Washing machine

A technology for a washing machine and a washing machine shell, applied in the field of washing machines, capable of solving the problems of increasing washing machine production processes, reducing production efficiency, and occupying washing machine space, and achieving the effects of being suitable for popularization and use, simple in structure, and remarkable in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

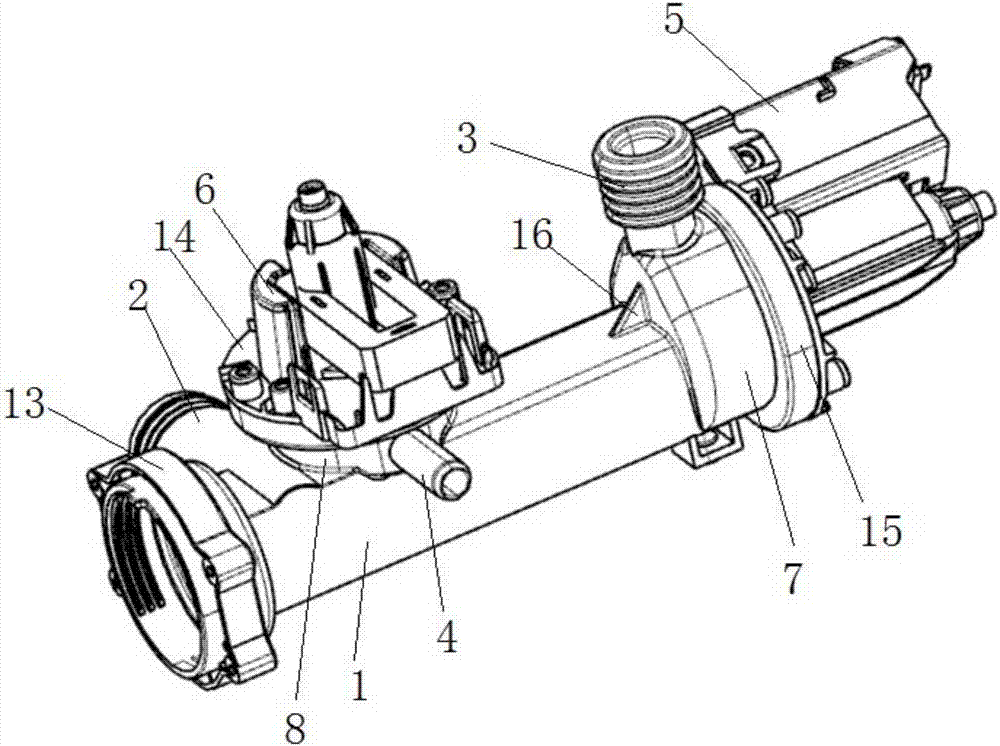

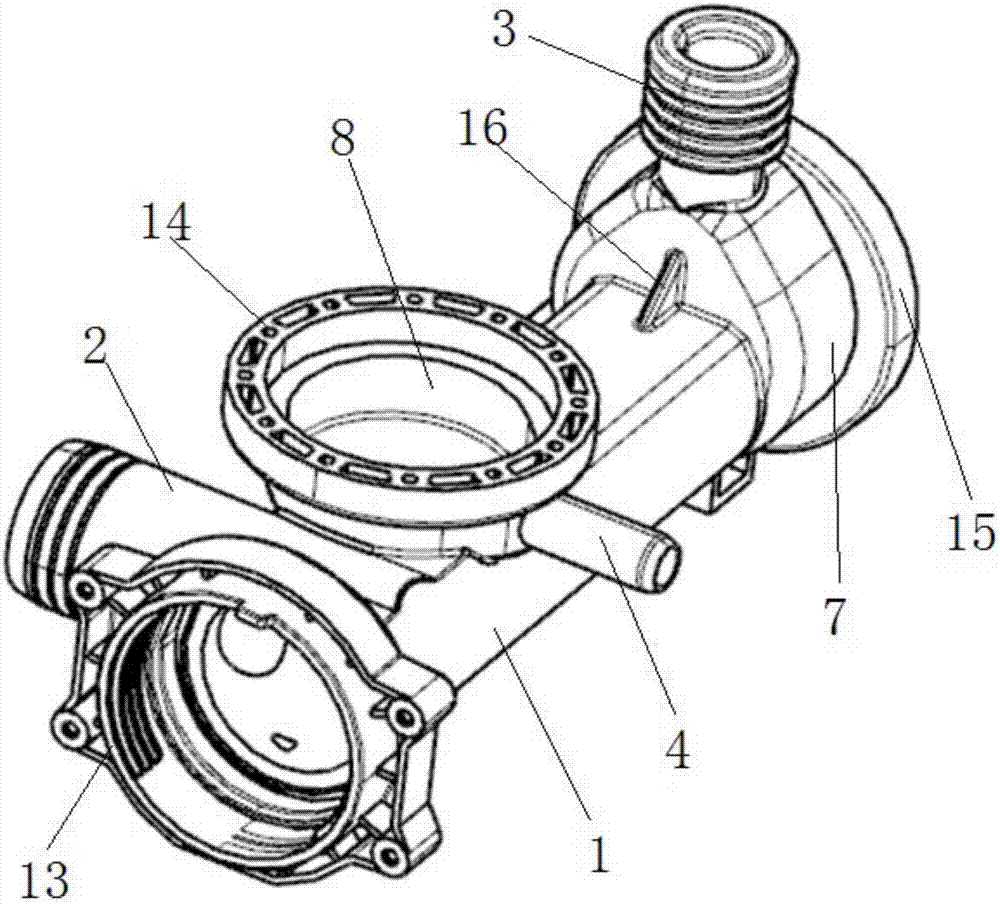

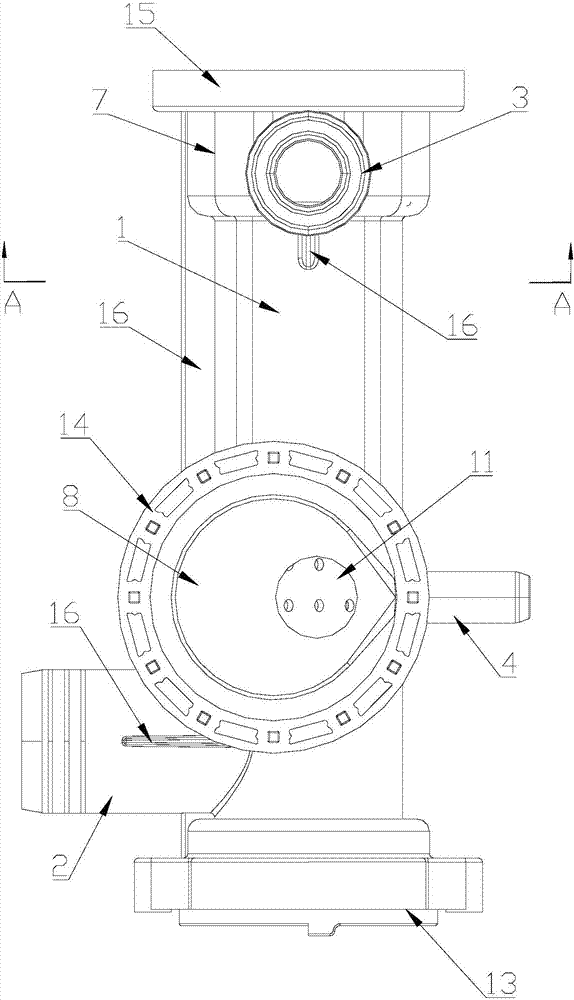

[0041] Such as Figure 1 to Figure 12 As shown, a double-head pump is introduced in this embodiment, which includes a columnar main pump body 1, and a filter element 9 extending along the axis is arranged in the main pump body 1, and the filter element 9 divides the main pump body 1 into parts to be treated. Filtration chamber 17 and filtered chamber 18; One end of main pump body 9 is provided with the drainage pump chamber 7 that will be connected to filter chamber 17 and filtered chamber 18, and drainage pump chamber 7 is equipped with drainage pump 5, and drainage pump chamber 7 The side is connected with the drain pipe 3, and the drain pump 5 guides the water inflow from the water inlet pipe 2 in the main pump body 1 directly to the drain pipe 3 through the drain pump cavity 7; the other end of the main pump body 1 is provided with a chamber to be filtered 17 is connected to the water inlet pipe 2 and the circulation pump chamber 8 connected to the filtered chamber 18, the...

Embodiment 2

[0056] Such as Figure 1 to Figure 8 As shown, this embodiment introduces a double-head pump shell structure, which includes a columnar main pump body 1, and the two ends of the main pump body 1 are respectively provided with a water inlet pipe 2 and a drain pump cavity 7, which are close to the water inlet pipe. 2 The side wall of the main pump body 1 at one end is provided with a circulating pump chamber 8; The end is provided with a circulation pump installation joint 14, and the side wall of the circulation pump chamber 8 is provided with a circulating water outlet pipe 4 protruding radially outward; the drainage pump chamber 7 is provided with a drain pipe 3 and a drainage pump installation joint 15 , the drain pump installation joint 15 protrudes outward along the axial direction of the main pump body 1 , and the drain pipe 3 protrudes outward along the radial direction of the main pump body 1 .

[0057] Through the above settings, the circulation pump chamber and the d...

Embodiment 3

[0071] Such as figure 1 and Figure 7 to Figure 12 As shown, a double-head pump filter element is introduced in this embodiment. The double-head pump includes a circulation pump cavity 8 for the circulation pump 6 to install, and a drainage pump cavity 7 for the drainage pump 5 to install; the filter element 9 includes a bracket, One end of the bracket is provided with a first filtering structure for filtering the water flowing into the drainage pump chamber 7, and a second filtering structure for filtering the water flowing into the circulating pump chamber 8 is also provided on the bracket.

[0072] By setting the above-mentioned filter elements, the dual-head pumps can be filtered separately when using the circulating pump and the drainage pump, so that the influent water can be filtered according to different requirements and then flow into the corresponding chamber and then flow out, avoiding the need for water flow If foreign matter flows into the pump cavity, it will c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com