Efficient variable frequency motor speed reduction and clutch device and washing machine

A technology of clutch device and variable frequency motor, which is applied in the field of washing machines, can solve the problems of complex installation and connection, many connecting parts of the main body parts, and the efficiency of the motor is not greatly improved, so as to achieve increased washing capacity, simple structure, and reduced height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

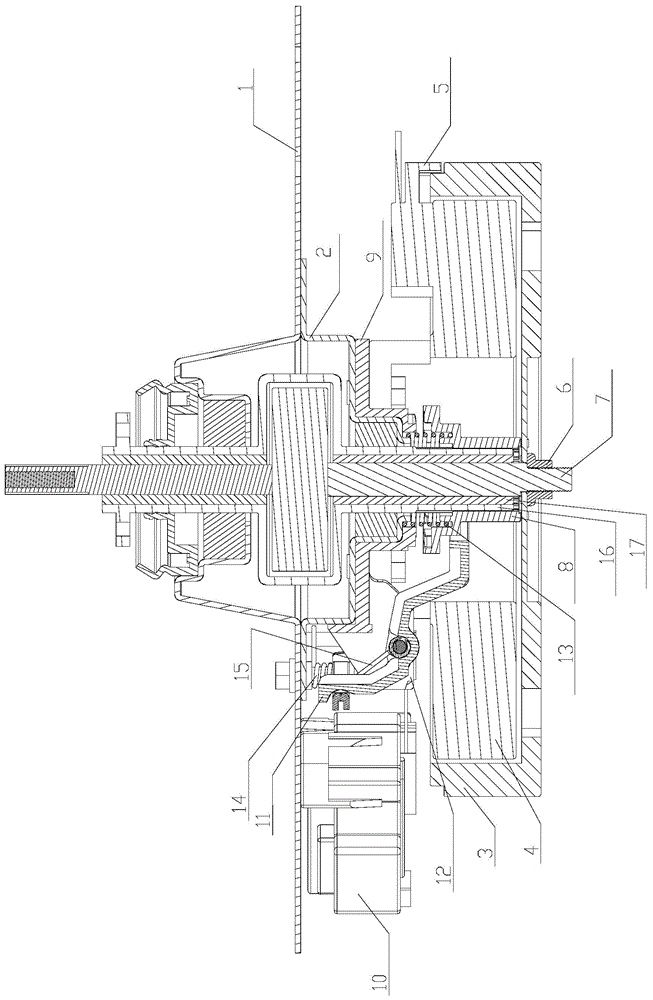

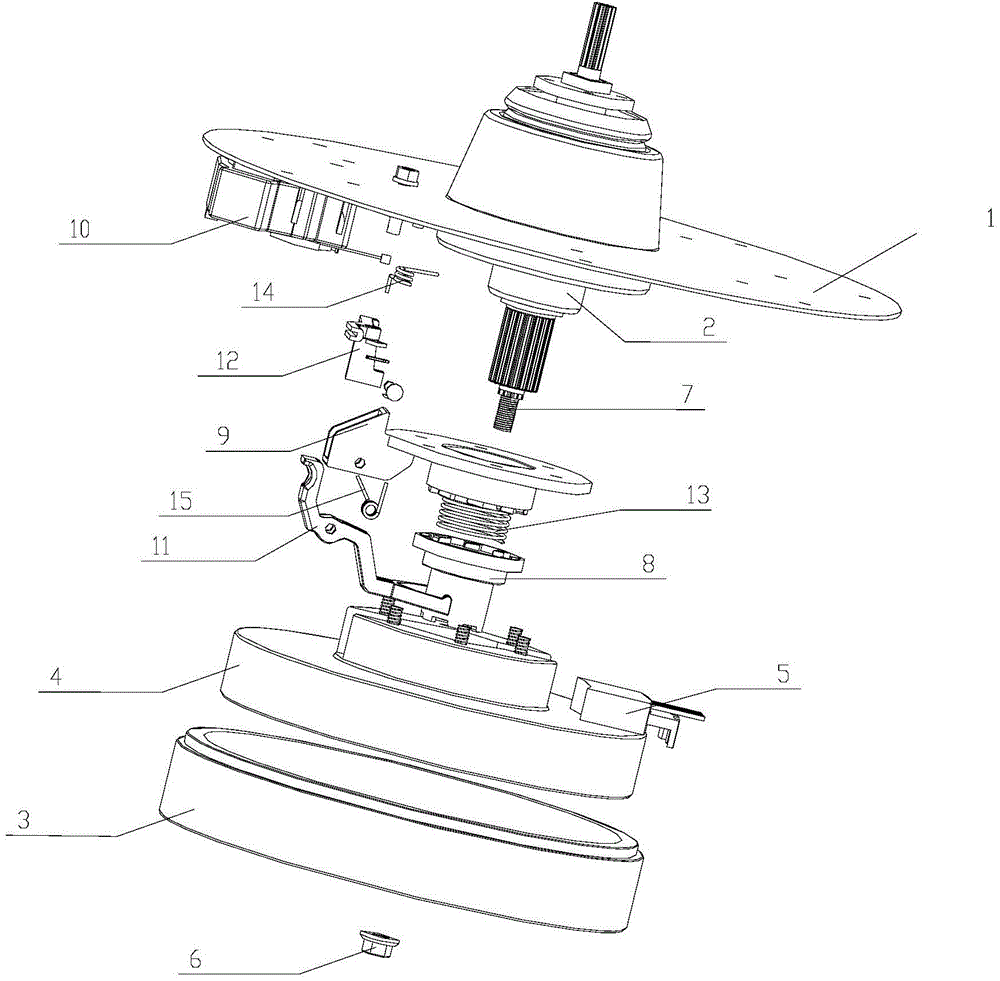

[0024] A high-efficiency variable frequency motor deceleration clutch device, comprising: an outer rotor motor composed of a rotor 3 and a stator 4, and an input shaft 7 fixedly connected to the rotor 3; the input shaft 7 is relatively axially rotatable through an oil-impregnated bearing 17. Inside the input shaft sleeve 16; a clutch shaft sleeve 8 is arranged between the casing and the rotor 3; The input shaft sleeve 16 is connected in a non-rotatable manner; a clutch spring 13 is arranged between the clutch shaft sleeve 8 and the housing; the clutch shaft sleeve 8 is connected with the traction motor 10 through the control mechanism; the clutch shaft sleeve 8 is connected between the control mechanism and the traction motor 10 Under the action of , the clutch sleeve slides up and down to switch between the first position and the second position.

[0025] In this embodiment, when the clutch sleeve 8 is in the first position, the input sleeve 8 engages with the fixed bracket 9...

specific Embodiment 2

[0032] In this embodiment, the clutch sleeve 8 is connected with the traction motor through a control mechanism. Therefore, the clutch sleeve 8 slides up and down under the action of the traction motor 10, so that the clutch sleeve 8 is switched between the first position and the second position.

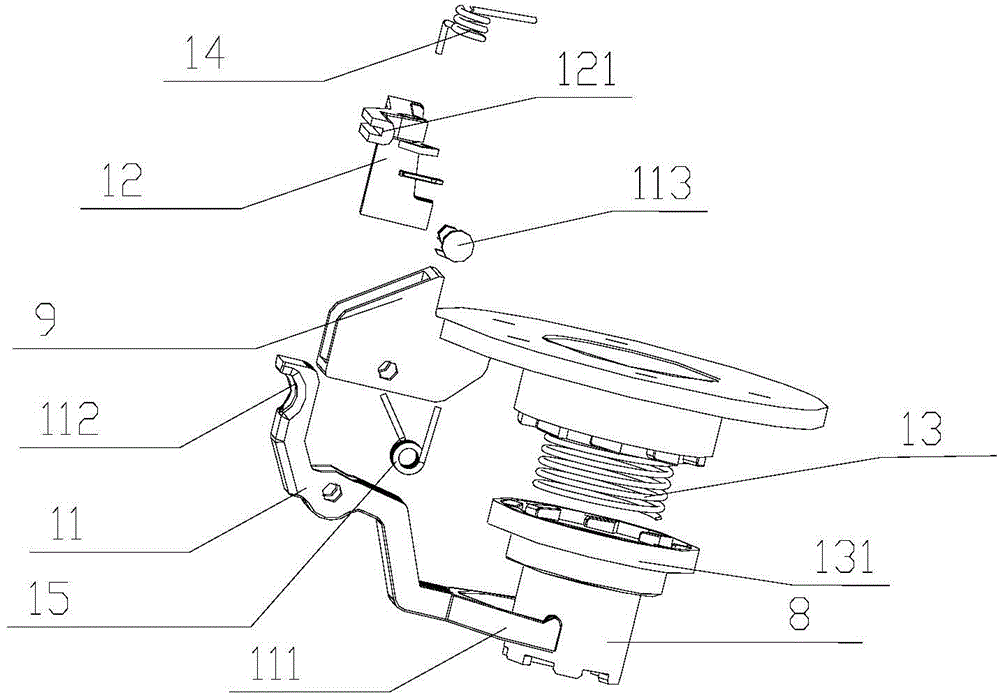

[0033] In this embodiment, the control mechanism includes a connecting arm connected to the traction motor 10 to generate a controlled displacement, a shift fork 11 that is rotatably connected to the housing to limit the position of the clutch bushing 8, and a clutch bushing 8 provides a clutch spring 13 with a sliding force; the shift fork 11 is driven by the connecting arm 12 to contact and limit the clutch sleeve 8 to slide downward.

[0034]In this embodiment, one end of the connecting arm 12 is connected to the traction motor 10 , and the other end is provided with a blocking arm 121 that limits the displacement of the shift fork 11 ; the connecting arm 12 is mounted on the hou...

specific Embodiment 3

[0043] In this embodiment, a washing machine equipped with a high-efficiency variable frequency motor deceleration clutch device includes: an outer tub installed in the body, an inner tub, and a pulsator arranged in the inner tub; the clutch device is fixedly installed on the washing machine, The input shaft is connected with the pulsator of the washing machine through a reduction gear, so that the input shaft drives the pulsator of the washing machine to rotate. The input shaft sleeve is engaged with the dehydration shaft through the transmission mechanism, so that the input shaft sleeve drives the inner tub of the washing machine to rotate.

[0044] When washing, the clutch sleeve is in the first position, the pulsator rotates, and the inner tub does not rotate; when dehydrating, the clutch sleeve is in the second position, the pulsator and the inner tub rotate simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com