Washing machine and driving system thereof

A drive system and washing machine technology, applied in the field of washing machines, can solve the problems of complex installation structure and difficulty in ensuring the air gap between the stator and rotor of the motor, and achieve the effects of increasing washing capacity, improving clutch reliability, and compact axial dimension design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

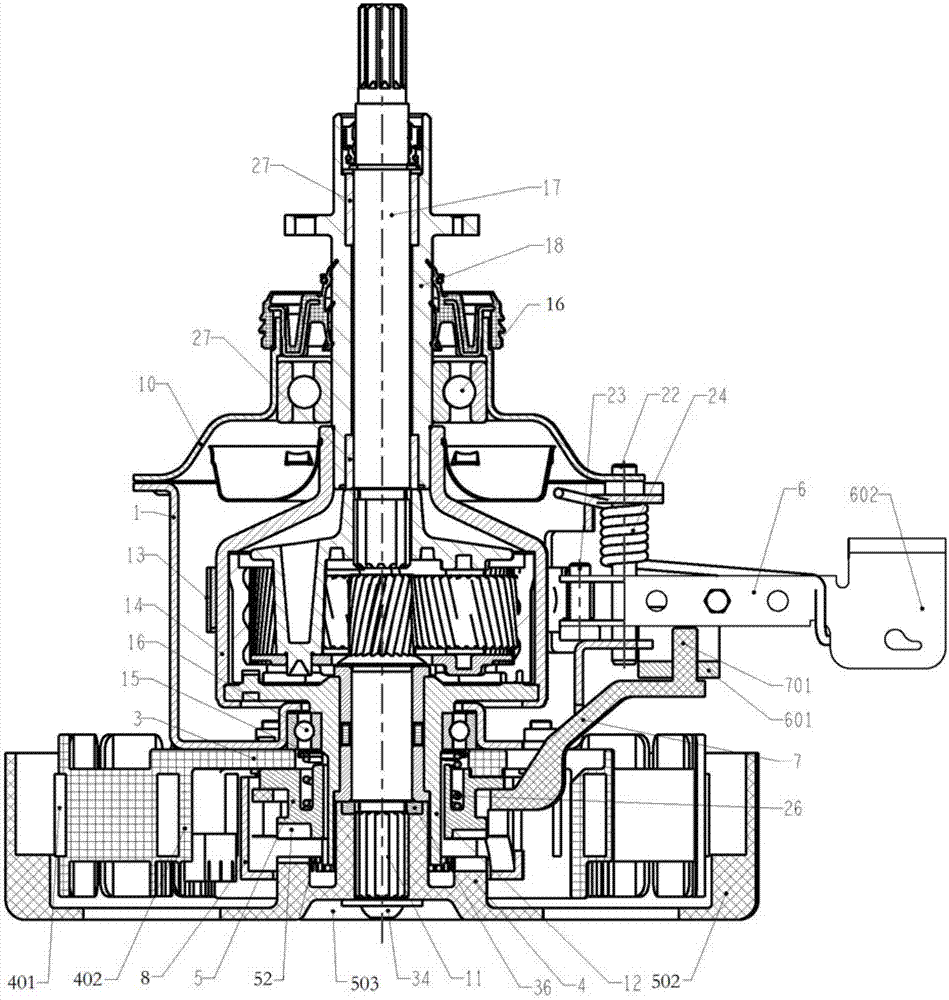

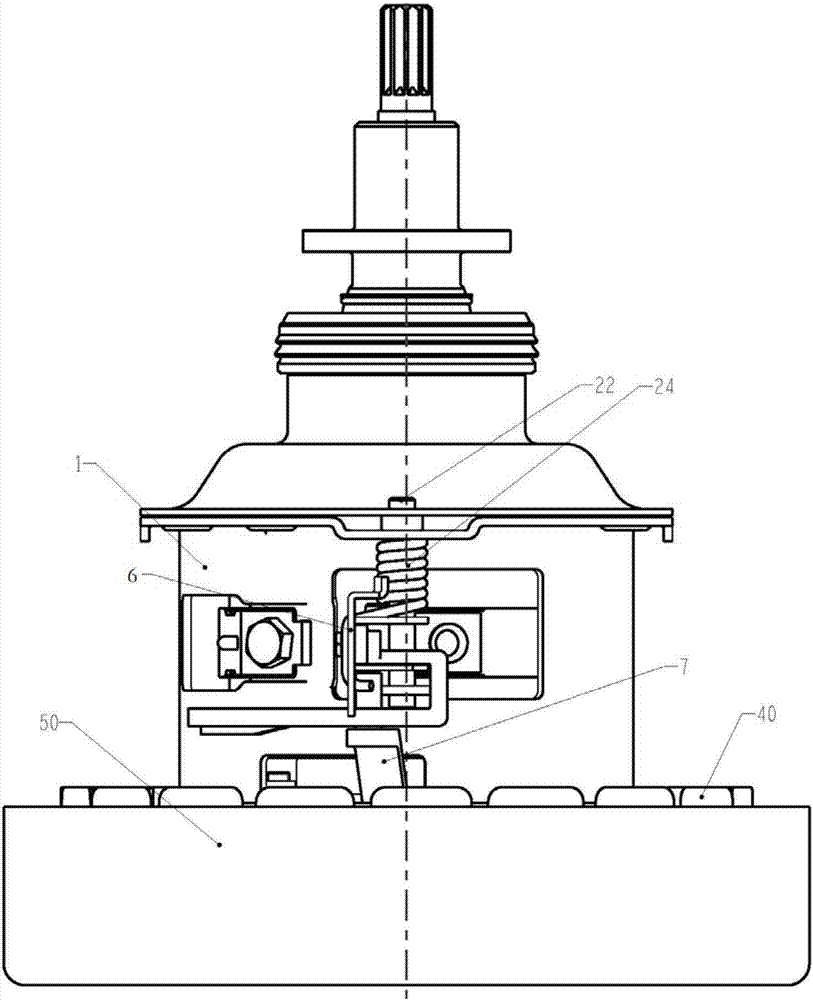

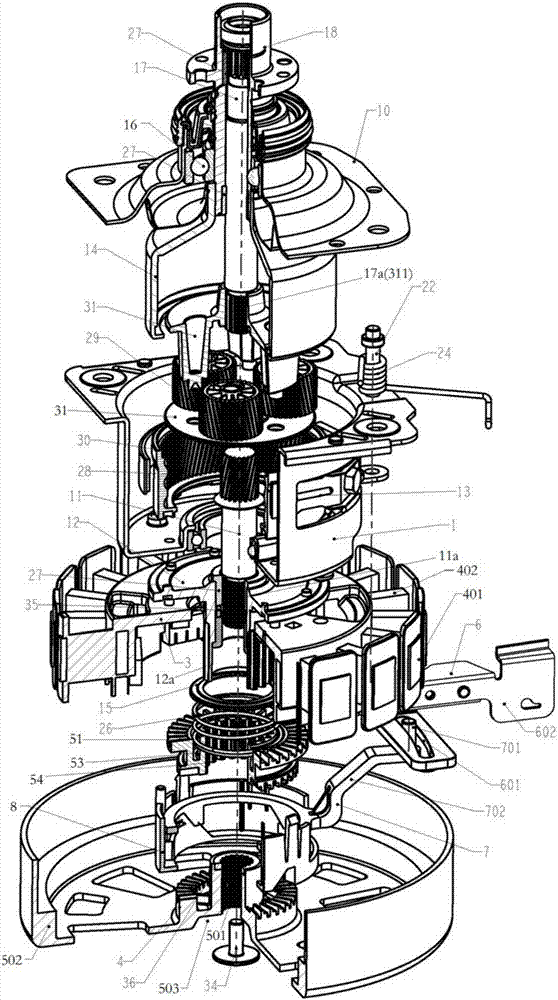

[0038] Such as figure 1As shown in , the driving mechanism of a washing machine according to a preferred embodiment of the present invention includes a motor assembly as a power source, a clutch mechanism for selectively engaging different parts of the motor assembly, a reduction transmission assembly, and a clutch mechanism for operating Action clutch control mechanism. in:

[0039] The motor assembly includes a stator portion 40 and a rotor portion 50 .

[0040] The clutch mechanism includes a clutch ring gear 5 and a clutch compression spring 26 that provides elastic force for the action of the clutch ring gear 5 .

[0041] The deceleration transmission assembly is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com