Bag making machine for producing paper bag with additional pages

A technology of adding pages and bag making machines, which is applied in the field of paper bag making machines, can solve the problems of increasing manpower and energy consumption, and rising costs, and achieve the effects of low manpower and energy consumption, preventing paper jams, and reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

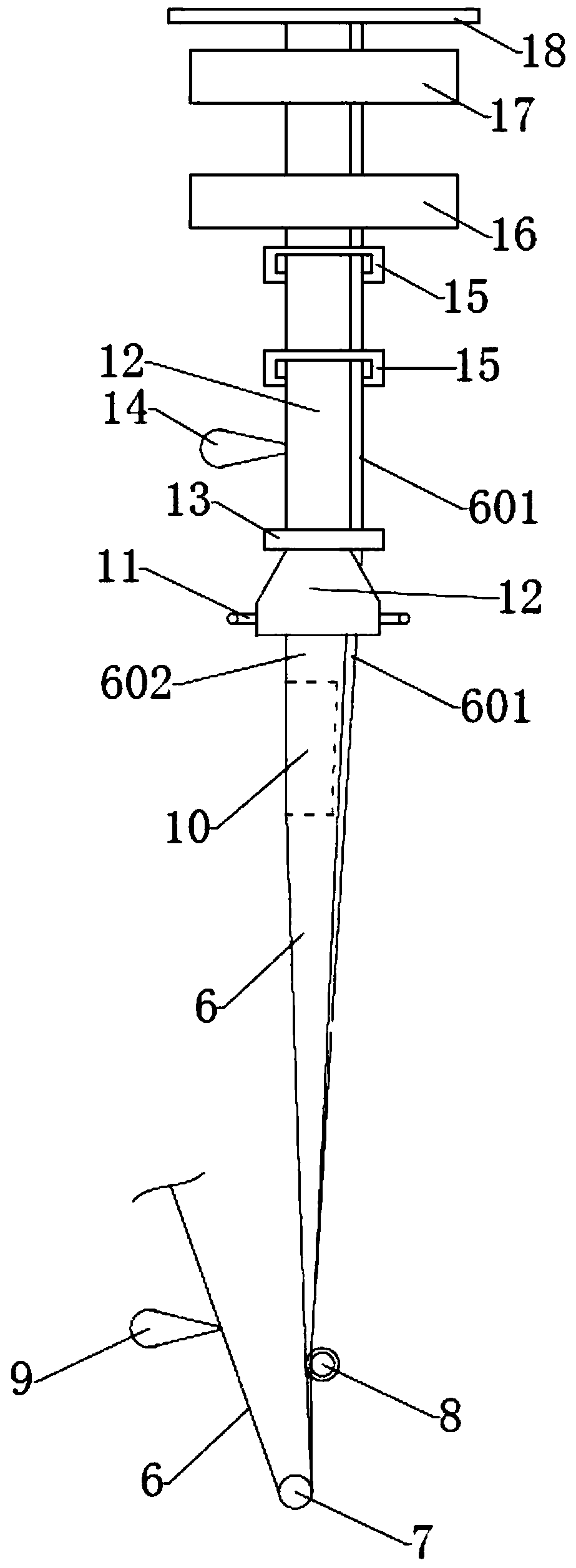

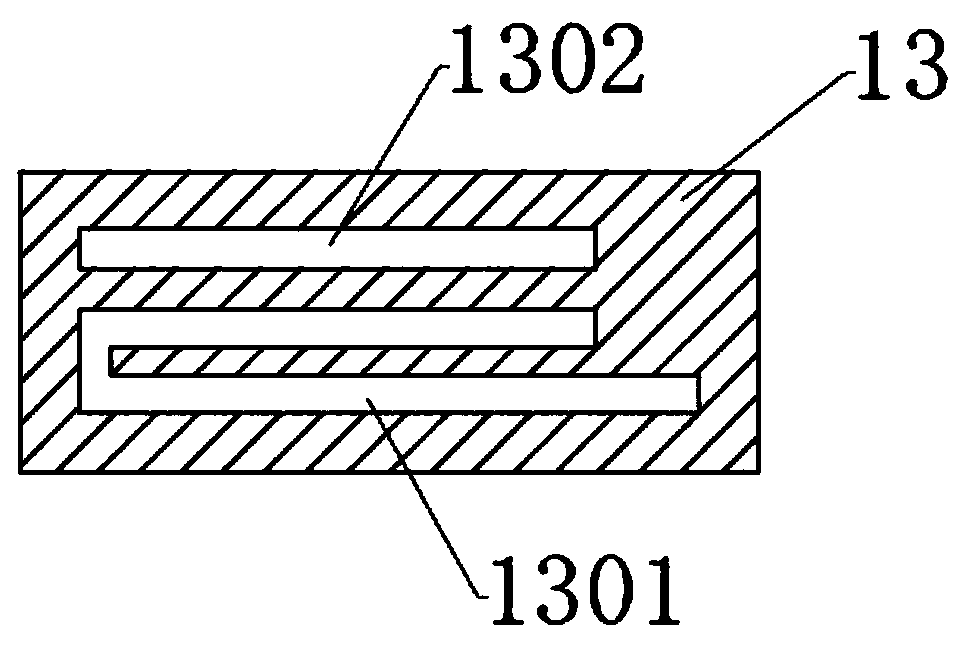

[0030] A bag-making machine for producing paper bags with additional pages, comprising a tension roller I7, on which a paper bag raw material strip 6 is wound, and behind the tension roller I7, along the conveying direction of the paper bag raw paper strip 6, there are sequentially arranged Folding device 13, pressing frame 15, hot press 16, paper pulling device 17 and cutting knife 18, paper feed roller 11 is arranged on the top of folding device 13, is wound with additional page raw material strip 12 on the paper feed roller 11, additional page The other end of the raw paper strip 12 is introduced into the folding device 13; the paper bag raw paper strip 6 located between the folding device 13 and the cutting knife 18 is folded into two parts, the folding surface I 601 and the folding surface II 602, which are located between the folding device 13 and the cutting knife 18. The additional page raw paper strip 12 in the middle part is close to the top of the paper bag raw paper...

Embodiment 2

[0034] On the basis of Example 1, between the tension roller I7 and the folding device 13, an orientation arc 10 for extruding with the paper bag raw material strip 6 is provided. The surface of the orientation arc 10 is arc-shaped, and the orientation The arc of the surface of the arc 10 gradually increases along the conveying direction of the paper bag raw material strip 6, and the width gradually decreases.

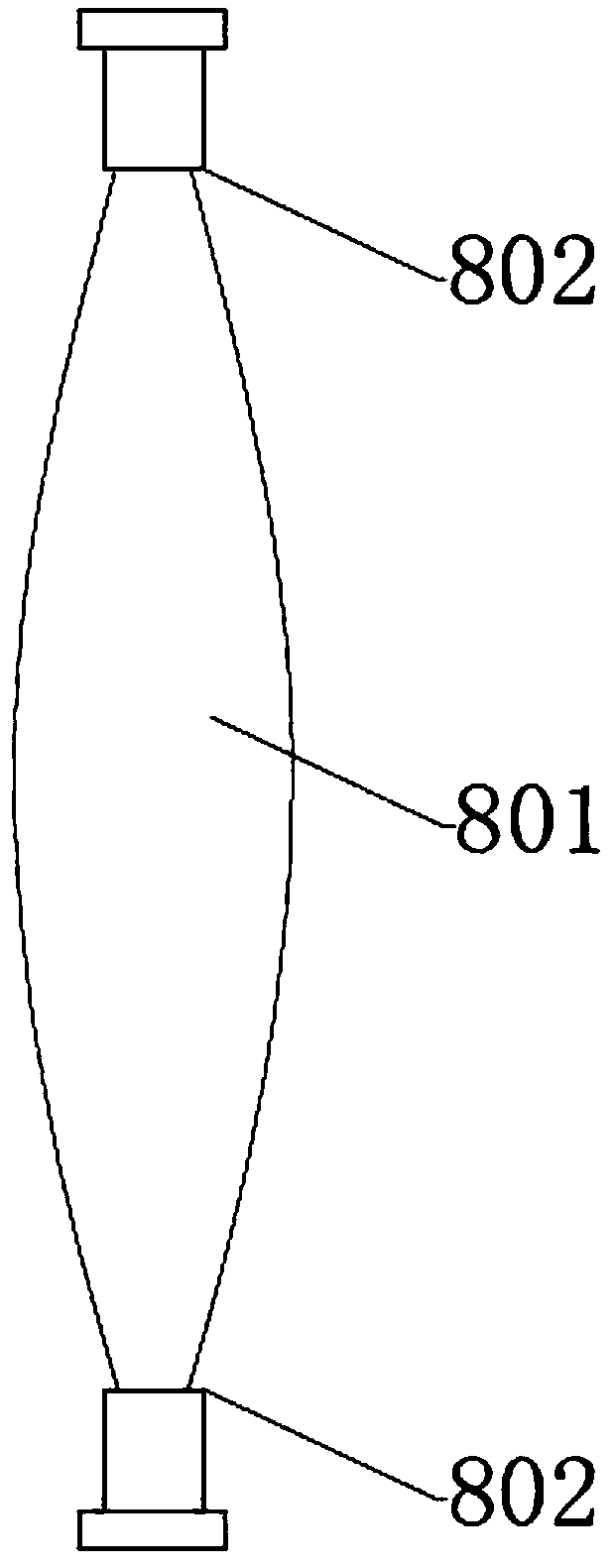

[0035] A tension roller II8 is arranged between the tension roller I7 and the directional arc sheet 10, and the two ends of the tension roller II8 are provided with limiting grooves 802, and the tension roller II8 is located in the shape of the tension part 801 between the two limiting grooves 802 It is spindle-shaped, and the distance between the two limit grooves 802 along the surface of the tensioning part 801 corresponds to the width of the paper bag raw material strip 6. The tension roller II8 and the orientation arc 10 are located on the same side of the paper bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com