Fountain barrel washing machine having self-contained water tank

A drum washing machine, spray type technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of increasing the washing capacity of washing machines, the impact of thermal efficiency, and difficult maintenance, etc., to simplify the structure, improve thermal efficiency, Power Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

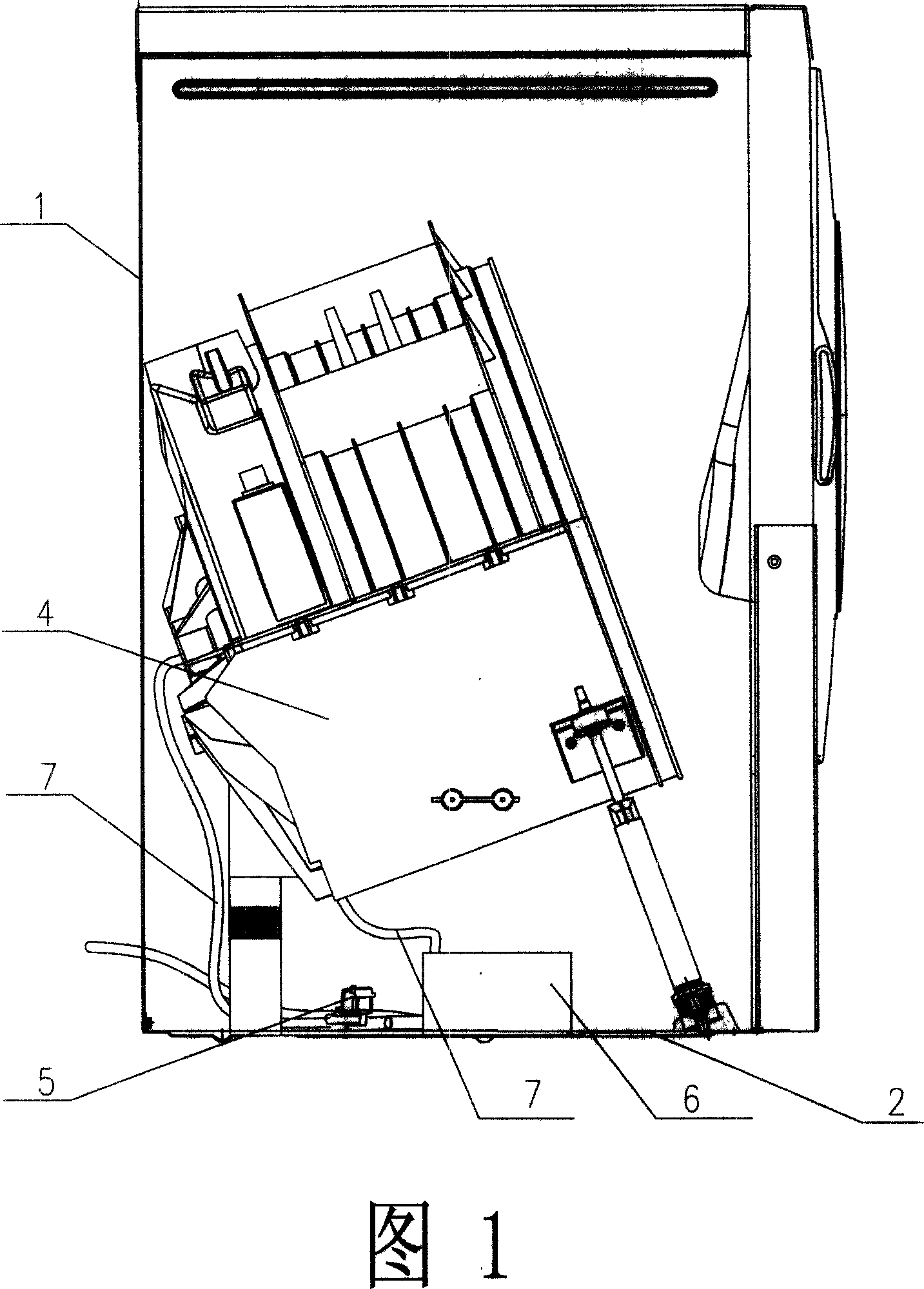

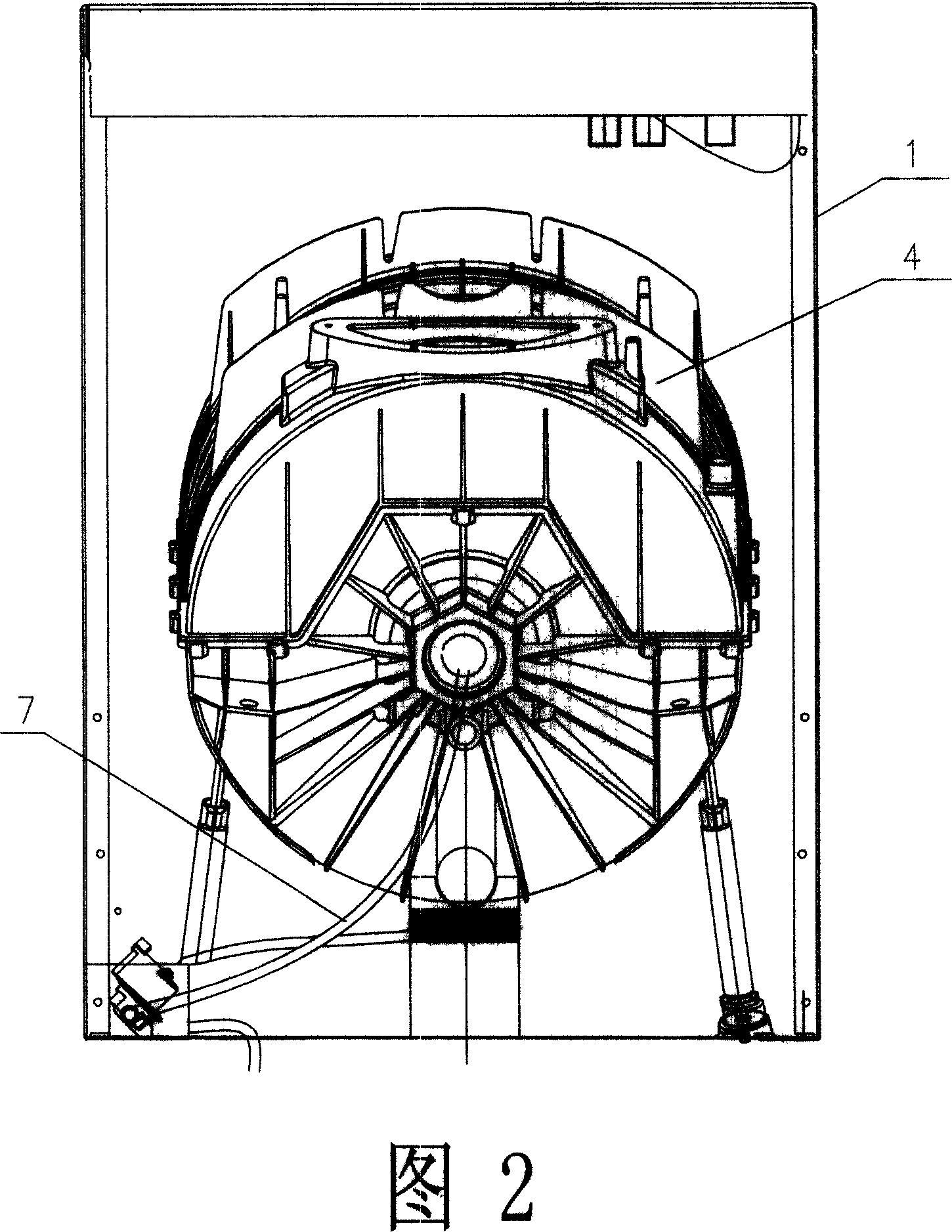

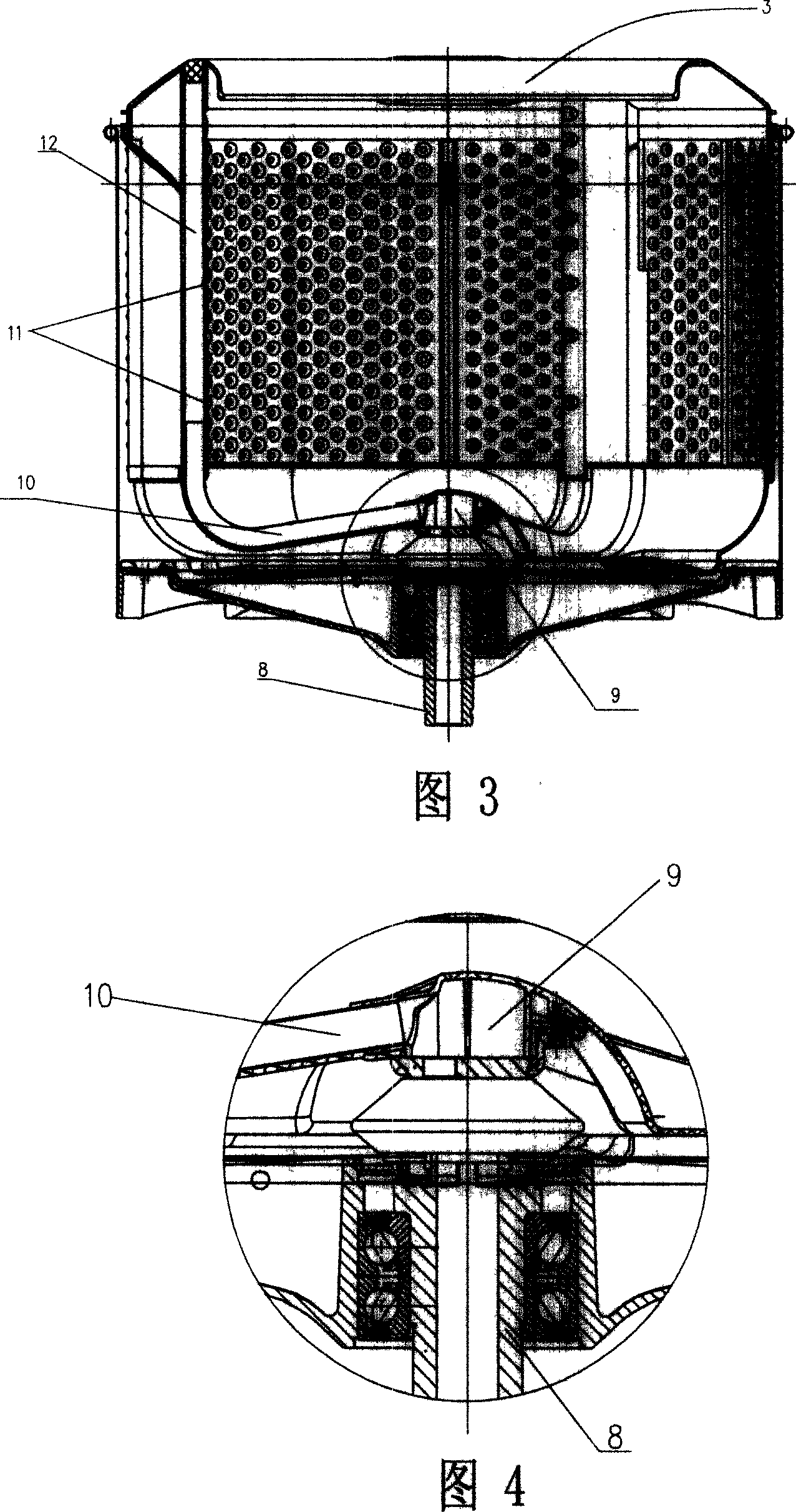

[0027]A spray type drum washing machine with a separate independent water tank shown in Figures 1 to 5, the drum washing machine is an inclined axis drum washing machine, which includes a washing machine shell 1, a bottom plate 2, a drum 3, a fixed outer tub 4, a shock absorber The supporting mechanism, the driving mechanism of the drum, the water circulation system and the water inlet / drainage mechanism of the washing machine, wherein the drum 3 is installed in the fixed outer tub 4, the central axis of the fixed outer tub 4 is oblique and horizontal, and the water circulation system includes circulating water connecting hoses 7. The spray mechanism, the water pump 5 and a separate water storage tank 6 separated from the fixed outer barrel 4. The water pump 5 is installed on the bottom plate 2. The water inlet / drainage mechanism of the washing machine is connected to the hose on the corresponding link of the water circulation system through the three-way valve Connected, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com