Variable-frequency simulated hand-wash motor reduction clutch and washing machine

A clutch device and hand rubbing technology, applied in the field of washing machines, can solve the problems of being unsuitable for mass production, complicated installation and connection, and many main parts connecting parts, etc., and achieve the effects of being suitable for popularization, increasing washing capacity, and compact installation structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

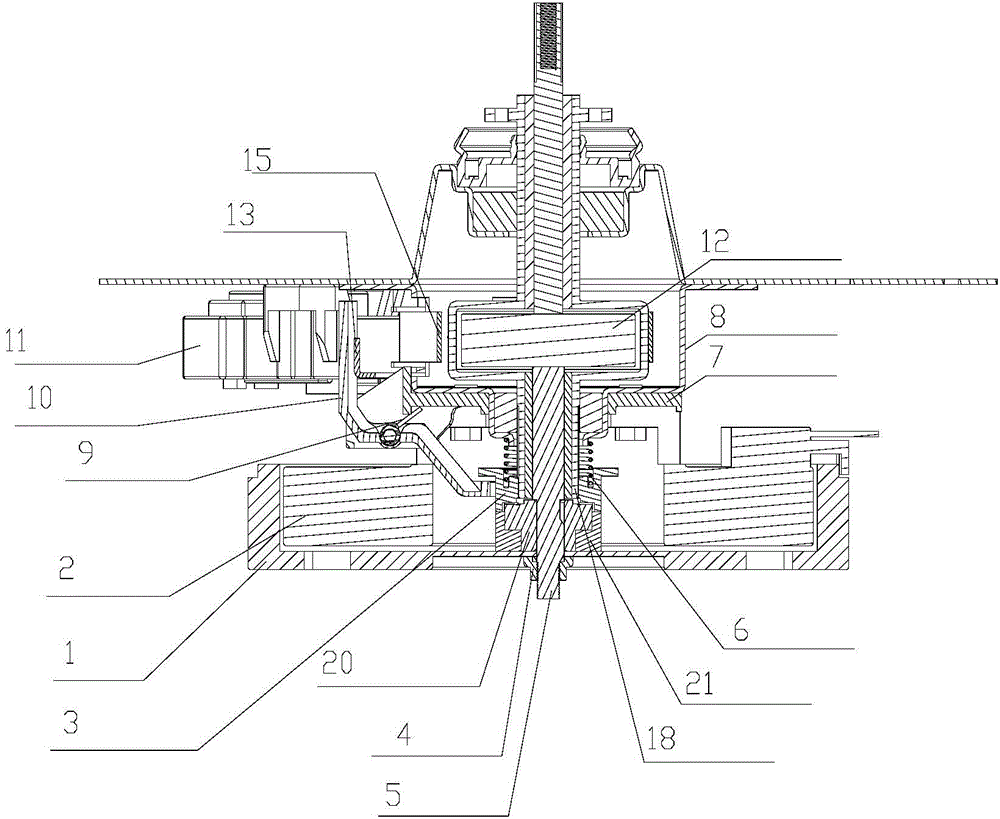

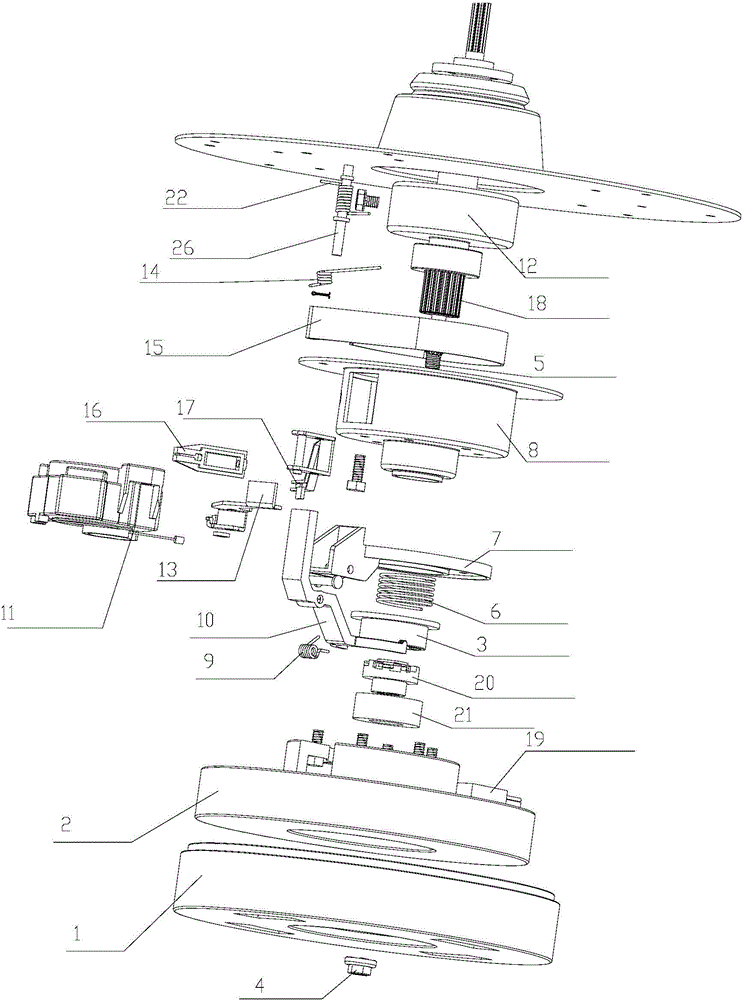

[0034] Such as figure 1 and figure 2 As shown, in this embodiment, a frequency conversion hand rub type motor deceleration clutch device is introduced, including: an input shaft 5, a motor rotor 1 fixedly connected with the input shaft 5, and a dehydration shaft rotating with it is installed on the input shaft 5 Sleeve 20, the dehydration shaft sleeve 20 engages or disengages with the input shaft 5 through the clutch shaft sleeve 3 sliding up and down; the brake wheel 12 is connected with the dehydration shaft 18; under the action of the control device, the traction motor 11 Produce a displacement traction brake belt 5 and change from embracing the brake wheel 12 to loosen the brake wheel 12; the traction motor 11 produces a displacement again to make the clutch sleeve 3 and the input shaft 5 change from disengagement to engagement.

[0035] In this embodiment, the motor is composed of an outer rotor 1 motor composed of a rotor 1 connected to the input shaft 5 and a stator 2...

Embodiment 2

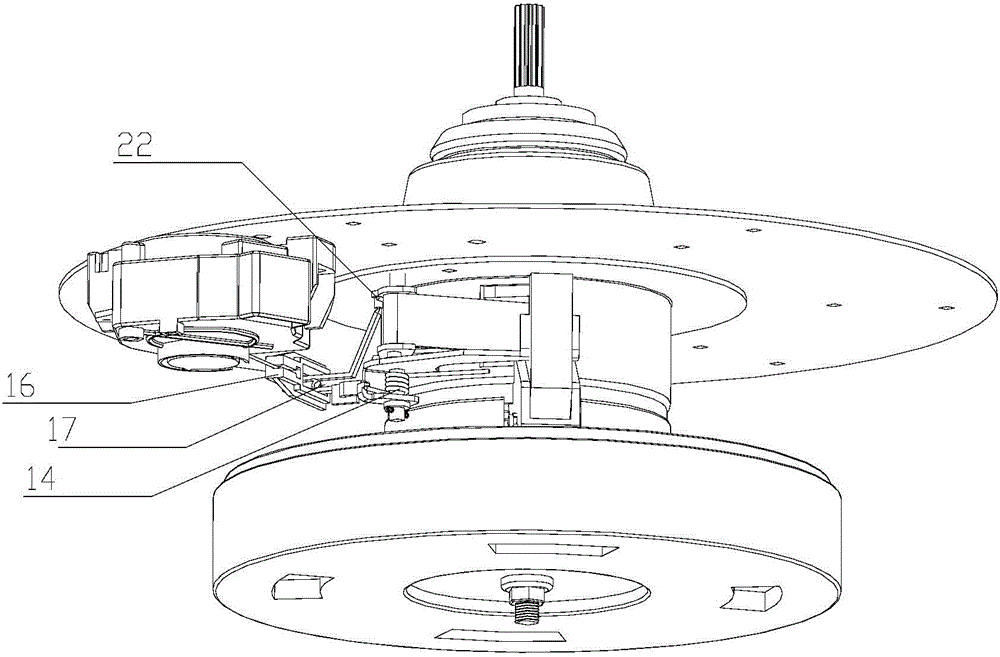

[0044] Such as figure 1 and figure 2 As shown, in this embodiment, the specific connection structure of the control device of the clutch device is as follows: one end of the connecting arm 16 is provided with a mounting groove fixedly connected with the displacement output end of the traction motor 11, and the other end is formed by a square through hole. ; The brake arm 17 is installed in the square through hole. The braking arm 17 is mounted on its lower part rotatably around the mounting pin shaft 26 , and the mounting pin shaft 26 is arranged on the housing 8 . One end of the brake arm 17 is connected to the connecting arm 16, and the other end is fixedly connected to the brake band 15 as the first output end. output. Described depression bar 13 is installed on its top around the mounting pin shaft 26 rotatably. One end of the pressing rod 13 is in contact with or out of the brake arm 17 , and the other end is in contact with the shift fork 10 . The shift fork 10 is ...

Embodiment 3

[0054] This embodiment introduces a control method of a frequency conversion hand rubbing motor deceleration clutch device, which includes: the traction motor drives the connecting arm to generate the first displacement, so that the brake band is separated from the brake wheel on the dehydration shaft, and the dehydration shaft It can rotate freely; it drives the connecting arm to produce a second displacement, so that the clutch sleeve and the dehydration sleeve are engaged, so that the dehydration shaft rotates together with the input shaft.

[0055] The deceleration clutch device of the frequency conversion hand rubbing motor includes three states: the first state, the brake band hugs the brake wheel, and the dehydration bushing is separated from the clutch bushing. At this time, the input shaft can follow the rotor of the motor Rotate, the dehydration shaft is locked and cannot rotate;

[0056] In the second state, the brake band releases the brake wheel, and the dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com