Washing machine outer barrel and washing machine

A washing machine and outer tub technology, applied in the field of washing machines, can solve the problems of reducing the space between the shell and the outer tub, reducing the washing capacity of the washing machine, limiting the washing capacity of the washing machine, etc., so as to save assembly space, avoid collision and interference, avoid impact and damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

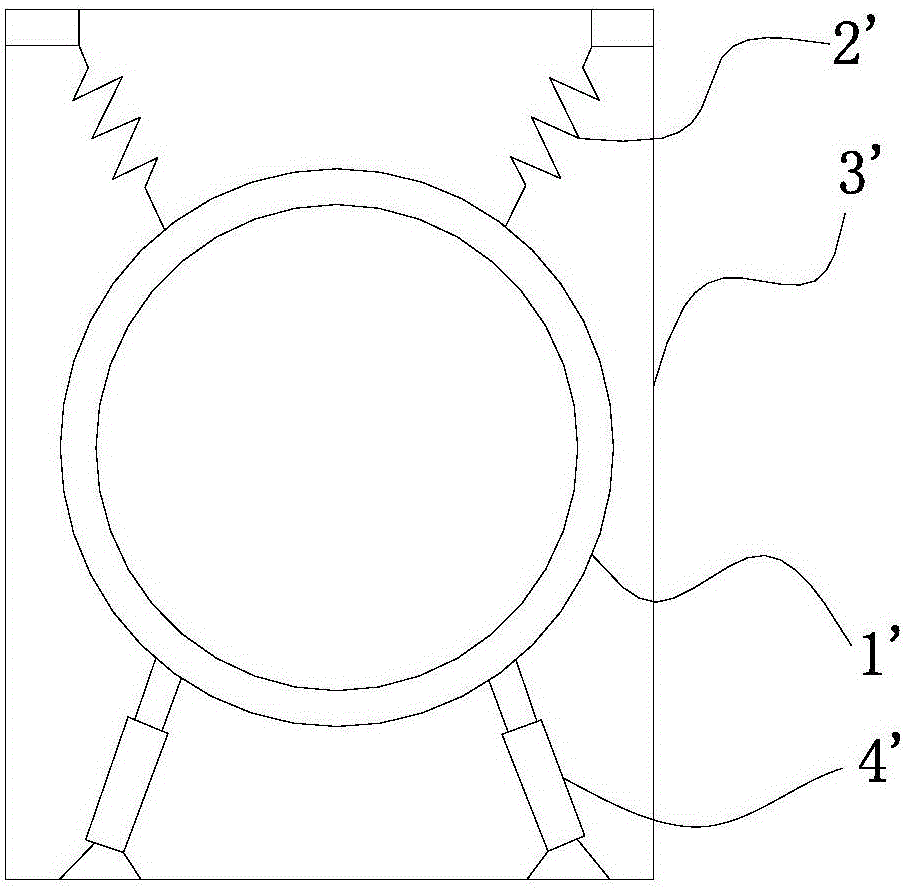

[0047] In the case of the existing washing machine with a fixed shell space, due to the increase in the diameter of the cylindrical outer cylinder, the outer cylinder collides with the shell during the working process to cause deformation of the shell, or the diameter of the outer cylinder is reduced to prevent the outer cylinder from colliding with the shell during the working process of the washing machine As a result of problems such as reduced washing capacity of the washing machine, this embodiment proposes a new outer cylinder of the washing machine.

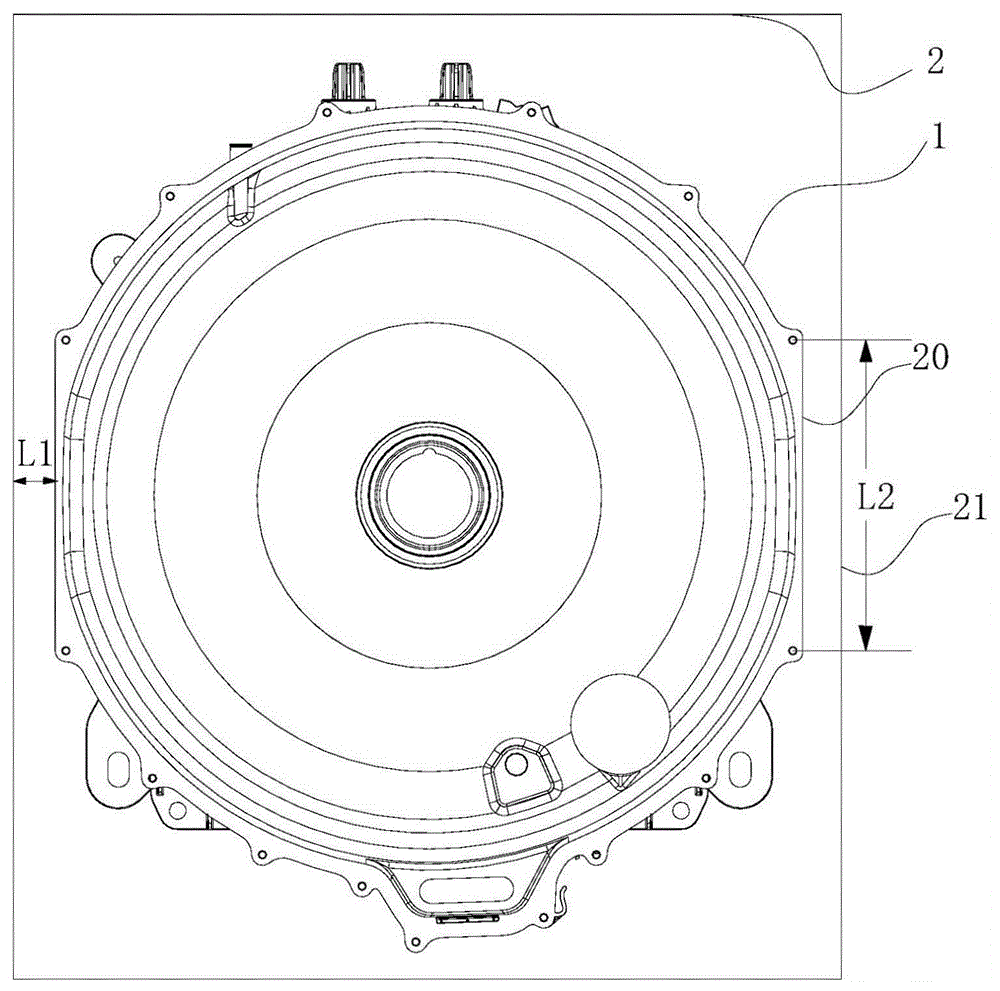

[0048] figure 2 It is a structural schematic diagram of the outer tub of the washing machine provided in this embodiment. Such as figure 2 As shown, the two opposite side walls of the washing machine outer tub 1 in this embodiment form a non-circular surface that avoids collision with the side plates 21 of the housing 2, that is, the outer drum of the washing machine forms a cylinder wall close to the side plates 21 on ...

Embodiment 2

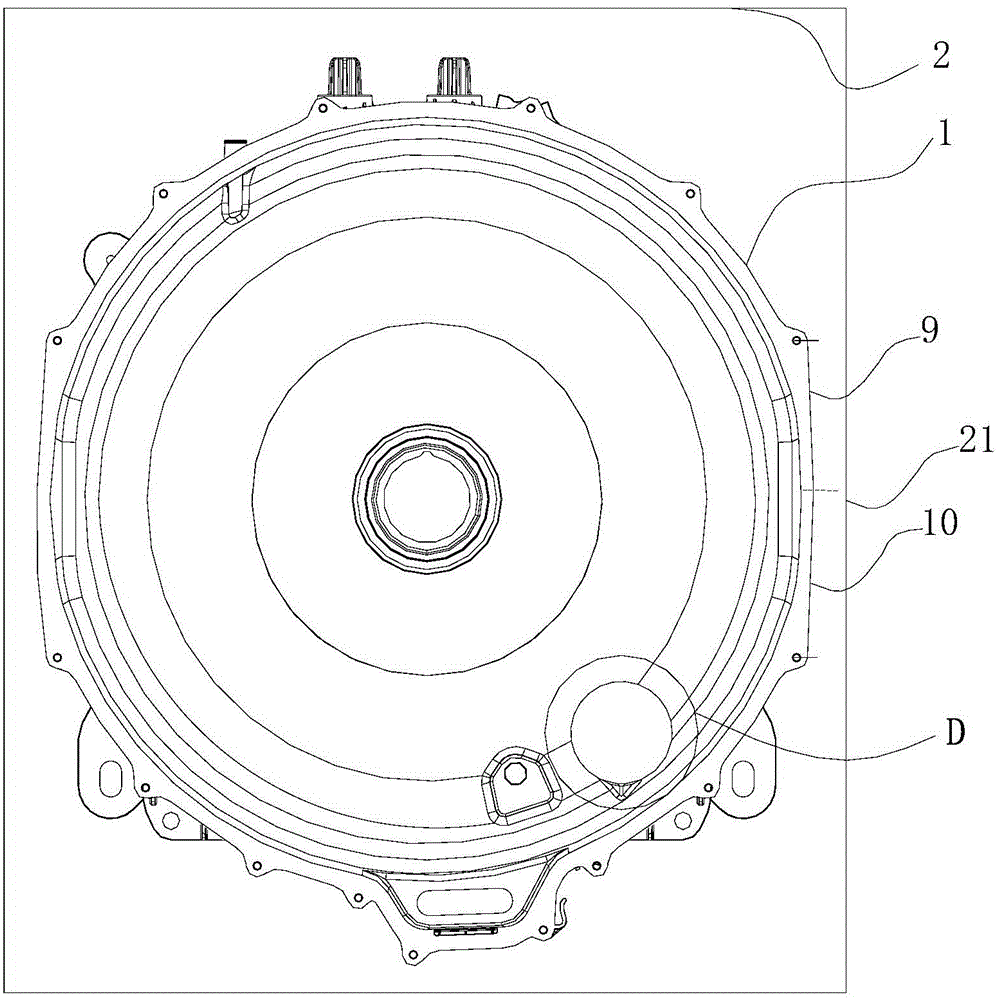

[0053] image 3 A schematic structural view of the outer tub of a washing machine provided in this embodiment, as shown in image 3 As shown, the difference between the structure of the washing machine tub described in this embodiment and the structure of the washing machine tub described in Embodiment 1 is:

[0054] The two opposite side walls of the outer tub of the washing machine 1 form a non-circular surface that avoids collision with the side plate 21 of the housing 2. It is a curved surface spliced by curved curved surfaces with different curvatures. The curved surfaces are arc surfaces protruding toward the side plate 21 of the housing 2 .

[0055] The reason why the non-circular surface is designed as the above-mentioned shape instead of a curved surface spliced by curved surfaces with different curvatures and concave toward the center of the outer cylinder 1 is mainly due to two reasons: one is to increase the diameter of the outer cylinder and the inner cylinde...

Embodiment 3

[0060] Figure 5 A schematic structural view of the outer tub of a washing machine provided in this embodiment, as shown in Figure 5 As shown, on the basis of the structure of the outer tub of the washing machine as described in Embodiment 1 (that is, the tubing walls close to the side panels on both sides of the washing machine casing form a plane to avoid collision with the side panels of the casing), the tub 1 of this embodiment The outer side wall 11 and the outer bottom wall 12 are provided with mesh reinforcing ribs.

[0061] In this embodiment, preferably, the mesh reinforcing ribs arranged on the outer wall 11 of the outer cylinder 1 consist of a plurality of radial ring reinforcing ribs 5 perpendicular to the axis of the cylinder and a plurality of axial reinforcing ribs parallel to the axis of the cylinder. 6 are fixedly connected. The reticular reinforcing ribs arranged on the outer bottom wall 12 of the outer cylinder 1 are fixedly connected by a plurality of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com