Fabric article treating system

a technology of fabric article and treatment system, which is applied in the direction of textile dry-cleaning apparatus, detergent compounding agent, sustainable building, etc., can solve the problems of ineffective or economical delivery of detergent actives or rinse actives, inability to effectively partition out actives from aqueous wash medium and onto fabric surface, and loss of most actives in wash and rinse fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

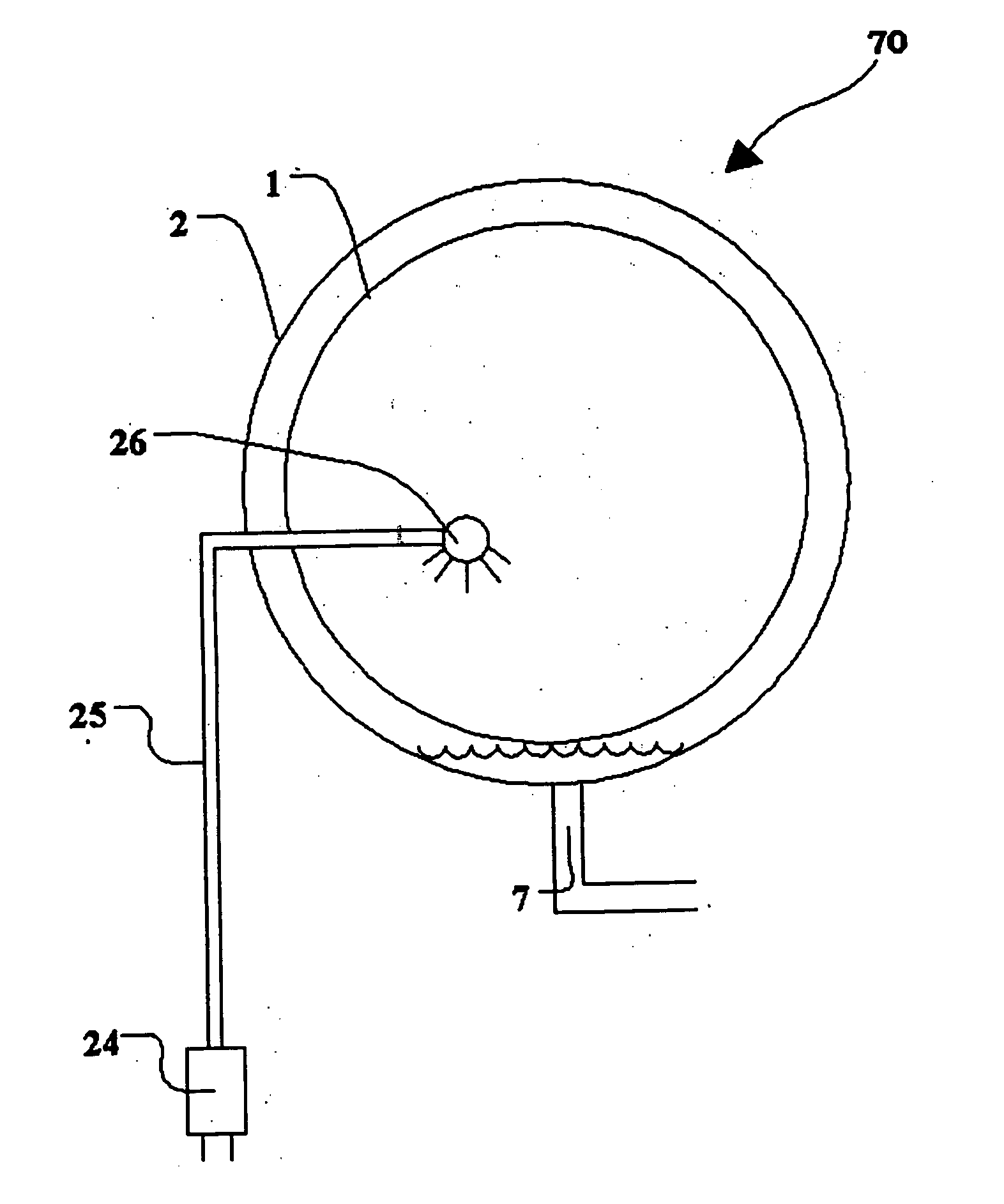

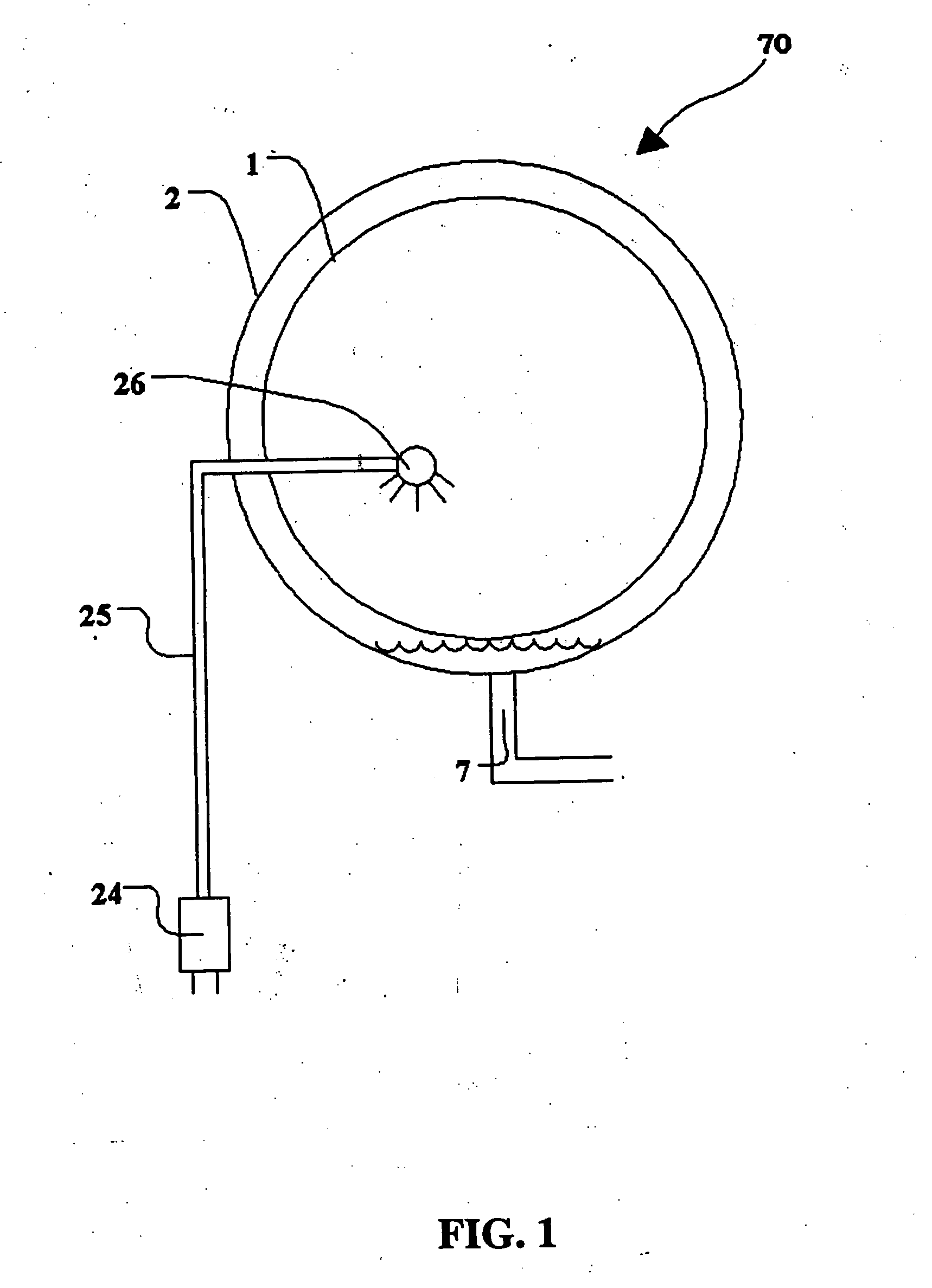

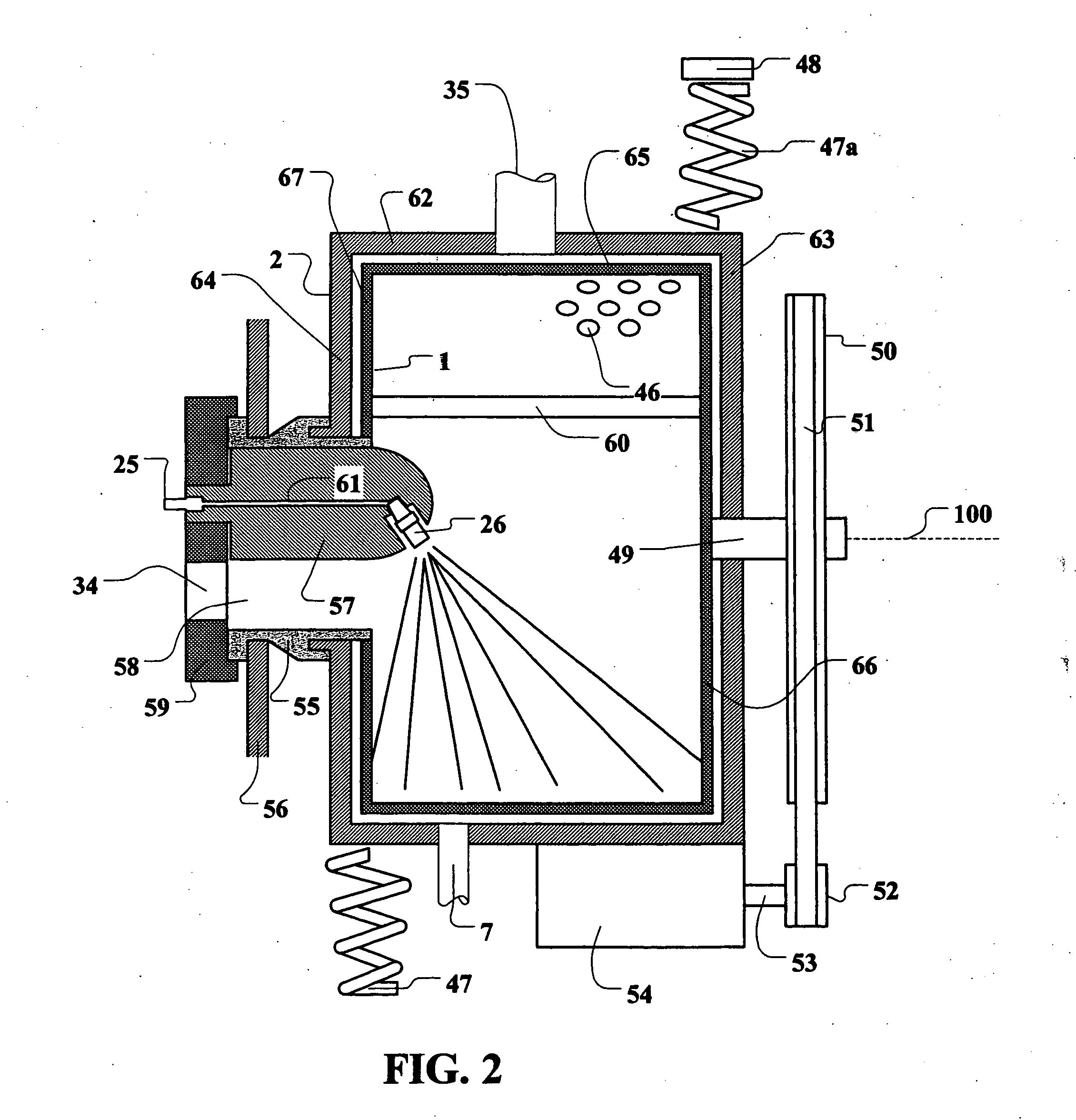

Image

Examples

example 1

place a load of fabric articles (such as garments) into a horizontal axis automatic washing machine; begin tumbling the fabric articles at a speed capable of generating a force of about 1 G; spray / mist a wash liquor comprising 75 g of a detergent composition diluted in enough water such that the resulting liquor to fabric ratio is between 0.25:1 to 2:1 onto the tumbling clothes according to droplet size and other spray / mist requirements described above; continue tumbling for a total tumbling time of about 15 minutes; rapidly add (e.g., by pumping at a rate of 1.87 liters per minute) fresh water to the tumbling load such that the resulting liquor to fabric ratio is about 15:1; high-speed spin to remove all excess liquor; resume tumbling and spray / mist a finishing composition comprising 50 g of finishing actives diluted in enough water such that the resulting liquor to fabric ratio is between about 2:1 to 5:1 onto the tumbling clothes according to the spray / mist requirements of...

example 2

place a load of garments into the horizontal axis machine; begin tumbling the fabric articles at a speed capable of generating a force of about 0.5 G to about 3 G; add fresh water and spray / mist 75 g of detergent composition onto the tumbling clothes such that the resulting liquor to fabric ratio is about 7:1; continue tumbling for a total tumbling time of 15 minutes while heat is applied to partially remove water from the applied liquor such that the remaining liquor to fabric ratio is about 0.75:1 or less; rapidly add fresh water to the tumbling load such that the resulting liquor to fabric ratio is about 15:1; high-speed spin to remove of at least all free liquor; rapidly add fresh water to the tumbling load such that the resulting liquor to fabric ratio is about 7:1; high-speed spin to remove of at least all free liquor; resume tumbling and spray a rinse liquor comprising about 30-50 g of a rinse active and enough water such that the resulting liquor to fabric ratio is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| average molecular weight | aaaaa | aaaaa |

| average molecular weight | aaaaa | aaaaa |

| period of time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com