Pulsator washing machine

A pulsator washing machine and cabinet technology, applied in the field of washing machines, can solve the problems of wasting washing water, failure to slow down the vibration of washing machines, and too large space, and achieve the effects of increasing washing volume, low noise, and preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

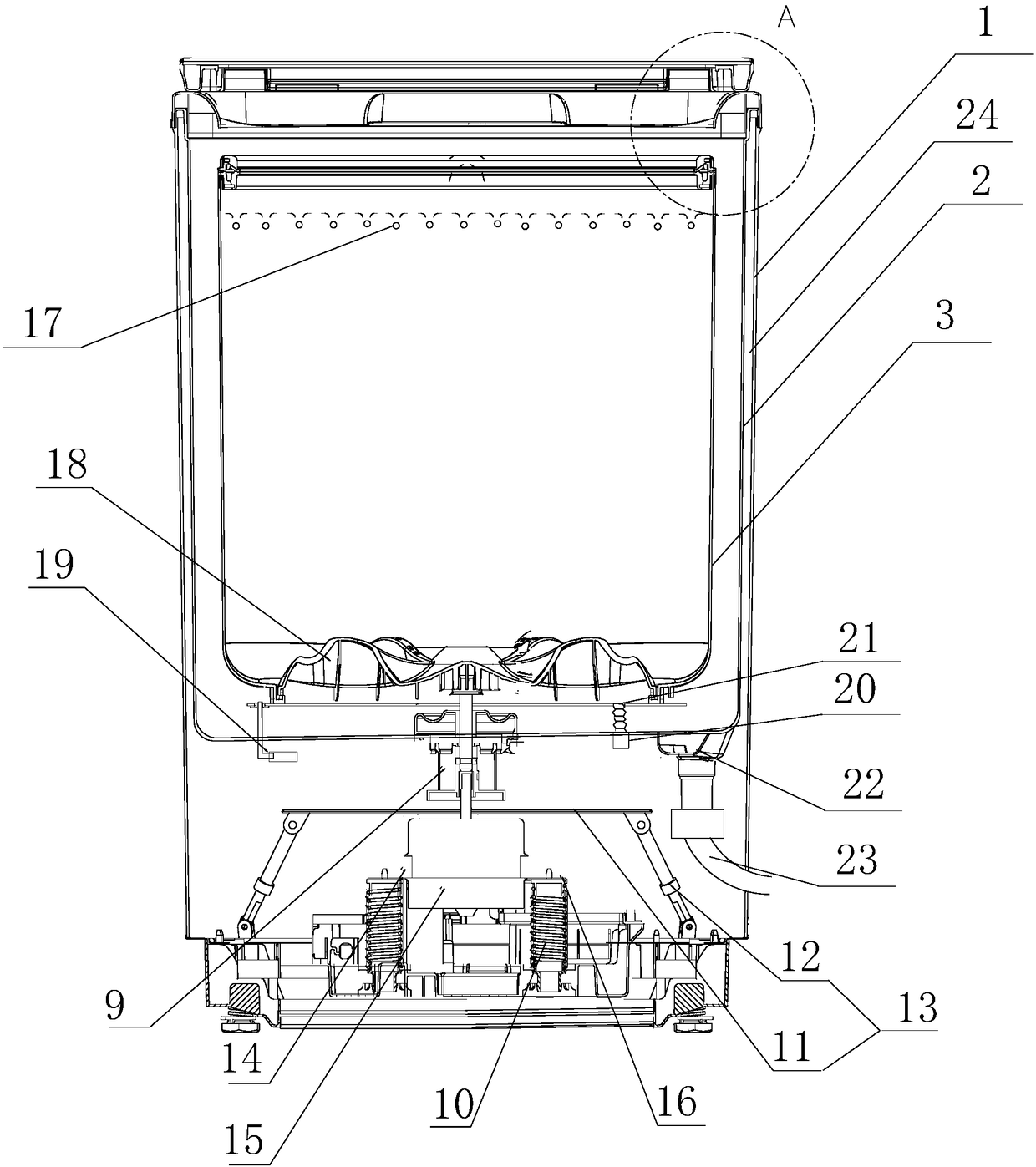

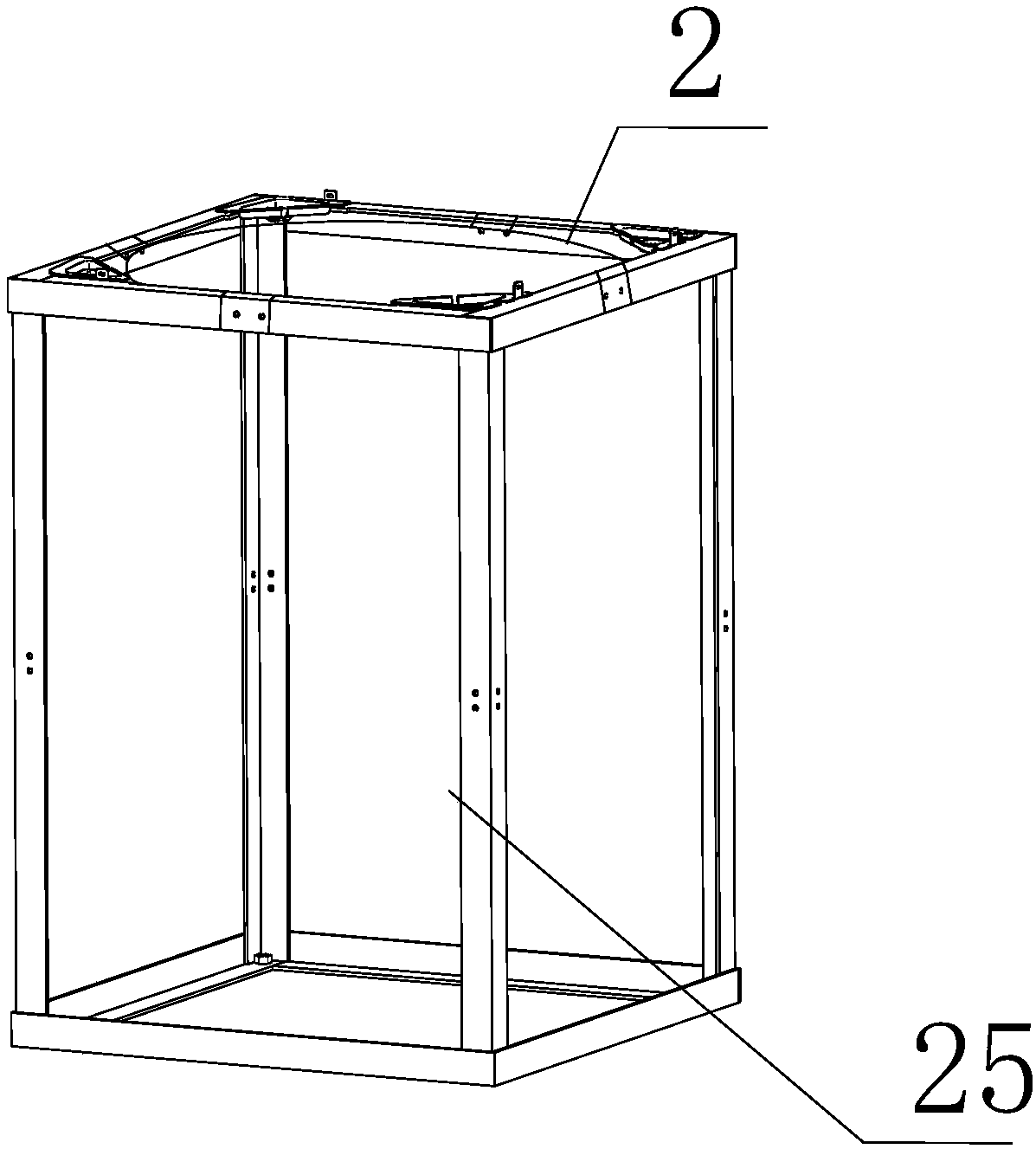

[0042] Such as Figure 1 to Figure 3As shown, the purpose of the present invention is to provide a pulsator washing machine, comprising a casing 1, an outer tub 2 and an inner tub 3, the outer tub 2 is placed in the casing 1, the inner tub 3 is installed in the outer tub 2, and the outer tub 2 The top of the box body 1 is fixedly connected, and the bottom of the inner and outer barrels 2 of the box body 1 is provided with a shock absorber for slowing down the vibration of the outer barrel 2.

[0043] The pulsator washing machine of the present invention comprises a casing 1, an outer tub 2 and an inner tub 3, the outer tub 2 is placed in the casing 1, the inner tub 3 is installed in the outer tub 2, and the three can be coaxially arranged. Between the box body 1 and the outer tub 2, the suspension rod damping assembly installed on the traditional pulsator washing machine is removed, and the upper part of the outer tub 2 is fixedly connected to the box body 1, and is installed ...

Embodiment 2

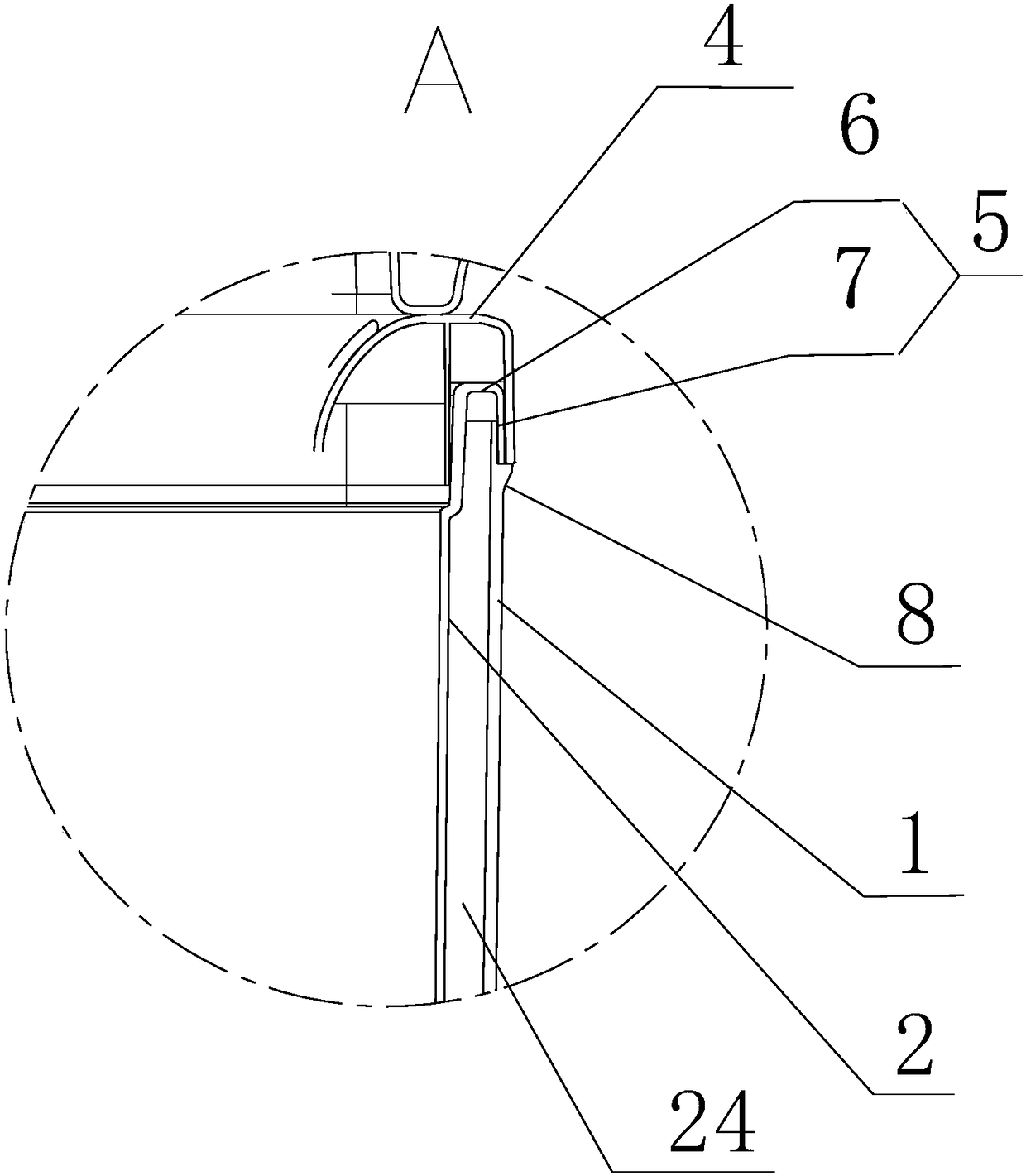

[0052] Such as Figure 1-3 As shown, the upper edge of the outer bucket 2 in this embodiment is turned outward to form a folded portion 5, and the folded portion 5 includes the upper edge of the outer bucket 2 extending horizontally to the box body 1, which is used to make the outer bucket 2 side The horizontal part 6 that the wall and the inner wall of the box body 1 are spaced apart.

[0053] The outer barrel 2 is arranged in the box body 1, and the horizontal portion 6 on the upper edge of the outer barrel 2 is formed by extending the upper edge of the outer barrel 2 horizontally toward the direction of the corresponding box body 1, and the horizontal portion 6 is placed laterally on the outer barrel 2 and the box body 1, a gap 24 between the outer barrel 2 and the box body 1 is formed, so as to prevent the outer barrel 2 from colliding with the box body 1.

[0054] To further define, the folded portion 5 also includes a vertical portion 7 formed by extending the horizonta...

Embodiment 3

[0062] Such as figure 1 As shown, this embodiment is a further limitation of Embodiment 1 or Embodiment 2. A motor 14 is provided at the bottom of the box body 1 , and a deceleration clutch device 9 is provided above the motor 14 . The deceleration clutch device 9 is fixed on the bottom of the outer barrel 2 . The output shaft of the deceleration clutch device 9 passes through the bottom of the inner tub 3 and is connected with the pulsator 18 of the washing machine.

[0063] A shock absorbing device for slowing down the vibration of the outer barrel 2 is provided below the inner and outer barrels 2 of the box body 1 . The damping device includes a first damping device 10 arranged on the motor 14 . The first damping device 10 is a damping spring, and the damping spring is arranged vertically. One end of the damping spring is fixedly connected to the stator 15 of the motor 14 , and the other end is fixedly connected to the bottom wall of the casing 1 .

[0064] When the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com