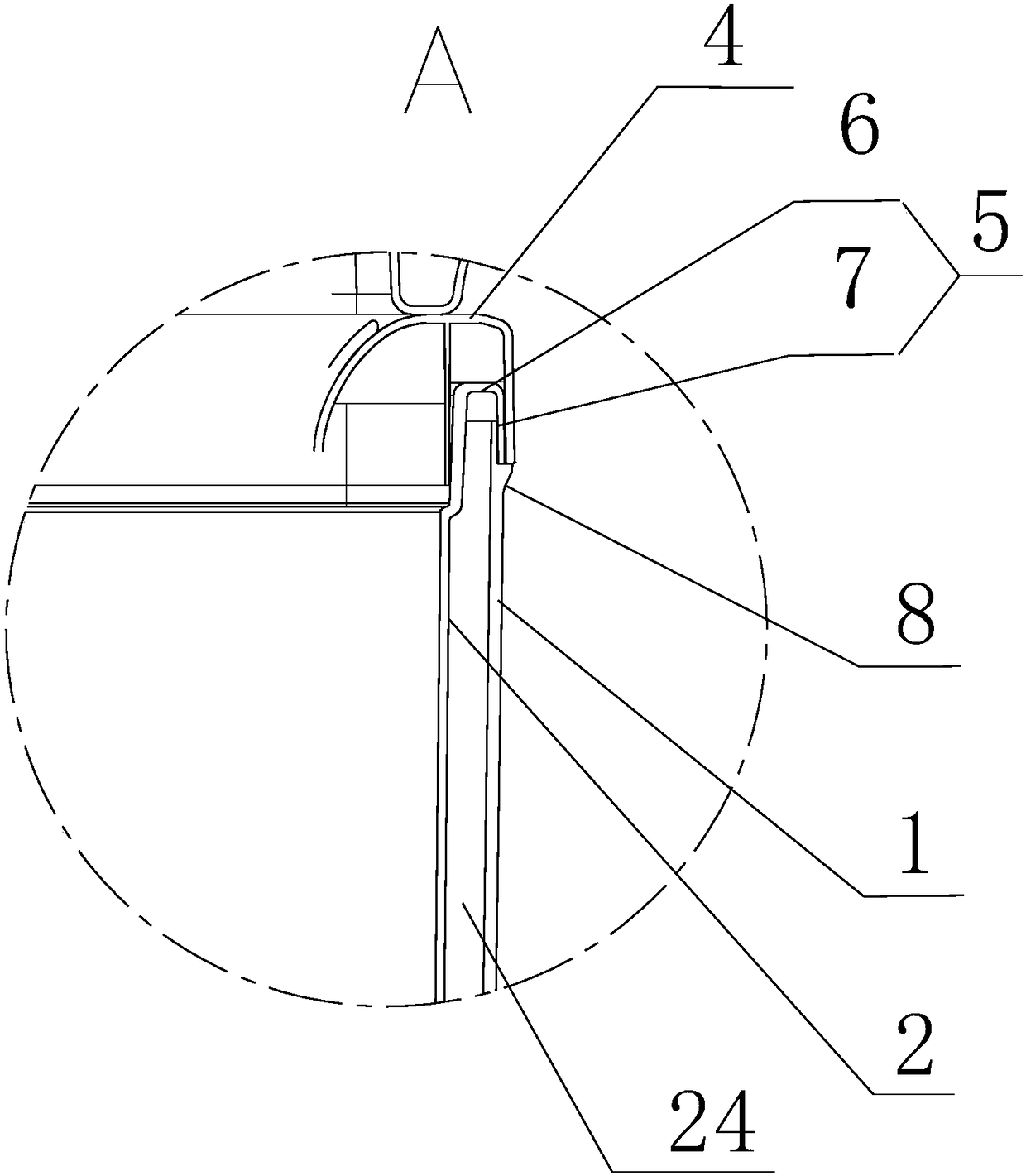

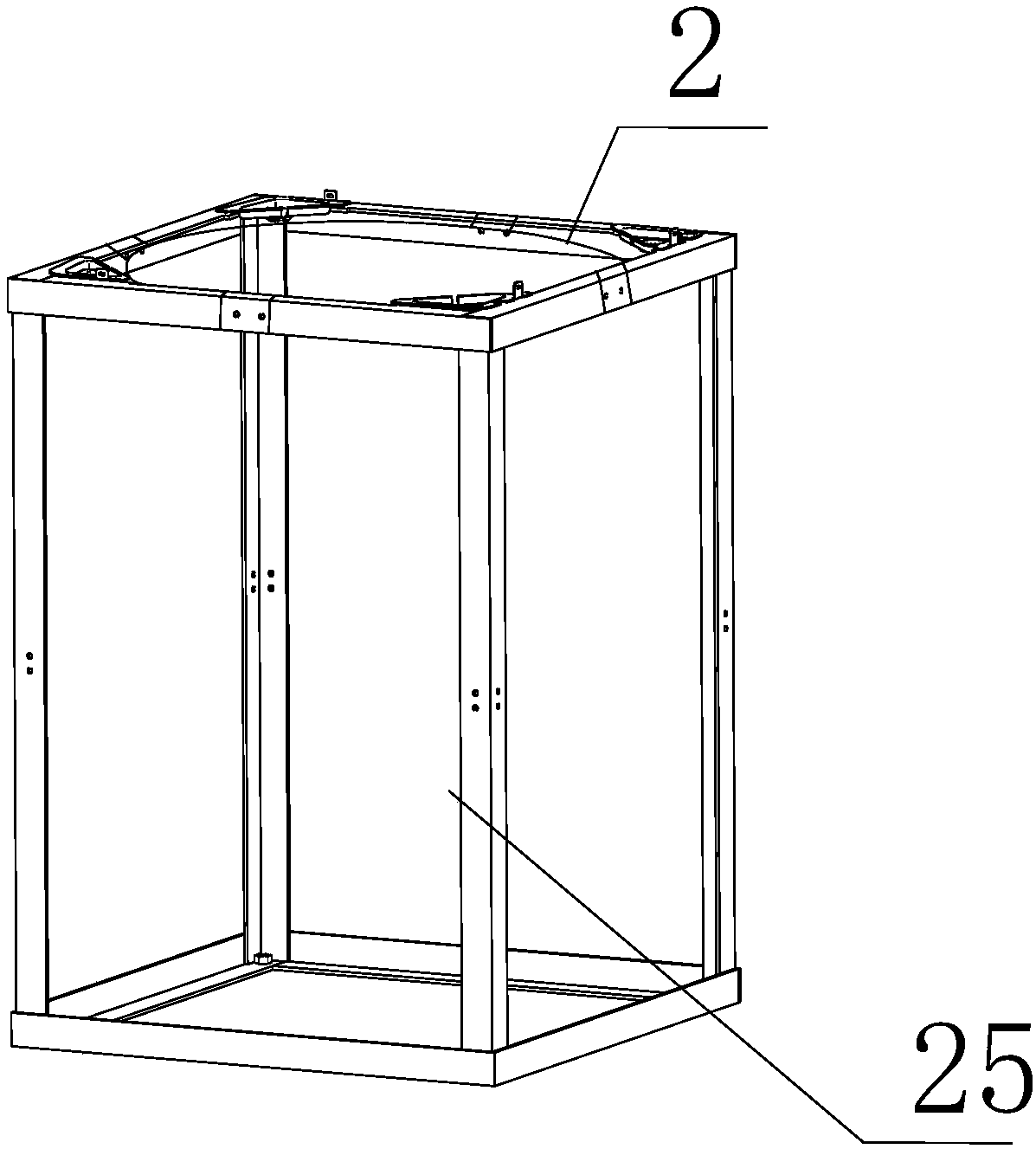

Disclosed are an auxiliary washing machine and a clothes treatment apparatus using the same. The clothe treatment apparatus includes a main washing machine configured to treat laundry and an auxiliary washing machine located at one side of the main washing machine. The auxiliary washing machine includes a frame defining an accommodation space, a drawer configured to be accommodated in the accommodation space, the drawer defining a space for storage of wash water, a rotating structure placed within the drawer, the rotating structure having a rotating shaft penetrating the drawer so as to treat laundry, a suspension assembly configured to support vertical load of the rotating structure such that the rotating structure is supported to float with respect to the drawer and to alleviate horizontal vibration of the rotating structure, and a front panel located in front of the drawer, the front panel defining a front external appearance of the auxiliary washing machine.

Owner:LG ELECTRONICS INC

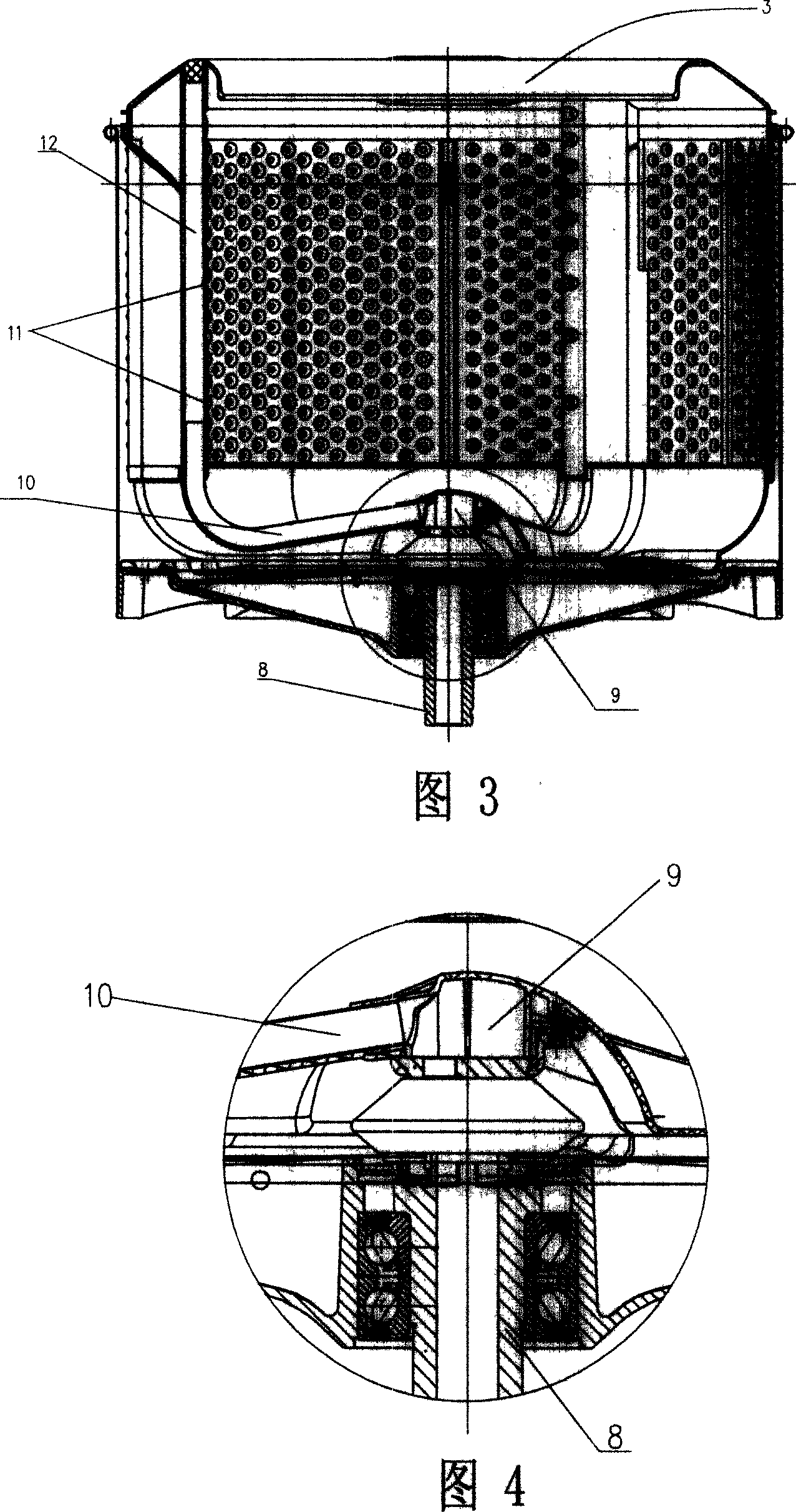

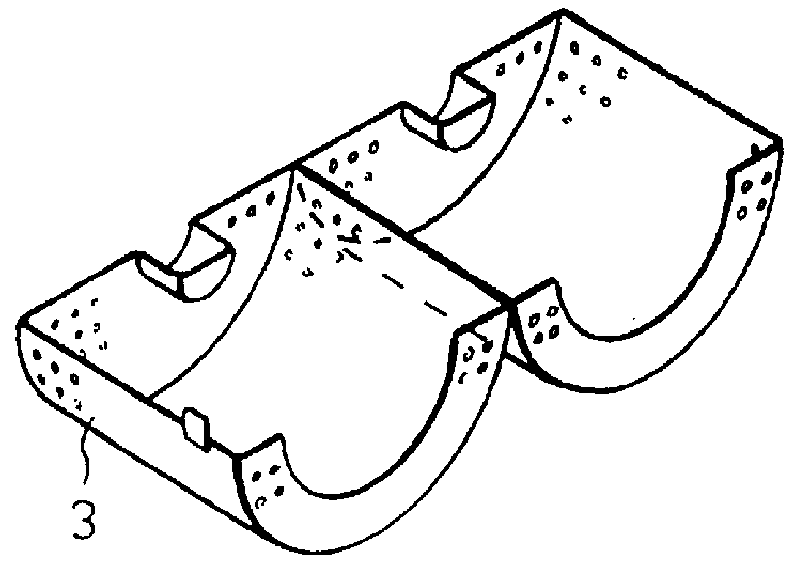

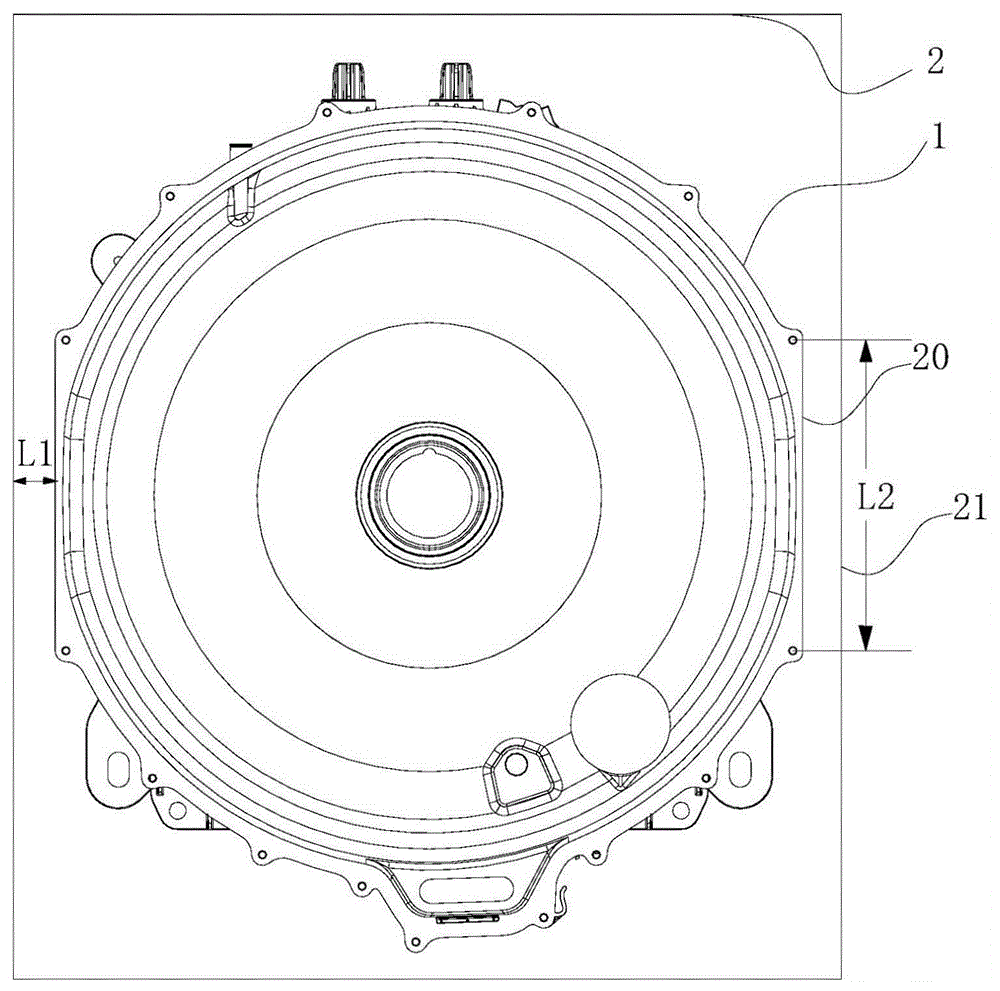

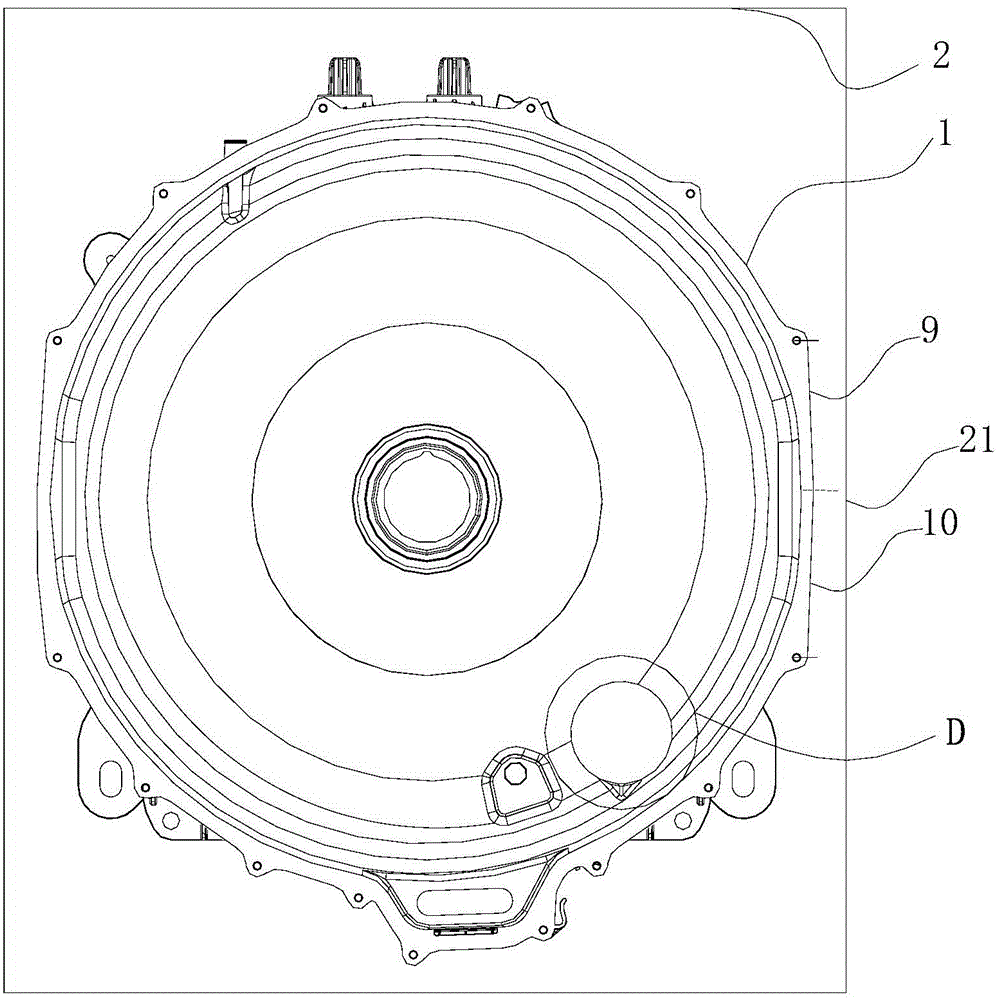

Inner drum assembly for washing machine

InactiveCN104278483ASolve the small vibrationSolve the problem of large vibration at the topOther washing machinesTextiles and paperWater savingImpeller

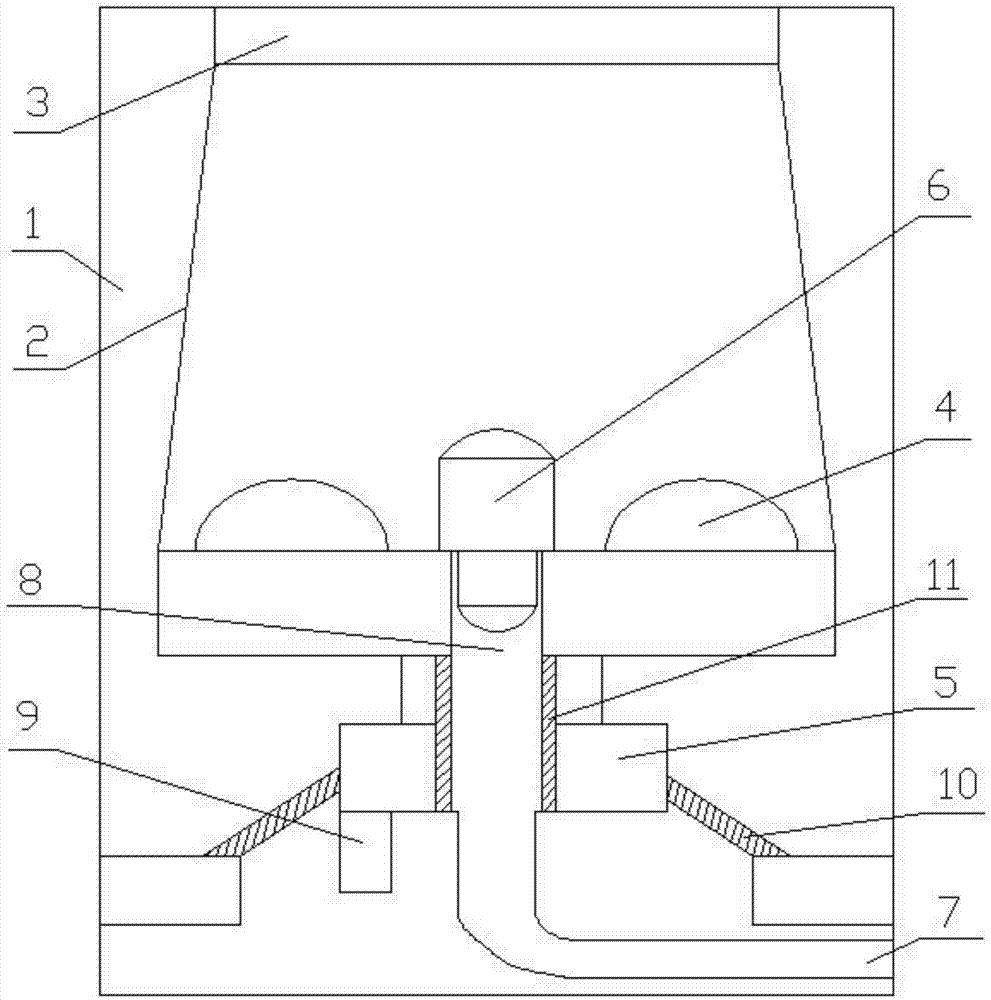

The invention discloses an inner drum assembly for a washing machine. The inner drum assembly for the washing machine comprises a box body, an inner drum, a balancing ring, an impeller and a motor; the top of the inner drum is connected with the box body by the balancing ring; the impeller is arranged at the bottom of the inner drum; the motor is in transmission connection with the impeller. The inner drum assembly is characterized by also comprising a drainage port, a drainage pipe and a centrifugal drainage valve, wherein the drainage port is formed in the bottom of the inner drum; the drainage pipe is communicated with the bottom of the drainage port; the centrifugal drainage valve is arranged on the drainage port; the diameter of the bottom of the inner drum is greater than that of the top of the inner drum. The inner drum assembly has the highest washing efficiency; a small gap is formed between the bottom of the inner drum and the box body; a big gap is formed between the top of the inner drum and the box body; the problems of small vibration of the bottom of the inner drum and big vibration of the top of the inner drum can be solved; the inner drum also can be guaranteed not to be in contact with the box body in the rotating process; the inner drum assembly has the highest washing capacity and is water-saving.

Owner:WHIRLPOOL CHINA

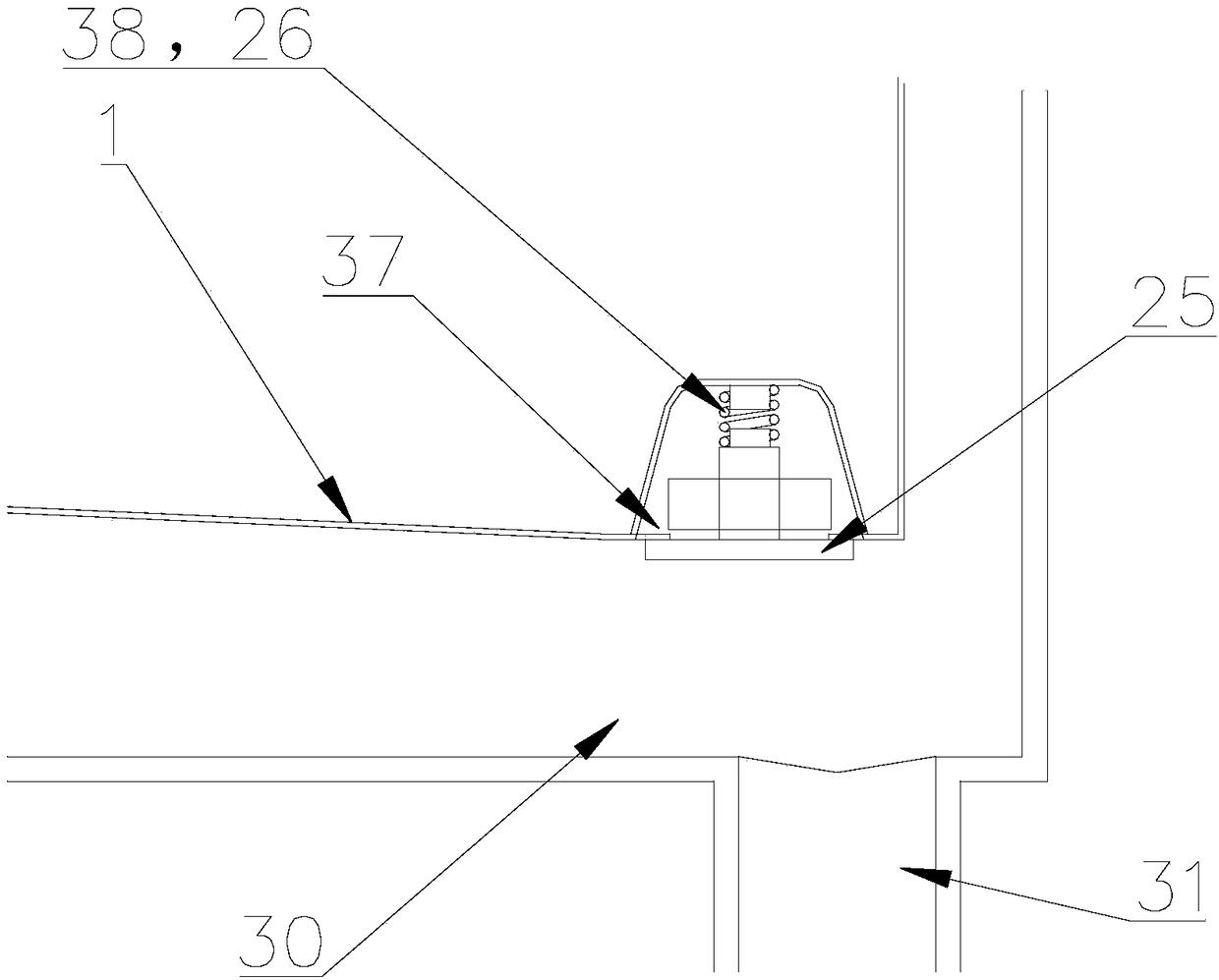

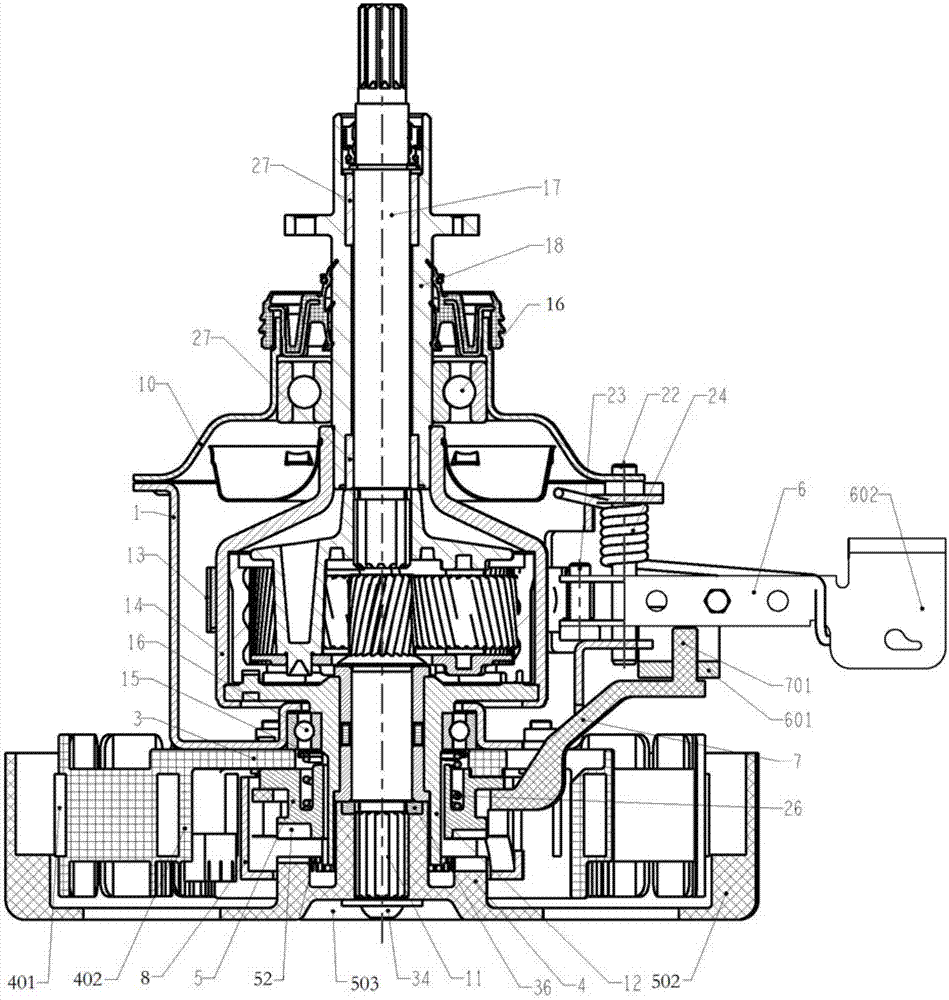

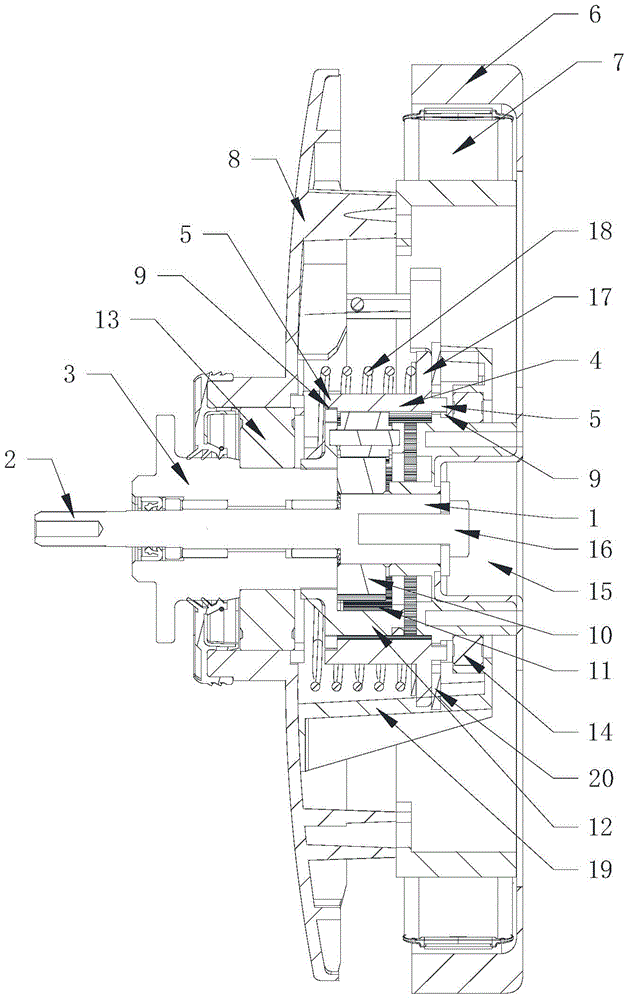

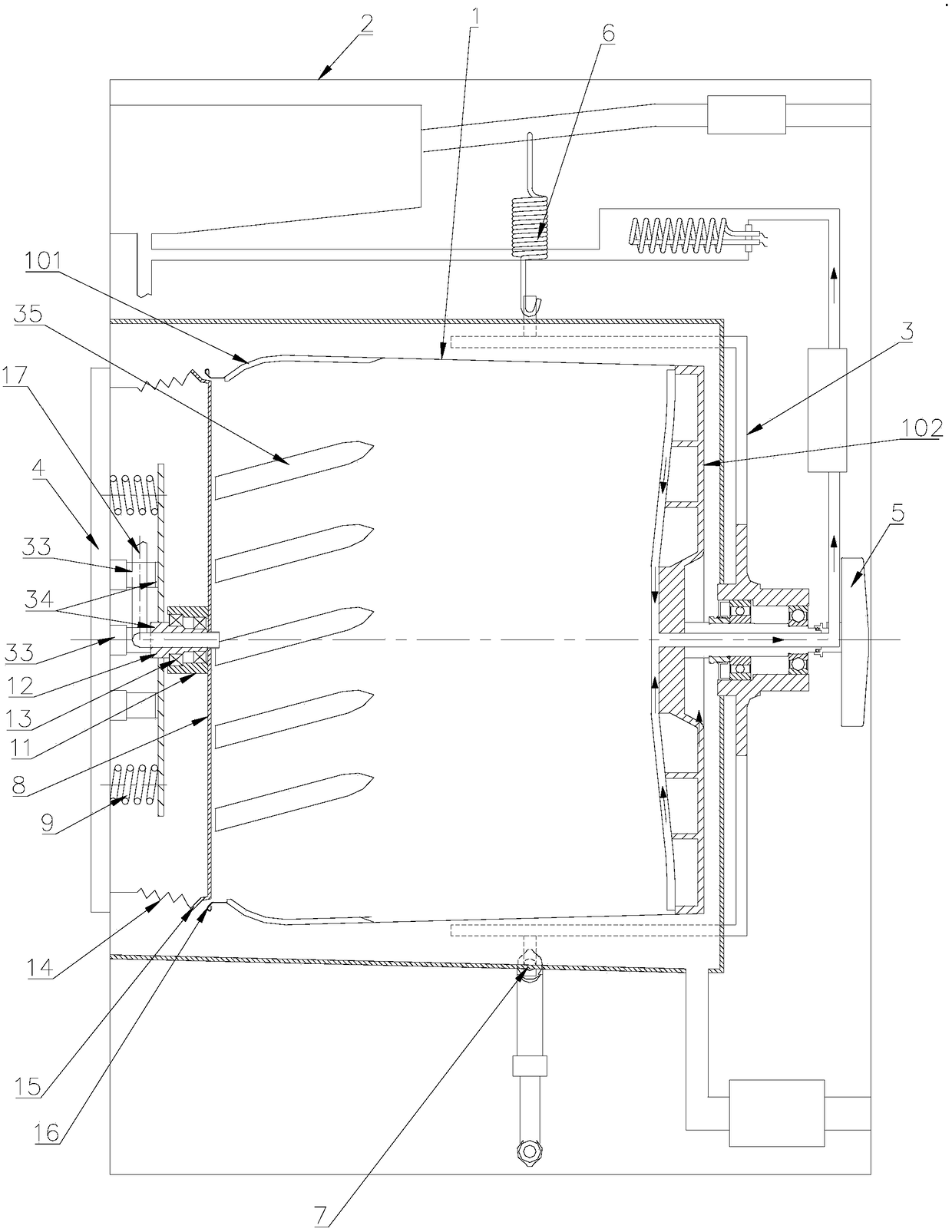

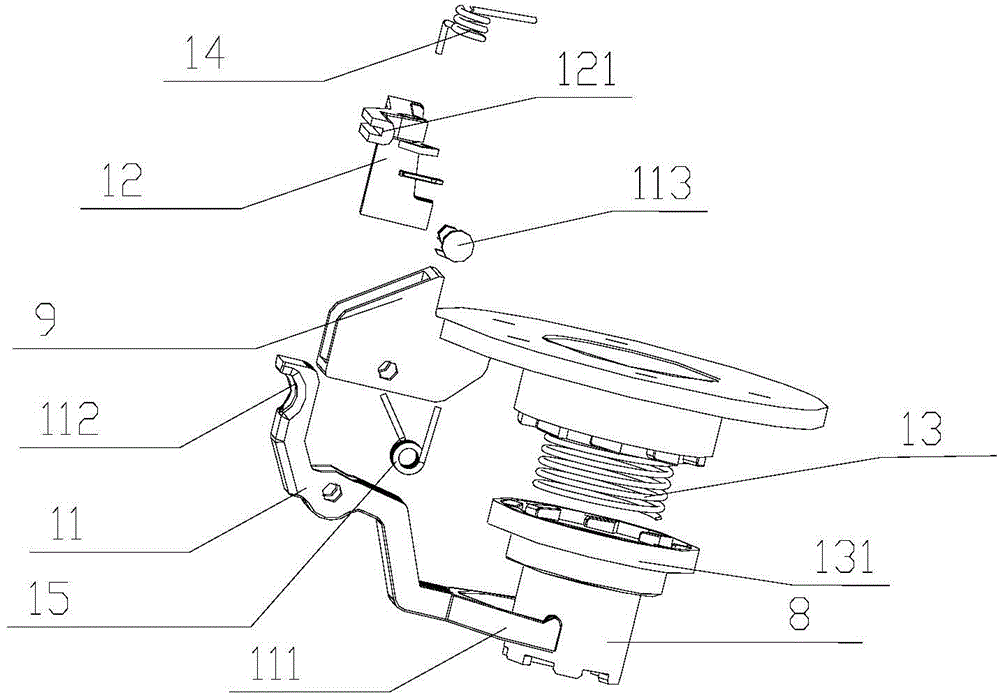

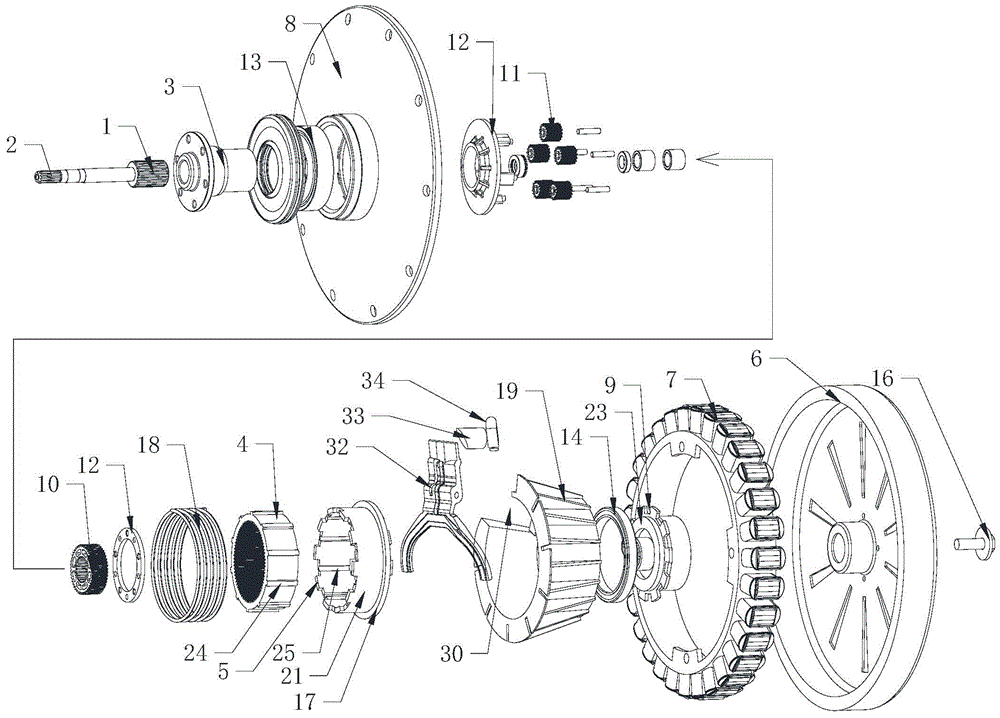

Decelerating clutch of full-automatic washing machine

ActiveCN104674507AImprove reliabilitySimple structureOther washing machinesWashing machine with receptaclesGear wheelTransmitted power

The invention discloses a decelerating clutch of a full-automatic washing machine. The machine mainly comprises an input shaft, an input shaft sleeve, an output shaft, an output shaft sleeve, a clutching mechanism, a housing, and a planetary gear system mounted in the housing; the planetary gear system comprises a planetary mechanism, a planetary gear rack and an inner gear; the input shaft distributes and transmits power to the output shaft sleeve and the output shaft through the inner gear and the planetary mechanism; the clutching mechanism comprises a clutching sleeve which is connected with the input shaft by sliding up and down through a spline, a spin drying plate mounted on the inner gear, and a brake plate mounted on the housing; the clutching sleeve is connected and disconnected with the brake plate and the spin drying plate by sliding up and down so as to achieve clutching switching of washing and spin drying. The decelerating clutch has the characteristics of being simple and compact in structure, low in manufacturing cost, safe and reliable in transmission, and efficient.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

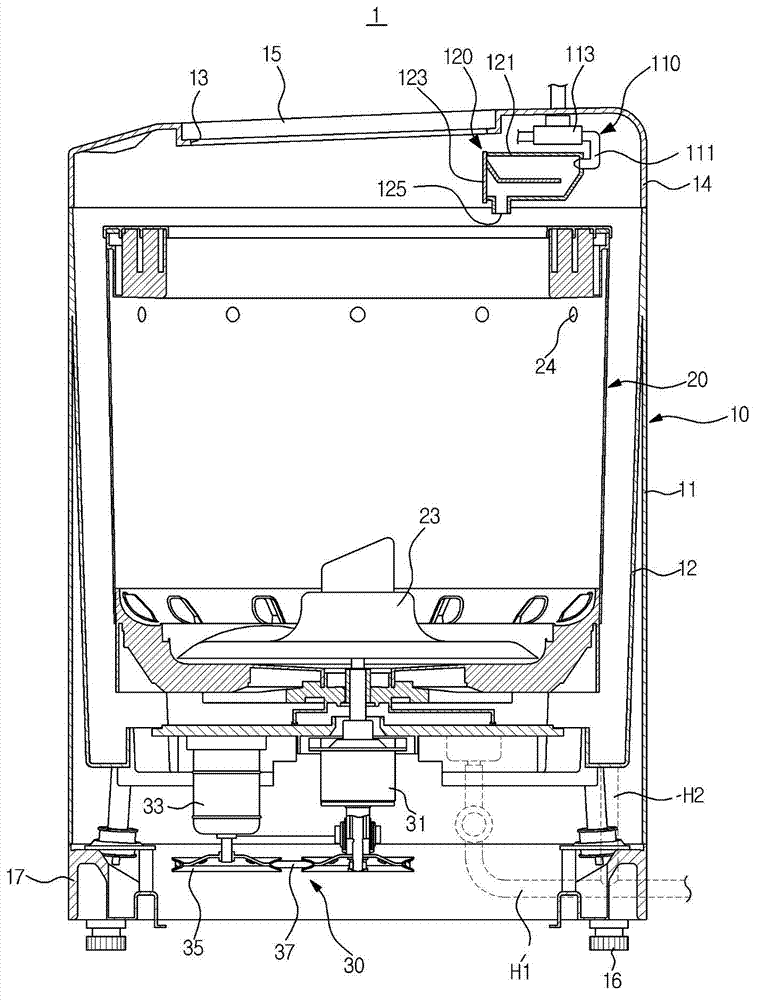

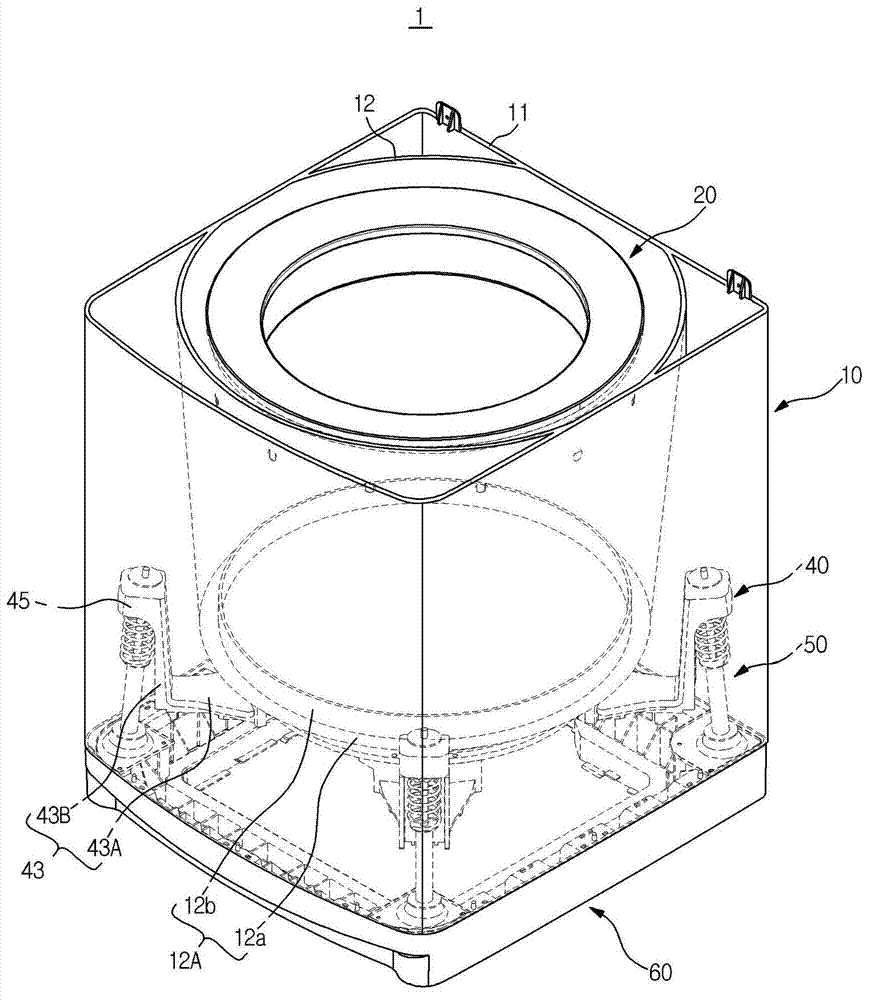

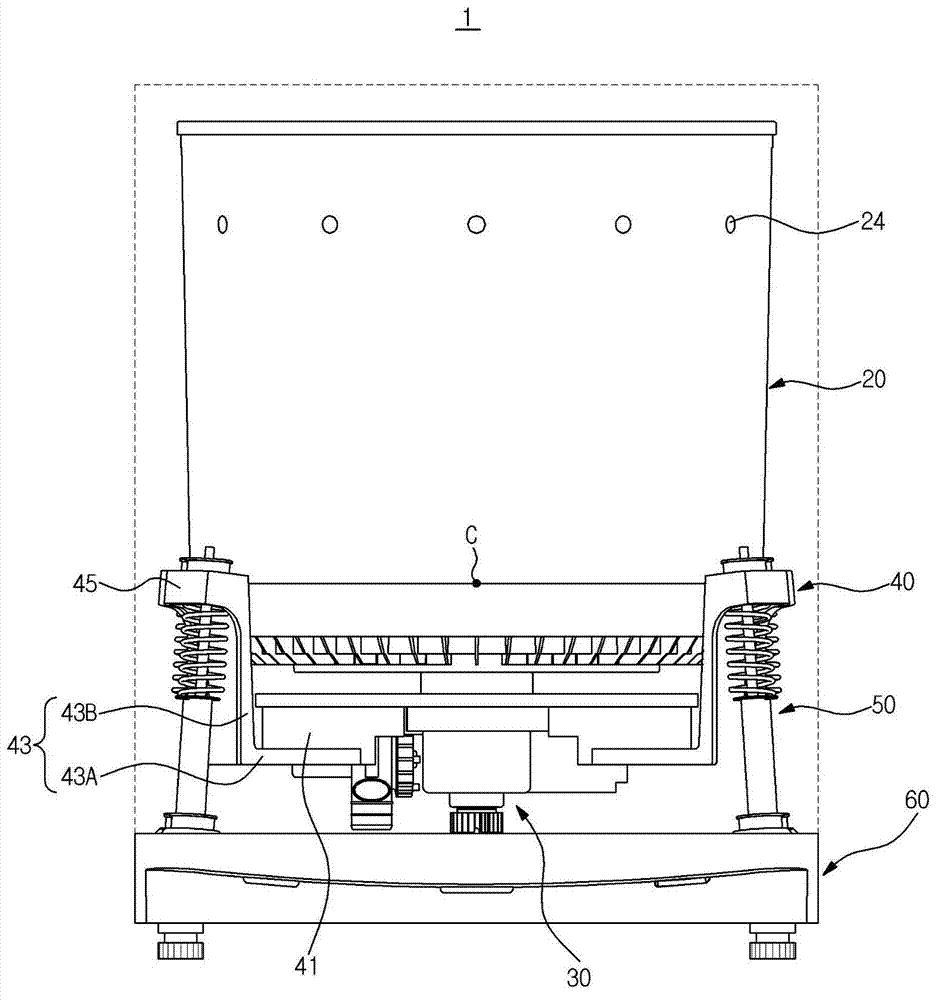

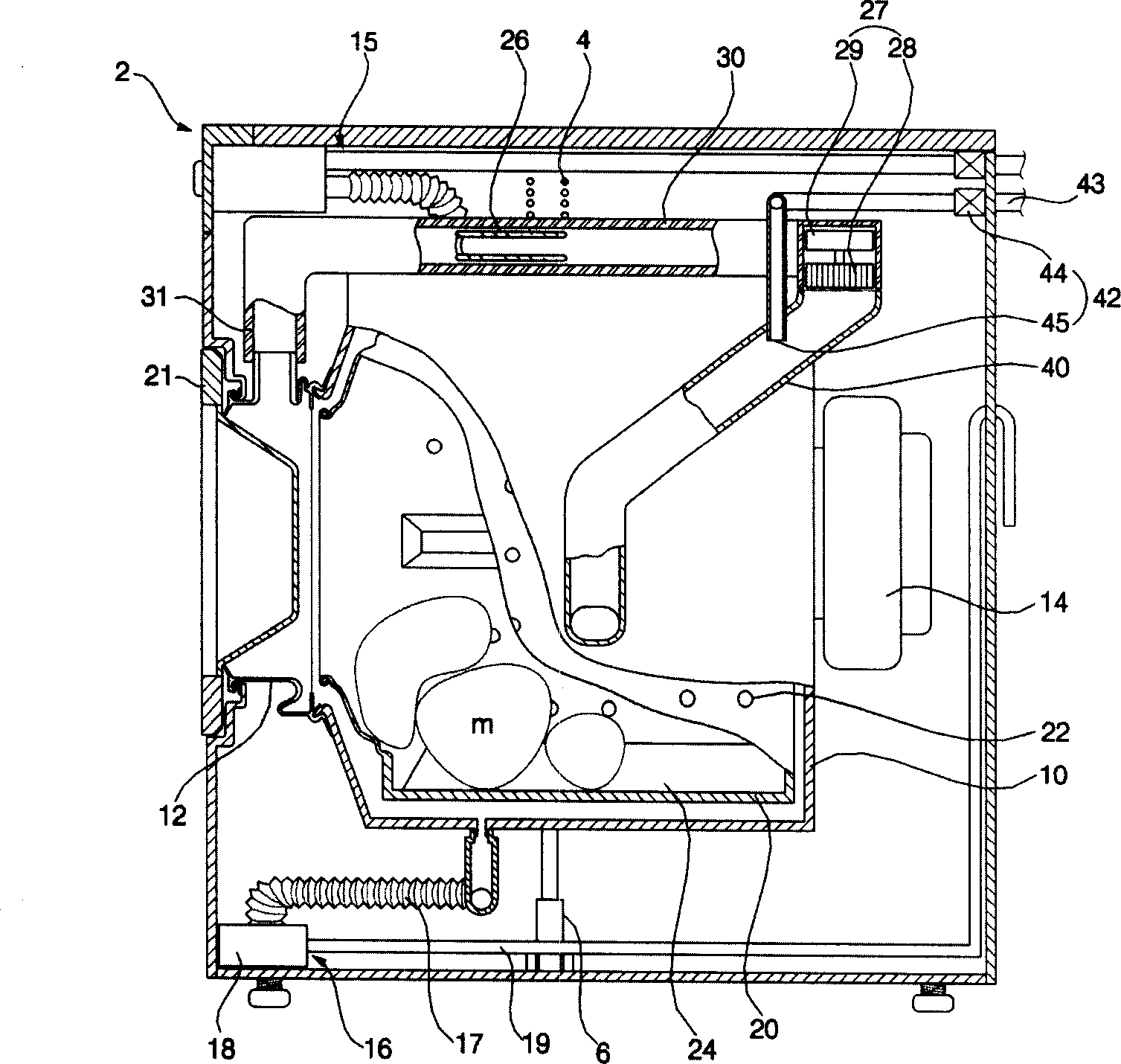

Washing machine

InactiveCN102877258AAbsorb vibrationIncrease washing capacityOther washing machinesWashing machine with receptaclesDrive shaftEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Washing machine

ActiveCN104947388AIncrease washing capacityReduce manufacturing costOther washing machinesWashing machine with receptaclesWater flowWaste management

The invention discloses a washing machine. The washing machine comprises an inner cylinder, a water return device and a filtering piece, wherein the water return device is arranged in the inner cylinder, a filtering channel and a spraying channel are defined in the water return device, the water return device is provided with a water inlet communicated with the filtering channel and the spraying channel, the water return device is further provided with a filtering water outlet and a spraying port, the filtering water outlet is connected with the filtering channel and the interior of the inner cylinder, and the spraying port is communicated with the spraying channel and the interior of the inner cylinder. The filtering piece is used for filtering water drained out from the filtering water outlet. According to the washing machine, the filtering function and the water flow spraying function are integrated, the two functions are achieved by the washing machine, meanwhile the washing capacity is large, the product image is improved, the needs of mass consumers are met, and the manufacturing cost of the washing machine is also reduced.

Owner:HEFEI MIDEA WASHING MACHINE

Washing machine

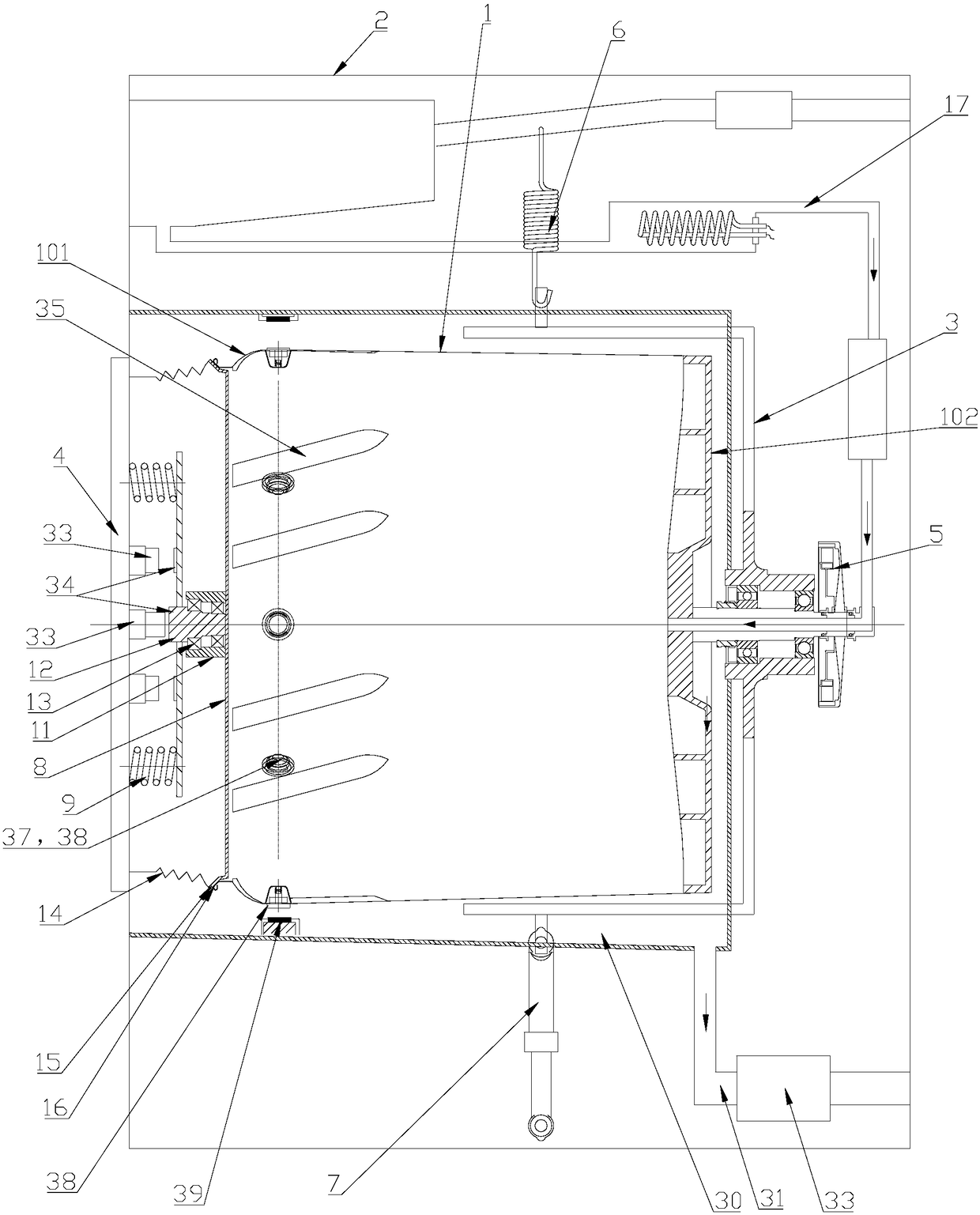

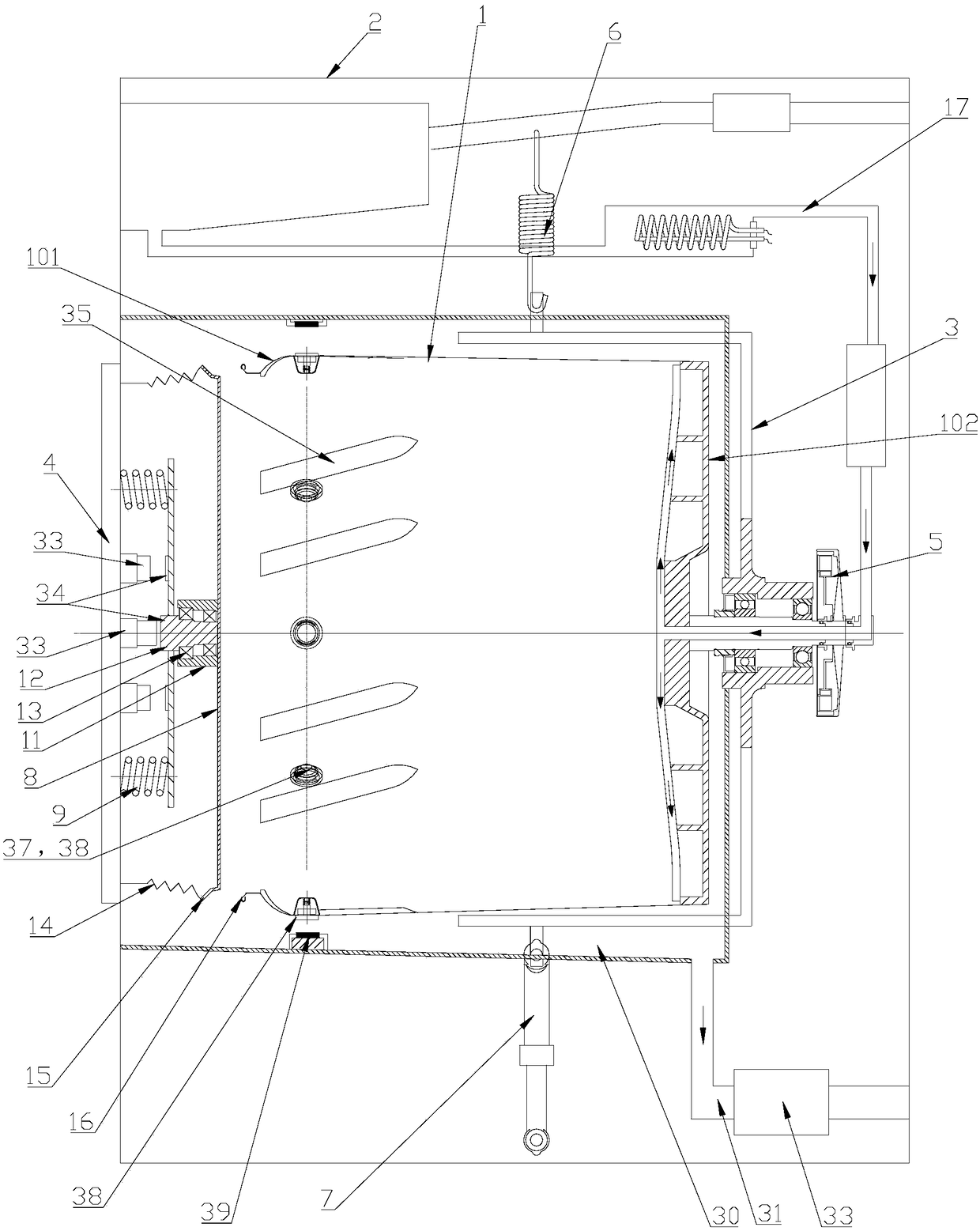

ActiveCN108796962AIncrease washing capacityTo achieve the purpose of normal drainageOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention relates to a washing machine. A door cover is installed on a washing machine shell, the inner side of the door cover is connected with an inner drum cover through an elastic mechanism, after the door cover is closed, the inner drum cover is compressed by the elastic mechanism at an inner drum opening, and an inner drum is sealed; a driving mechanism is arranged between the inner drumcover and the door cover, when the driving mechanism works, elastic force of the elastic mechanism to the inner drum cover is overcome, the inner drum cover breaks away from the inner drum opening, and water in the inner drum is discharged from the opened inner drum opening; the center of the inner drum bottom is communicated with one end of a water inlet pipe, the other end of the water inlet pipe is communicated with a water inlet box of the washing machine, and water enters the inner drum from the center of the inner drum bottom. In this way, the effect that in the rotating process of theinner drum, when the inner drum is sealed, and when dewatering and discharging are conducted, water in the inner drum is discharged outside normally is achieved; meanwhile, an outer drum is not neededfor sleeving the exterior of the inner drum, the volume of the inner drum is increased, and the washing volume of the washing machine is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

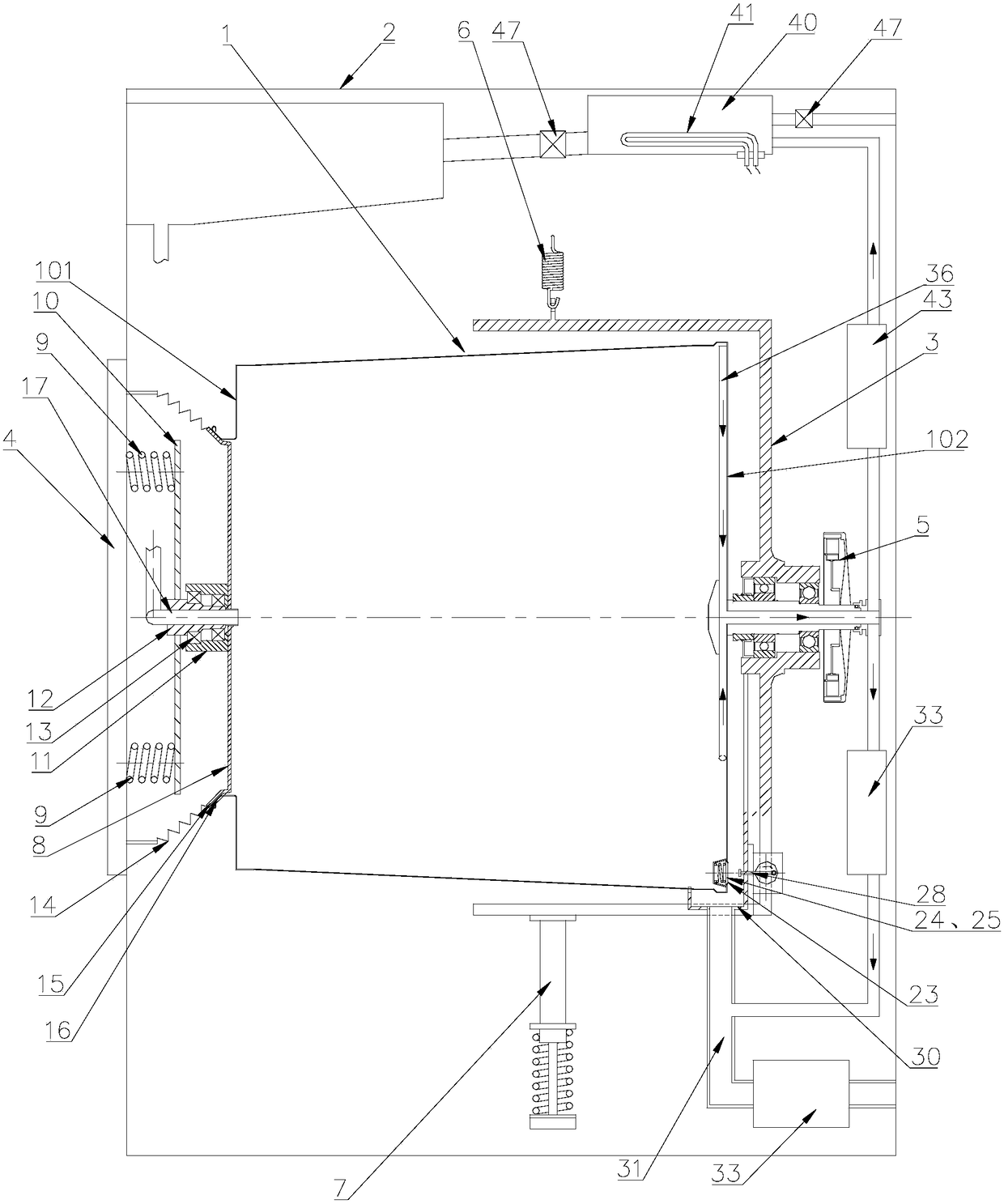

Washing machine and control method thereof

ActiveCN108796985AAccurate detection of water inflowTo achieve the purpose of normal drainageOther washing machinesControl devices for washing apparatusWater sourceWater flow

The invention relates to a washing machine and a control method. A sealed inner tub is installed inside a washing machine shell. The inner tub is communicated with a water inlet source of the washingmachine through a water inlet tube, a constant volume box is arranged on a water inlet tube, when the water level inside the constant volume box reaches a high water level, a water inlet is closed, awater outlet is opened, water flows into the inner tub; when the water level inside the constant volume box reaches the low water level, the water inlet is opened, and the water outlet is closed; thecorresponding water level of the inner tub is obtained by detecting the opening frequency of the water outlet of the constant volume box. According to the device and method, the constant volume box isarranged on the water inlet pipe of the washing machine, water is drained to the inner tub after water is stored in the constant volume box, the drainage frequency of the constant volume box is detected, and the precise water level in the inner tub of the washing machine can be obtained; meanwhile, a water level detecting device of the washing machine is arranged on the water inlet pipe of the inner tub, and the washing machine with the dual functions of inner tub rotation and water containing can work normally; in addition, the inner tub does not need to be sleeved with an outer tub, the volume of the inner tub is increased, and the washing capacity of the washing machine is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Dehydration structure of washing machine

ActiveCN108796994AIncrease volumeIncrease washing capacityOther washing machinesTextiles and paperDual effectEngineering

The invention relates to a dehydration structure of a washing machine. An inner tub is installed inside a washing machine shell. At least one dehydration opening is formed in the side wall of the inner tub, a dehydration valve is arranged at the dehydration opening, a valve element of the dehydration valve is connected with the inner tub through a limiting spring, and the valve element closes thedehydration valve under the effect of the limiting spring; when the inner tub dehydrated and rotates, rotating centrifugal force overcomes elasticity of the limiting spring to push a valve element tomove and turn on the dehydration valve to drain water. In this way, when the inner tub rotates normally, water contained in the inner tub cannot flow out from the dehydration opening, the effects thatthe inner tub is sealed in the inner tub washing process, during dehydration, the dehydration valve opens the inner tub under the effect of centrifugal force, and water is drained from clothes and drained outside normally are achieved, and the purpose of normal dehydration of the washing machine with the dual effects of inner tub rotation and water containing is achieved; meanwhile, the inner tubdoes not need to be sleeved with an outer tub, the volume of the inner tub is increased, and the washing capacity of the washing machine is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Washing machine

ActiveCN102912593APrevent penetrationIncrease washing capacityOther washing machinesTextiles and paperMechanical engineeringEngineering

A washing machine capable of increasing the washing capacity without enlarging the external appearance and also discharging a washing water during a washing operation or a spin-dry operation while completely isolated from electronic parts and thus reducing the risk of a power failure and fire, the washing machine including a body, a rotating tub rotatably disposed inside the body, a pulsator rotatably disposed inside the rotating tub, a driving part provided on a lower portion of the rotating tub to selectively rotate the rotating tub and the pulsator, a base plate to which the driving part is fixed, wherein a waterproofing member is provided between the base plate and a bottom of the body to seal the driving part and to prevent water from reaching the driving part.

Owner:SAMSUNG ELECTRONICS CO LTD

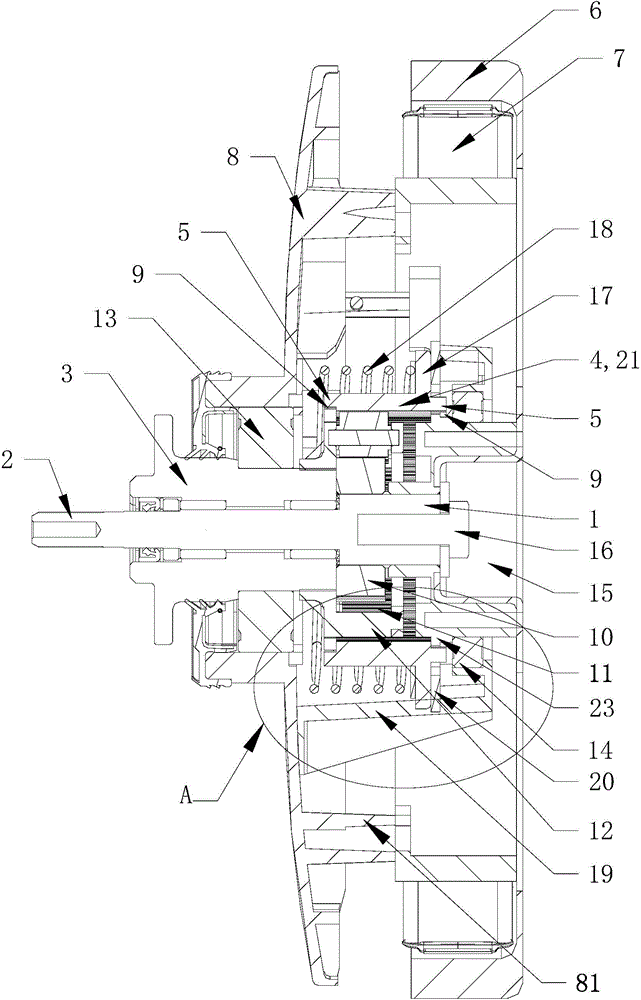

Washing machine and driving system thereof

ActiveCN107287829AImprove efficiencyHigh positioning accuracyOther washing machinesTextiles and paperLaundry washing machineClutch control

The invention relates to the field of washing machines and discloses a washing machine driving system and a washing machine with the same. A clutch mechanism of the driving system is axially positioned between a stator portion (40) and a rotor portion (50) of a motor component and can be driven by a clutch control mechanism to slide towards the stator portion (40) or the rotor portion (50) to make a first joint tooth portion (3) mesh with an upper tooth portion (51) or a second joint tooth portion (4) mesh with a lower tooth portion (52). Precision in positioning between the rotor portion (50) and the stator portion (40) is improved, an rotor-stator air gap can be reduced reasonably, efficiency of the motor component is improved, and simplification of a mounting structure and matching design is facilitated due to joint manufacturing of the clutch mechanism and the motor component.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Washing machine

ActiveCN108796964AIncrease volumeTo achieve the purpose of normal water intakeOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention relates to a washing machine. A door cover is installed on a washing machine shell. The door cover is in sealed connection with the lower portion of an opening of an inner tub so that the inner tub cover can be buckled on the opening of the inner tub to seal the water containing position at the lower portion of the inner tub; a certain gap is arranged between the upper end of the door cover and the opening of the inner tub, and a water inlet pipe is communicated with the interior of the inner tub through the gap so that water can flow into the inner tub from the gap at the upperportion of the door cover; a drainage outlet is formed in the inner tub, and a drainage valve is installed at the drainage outlet; the washing machine is further provided with a positioning locking mechanism for rotating the inner tub to the fixed drainage position to be fixed; a valve element turn-on mechanism for turning on the drainage valve after the inner tub is rotated to the fixed drainageposition is arranged on the washing machine so that when the washing machine drains, the drainage valve is turned on after the inner tub is rotated to the fixed drainage position so that washing waterin the inner tub can be drained out. In this way, the inner tub has the dual functions of rotating and containing water; meanwhile, the inner tub does not need to be sleeved with an outer tub, the volume of the inner tub is increased, and the washing capacity of the washing machine is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

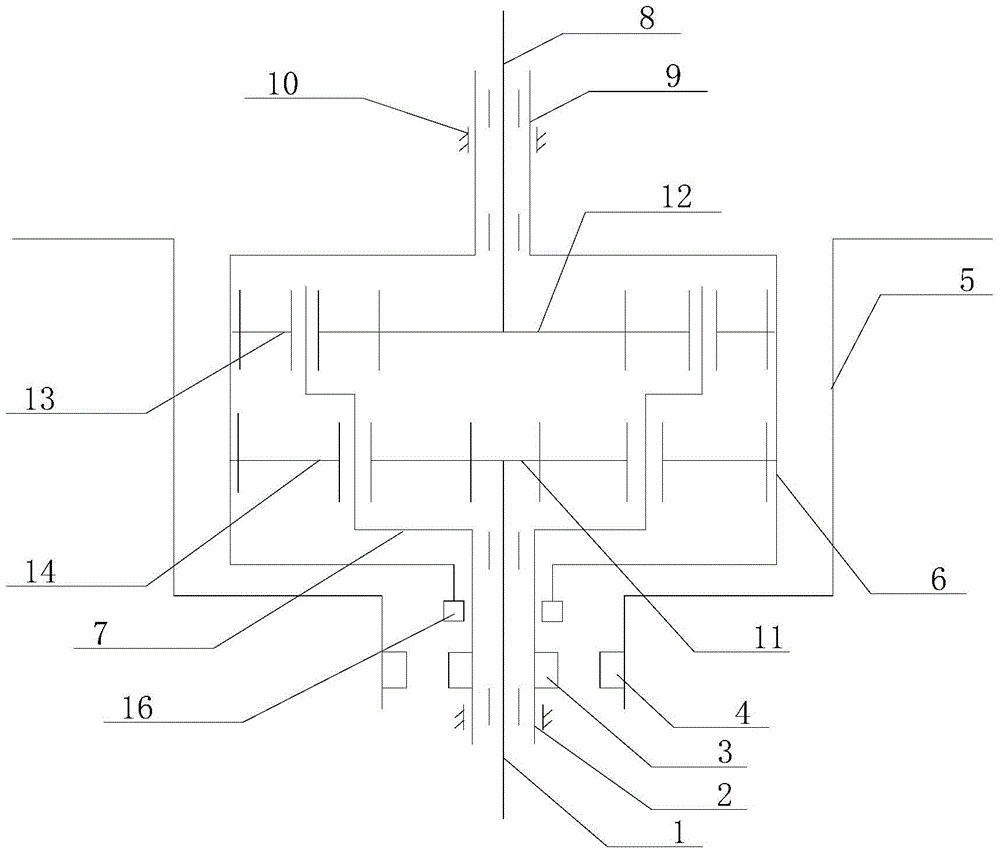

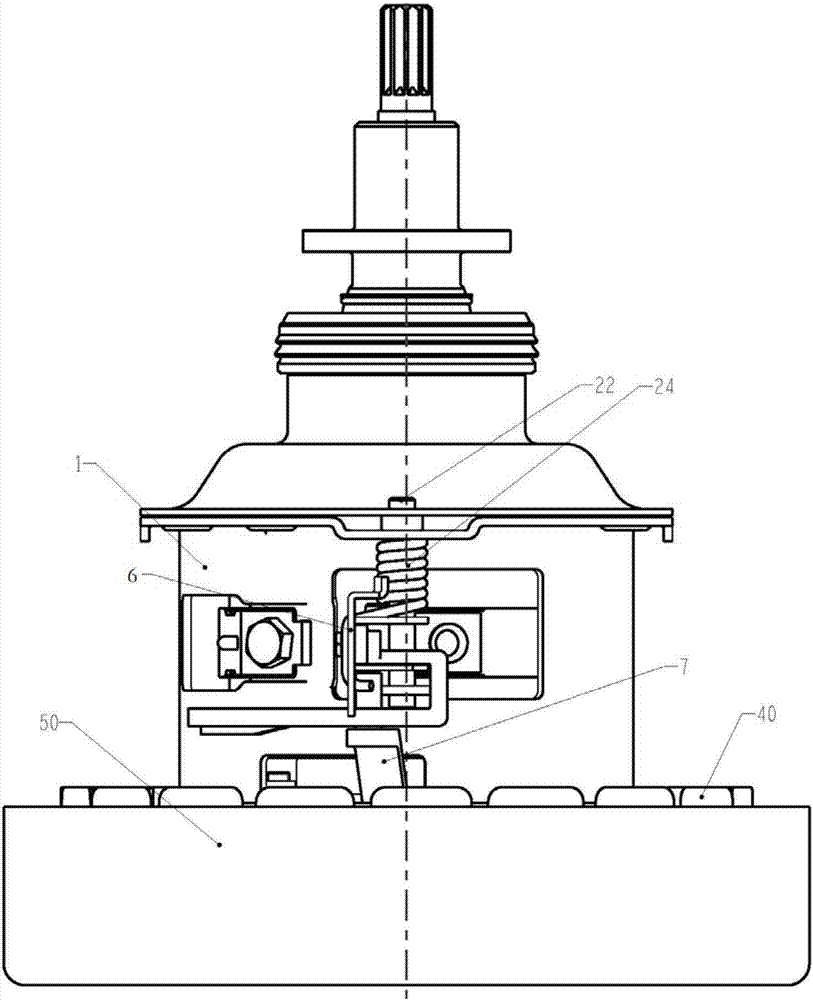

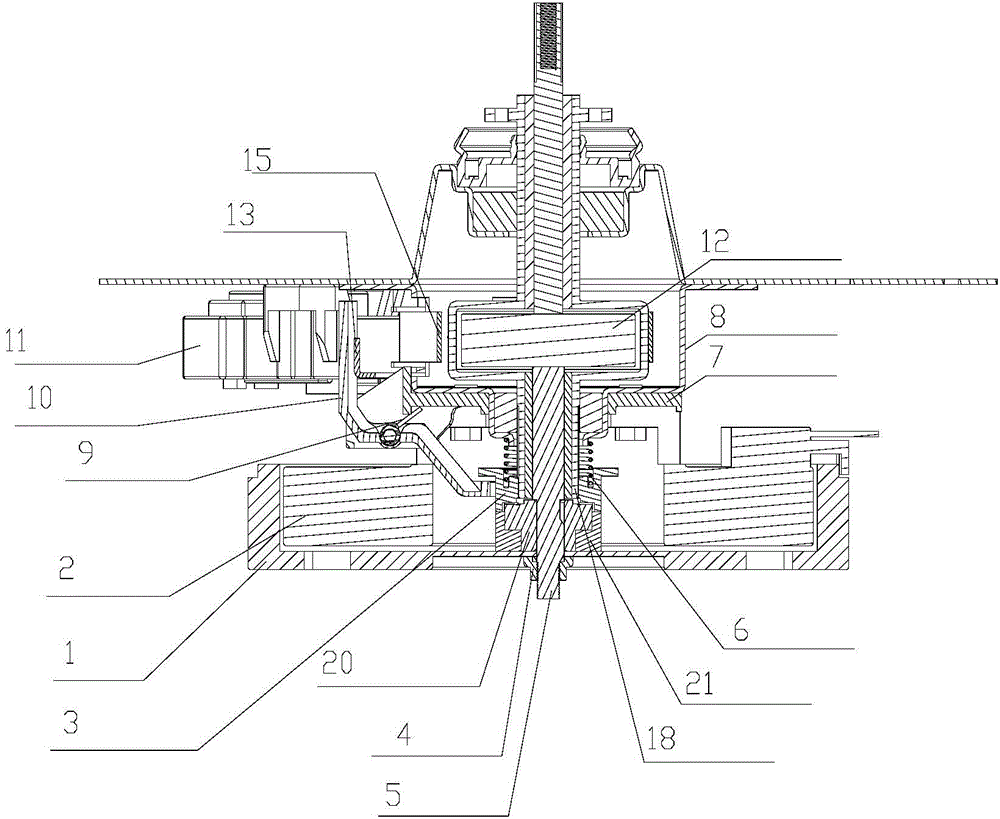

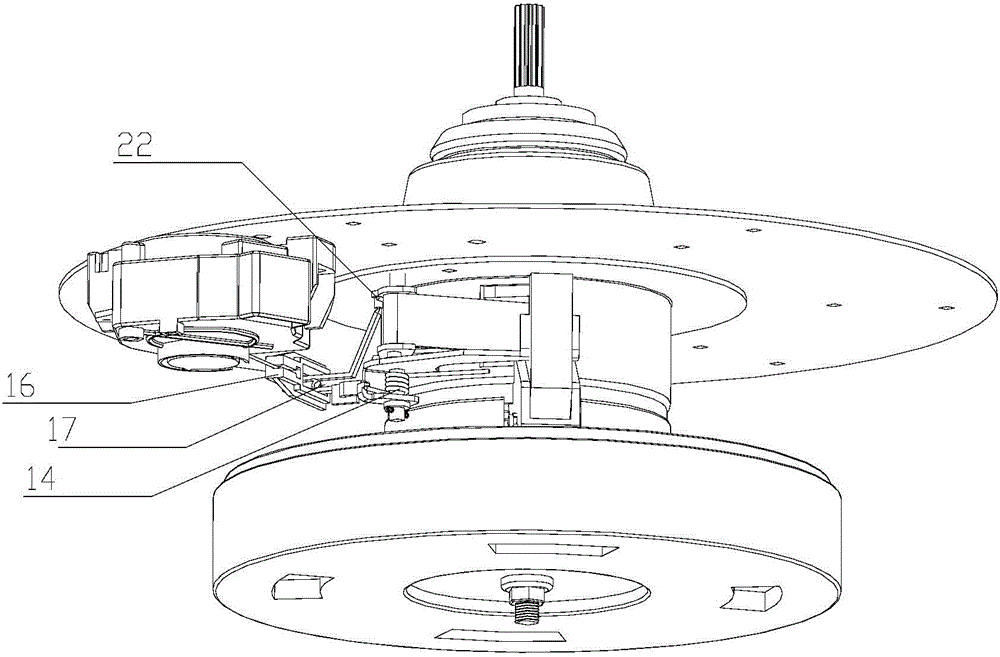

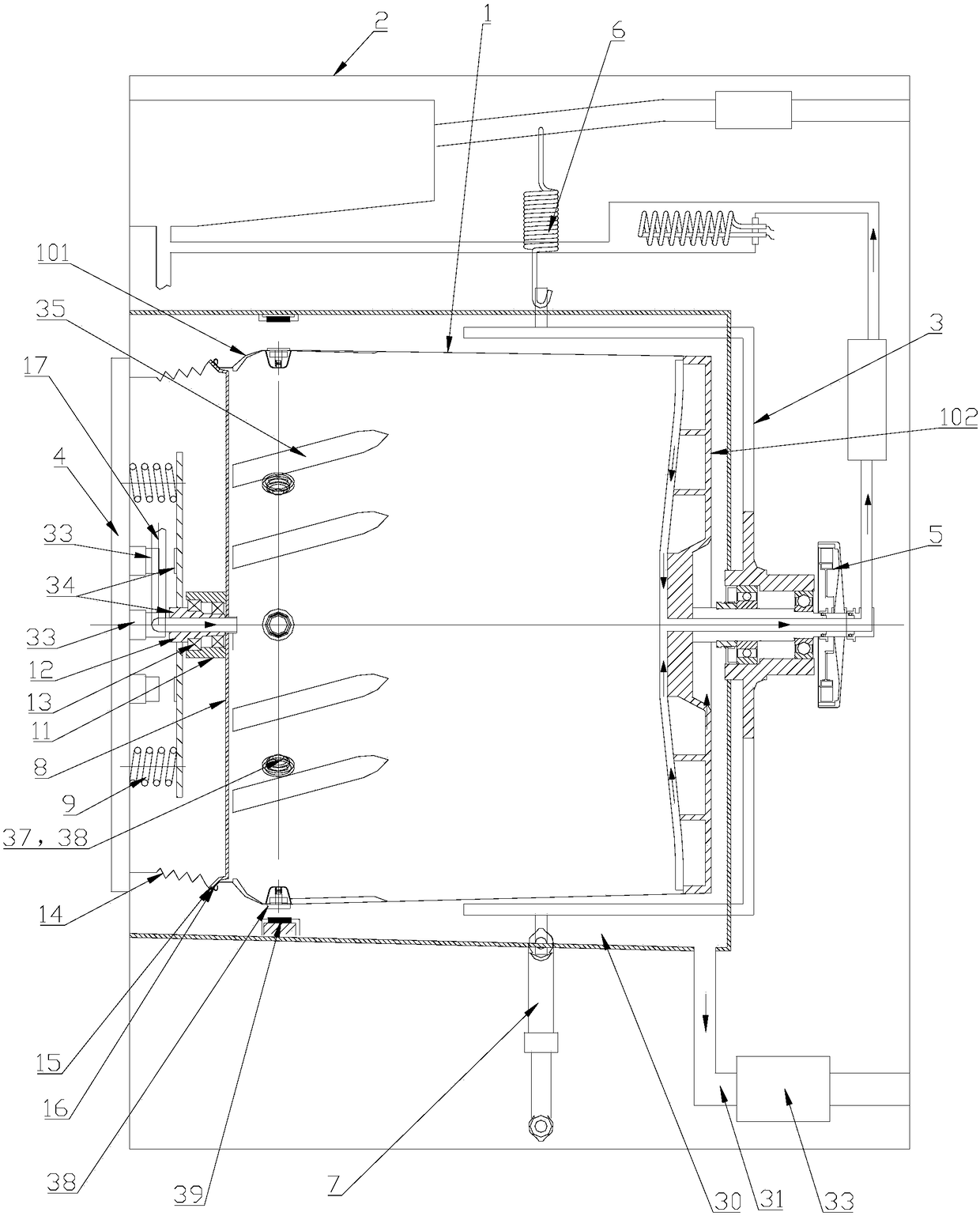

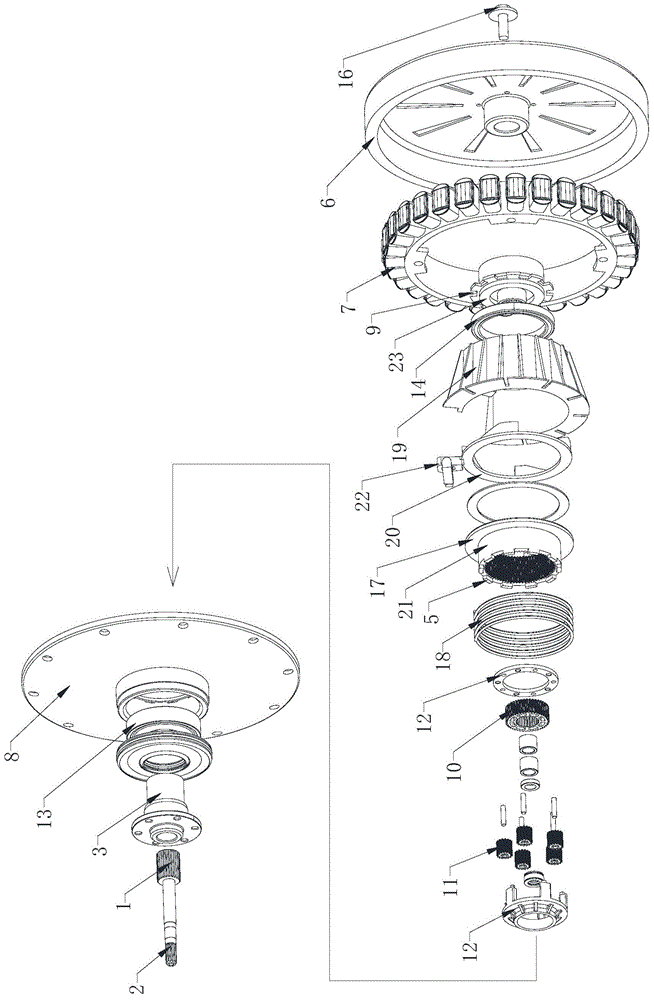

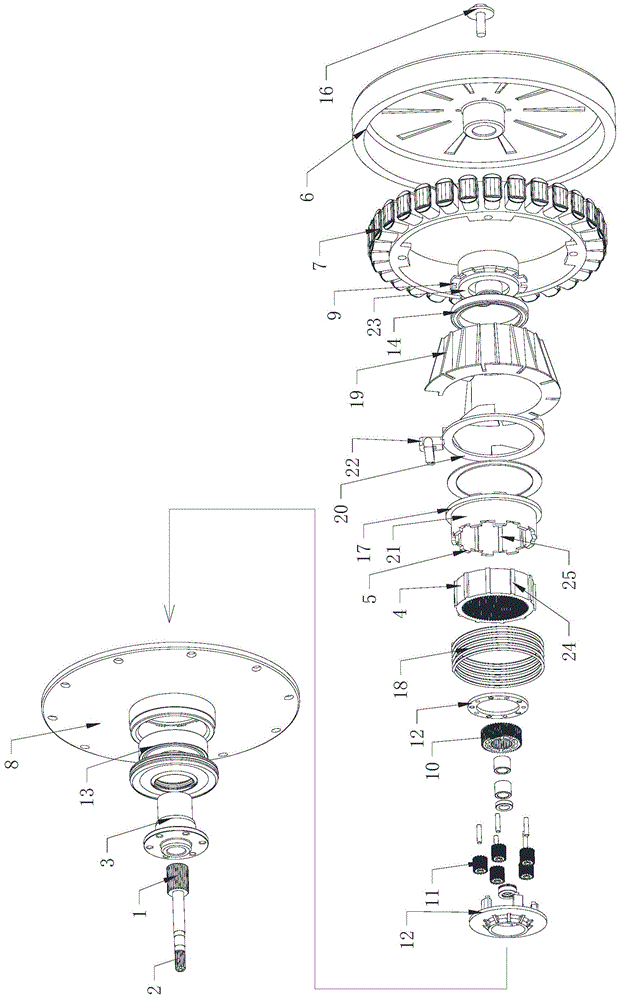

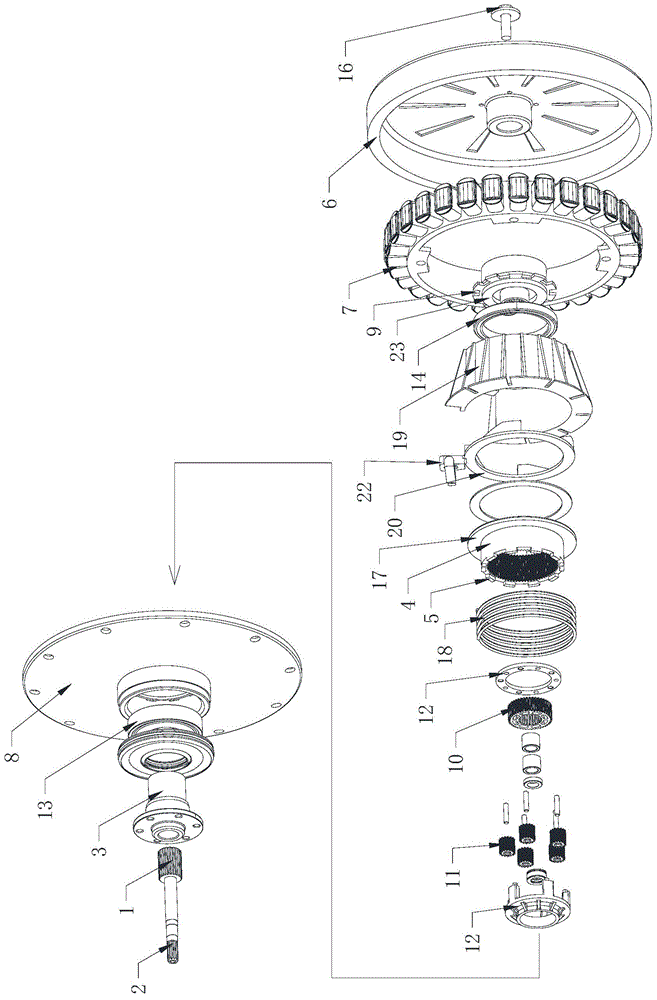

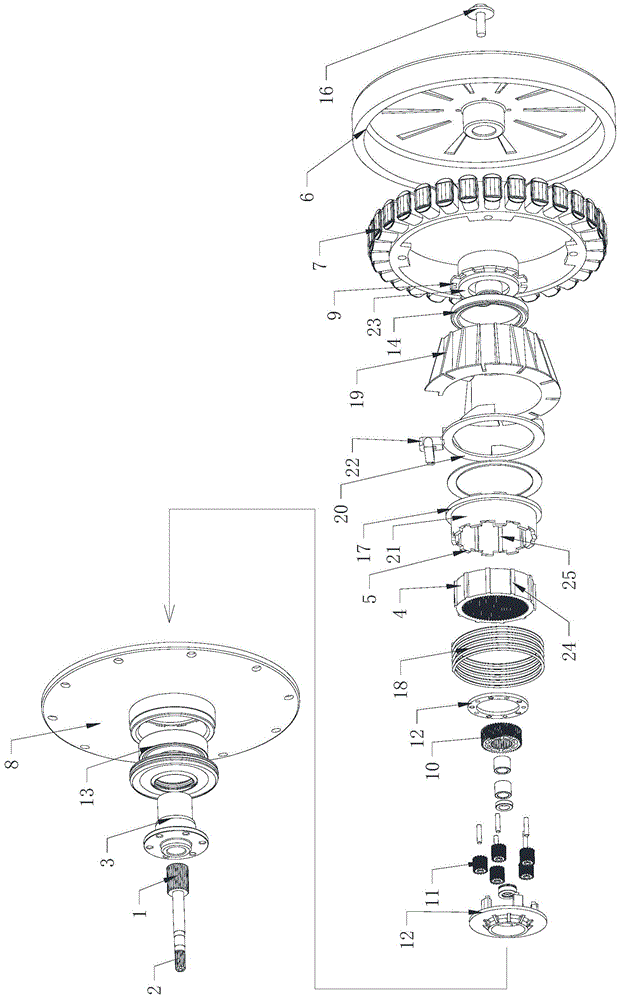

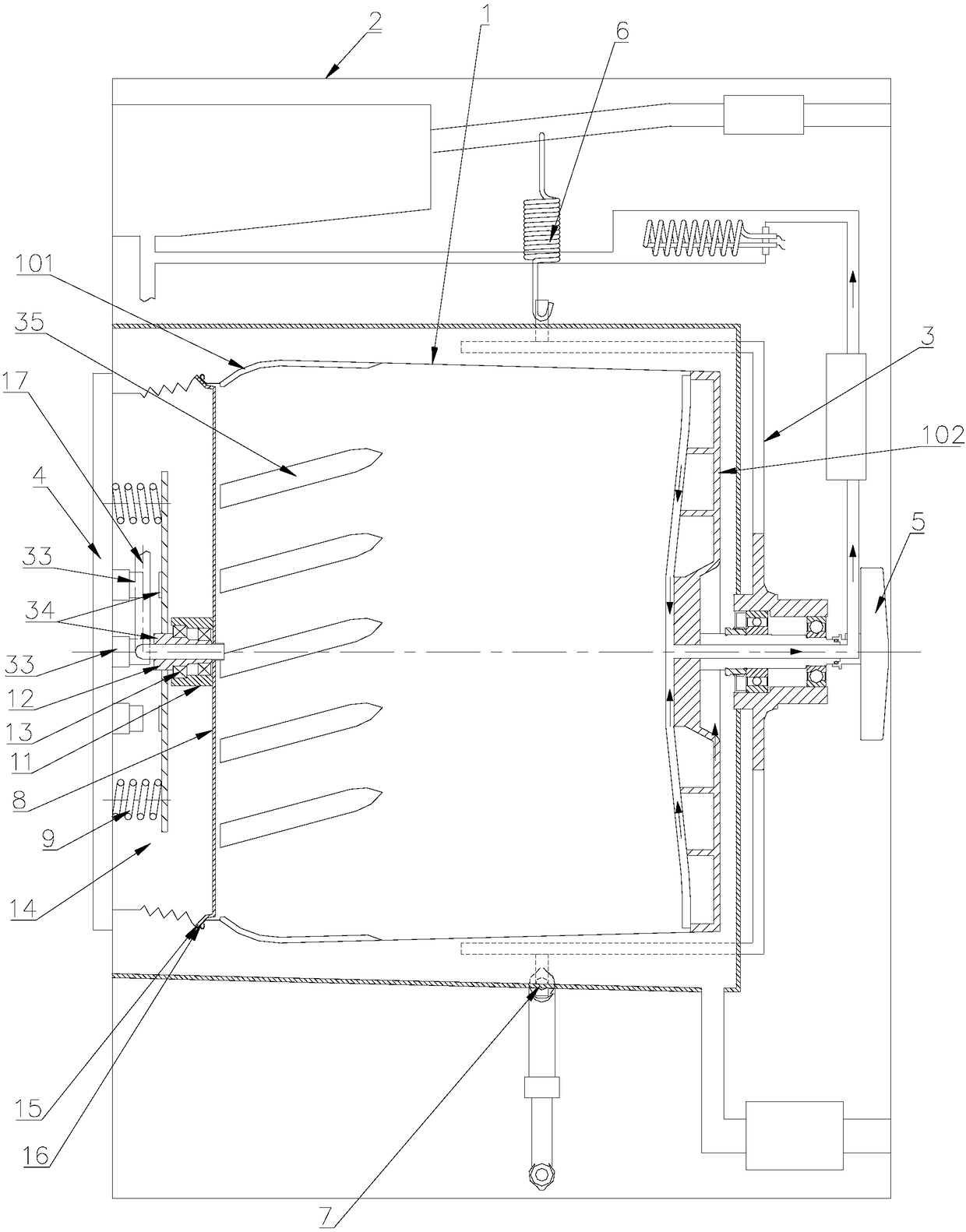

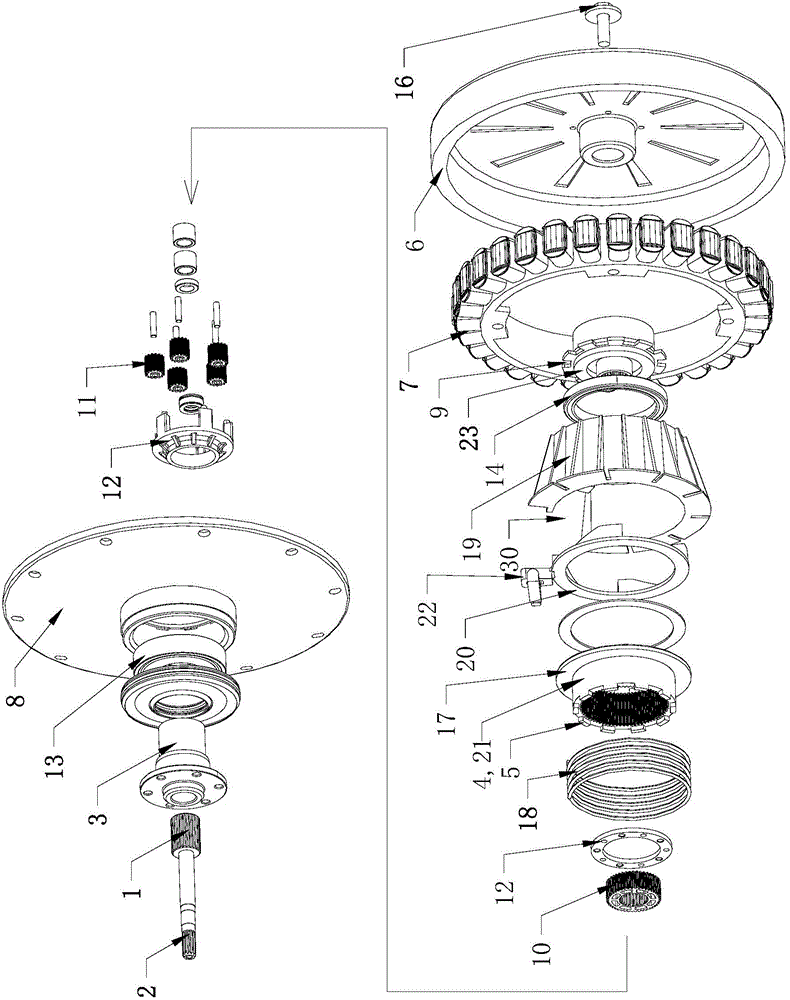

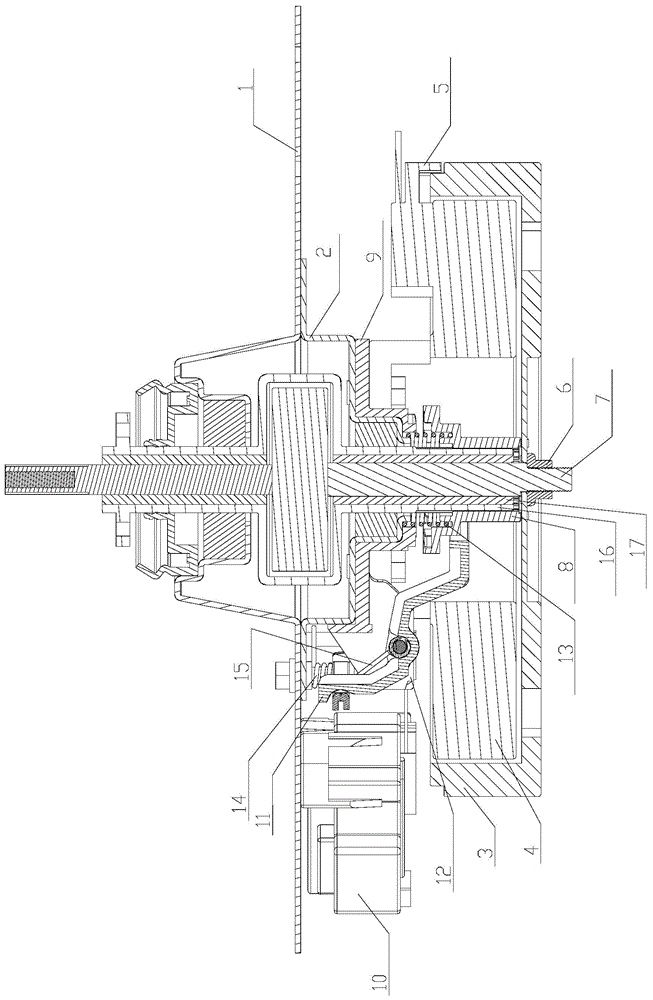

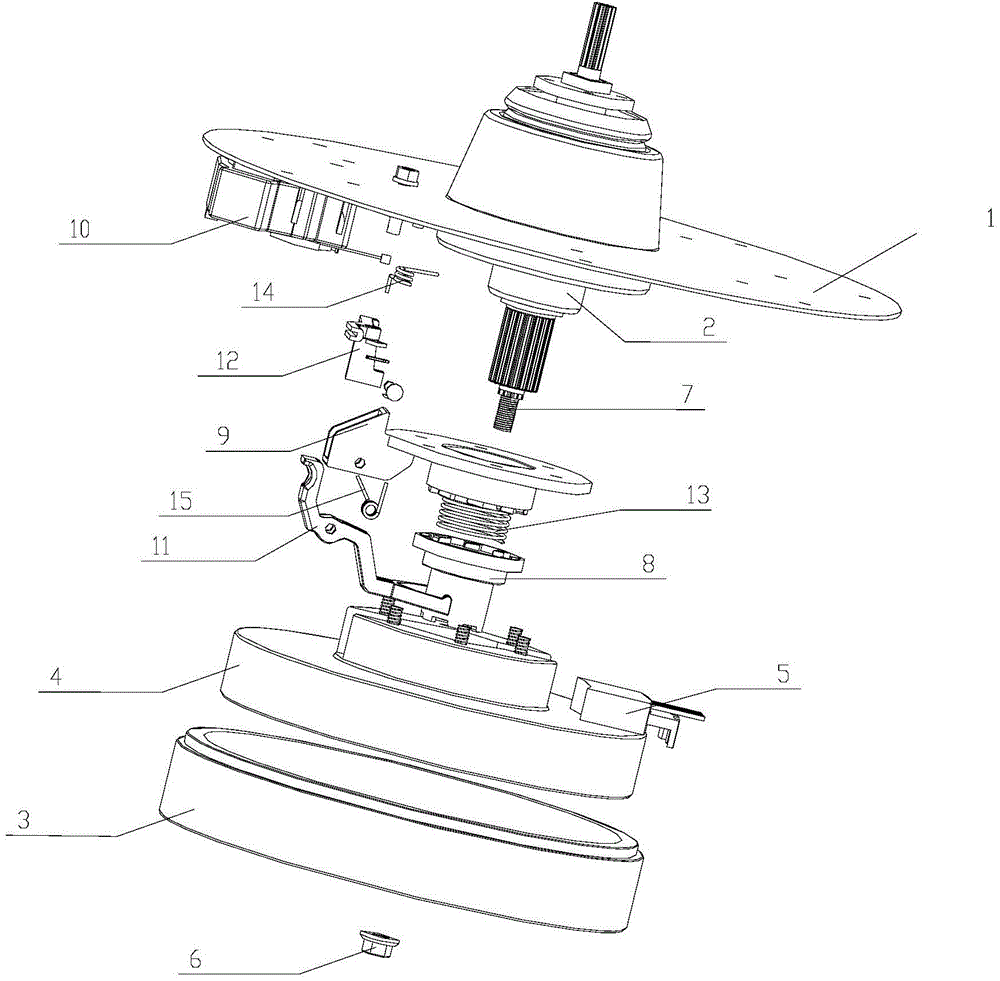

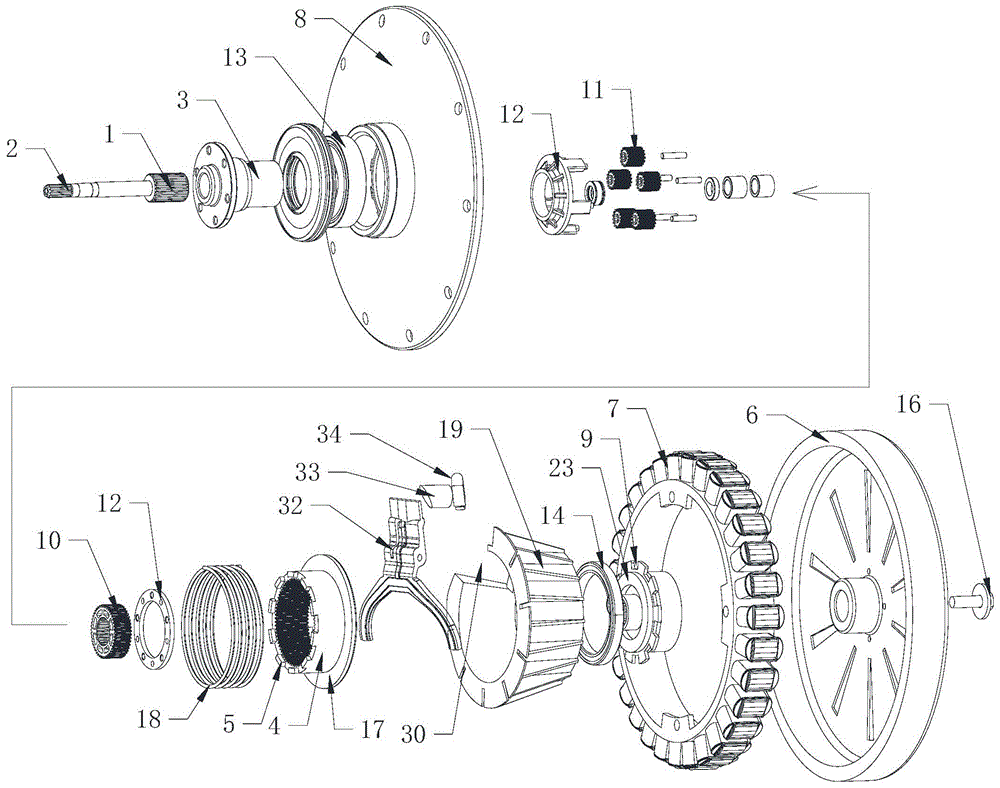

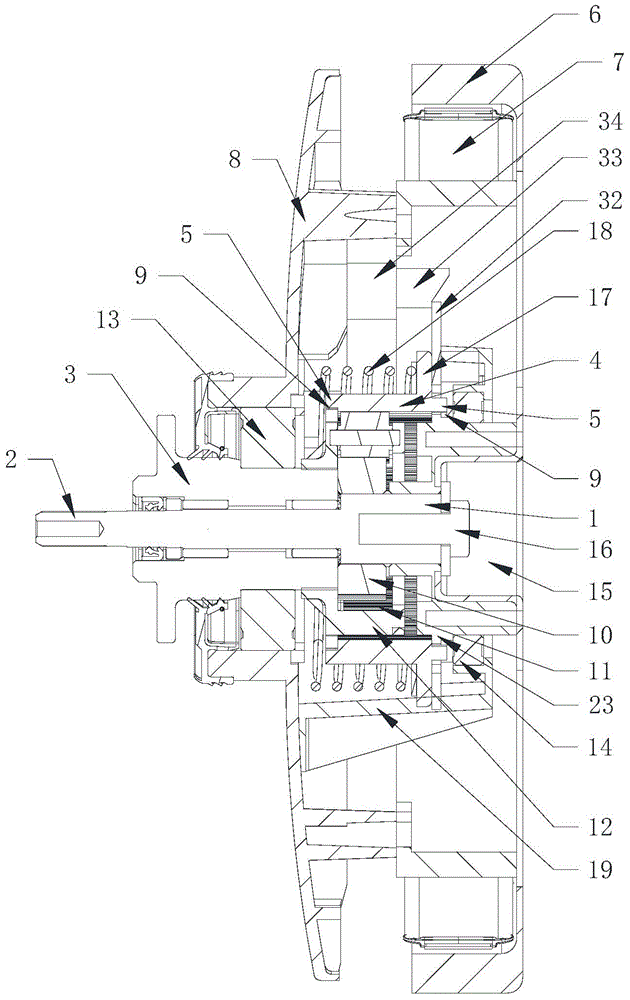

Variable-frequency simulated hand-wash motor reduction clutch and washing machine

ActiveCN104372561AIncrease washing capacityReduce volumeOther washing machinesMechanical energy handlingMotor speedFree rotation

A frequency-variable hand rubbed-type motor speed reduction clutch apparatus, and a washing machine. The clutch apparatus comprises: an input shaft (5) connected to a motor rotor (1); a dehydration shaft (18); and a clutch apparatus housing (8) in which the input shaft (5) and the dehydration shaft (18) are mounted. A braking wheel (12) and a braking belt (15) fitted to the braking wheel (12) are disposed on the dehydration shaft (18). A dehydration shaft sleeve (20) rotating together with the input shaft (5) is mounted on the input shaft (5). A clutch shaft sleeve (3) sliding up and down, and engaging with or separated from the dehydration shaft sleeve (20) is mounted on the dehydration shaft (18). The braking belt (15) and the clutch shaft sleeve (3) are separately connected to a traction motor (11) by means of a control apparatus. The traction motor (11) generates a first displacement, the first displacement is transmitted by the control apparatus and drives the braking belt (15) to move, so that the braking belt (15) changes from grasping the braking wheel (12) to loosening the braking wheel (12), and the dehydration shaft (18) changes from a braked state to a free rotation state. The traction motor (11) generates a second displacement, the second displacement is transmitted by the control apparatus and drives the clutch shaft sleeve (3) to move, so that the clutch shaft sleeve (3) changes from being separated from to engaging with the dehydration shaft sleeve (20), and the dehydration shaft (18) rotates together with the input shaft (5).

Owner:QINGDAO HAIER WASHING MASCH CO LTD

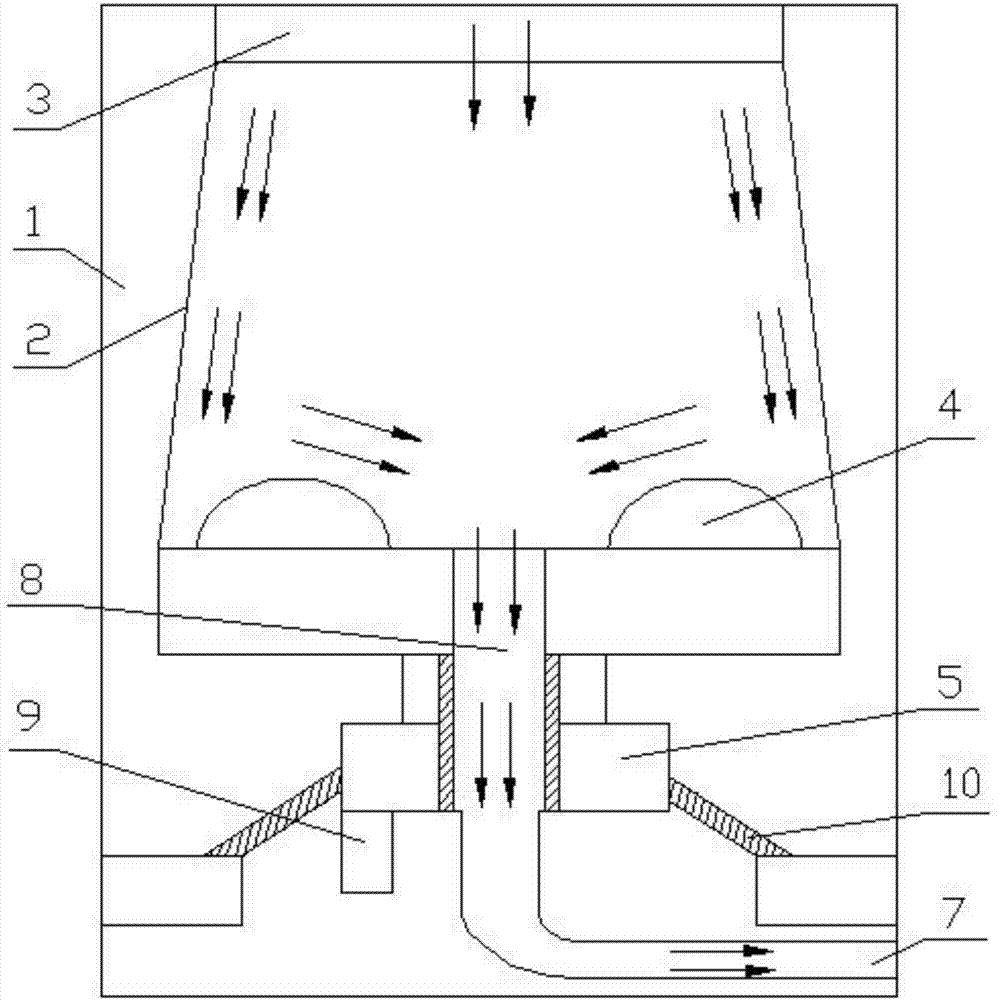

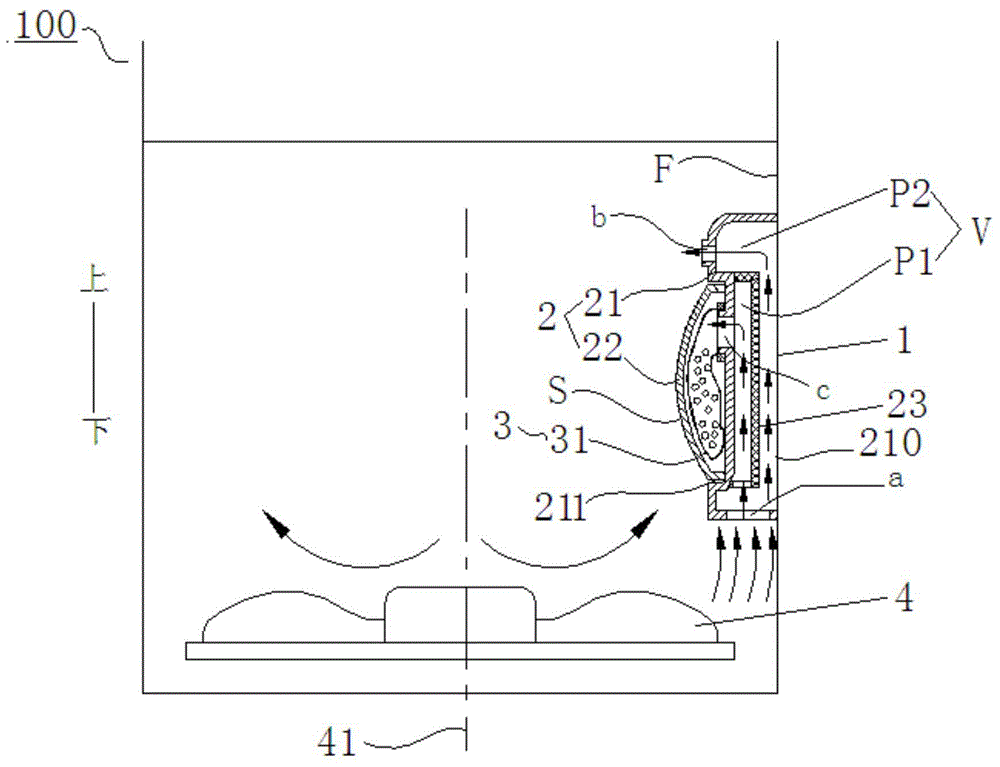

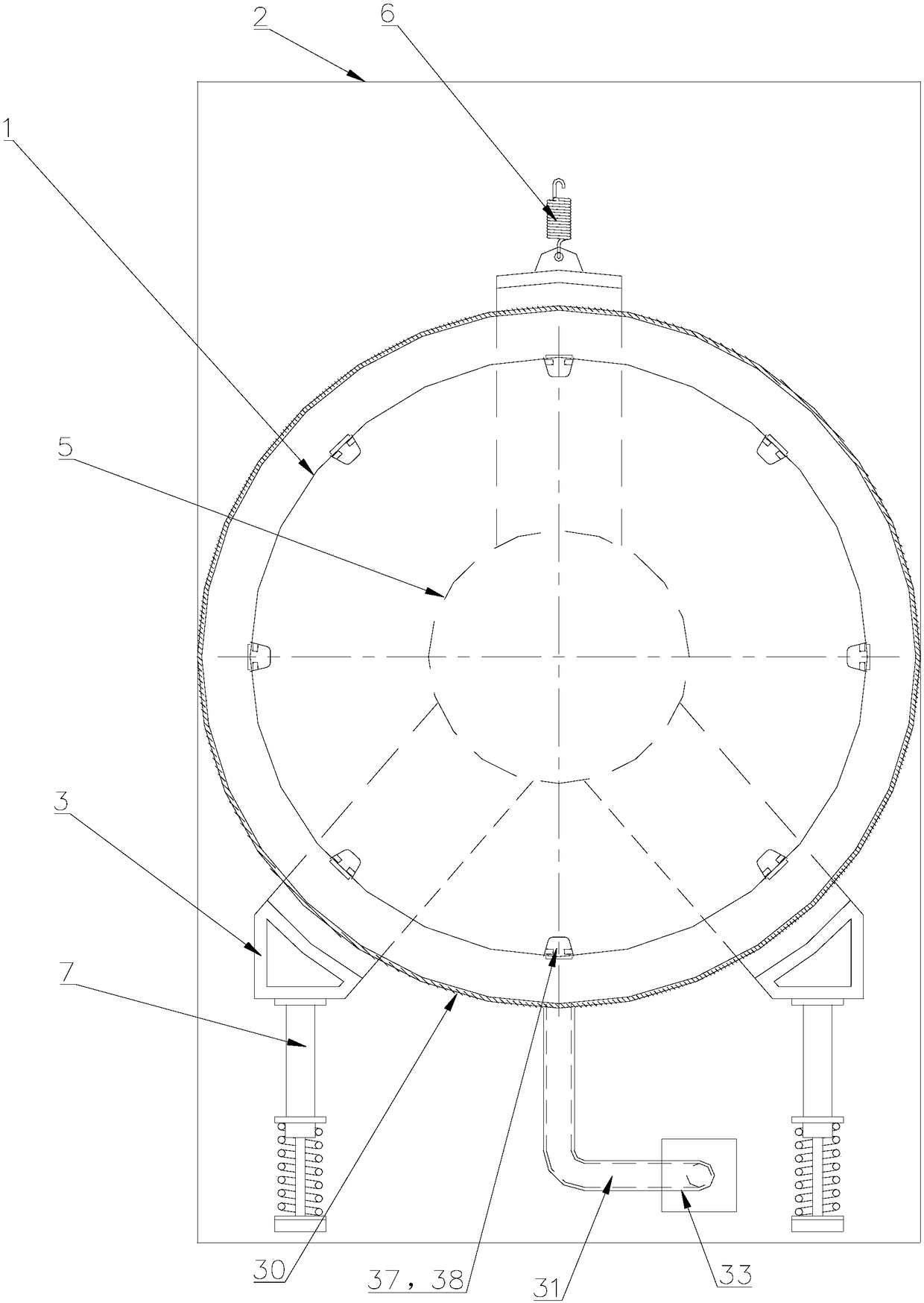

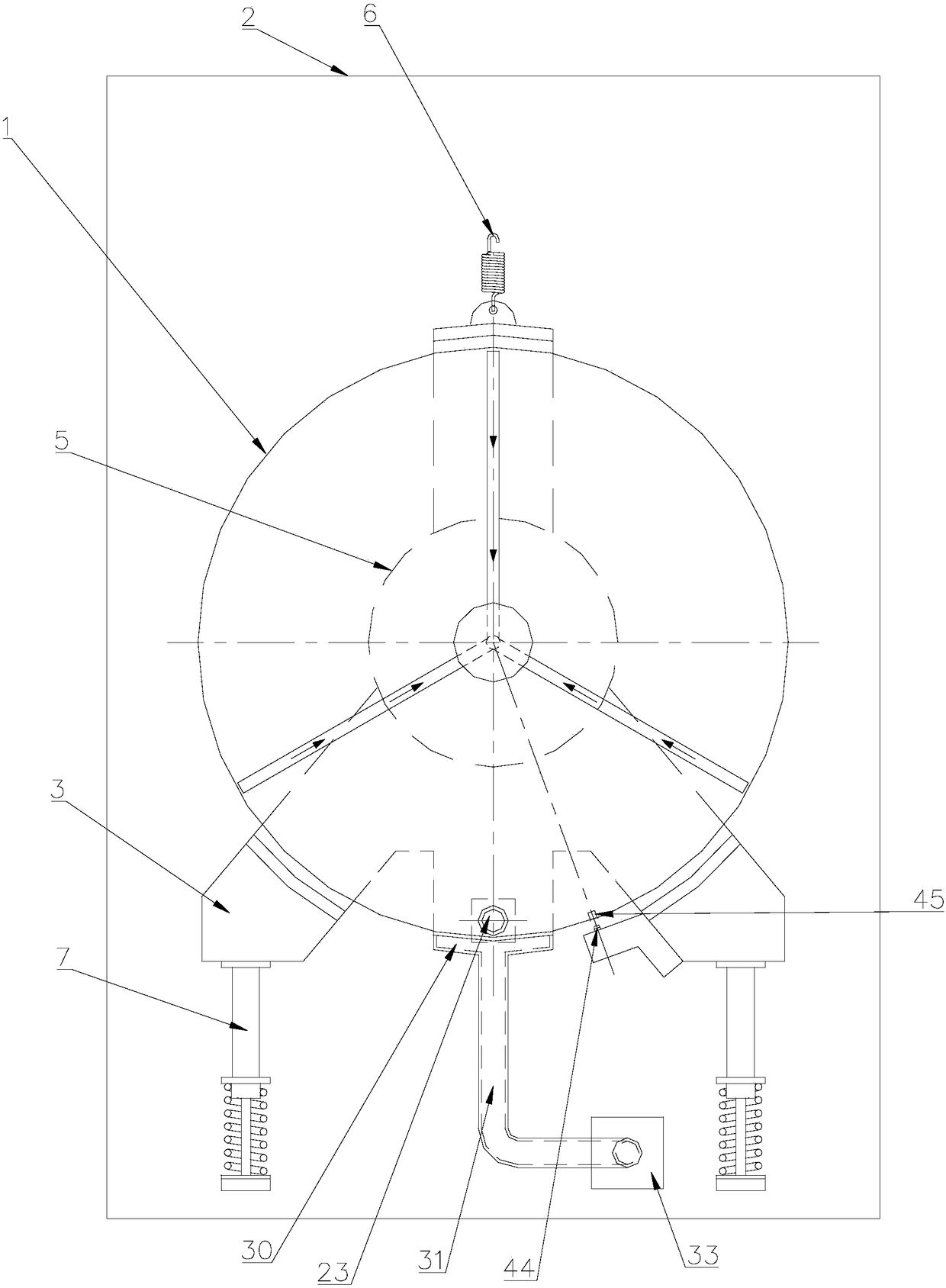

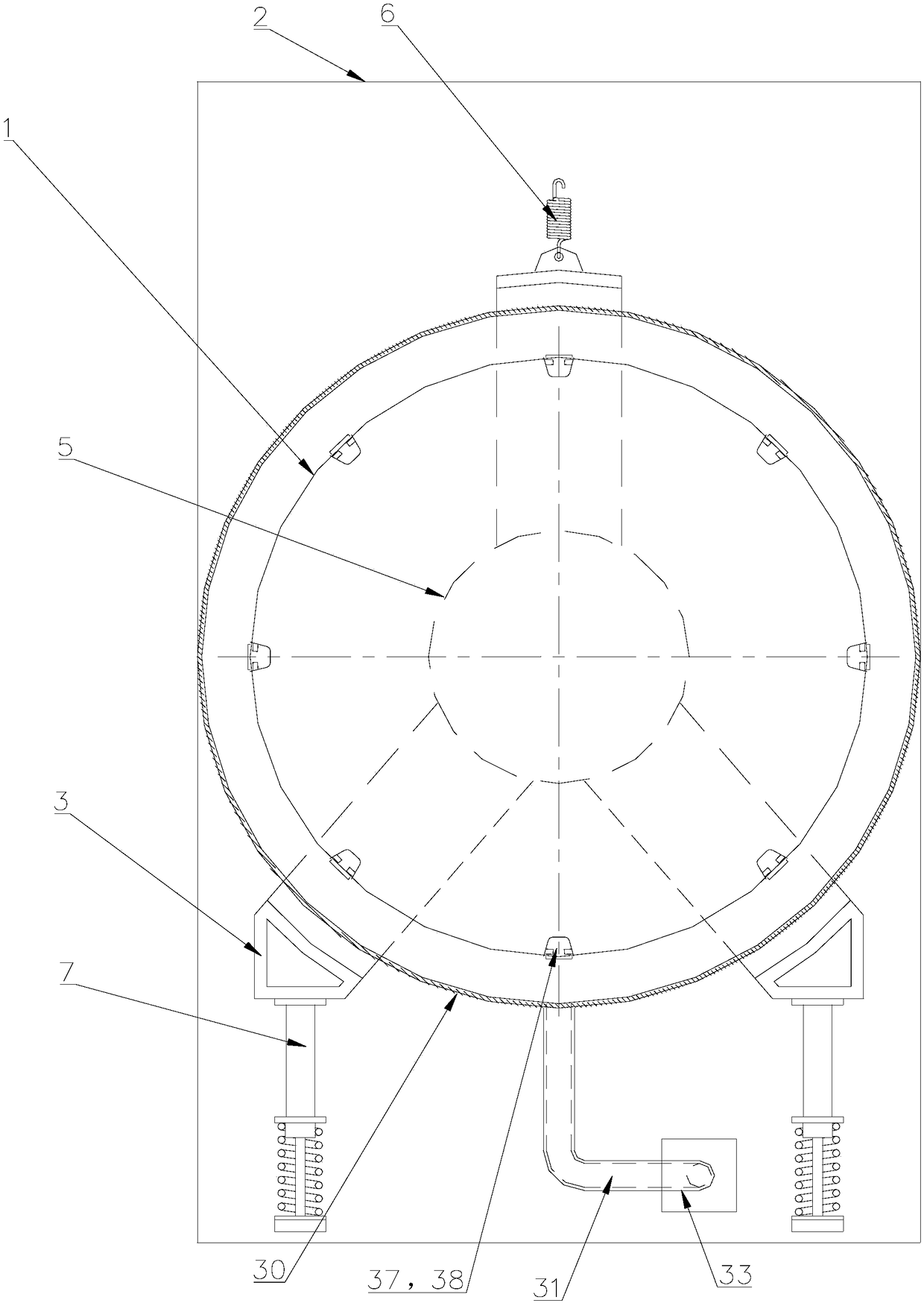

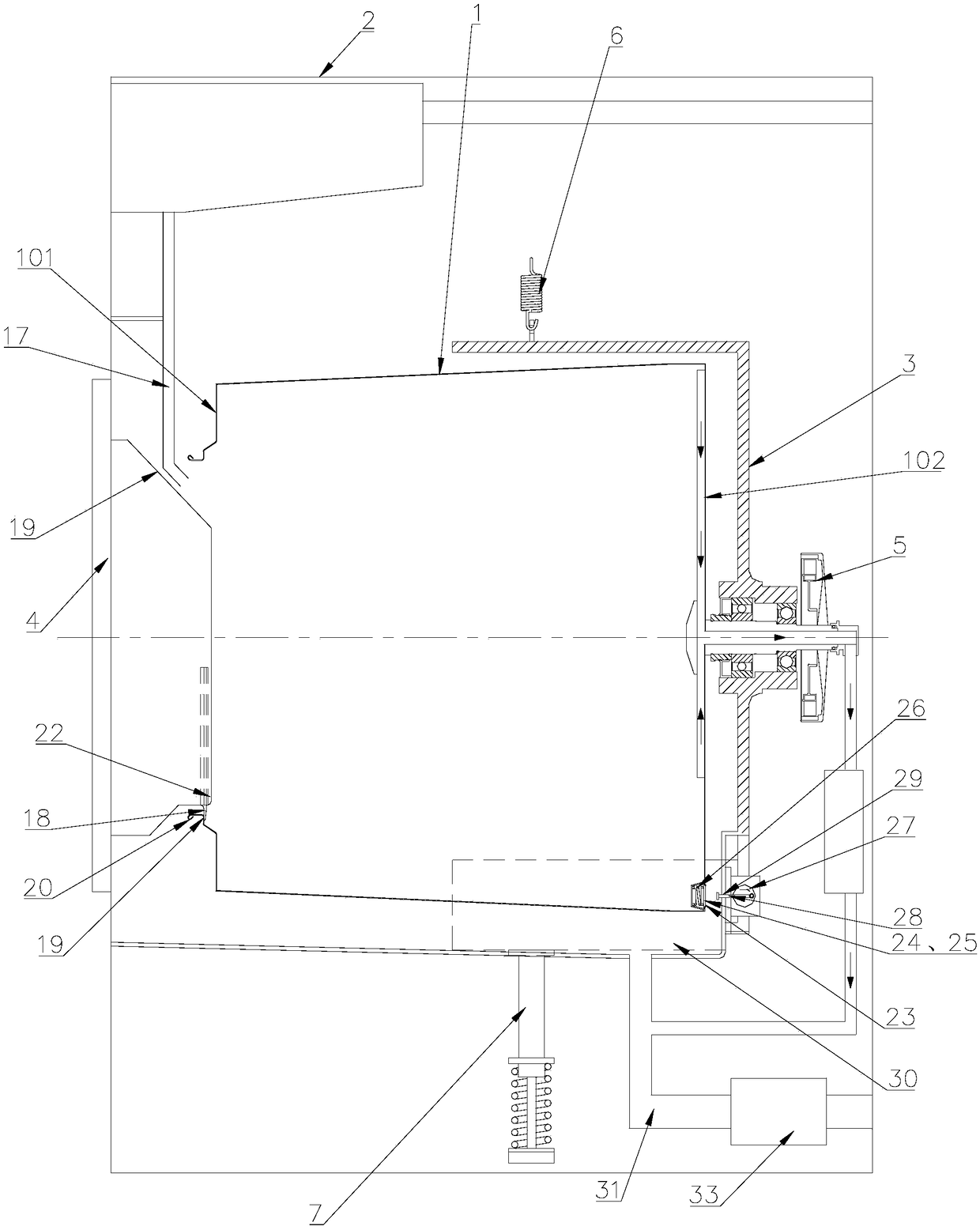

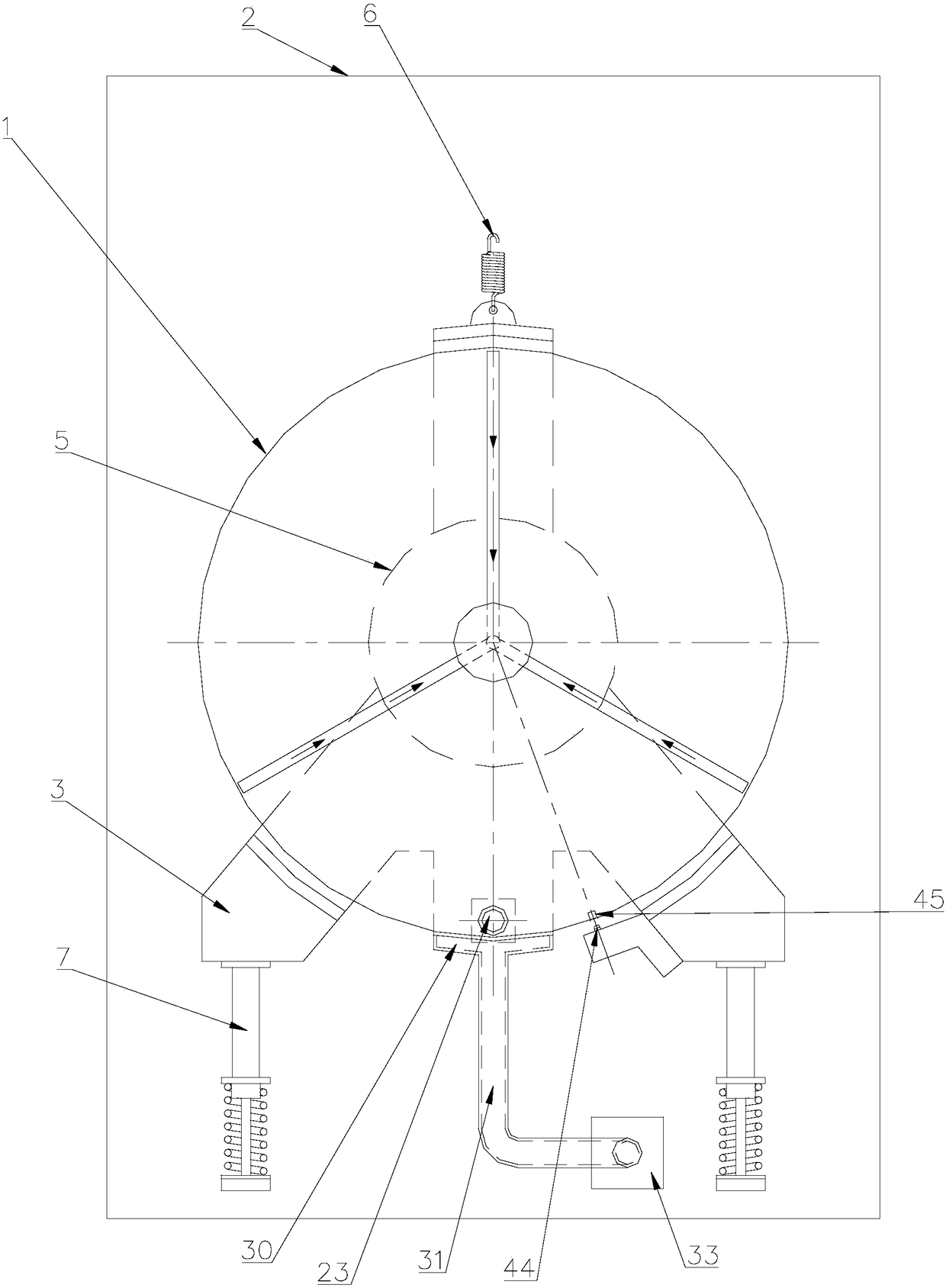

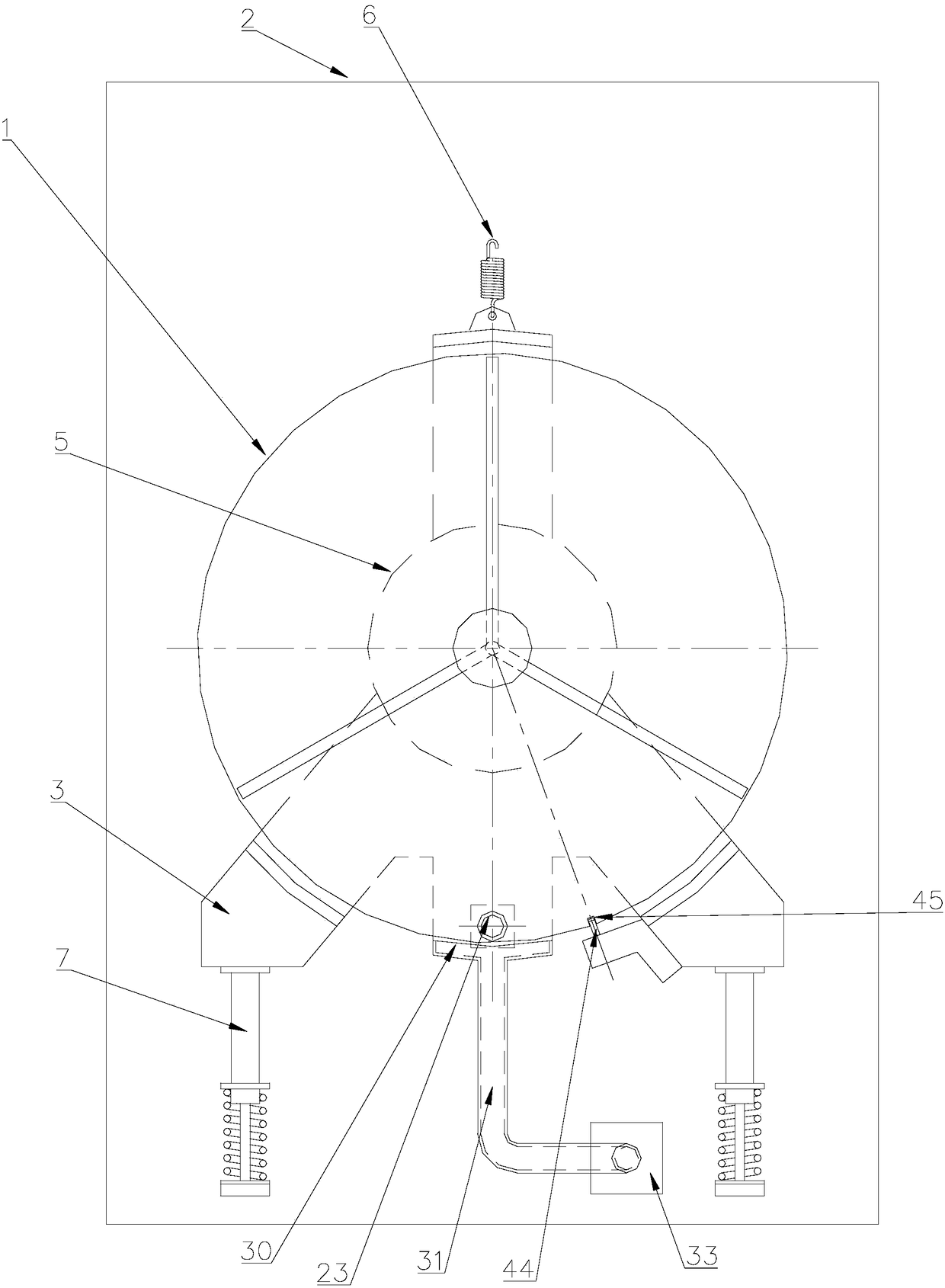

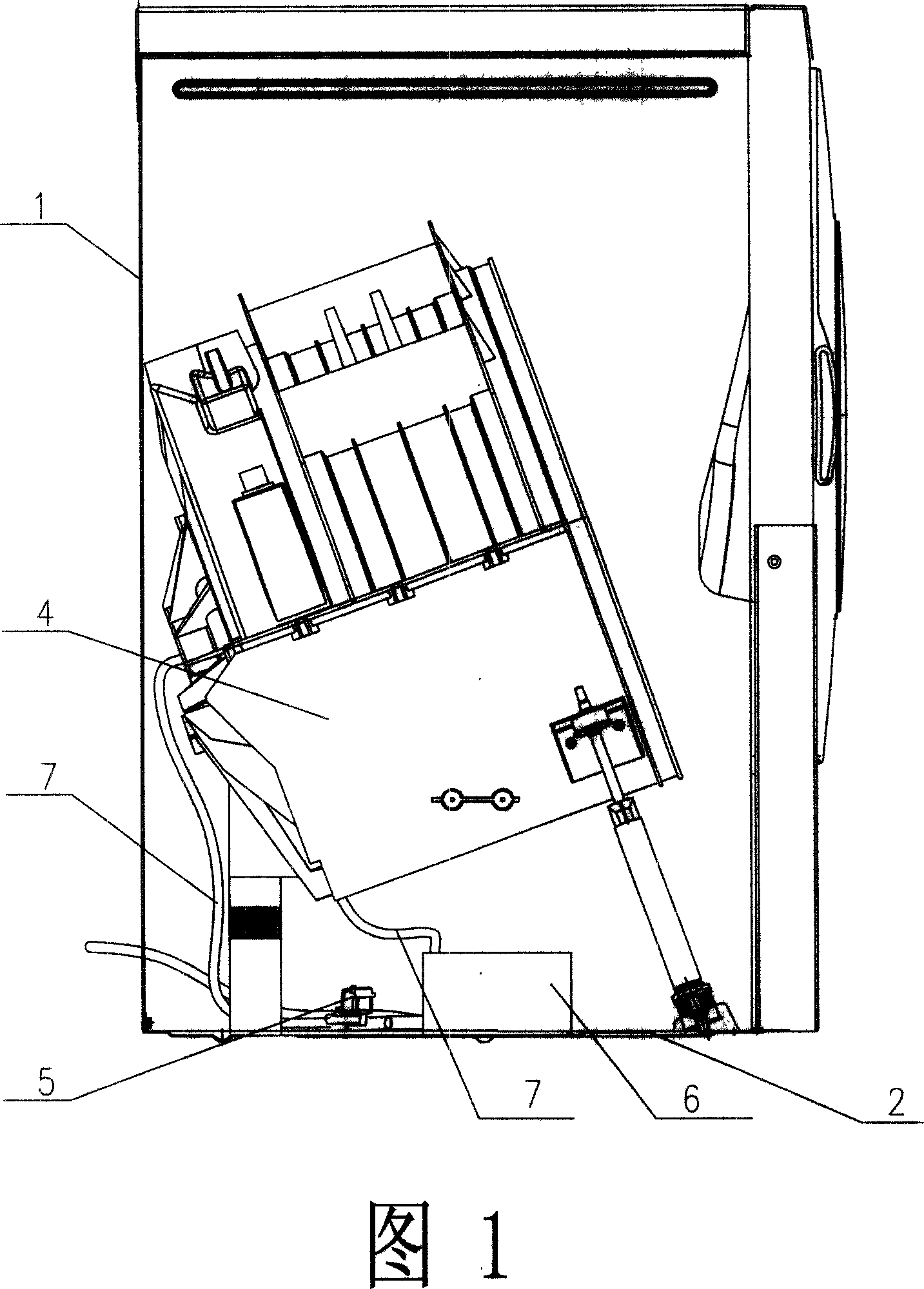

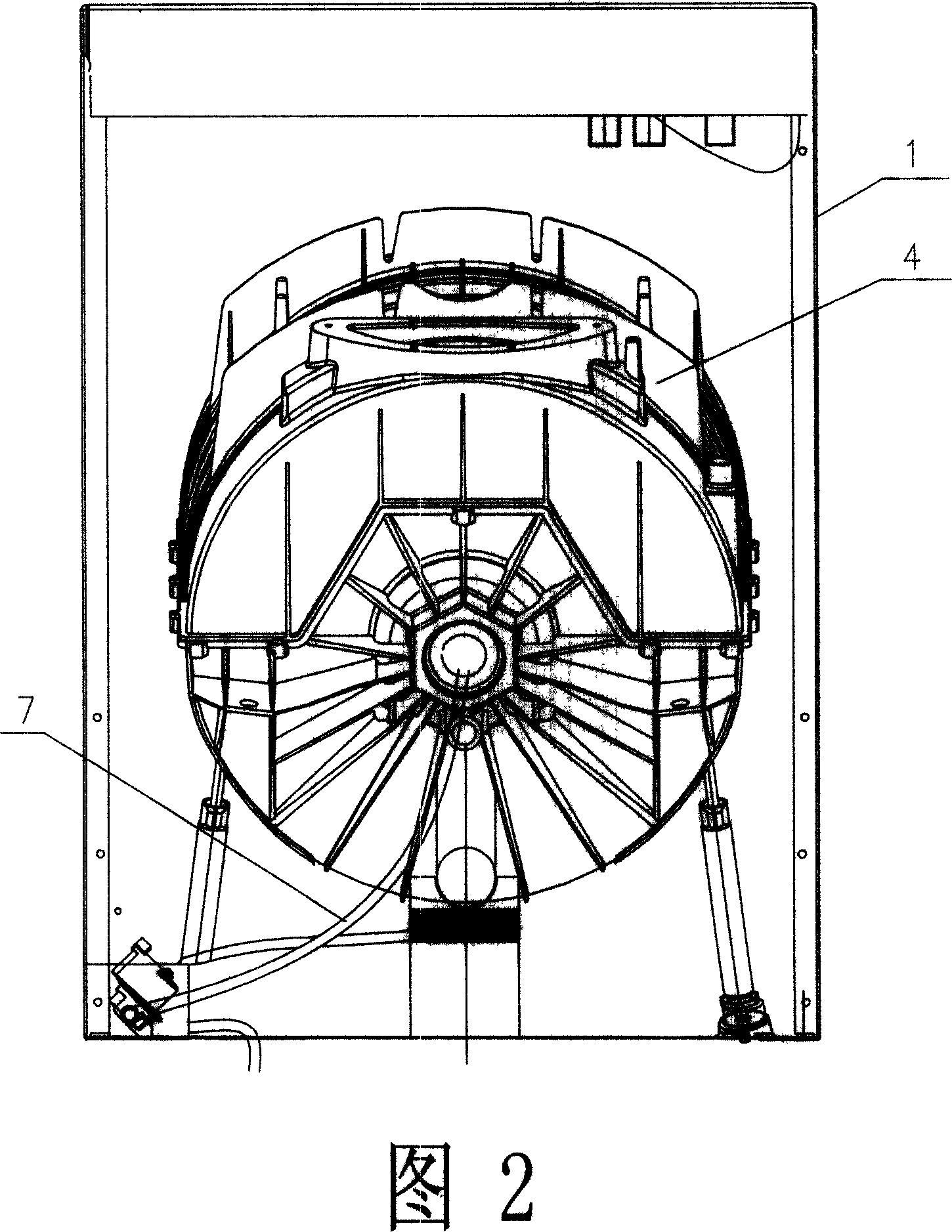

Fountain barrel washing machine having self-contained water tank

InactiveCN101012616ALarge design spaceLarge diameterOther washing machinesWashing machine with receptaclesWater cyclingEngineering

The invention discloses a spraying drum washing machine with independent water tank, comprising outer shell of washing machine, bottom board, rolling drum, fixed outer barrel, damping and supporting mechanism, driving mechanism of rolling drum, water cycling system, water inlet and outlet mechanism of washing machine. The rolling drum is set in the fixed outer barrel. The water cycling system comprises connecting hose of cycling water, spraying mechanism and water pump. Water inlet and outlet mechanisms of washing machine are connected with the water cycling system. An independent water tank, which is separated with the fixed outer barrel, is added in the water cycling system. The water tank is located in the space between the outer shell and the fixed outer barrel. The invention is provided with independent water tank and it is favor of saving water and simplifying structure.

Owner:许继海

Washing machine

InactiveUS6065312AStir wellEnhance stirringOther washing machinesWashing machine with receptaclesMechanical engineeringEngineering

A washing machine having a generally cylindrical drum having a substantially closed back face, a front opening, and an axis inclined to the horizontal about which the drum is rotatable. The drum includes a plurality of outlets provided on the back face of the drum generally around the outer circumference of the back face. At least one of the outlets is below the height of the front opening for any angular position of the drum.

Owner:TITAN WASHING MACHINE

Washing machine

ActiveCN108796967AIncrease washing capacityTo achieve the purpose of normal drainageOther washing machinesWashing machine with receptaclesEngineeringCentrifugal force

The invention relates to a washing machine. A door cover is installed on a washing machine shell, the inner side of the door cover is connected with an inner drum cover through an elastic mechanism, after the door cover is closed, the inner drum cover is compressed by the elastic mechanism at an inner drum opening, and an inner drum is sealed; a driving mechanism is arranged between the inner drumcover and the door cover, when the driving mechanism works, elastic force of the elastic mechanism to the inner drum cover is overcome, the inner drum cover breaks away from the inner drum opening, water in the inner drum is discharged from the opened inner drum opening; an inner drum is installed in the washing machine shell, at least one dewatering opening is formed in the side wall of the inner drum, dewatering valves are arranged at the detwatering openings respectively, a valve element of each dewatering valve is connected with the inner drum through a limiting spring, and the valve elements are subjected to the action of the limiting springs to close the dewatering openings. In this way, the effect that in the rotating process of the inner drum, when the inner drum is sealed, and when dewatering and discharging are conducted, water in the inner drum is discharged outside normally is achieved; meanwhile, an outer drum is not needed for sleeving the exterior of the inner drum, thevolume of the inner drum is increased, and the washing volume of the washing machine is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

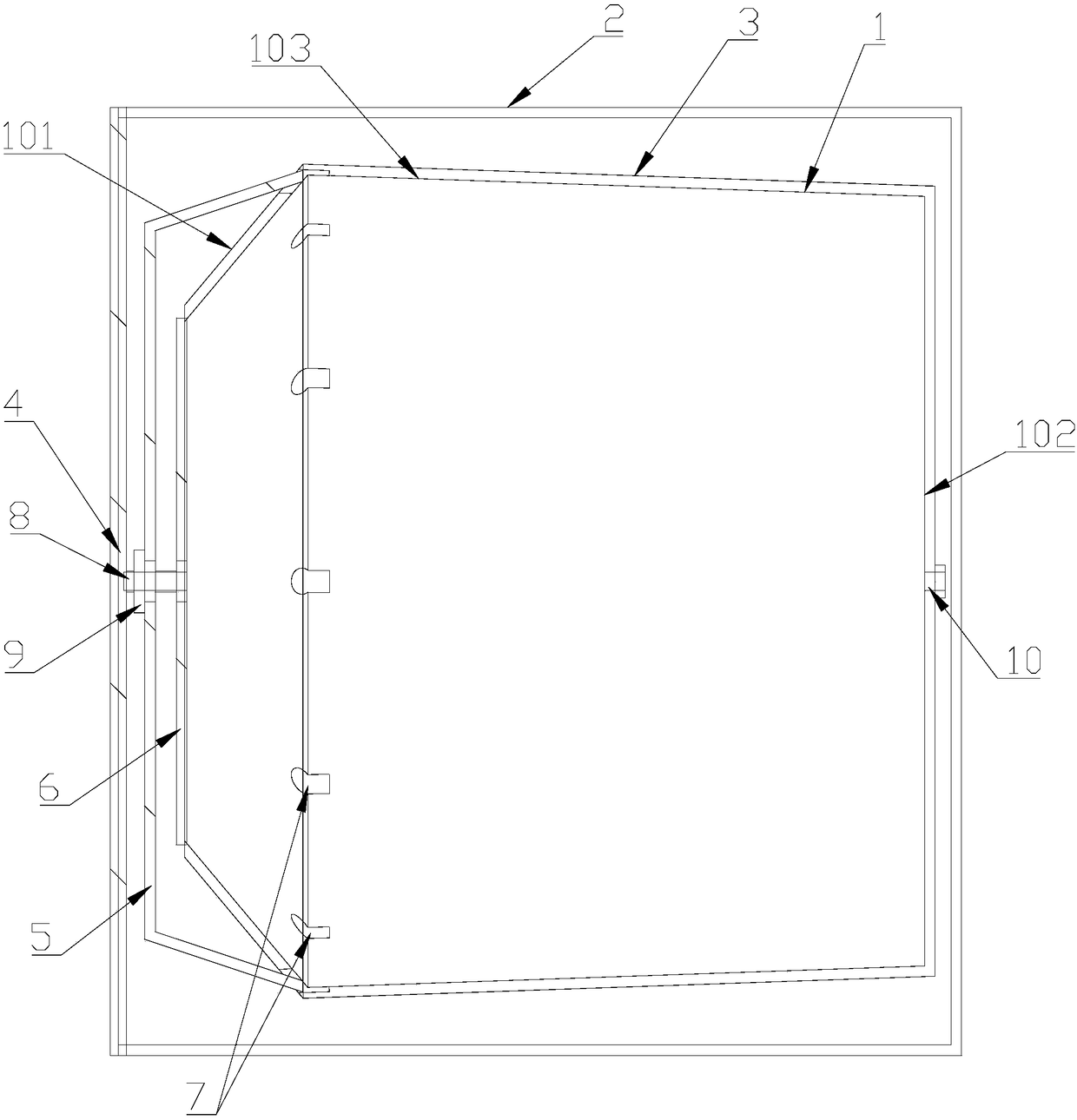

Decelerating clutch casing of washing machine and washing machine

ActiveCN105316902ACompact installationShorten the axial lengthClutchesOther washing machinesAgricultural engineeringClutch

The invention provides a decelerating clutch casing of a washing machine. A decelerating clutch comprises a decelerating device and a clutch device; the decelerating clutch casing comprises an inner chamber, the decelerating device and at least parts of the clutch device are arranged in the inner chamber, and the clutch device arranged in the inner chamber comprises a clutch shaft sleeve and a clutch compression plate capable of driving the cultch shaft sleeve to move axially; the decelerating clutch casing cooperates with the clutch compression plate to enable the clutch compression plate to move axially; at least part of the decelerating clutch casing extends into an inner chamber of a stator of a direct driving motor. Structures of the decelerating device and the clutch device are mounted compactly, so that the overall height of the decelerating clutch casing is decreased, the overall height of the decelerating clutch is decreased, and the washing capacity of the washing machine with the same volume is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Washing machine deceleration clutch and washing machine

ActiveCN105463769AAxial space savingCompact structure and installationClutchesOther washing machinesEngineeringDrive motor

The invention provides a washing machine deceleration clutch and a washing machine. The washing machine deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is formed by a clutch platen and a clutch shaft sleeve; the clutch shaft sleeve covers the circumferential periphery of the deceleration device; the clutch platen rotationally move surrounding the axis to drive the clutch shaft sleeve to axially move; a first position of the clutch shaft sleeve movement is connected with a fixing device; the fixing device and an external cylinder of the washing machine are relatively fixed, so a washing work condition can be achieved; a second position of the clutch shaft sleeve movement is connected with a rotor of a direct-drive motor, so a dehydrating work condition can be achieved. The clutch device is arranged on the circumferential periphery of the deceleration device, so overall height of the deceleration clutch can be reduced, washing machine size can be reduced with the same of the washing capacity or washing capacity can be increased with the same of the washing machine size.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Drum washing machine

ActiveCN1814896ASmall sizeIncrease washing capacityOther washing machinesWashing machine with receptaclesEngineeringElectric motor

A drum type washing machine includes a cabinet, a tub fixed in the cabinet, and a drum that performs a washing process. A motor rotates the drum, a supporting device that extends from a rotation shaft of the motor to the cabinet rotatably support the drum. A buffering-and-sealing device is provided at the rear side of the tub to buffer a space between the rotation shaft and the tub and to seal the rear side of the tub. A drying device extends from one side of the tub to the other side of the tub to circulate air in the drum and to dry laundry in the drum. Thus, the size of the washing machine is reduced, the washing capacity thereof is increased, and laundry is dried by the drying device.

Owner:LG ELECTRONICS INC

Drainage structure of washing machine

ActiveCN108797021AIncrease washing capacityTo achieve the purpose of normal drainageOther washing machinesTextiles and paperEngineering

The invention relates to a drainage structure of a washing machine. A door cover is installed on a washing machine shell. The inner side of the door cover is connected with an inner tub cover throughan elasticity mechanism so that the inner tub cover can be compressed on an opening of an inner tub through the elasticity mechanism after the door cover is closed, and the inner tub is sealed; a driving mechanism is arranged between the inner tub cover and the door cover, elasticity of the elasticity mechanism for the inner tub cover is overcome when the driving mechanism works so that the innertub cover can be disengaged from the opening of the inner tub, and water in the inner tub is drained from the open opening of the inner tub; In this way, the inner tub is sealed in the inner tub rotating process, and the effect of normally draining water contained in the inner tub during drainage is achieved; meanwhile, the inner tub cover can open or close the opening of the inner tub under the effect of the driving mechanism; in addition, the inner tub does not need to be sleeved with an outer tub, the volume of the inner tub is increased, and the washing capacity of the washing machine is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

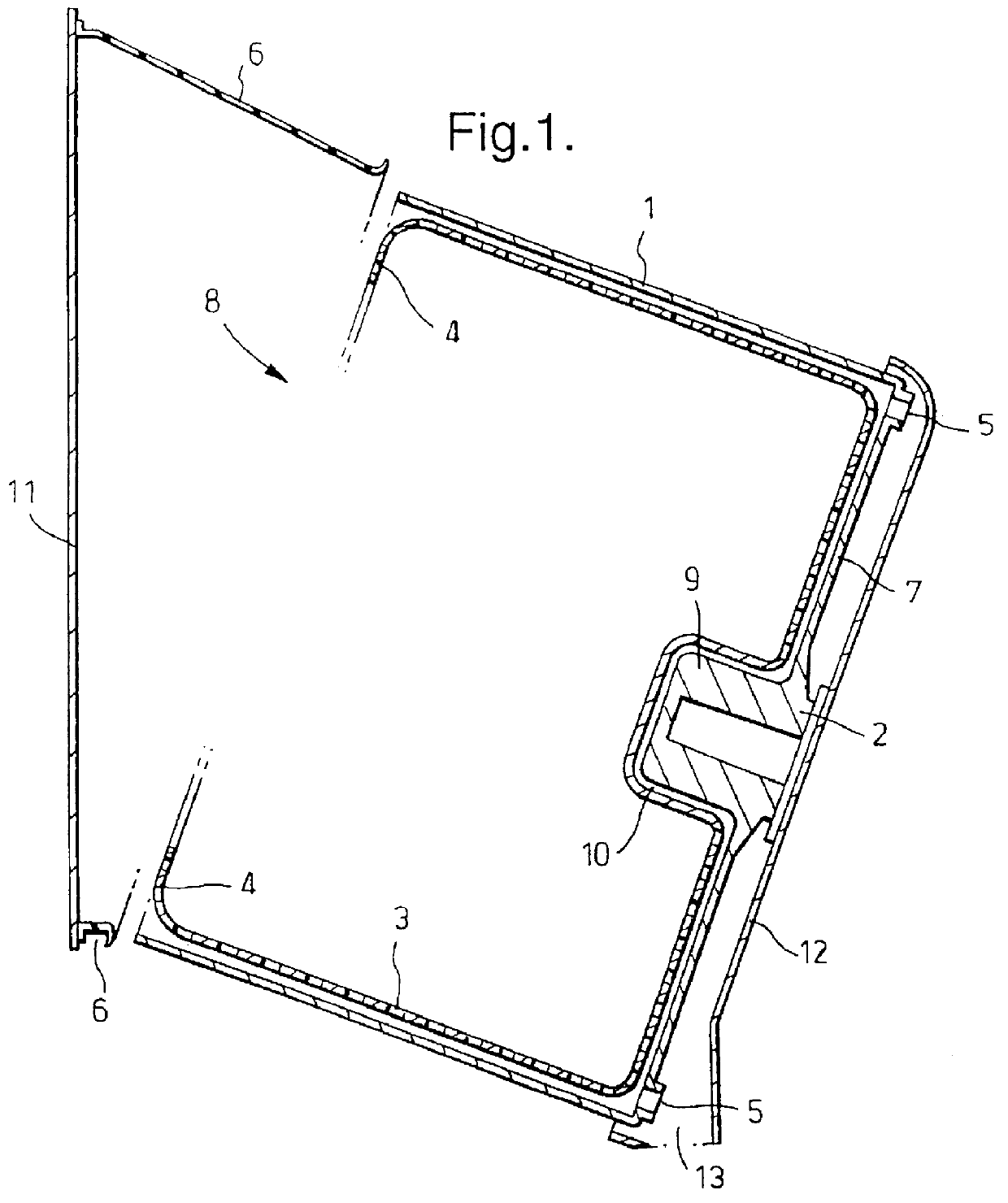

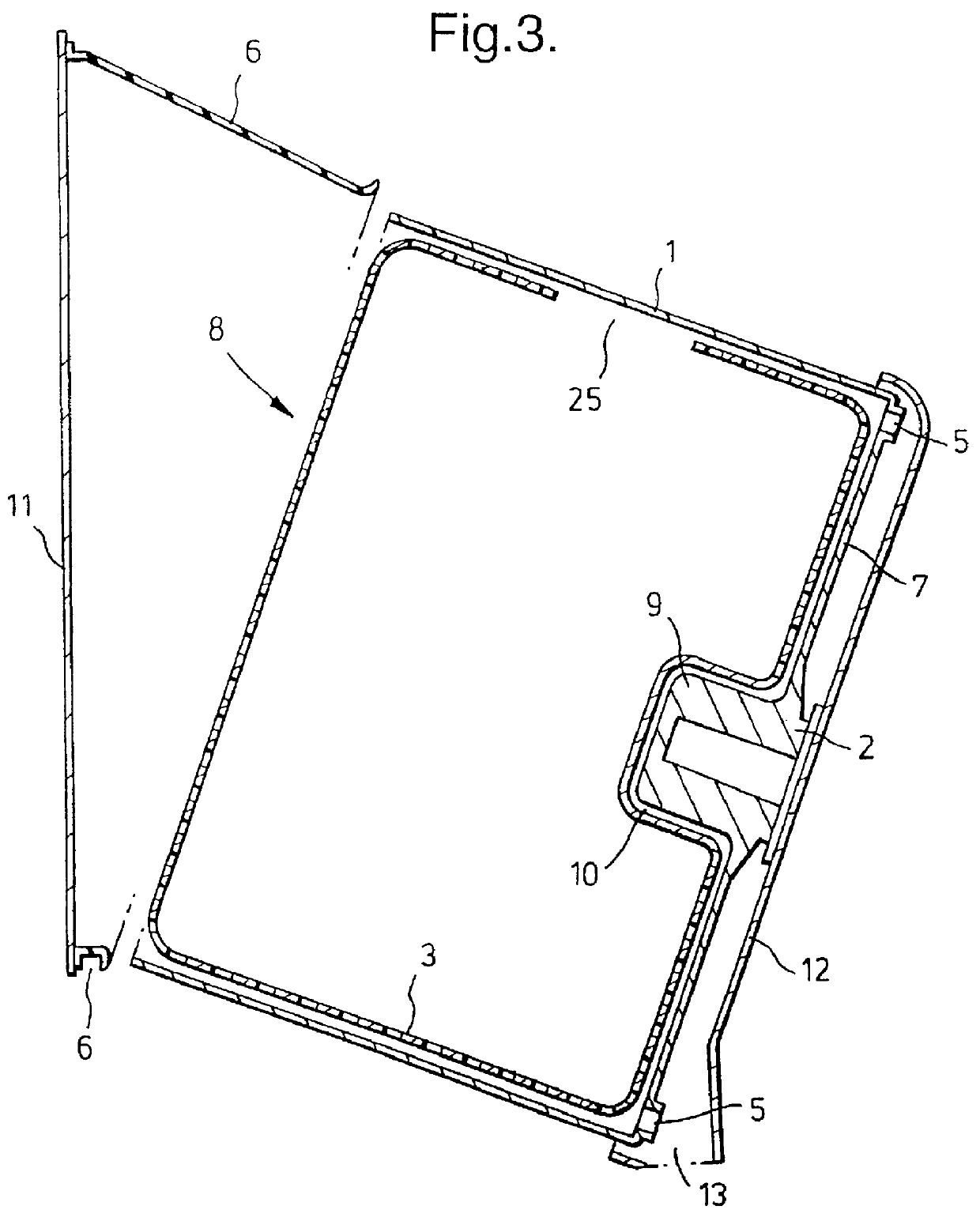

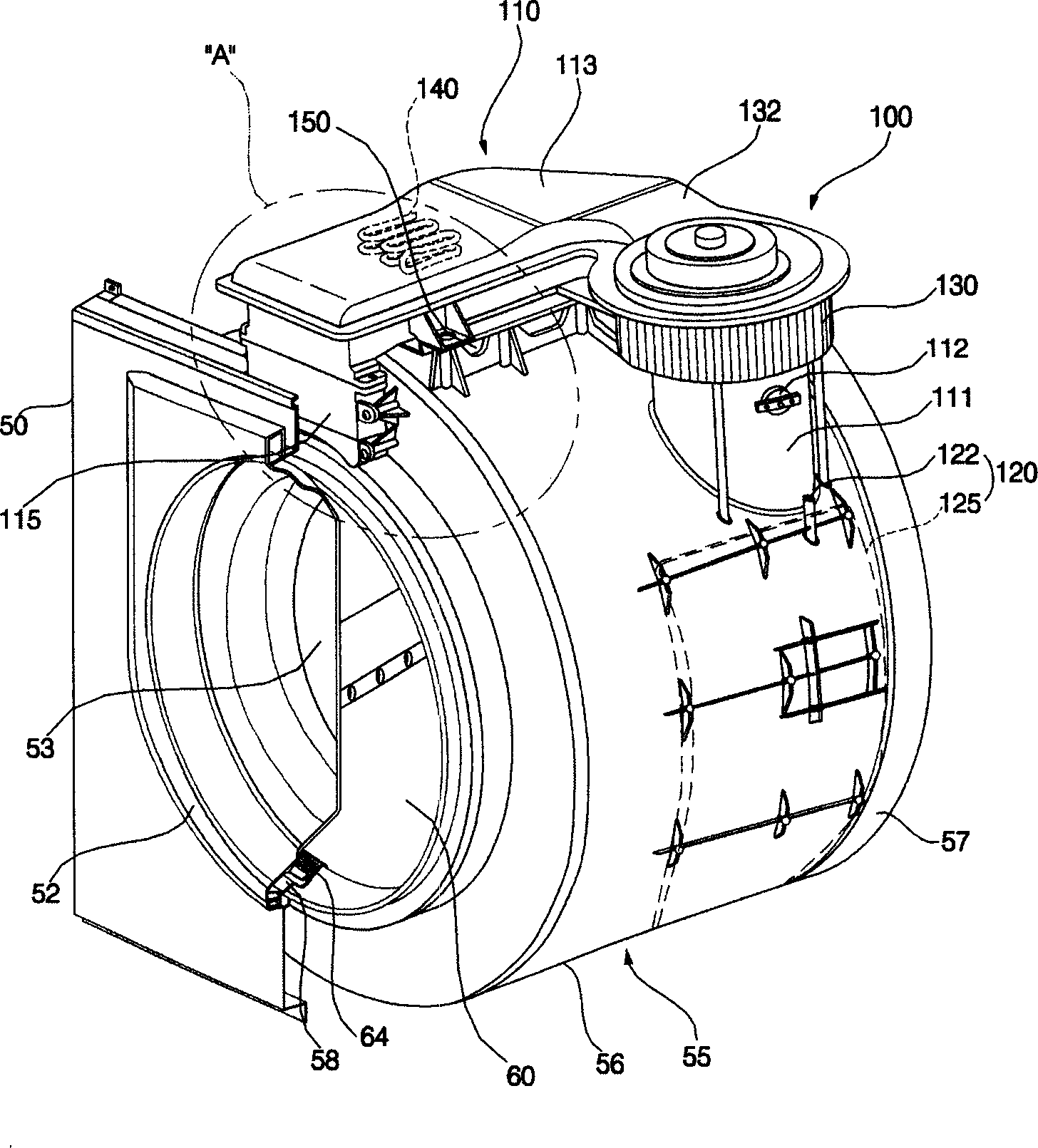

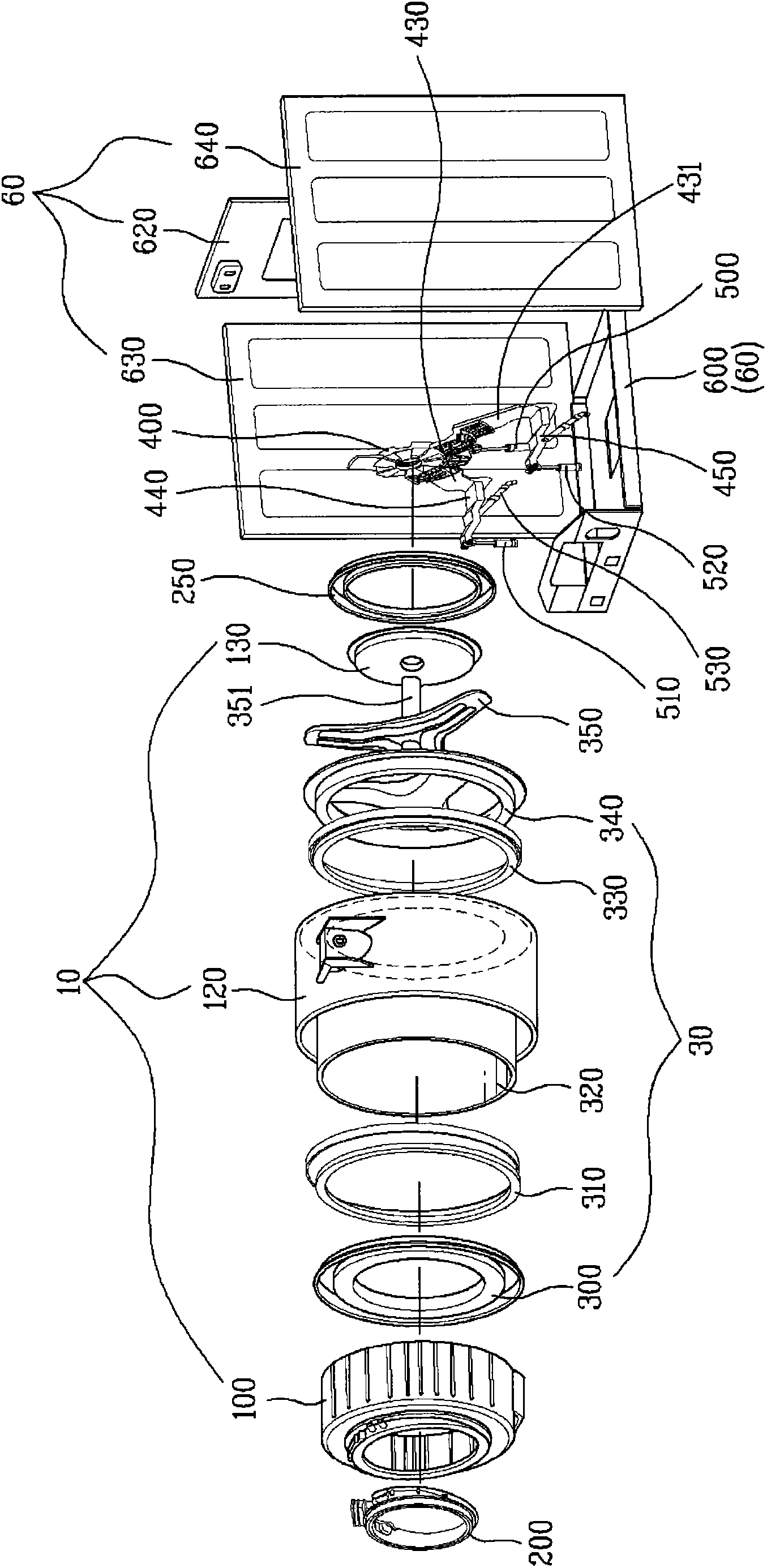

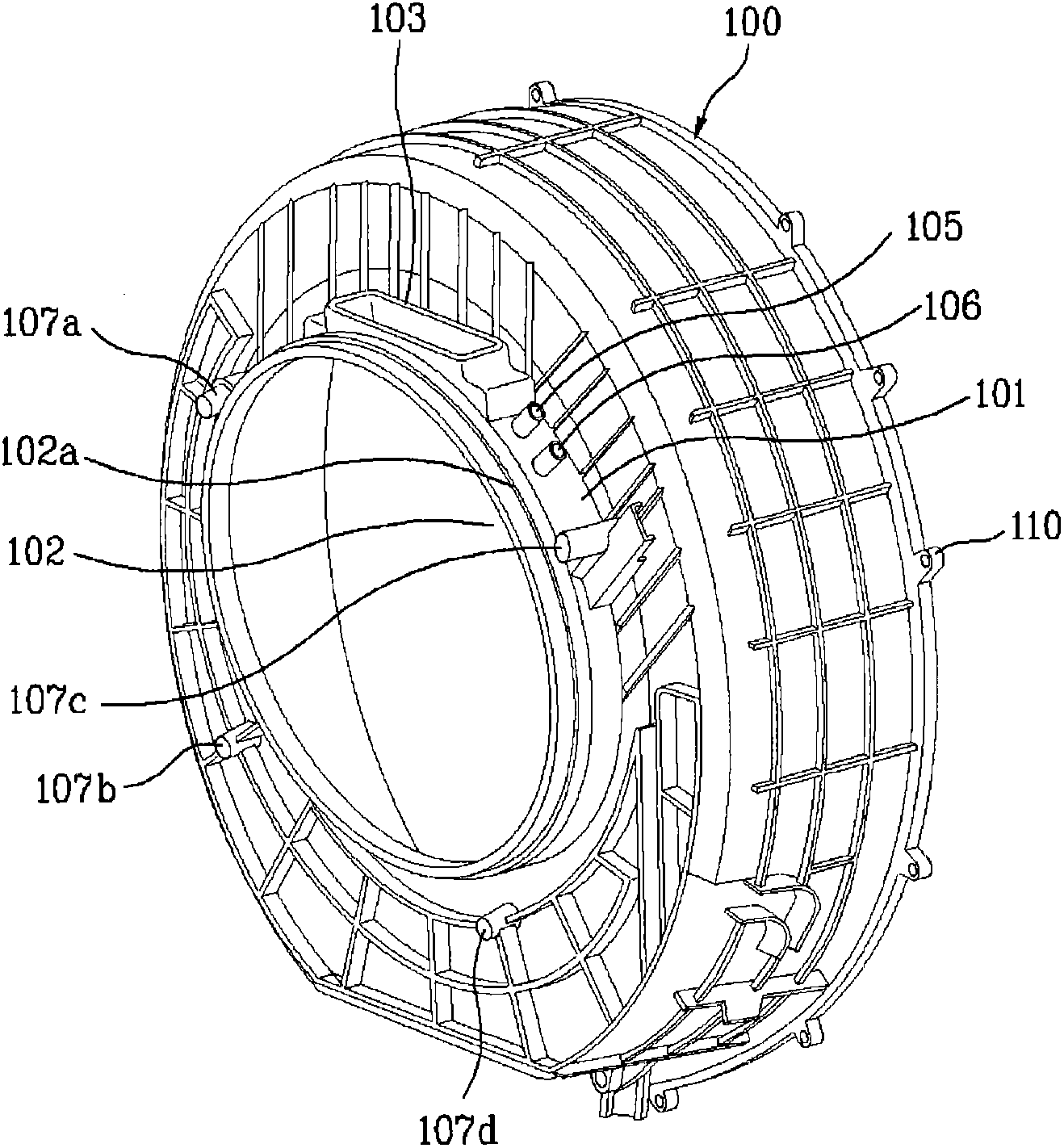

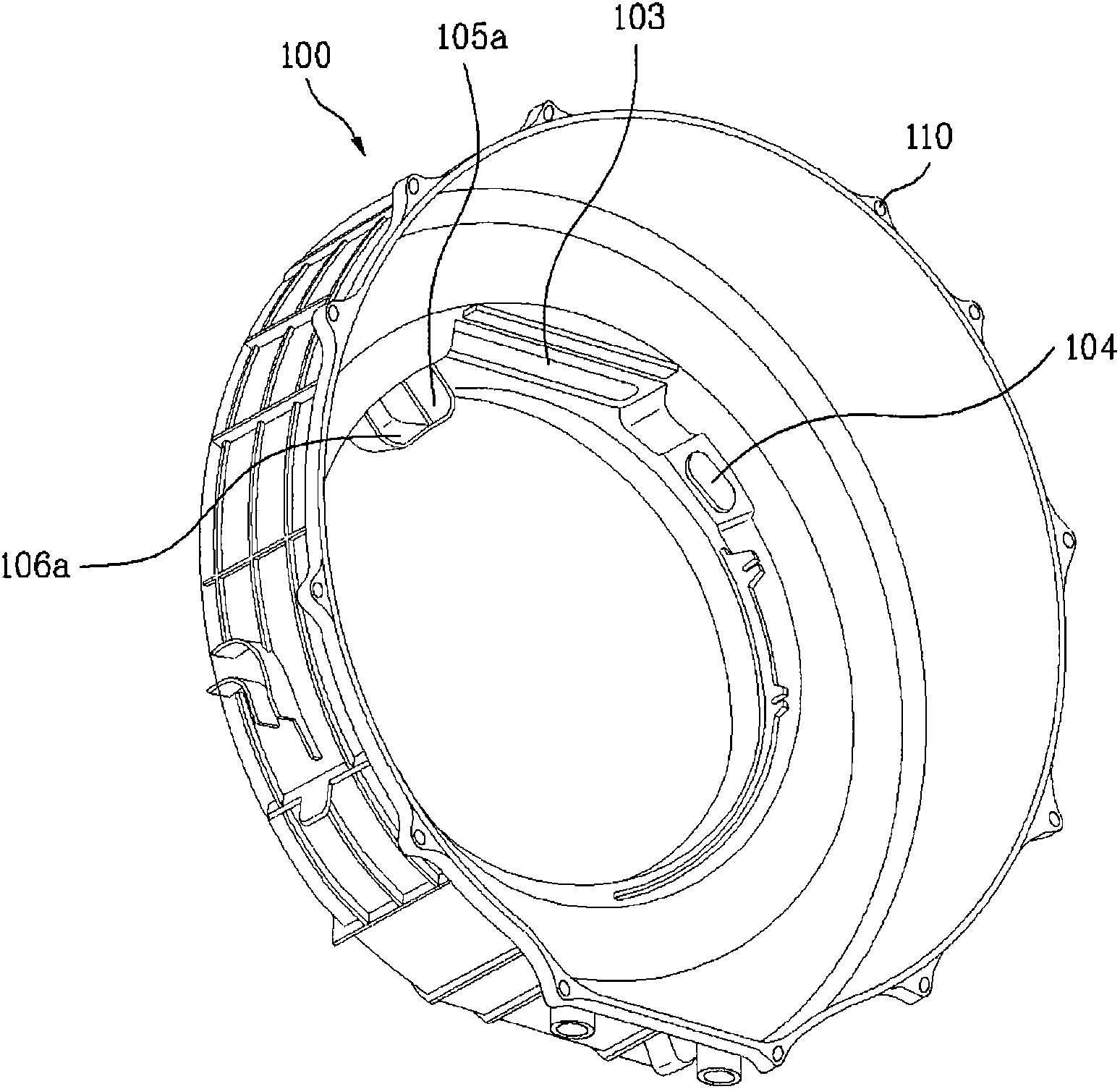

Manufacturing Method Of Laundry Machine

ActiveCN102428220AImprove stabilityIncrease washing capacityOther washing machinesWashing machine with receptaclesCouplingEngineering

A manufacturing method of a laundry machine is disclosed. The manufacturing method of the laundry machine includes a suspension preparing step configured to prepare a suspension unit (40) configured to flexibly support a drum (30), a tub rear securing step configured to secure a tub rear (120) to the suspension unit (40), a drum securing step configured to a shaft (351) or the drum (30) to the suspension unit (40) via an inside of the tub rear (120), a tub front coupling step configured to couple a tub front (100) to the tub rear (120), a tub seating step configured to seat the tub front (100) and the tub rear (120) in a cabinet cabinet base (600)m and a suspension securing step configured to secure the suspension unit to the cabinet base (600).

Owner:LG ELECTRONICS INC

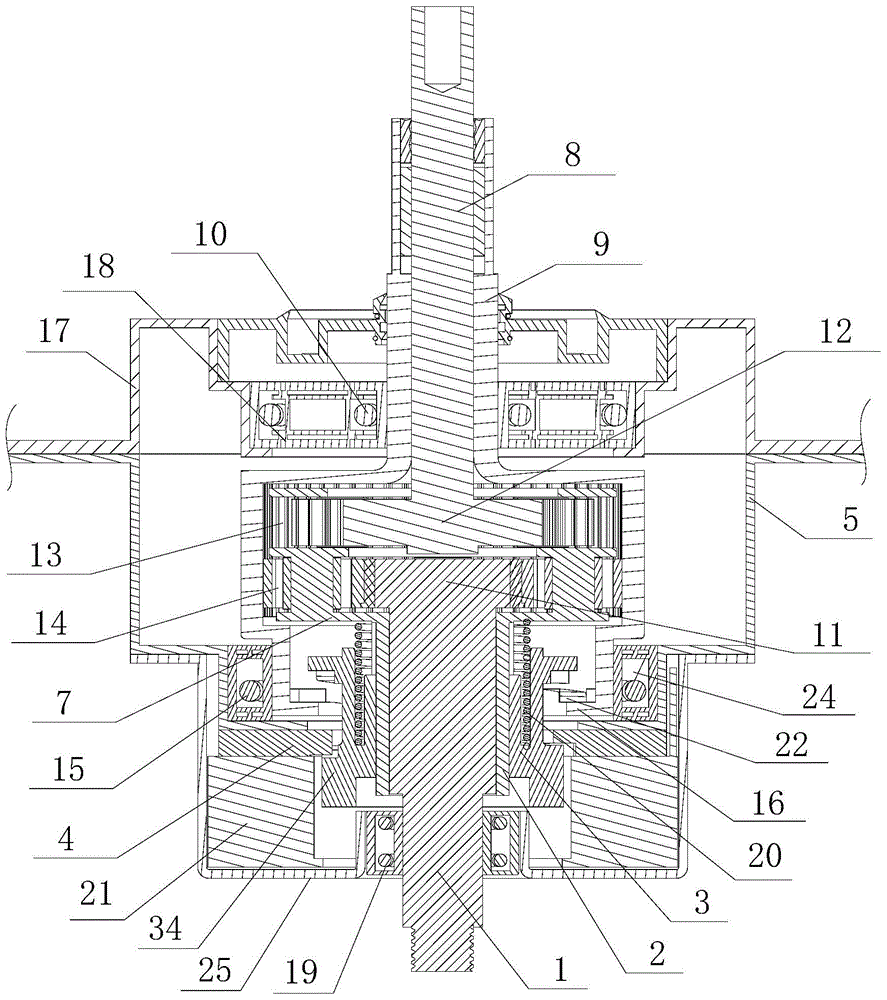

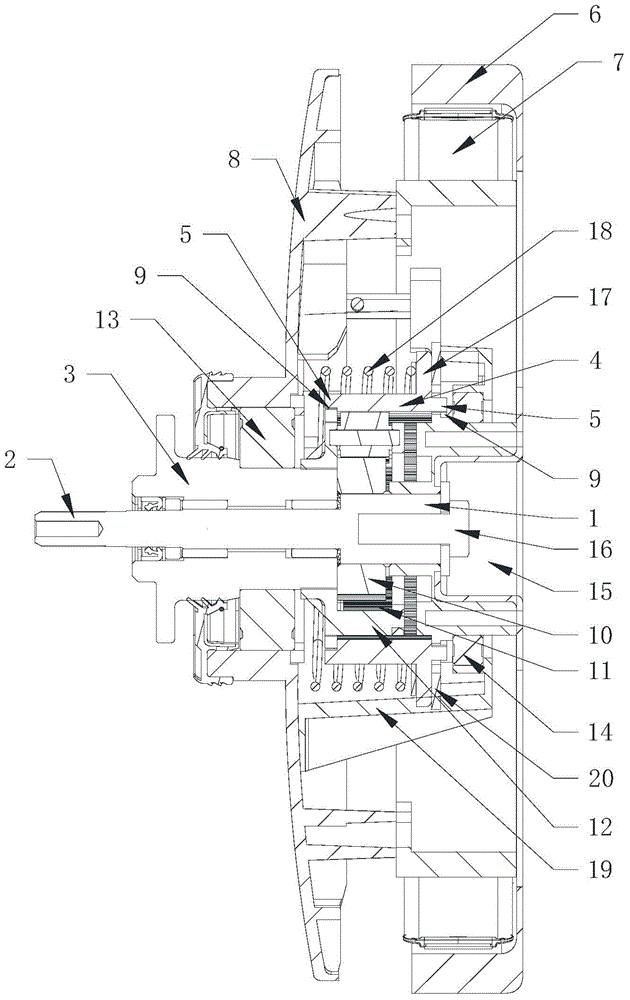

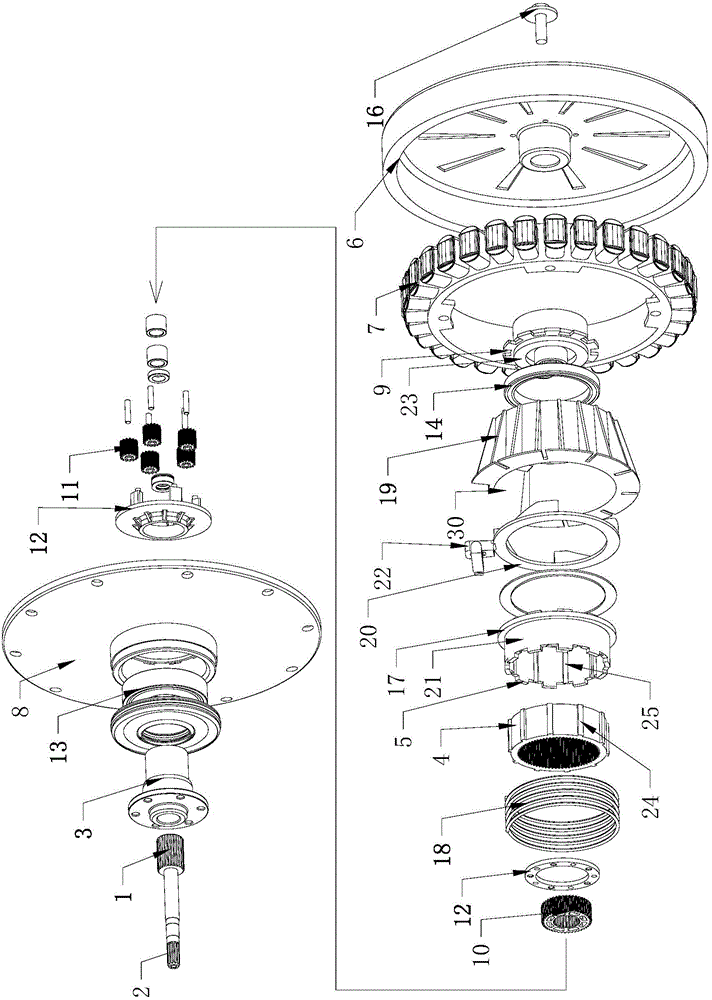

Decelerating clutch and washing machine

ActiveCN105316905AImprove support reliabilityLower the altitudeOther washing machinesTextiles and paperClutch controlDehydration

The invention relates to a decelerating clutch of a washing machine and the washing machine. The decelerating clutch comprises an input shaft, a decelerating device, a clutch device, an output shaft, an output shaft sleeve and a motor, wherein the clutch device comprises a clutch shaft sleeve which can slide up and down, and end face teeth which are engaged with a fixed device or a motor rotor are respectively formed on the upper and lower ends of the clutch shaft sleeve; at least a part of the decelerating device and / or the clutch device is installed in the hollow part of the motor, so that at least a part of projection of the decelerating device and / or the clutch device coincides with that of the motor on the axis of the decelerating clutch. According to the decelerating clutch and the washing machine, the end face teeth which are engaged with the fixed device or the motor rotor are respectively formed on the upper and lower ends of the clutch shaft sleeve, so that the clutch shaft sleeve is controlled to slide, the output shaft sleeve and the output shaft rotate at the same speed or at differential speed, and the washing machine is controlled to be switched between a dehydration state or a washing state by the decelerating clutch.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Washing machine

ActiveCN108797025AAchieve cloggingIncrease volumeOther washing machinesTextiles and paperPulp and paper industry

The invention relates to a washing machine. A door cover is installed on a washing machine shell, an inner drum outer cover capable of stretching in the inner drum direction is installed on the innerside of the door cover, an outlet communicated with the interior of an inner drum is formed in an inner drum opening, and the inner drum outer cover generates stretching motion under the action of thedriving mechanism, so that the outlet is blocked or opened, and water contained in the inner drum is discharged from the outlet. In this way, the inner drum outer cover can generate stretching displacement in the axis direction of the inner drum relative to the door cover, and correspondingly fit or separate relative to the inner drum opening in the door cover stretching process, and then the purpose that the outlet is blocked, and then the water stored in the inner drum is used for normal washing of the washing machine is achieved; or the purpose that the outlet is opened, washing water in the inner drum is discharged outside is achieved. Meanwhile, in the washing process of the washing machine, the washing water is only contained in the inner drum, pollution of the washing water to theouter wall of the inner drum is avoided, and the cleanliness of washing of the washing machine is improved. In addition, an outer drum is not needed for sleeving the exterior of the inner drum, the volume of the inner drum is increased, and the washing volume of the washing machine is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Method for washing active carbon

The invention relates to a method for washing active carbon, which comprises that: a carbonous precursor and KOH or NaOH are evenly mixed, and the weight ratio of the carbonous precursor to the KOH or the NaOH is 1 to 1 : 1-10; in the presence of inert atmosphere, temperature rises from room temperature to temperature of between 800 and 1,000 DEG C, when the temperature is reduced to be close to the room temperature, an activation product is taken out; after slurry is prepared from the activation product and water in weight ratio of 1: 5-10, the slurry is added from the upper part of a water scrubbing tower at a speed of between 1 and 100 kg / h, and the water is added from the lower part of the water scrubbing tower at a speed of between 20 and 2,000 L / h so that the activation product and the water are reversely contacted in the water scrubbing tower for washing the activation product; and the dwell time of the activation product in the water scrubbing tower is between 0.5 and 1 hour. The method has the advantages of substantially reducing water for washing, greatly lightening reclaiming pressure of subsequent waste lye, reducing reclaiming cost, lightening labor intensity of routine washing, improving washing productivity, and being favorable for scale washing.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

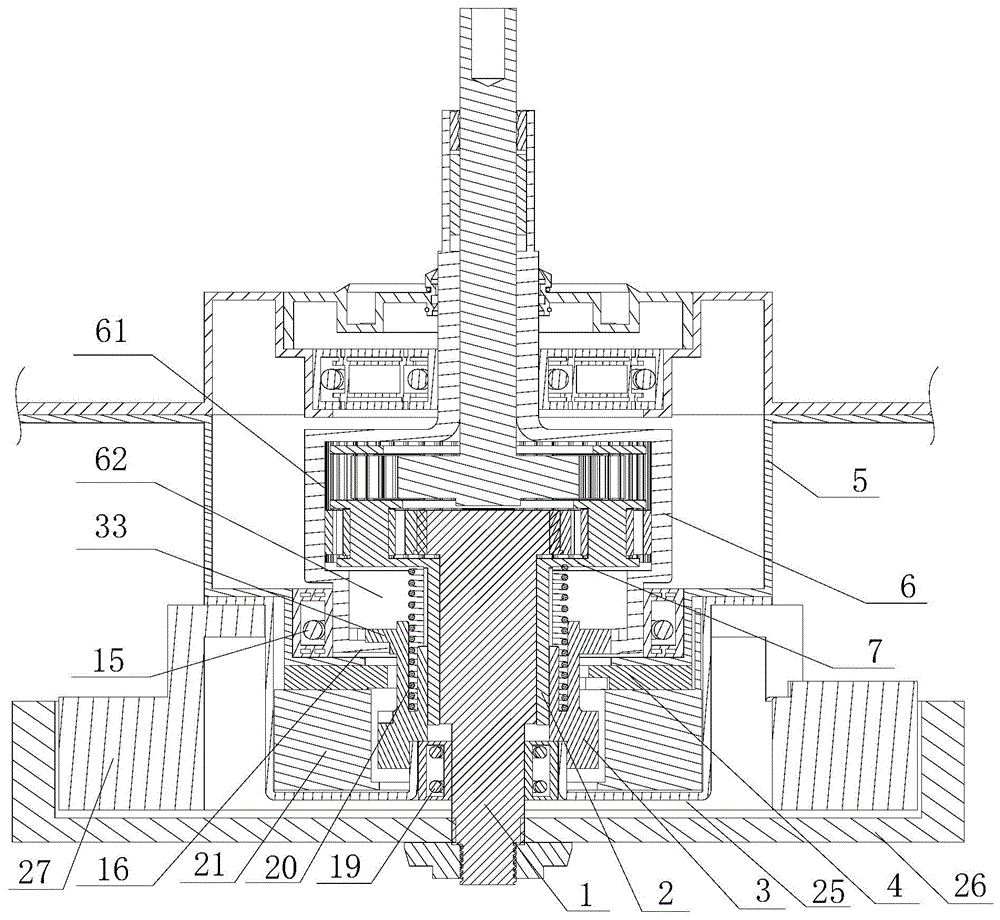

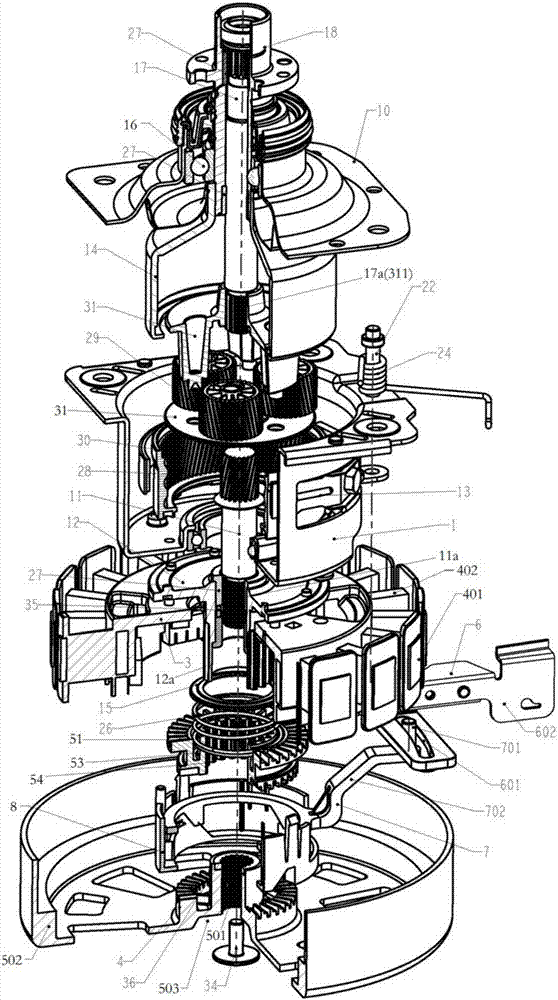

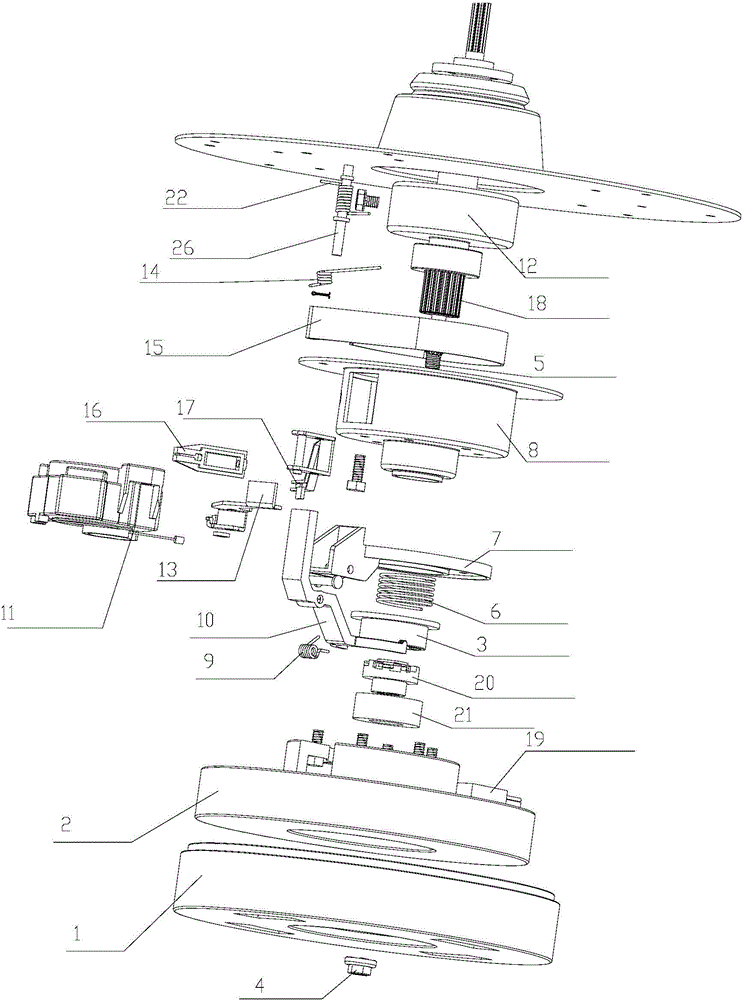

Efficient variable frequency motor speed reduction and clutch device and washing machine

ActiveCN104372571AAvoid swiping up and downReduce the overall heightOther washing machinesTextiles and paperMotor speedElectric machinery

The invention relates to the field of washing machines, in particular to an efficient variable frequency motor speed reduction and clutch device and a washing machine. The speed reduction and clutch device comprises a clutch device shell, an external rotor motor and an input shaft (7), wherein the external rotor motor is composed of a rotor (3) and a stator (4), and the input shaft (7) is fixedly connected to the rotor (3) and mounted on the shell. An input shaft sleeve (16) capable of rotating relatively around an axis is arranged outside of the input shaft (7), a clutch shaft sleeve (8) capable of sliding up and down is mounted on the input shaft sleeve (16), and the clutch shaft sleeve (8) is connected to a traction motor (10) through a control mechanism. When the clutch shaft sleeve (8) is located at a first position, the input shaft sleeve (16) is meshed with the shell through the clutch shaft sleeve (8), and when the clutch shaft sleeve (8) is located at a second position, the input shaft sleeve (16) is meshed with the rotor (3) through the clutch shaft sleeve (8). The controllable traction acting force of the traction motor is transmitted to the clutch shaft sleeve through the control mechanism formed by a connecting arm, a shifting fork and a clutch spring, and the clutch shaft sleeve can slide up and down.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

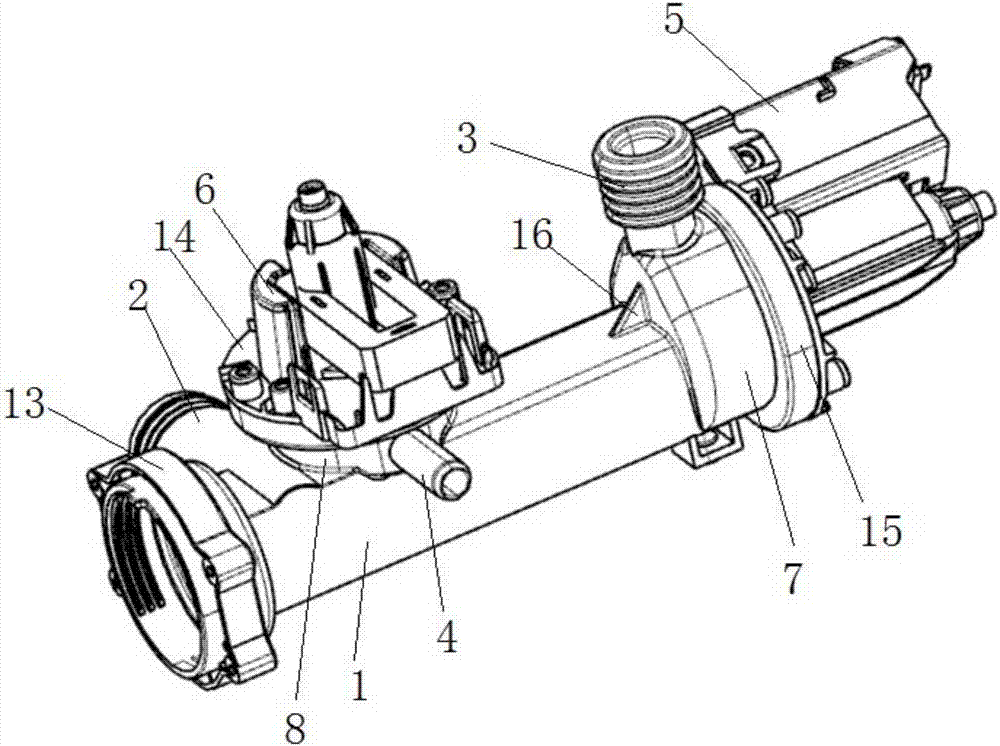

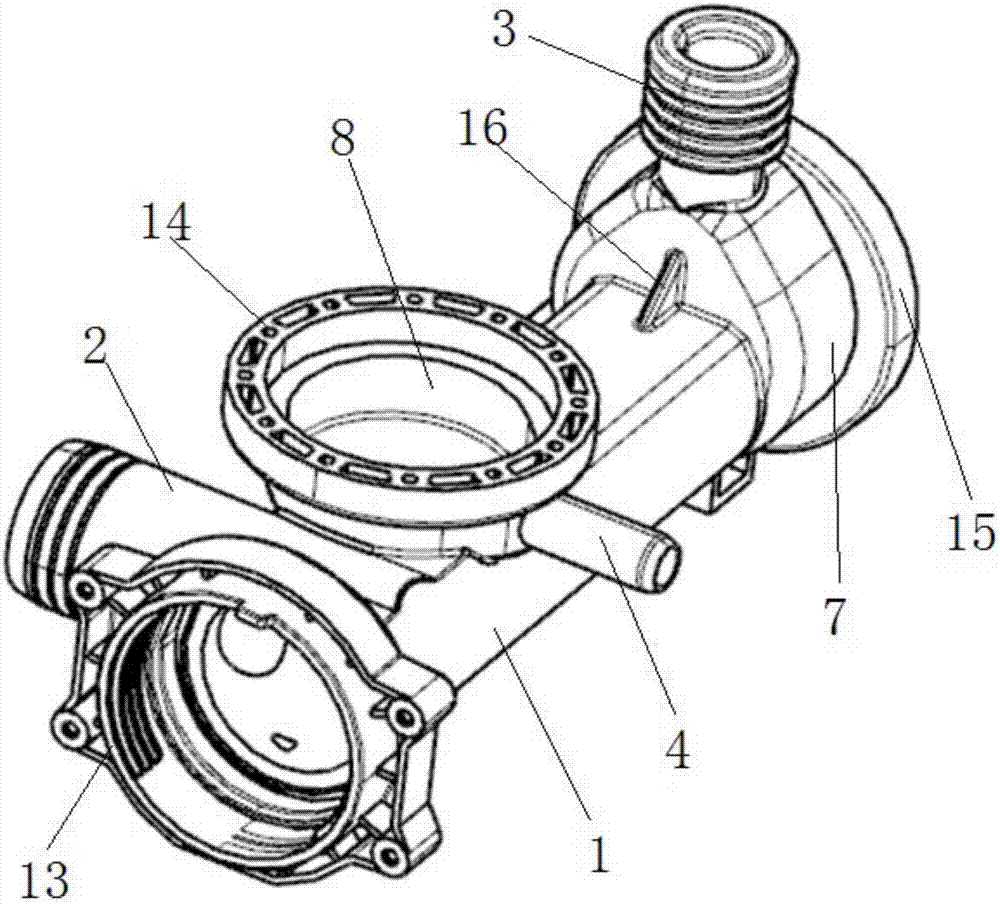

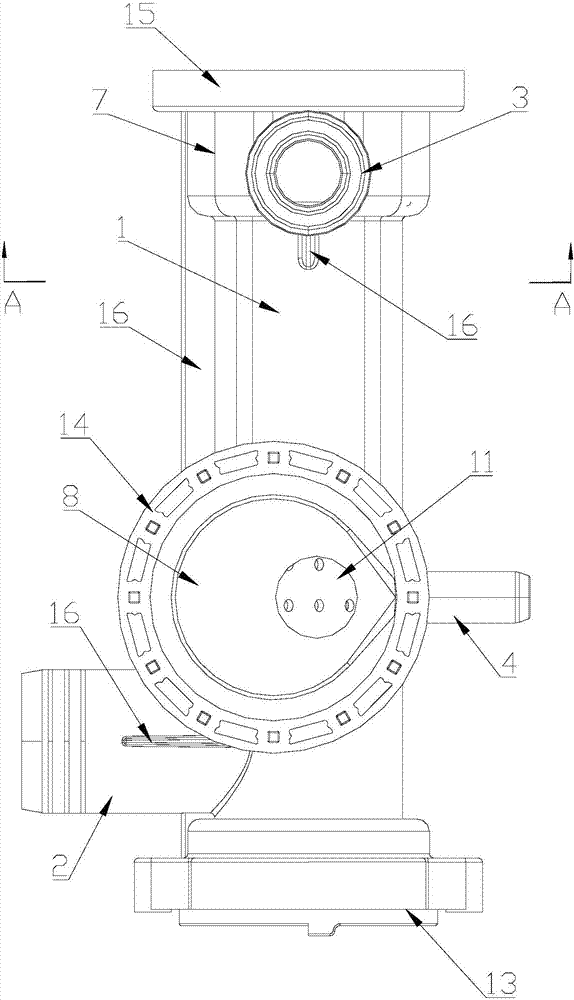

Washing machine

ActiveCN106930066ASimple structureGood effectOther washing machinesTextiles and paperWater flowWater holding

The invention relates to a washing machine. A water holding barrel is mounted in a washing machine housing. A double-head pump is arranged between the water holding barrel and a washing machine base. A water inlet pipe of a double-head pump communicates with a water outlet of the water holding barrel. A circulating pump and a draining pump are arranged on the double-head pump. Incoming water flowing into the double-head pump is circularly guided into a circulating water outlet pipe which communicates with a water inlet structure of the water holding barrel. The draining pump guides the incoming water flowing into the double-head pump to a drain pipe for discharging to the outside. The top surface of a main pump body of the double-head pump is arranged into a flat surface so as to reduce the height of the double-head pump, providing a certain safety gap between the double-head pump and the water holding barrel. By disposing the main pump body of the double-head pump into a horizontally arranged special-shaped structure, the overall height of the double-head pump is reduced, leading to an increased distance between the installed double-head pump and each of the water holding barrel of the washing machine and a counterweight part; thus, interference of the water holding barrel with the double-head pump due to vibration during washing of the washing machine is avoided, and the internal space of the housing of the washing machine is fully utilized so as to increase the washing capacity.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Pulsator washing machine

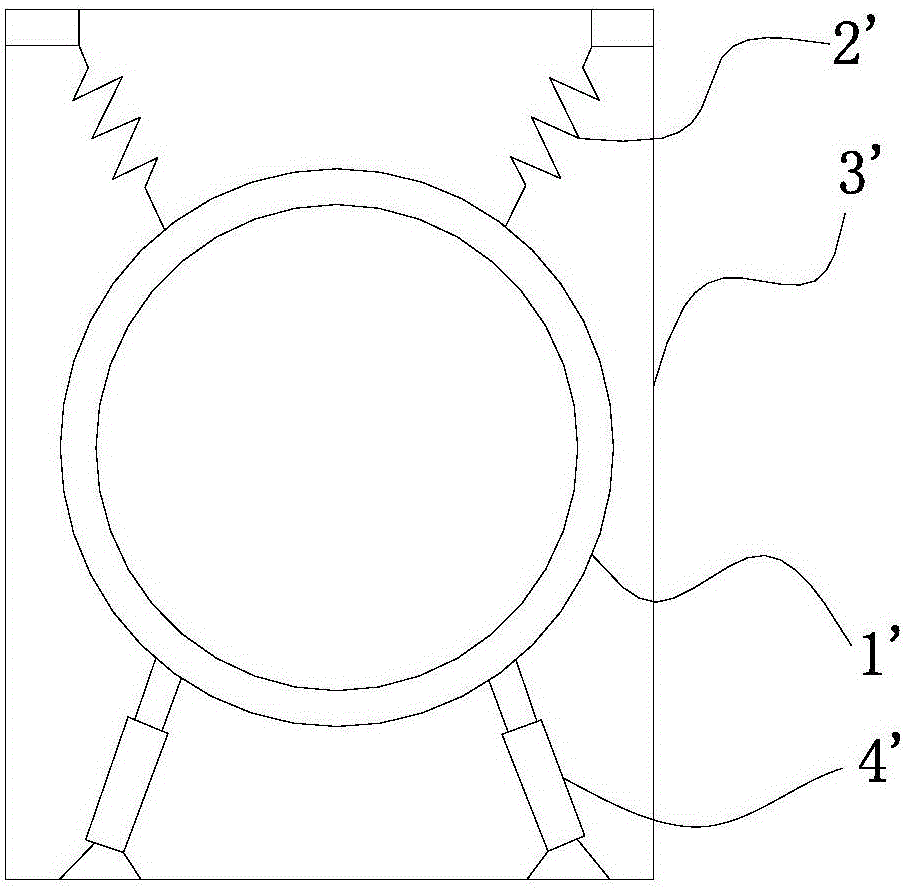

InactiveCN108457037ASave spaceIncrease washing capacityOther washing machinesWashing machine with receptaclesWater savingEngineering

The invention discloses a pulsator washing machine, including a box body, an outer barrel, and an inner barrel. The outer barrel is arranged in the box body, and the inner barrel is arranged in the outer barrel. The upper part of the outer barrel is fixedly connected with the box body. The lower part of the outer barrel is provided with a shock absorbing device for mitigating vibration of the outer barrel in the box body. The upper edge of the outer barrel is fixedly connected with the upper part of the box body. The side wall of the outer barrel and the inner wall of the box body are arrangedat interval. Space between the outer barrel and the box body is reduced, and effectively washing volume of the washing machine is enlarged. Vibration of the washing machine is reduced, and the washing machine achieves better damping effect. In addition, the washing machine is energy-saving and water-saving, and has low noise and low cost.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Washing machine outer barrel and washing machine

ActiveCN106283509AMake the most of the interior spaceIncrease washing capacityOther washing machinesTextiles and paperInterior spaceEngineering

The invention discloses a washing machine outer barrel, and relates to the technical field of washing machines. Non-circular surfaces avoided from colliding with side plates of a shell are formed on two opposite side walls of the washing machine outer barrel. The invention also provides the washing machine with the washing machine outer barrel. Under the condition that the shell of the washing machine is unchanged, the internal space of the washing machine is sufficiently utilized, the diameter of the outer barrel is increased, collision and interference between the outer barrel and the shell in the working process of the washing machine are effectively avoided, and the washing capacity of the washing machine is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Washing machine deceleration clutch and washing machine

ActiveCN105332239ALower the altitudeReduce volumeClutchesOther washing machinesElectric machineEngineering

The invention relates to a washing machine deceleration clutch and a washing machine. The deceleration clutch comprises an input shaft, a deceleration device, a clutch device, an output shaft and an output shaft sleeve, wherein the clutch device is at least partially arranged on the periphery of the deceleration device; the deceleration clutch axially occupies little space; the clutch device comprises a clutch shaft sleeve capable of axially moving and a driving device driving the clutch shaft sleeve to axially move; the clutch shaft sleeve is an annular gear of the deceleration device; the driving device drives the annular gear to axially move to control different output states of the output shaft and the output shaft sleeve; the driving device comprises at least one shifting fork rod; the shifting fork rod is provided with a fixing part; and one end of the shifting fork rod is provided with a shifting fork controlling the annular gear to axially move and the other end is provided with a driving end in transmission connection with a driving motor. The driving device is simply structured, has reliable control, small stroke, and compact structure and occupies small space; stable and reliable operation and low fault rate can be achieved; and with the compact structure, a modularized structure can be achieved and high component integration degree can be realized.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

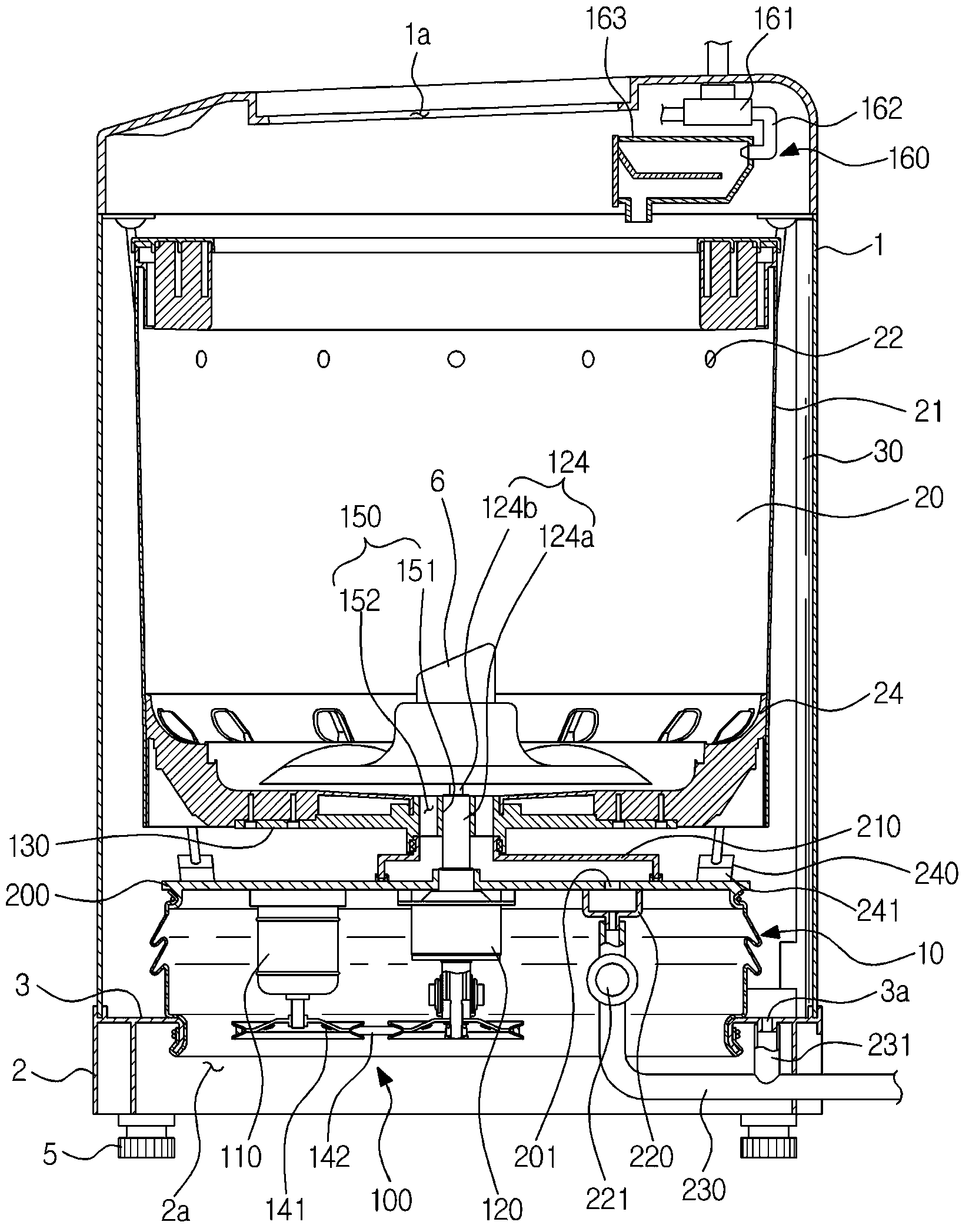

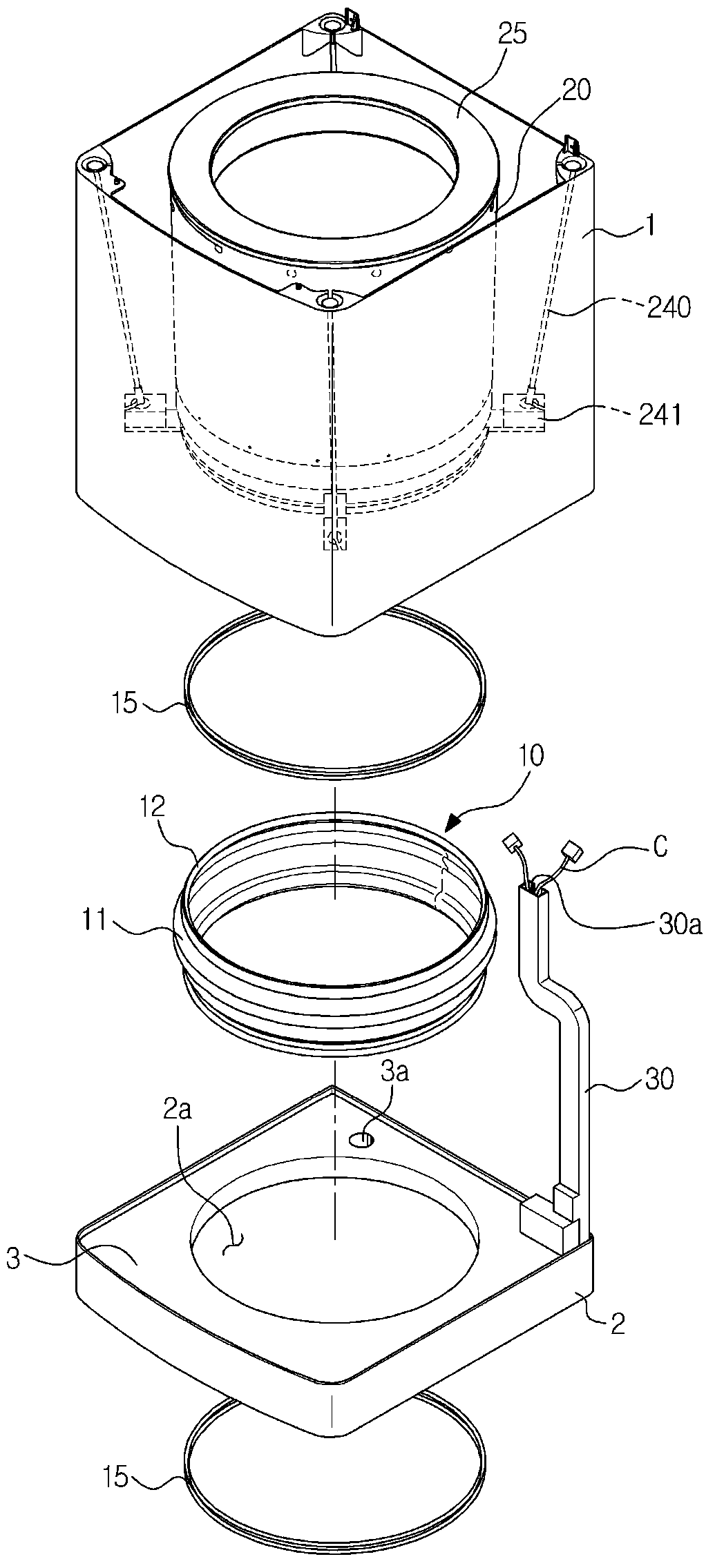

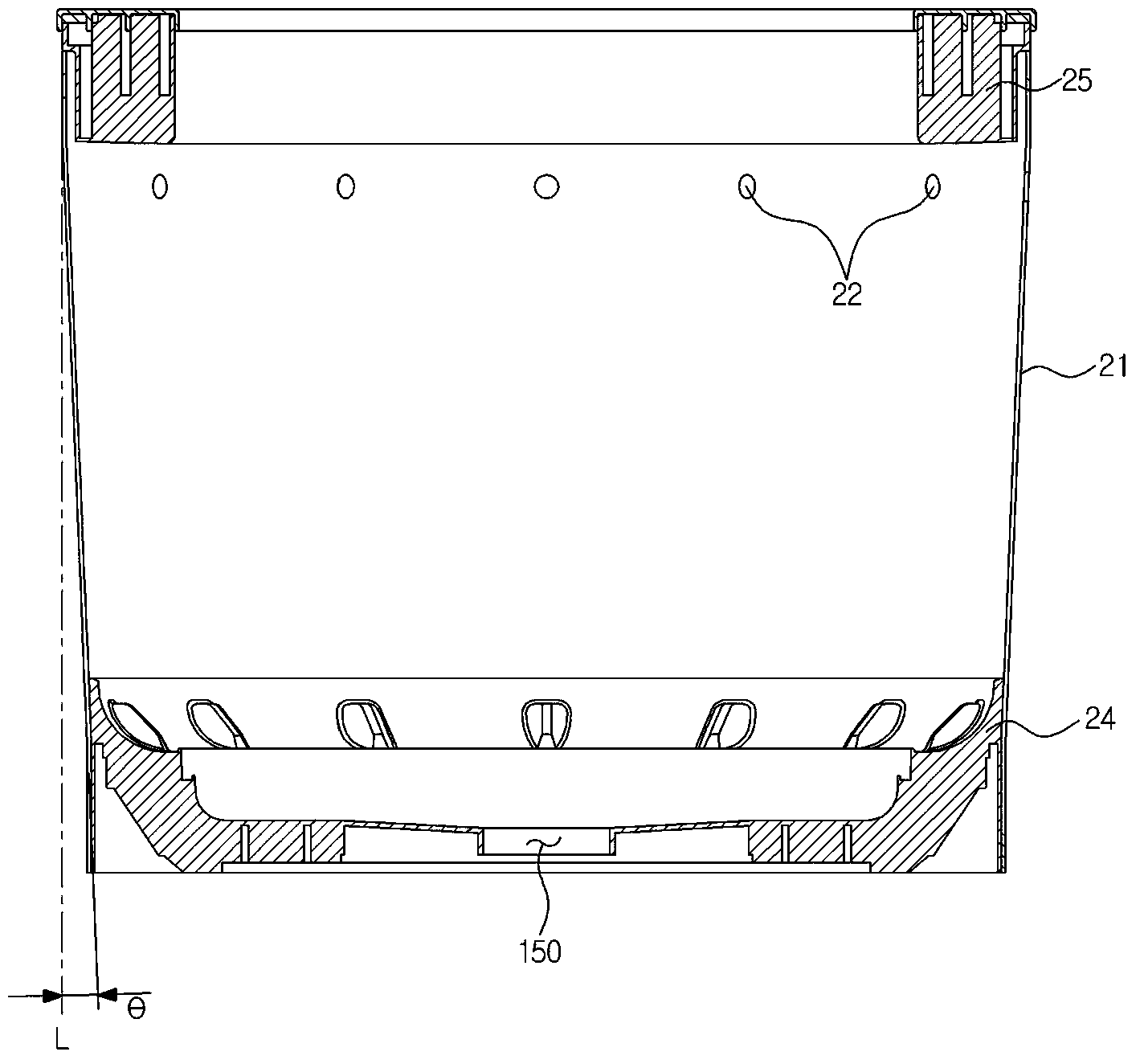

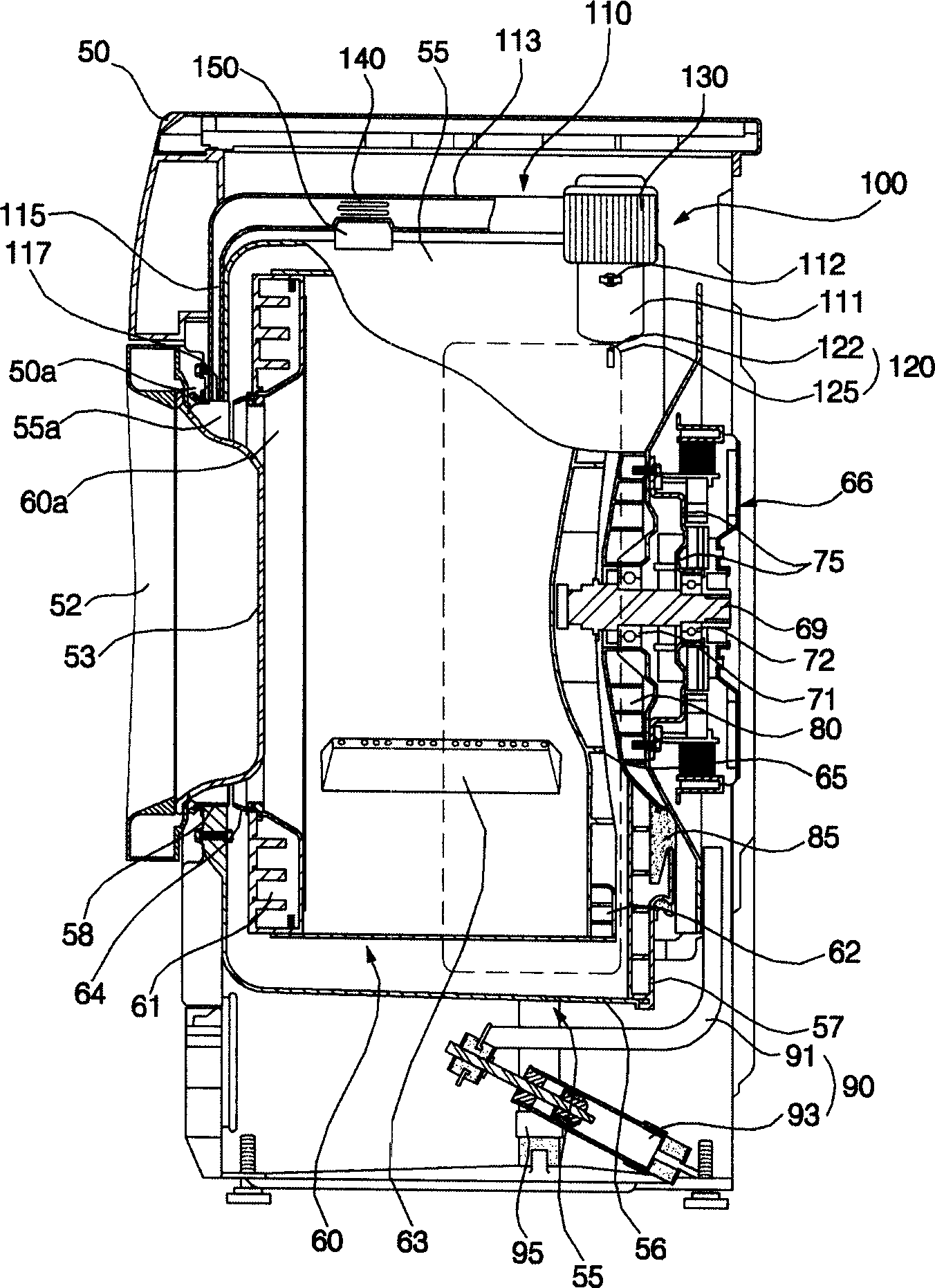

Washing Machine

ActiveUS20110197637A1Increase washing capacityReduce vibration and noiseOther washing machinesWashing machine with receptaclesElectric machineryDrive motor

Owner:LG ELECTRONICS INC

Circuit fixing structure of washing machine and washing machine

ActiveCN107453288AIncrease washing capacitySmooth transmissionElectrical apparatusOther washing machinesEngineeringElectrical and Electronics engineering

The invention provides a circuit fixing structure of a washing machine and the washing machine. The circuit fixing structure comprises a body, wherein a plurality of terminal fixing units for fixing wiring terminals of wires in a circuit are arranged on the body. The terminal fixing units for fixing the wiring terminals of the wires in the circuit are arranged on the body, so that the wiring terminals can be fixedly arranged inside the corresponding terminal fixing units respectively, the wiring terminals are distributed on the body, only relatively thin space near the body is occupied, the washing capacity of the washing machine is increased, and the available space inside a box body is increased; moreover, the wiring terminals cannot be contacted directly, the potential safety hazards are reduced, and the safety of the washing machine is improved; moreover, the wiring terminals are fixed, so that the transmission stability of the circuit is facilitated, and the stability of the washing machine is improved; and furthermore, the maintenance for the circuit is convenient and quick, particularly the maintenance or replacement for the wiring terminals is facilitated, and the maintenance speed and maintenance efficiency are improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com