Washing machine deceleration clutch and washing machine

A deceleration clutch and washing machine technology, which is applied in the field of washing machines, can solve the problems of large space occupied by the deceleration clutch, smaller washing tub space, and increased volume of the washing machine, so as to reduce the space occupied by the axial direction, increase the washing capacity, and save The effect of axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

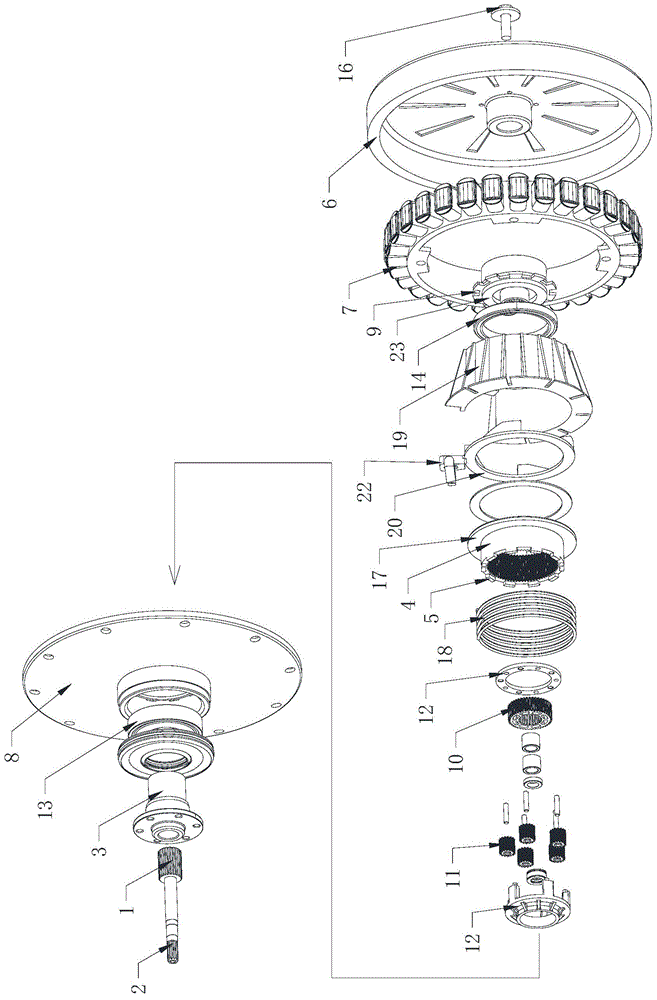

[0039] Such as Figure 1-2As shown, a deceleration clutch for a washing machine includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output shaft sleeve 3, and the clutch device includes a clutch pressure plate 20 and a clutch sleeve 21, and the clutch sleeve 21 Set on the peripheral periphery of the reduction gear, the projection on the straight line where the input shaft is located is at least partially overlapped, and the rotation of the clutch pressure plate 20 drives the clutch sleeve 21 to move axially; the reduction gear includes a reduction gear train and a reduction gear train The meshing ring gear; preferably, the reduction gear includes a planetary gear 11, and the clutch sleeve 21 is an inner ring gear that meshes with the planetary gear and can move axially; the clutch sleeve 21 moves axially Control the output shaft 2 and the output shaft sleeve 3 to realize the dehydration / washing working condition.

[0040] If the above-...

Embodiment 2

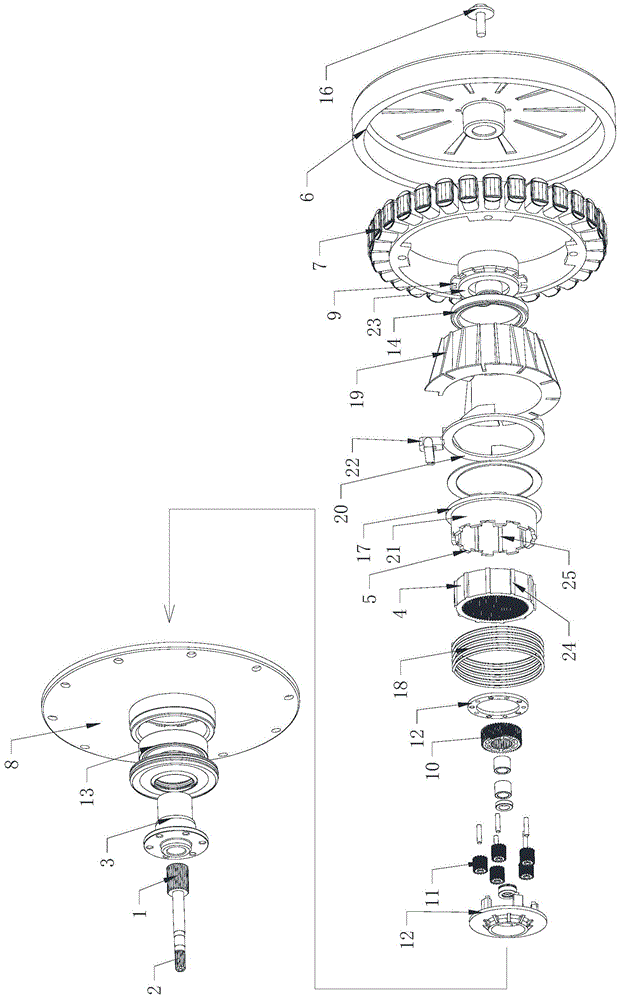

[0072] Such as image 3 , Figure 4 As shown, a washing machine deceleration clutch according to the present invention includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output sleeve 3, and the clutch device includes a clutch pressure plate 20 and a clutch sleeve 21, The clutch bushing 21 is set on the peripheral periphery of the reduction gear, and the rotation of the clutch pressure plate 20 drives the clutch bushing 21 to move axially; the reduction gear includes a planetary gear 11, and the clutch bushing 21 is for intermeshing with the planetary gear and can An axially movable ring gear, or the deceleration device includes a planetary gear 11 and an inner ring gear 4 that mesh with each other, and the clutch sleeve 21 and the ring gear 4 are engaged with each other and can move axially; the clutch sleeve 21 Axial movement controls the output shaft 2 and the output shaft sleeve 3 to realize the dehydration / washing working conditi...

Embodiment 3

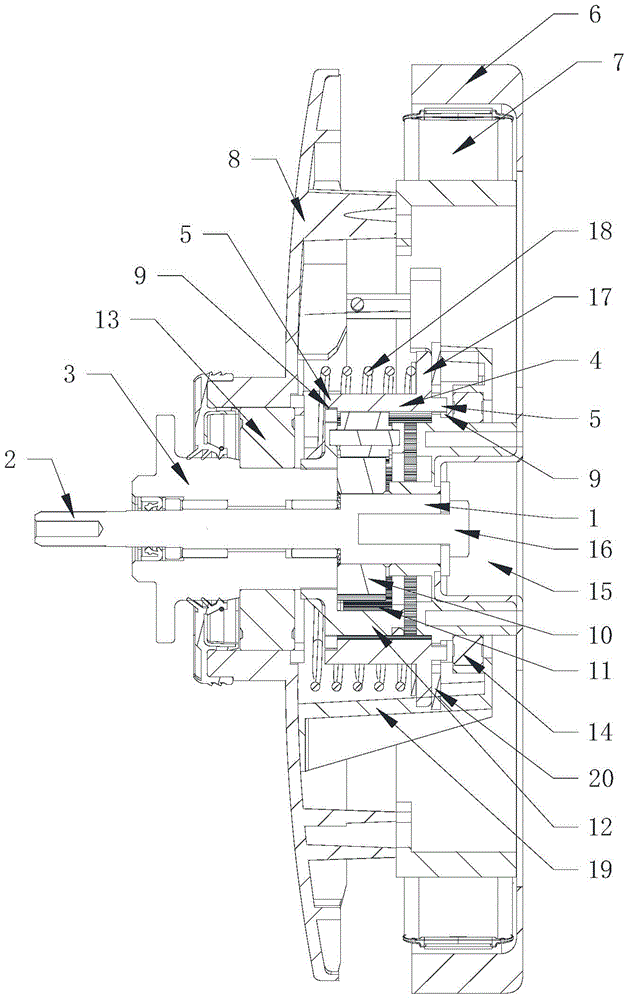

[0105] Such as Figure 1-7 As shown, a deceleration clutch for a washing machine includes: an input shaft 1, a deceleration device, a clutch device, an output shaft 2 and an output shaft sleeve 3, and the clutch device includes a clutch pressure plate 20 and a clutch sleeve 21, and the clutch sleeve 21 Installed on the periphery of the reduction gear, the clutch pressure plate 20 drives the clutch sleeve 21 to move axially to control the output shaft 2 and the output sleeve 3 to achieve dehydration / washing conditions; the clutch pressure plate 20 is connected to a drive motor, The driving motor drives the clutch pressure plate 20 to rotate.

[0106] The deceleration clutch of the washing machine of the present invention adopts the rotational movement of the clutch pressure plate 20 to drive the clutch shaft sleeve 21 to move axially to realize clutching. Since the clutch pressure plate 20 is used to rotate and drive the clutch mode, and the clutch sleeve 21 is set on the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com