Thermal power generation system based on high-moisture lignite pre-drying upgrading and recovering technology

A thermal power generation and power generation system technology, which is applied in the direction of steam recovery, drying solid materials, heating to dry solid materials, etc., can solve the problems of bulky boiler body, large greenhouse gas emissions, and large boiler auxiliary equipment capacity, etc., to achieve investment Effects of reducing, reducing exhaust steam, and reducing equipment power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

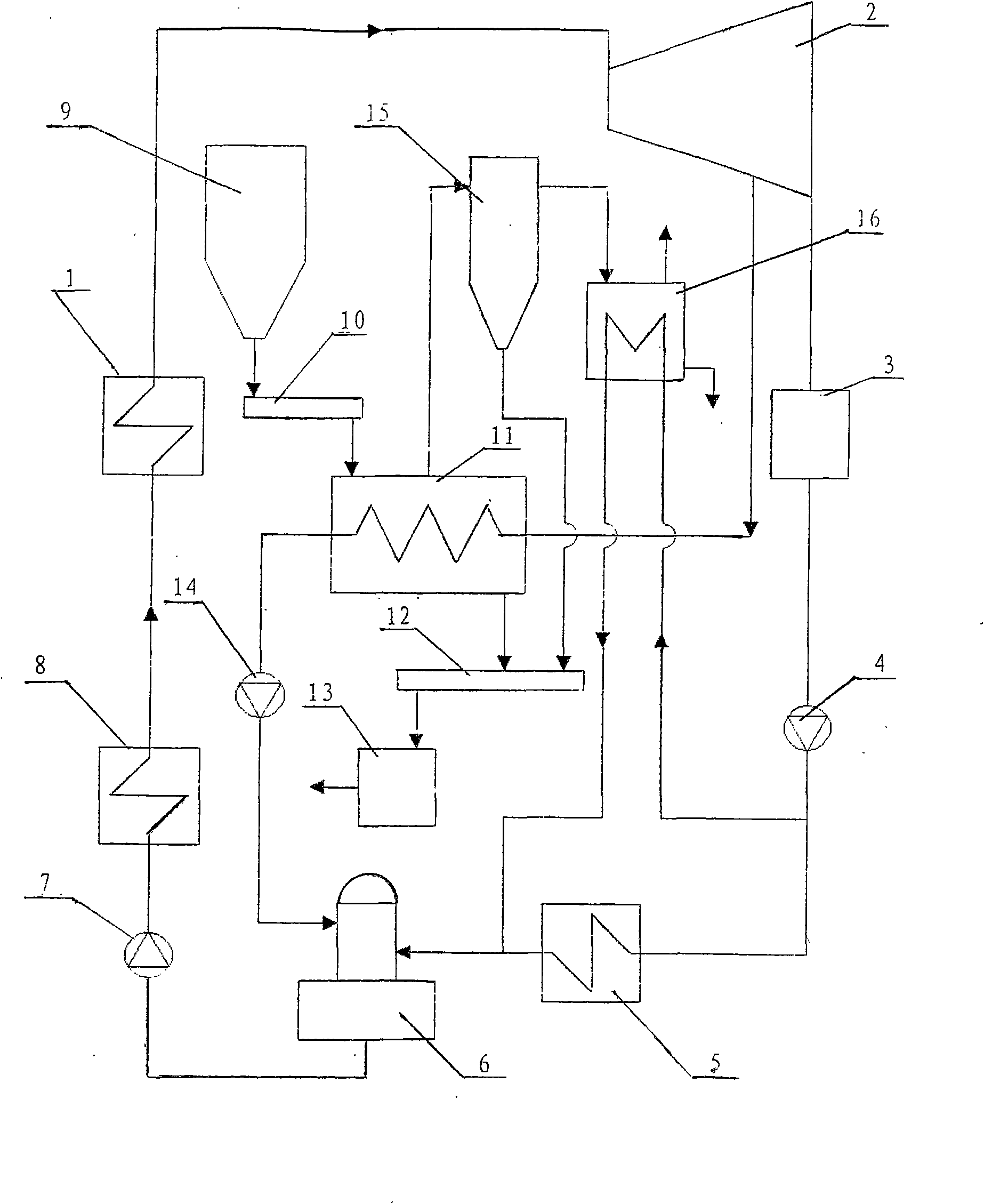

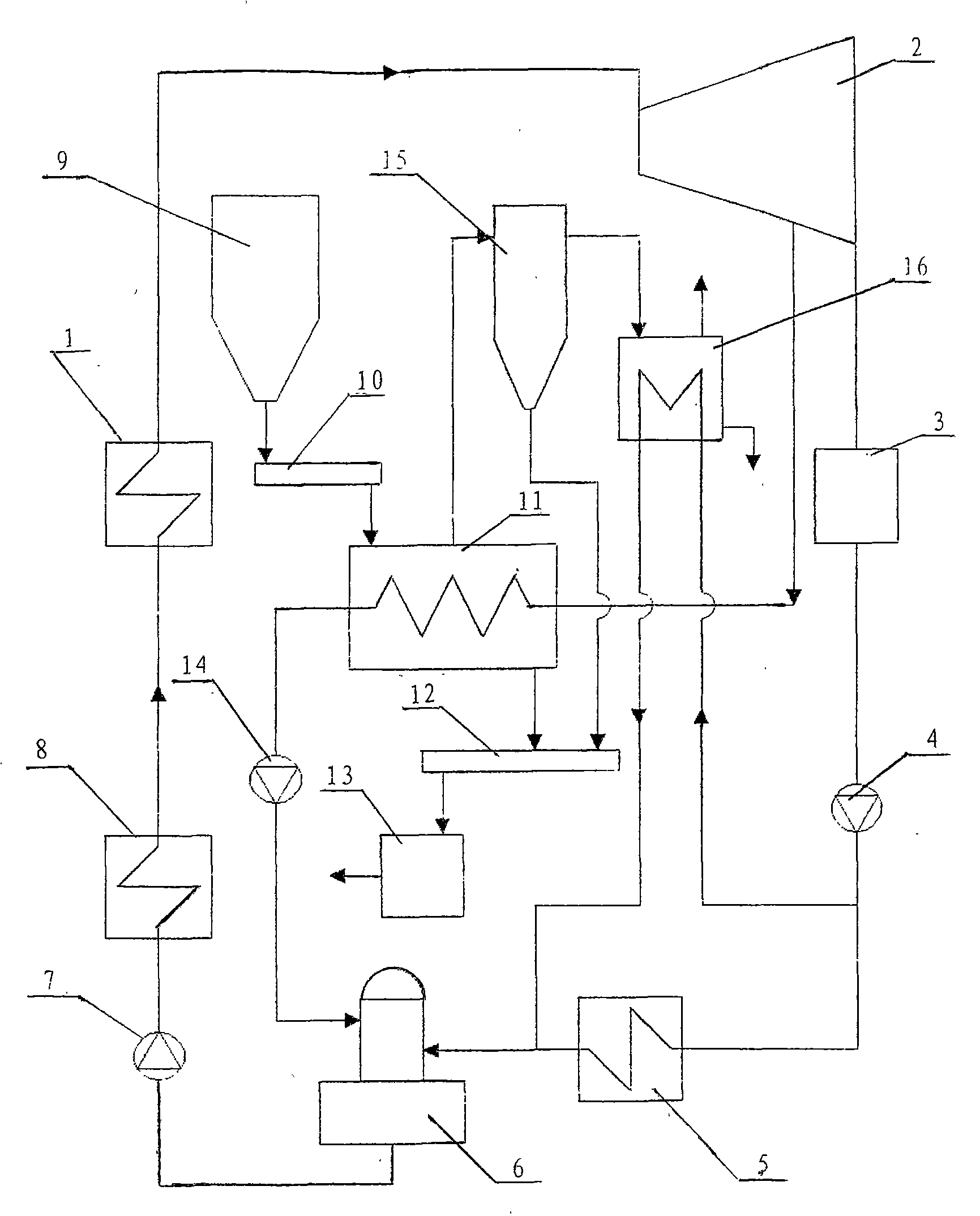

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0018] The steam outlet of the boiler (1) is connected to the steam turbine (2) through the main steam pipeline, the exhaust steam of the steam turbine is connected to the condenser (3), the condensate outlet of the condenser is connected to the condensate pump (4), and the low pressure heater ( 5) Connect the high-pressure water supply pipeline to the deaerator (6), the water supply outlet of the deaerator in sequence to the feed water pump (7), the high-pressure heater (8) to the boiler feed water inlet to form a conventional thermodynamic cycle system for thermal power generation; the steam turbine extracts steam at low pressure The port is connected to the steam inlet of the drying device, the condensate port of the drying device is connected to the drain pump, and the drain pump is connected to the deaerator; the wet coal feeder is connected to the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com