Inner drum assembly for washing machine

A washing machine and component technology, applied in the field of washing machines, can solve the problems of large ineffective space and achieve the effects of reducing ineffective space, expanding washing capacity, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

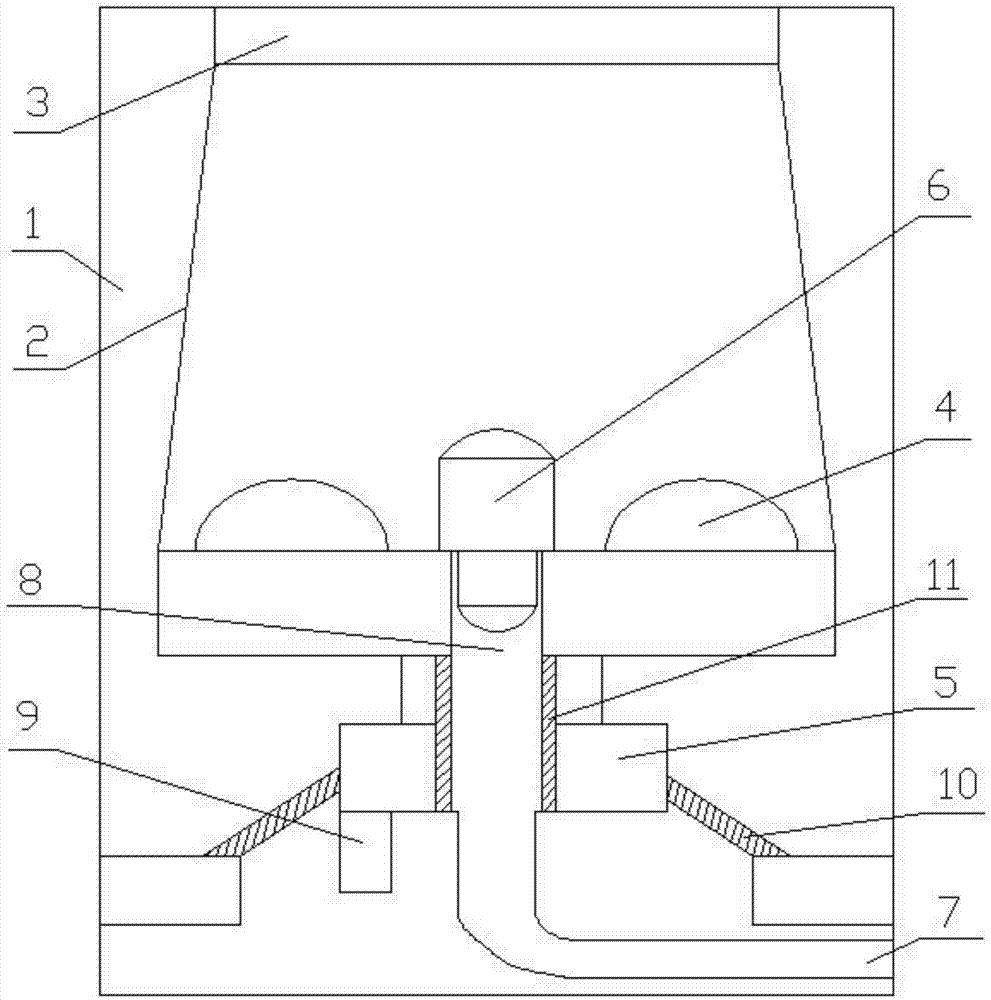

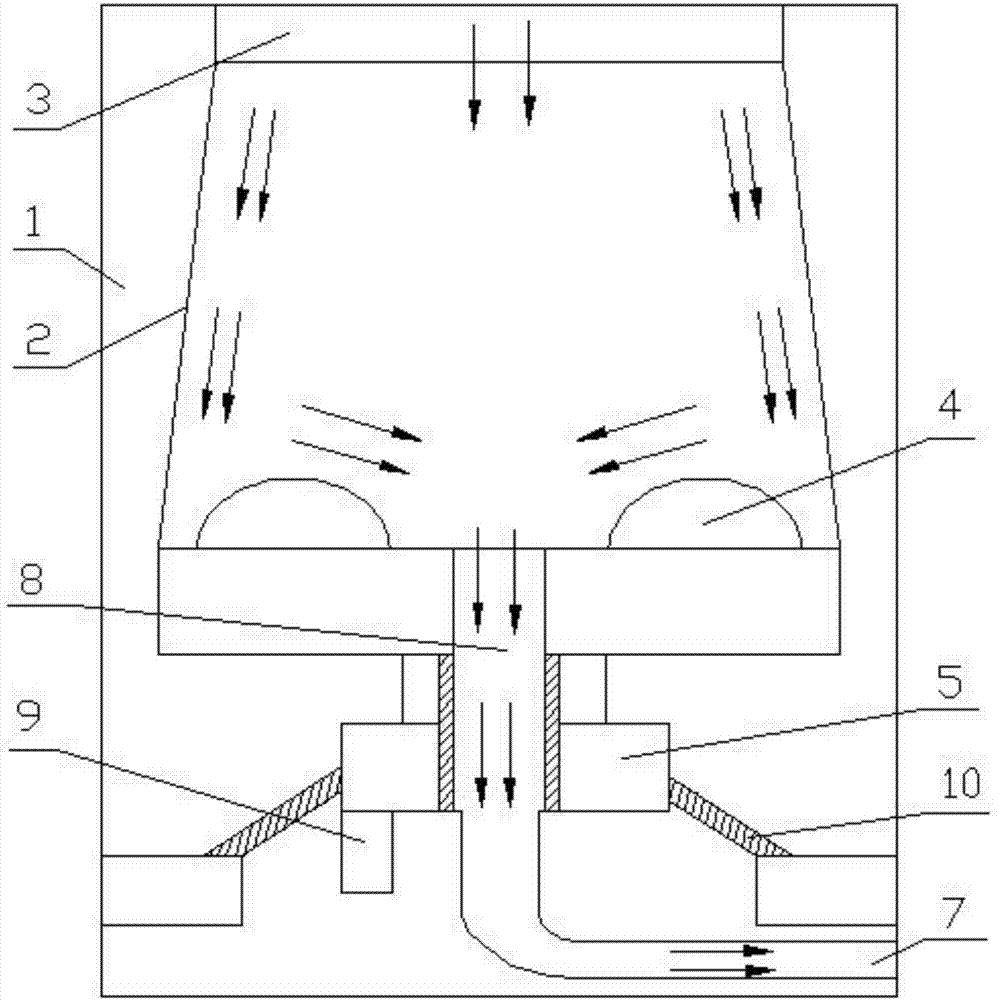

[0022] The present invention is described further below:

[0023] to combine figure 1 , figure 2 : An inner tub assembly of a washing machine, comprising a casing 1, an inner tub 2, a balance ring 3, a pulsator 4, a motor 5, a centrifugal drain valve 6, and a drain pipe 7. The top of inner barrel 2 is connected with casing 1 by gimbal 3, and pulsator 4 is positioned at the bottom of inner barrel 2, and motor 5 is connected with pulsator 4 transmission, drives pulsator 4 (inner barrel) to rotate.

[0024] The diameter of the bottom of the inner barrel 2 is greater than the diameter of the top, and the center of the bottom of the inner barrel 2 is provided with a drain port 8. If the drain port 8 is installed in a non-central position, the drainage effect will not be optimal; the centrifugal drain valve 6 is installed at the drain port 8 superior.

[0025] The barrel wall of the inner barrel 2 has no conventional drainage holes. When dehydrating, the water contained in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com