Patents

Literature

49 results about "Additional procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

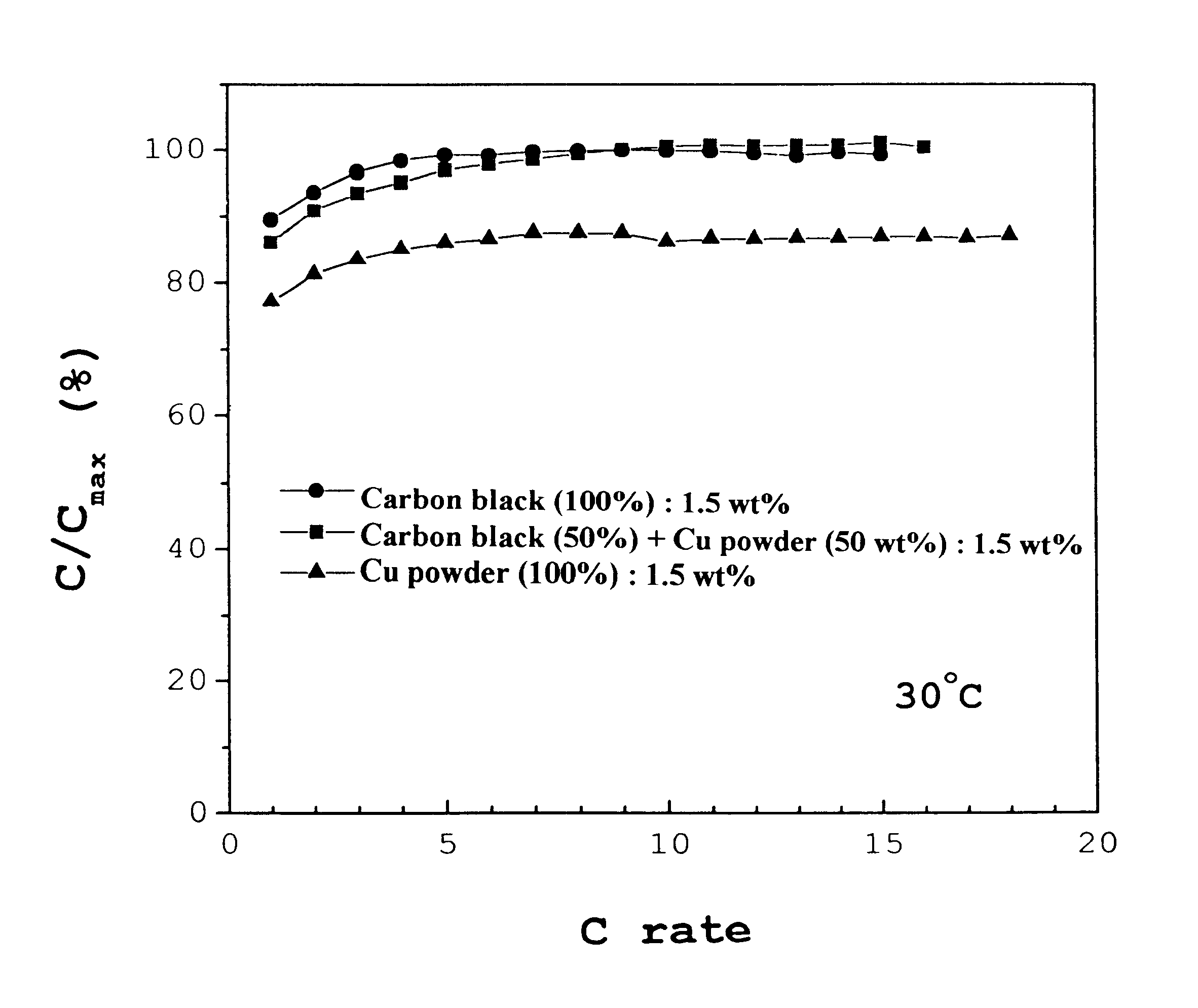

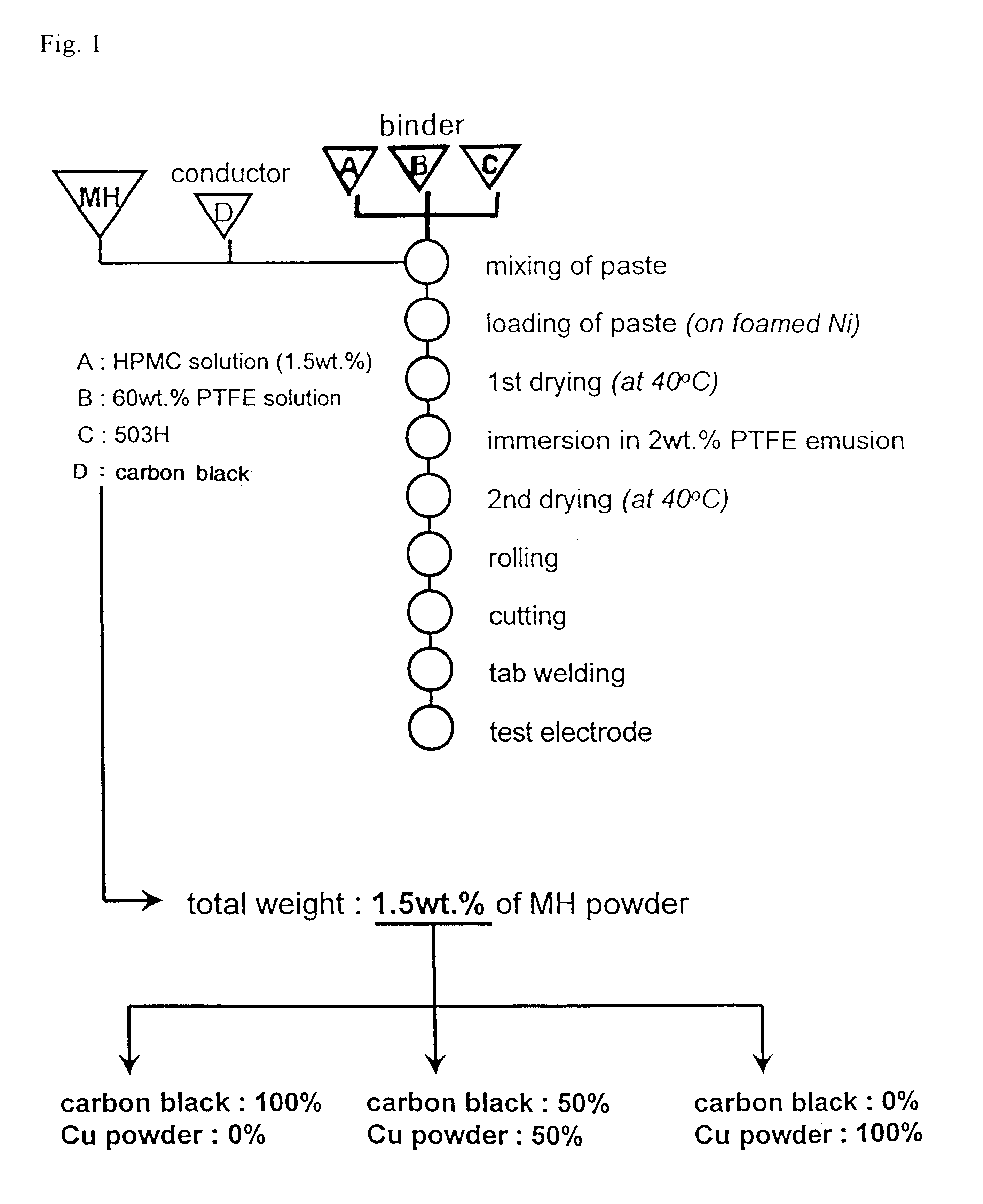

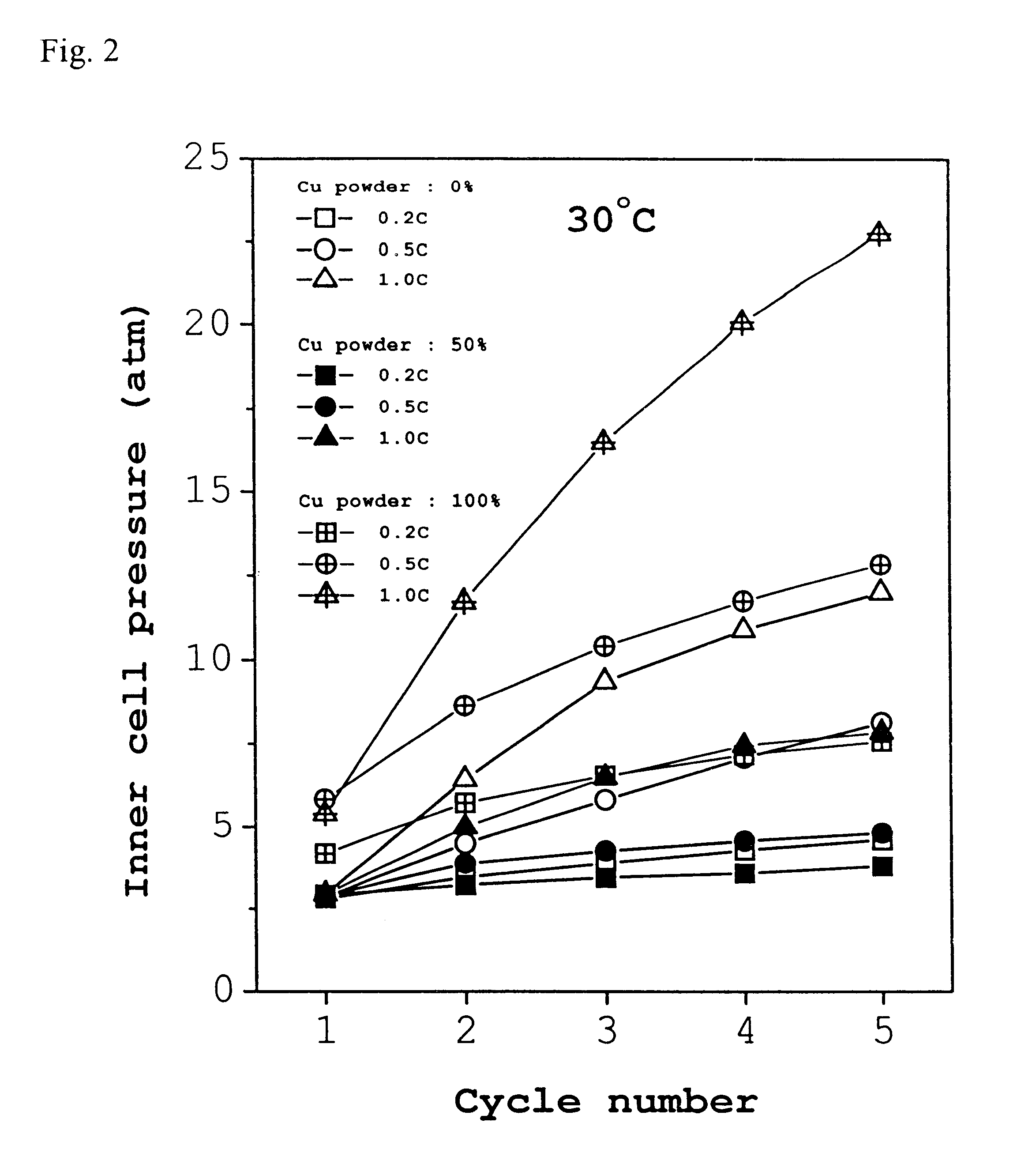

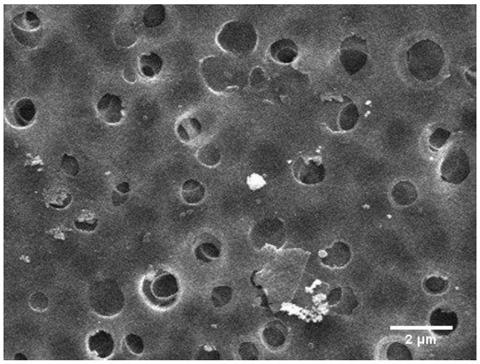

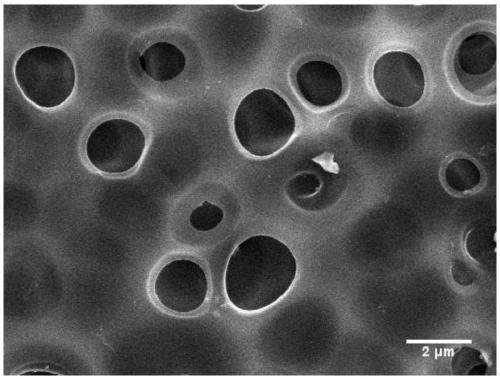

Method for preparing electrodes for Ni/Metal hydride secondary cells using Cu

InactiveUS6372383B1Improve surface propertiesIncrease effective reaction surfaceElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesHigh rateAdditional procedure

Disclosed is a method for preparing a high performance, negative electrode for Ni / metal hydride cells. A Zr-based hydrogen storage alloy, a binder comprising a mixture of polytetrafluoroethylene and 50th and a thickening agent (hydroxypropylmethyl cellulose), and a current collector comprising carbon black and copper are slurried and molded into a paste-type electrode. In a closed type cell, the copper repetitively undergoes melting and deposition on the electrode during charging and discharging cycles, allowing the electrode to show a similar change in surface morphology and electrochemical properties to that of a conventionally electroless plated electrode. Giving a contribution to the improvement in cell properties, including inner cell pressure, high rate dischargeability and energy density per volume, the method can substitute conventional alloy surface modifying methods, such as electroless plating methods and other pre-treatment processes necessary for the preparation of electrodes, which are difficult to practice owing to the production of pollution of the environment and to requirement of additional procedures.

Owner:KOREA ADVANCED INST OF SCI & TECH

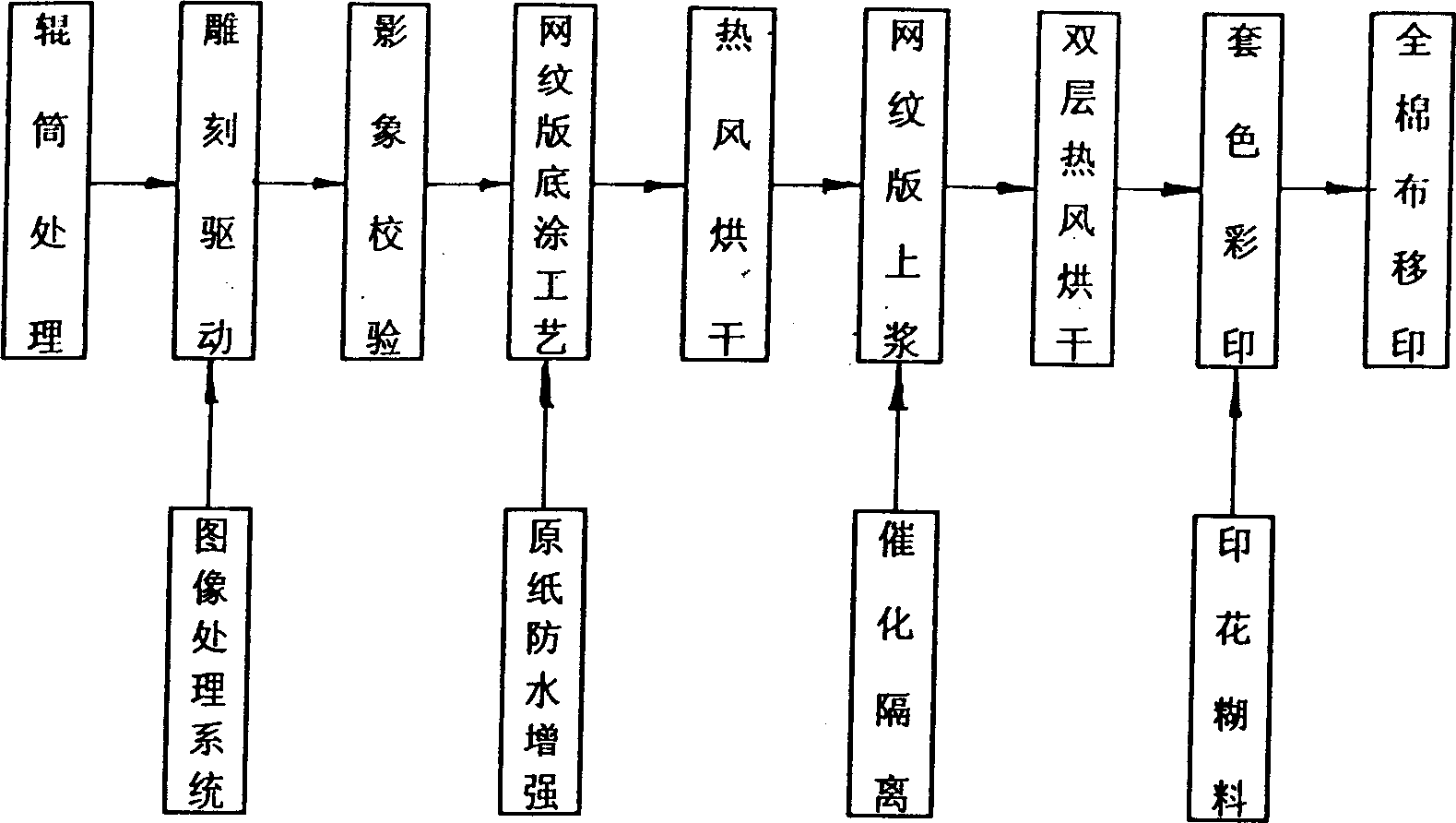

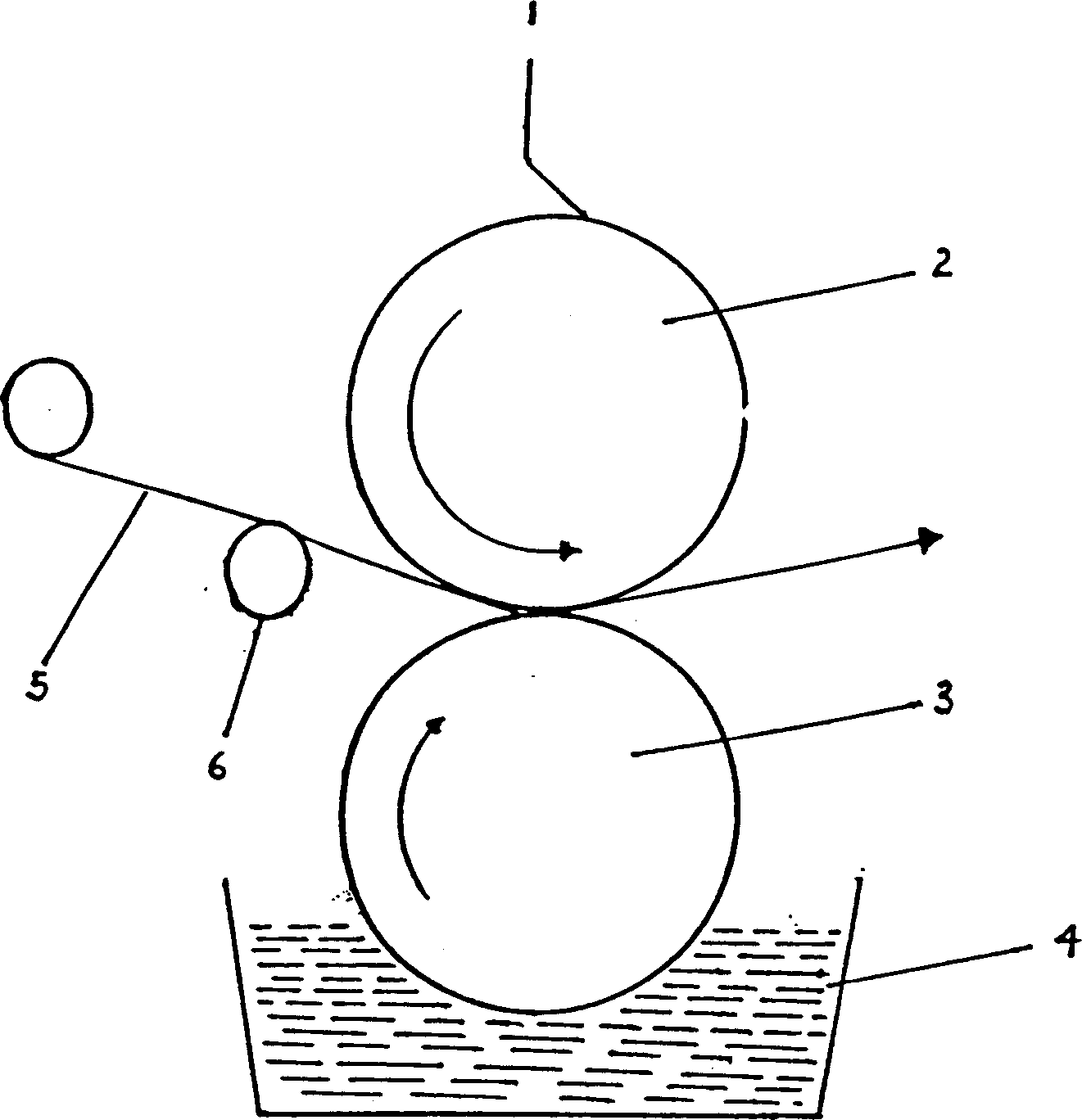

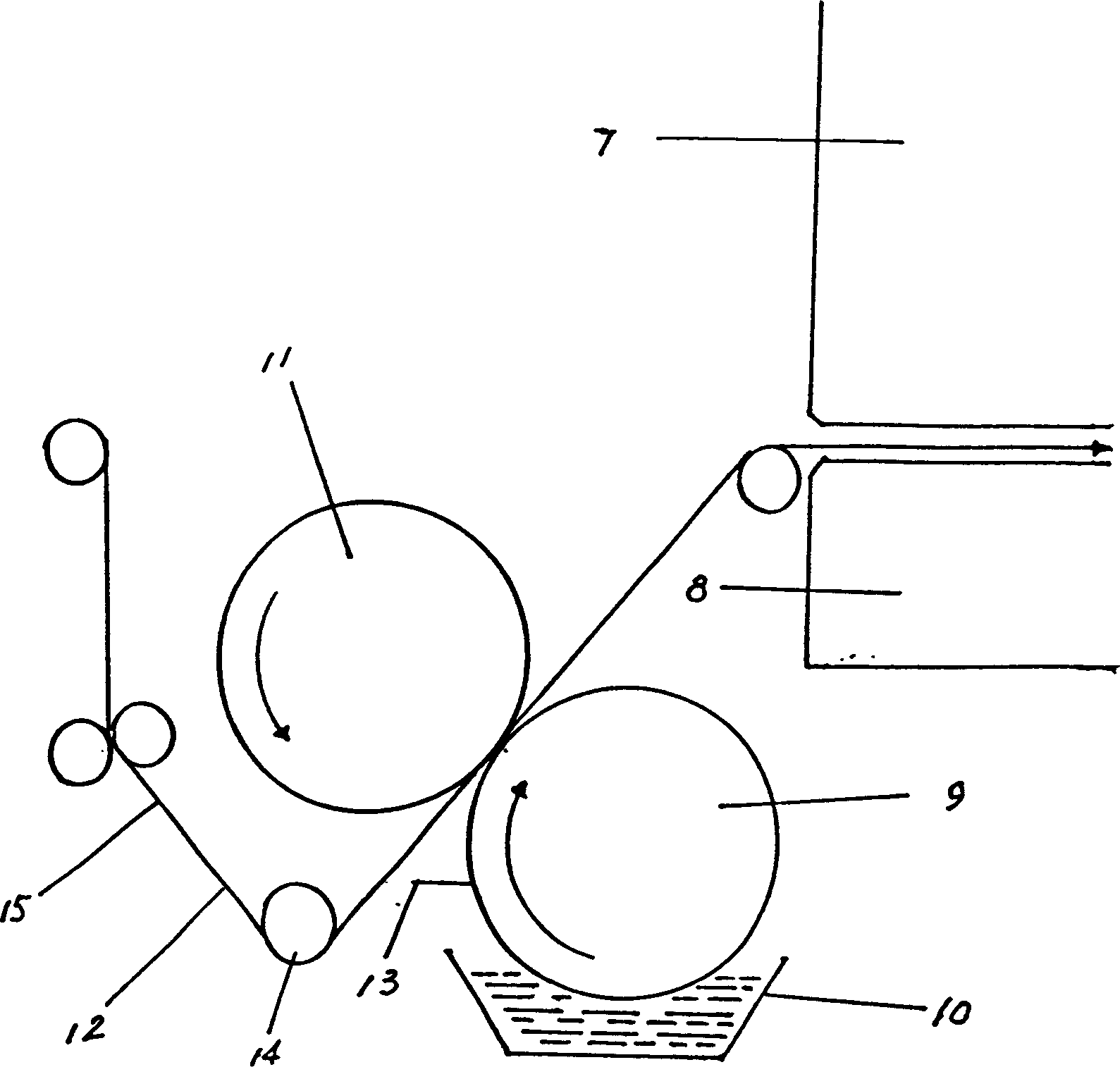

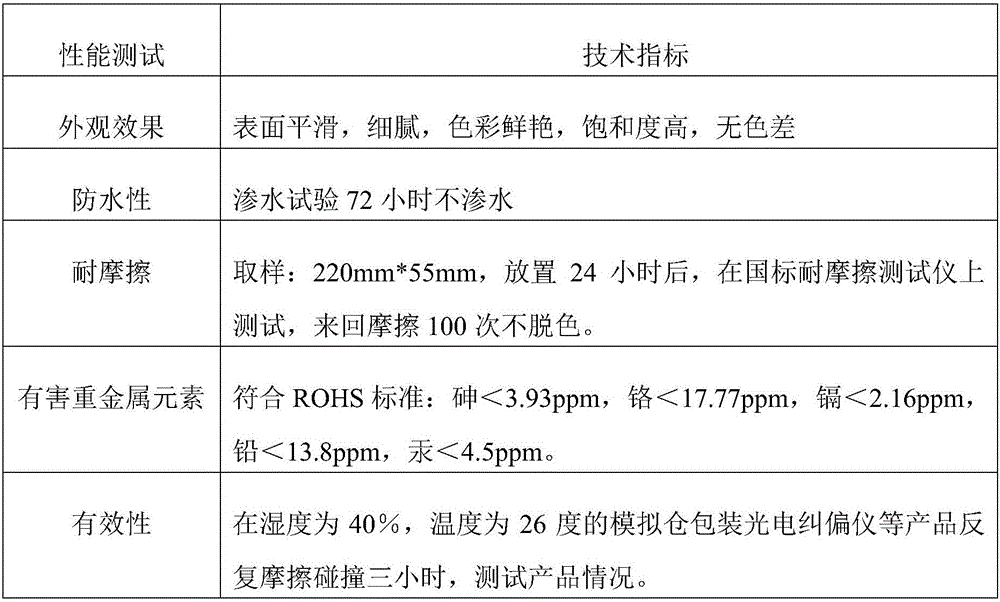

Production process for printing whole-cotton transfer printing paper using copper-plate press

ActiveCN1807121AImprove the authenticity rateImprove printing effectDecorative surface effectsTransfer printing processColor printingAdditional procedure

The invention relates the manufacturing technique of all-cotton transfer printing paper. The technology comprises the following steps: treating roller, engraving activation according to image processing system signal, checking image, raw-paper halftone etching basecoat technology, drying with hot wind, starching the halftone etching to catalyze isolated layer, drying with double-layer hot wind, screen printing color register color printing, and all-cotton bat printing. The raw-paper halftone etching basecoat technology, starching the halftone etching to catalyze isolated layer, drying with double-layer hot wind, and screen printing color register color printing are new additional procedure. The all-cotton transfer printing paper made with the method has better bat printing effect. The method has the advantages of easy operation, high standard-piece rate, low cost, environmental protection and saving energy.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

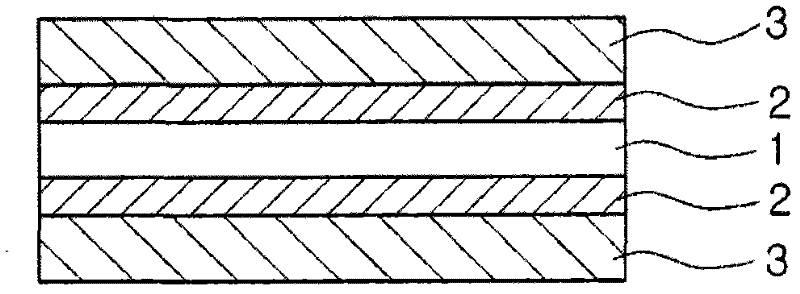

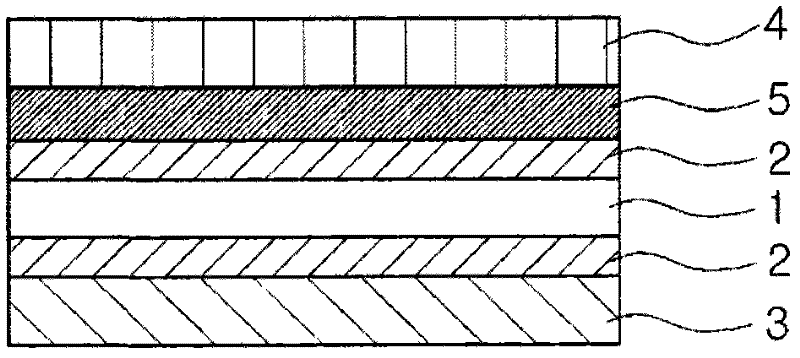

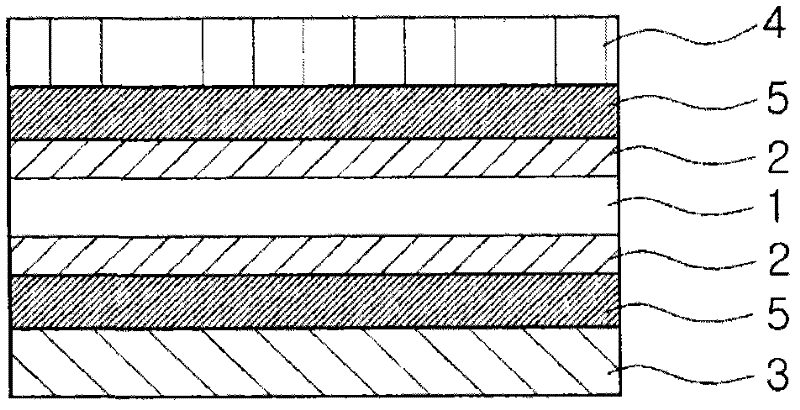

Waterborne priming coating compound, polarizing plate containing compound, and preparation method of optical film containing priming coating

InactiveCN102417807AFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesWater dispersibleAdditional procedure

The invention relates to a waterborne priming coating compound, a polarizing plate containing the waterborne priming coating compound, and a preparation method of an optical film containing the priming coating. For the priming coating compound has 100 parts of weight, the priming coating compound includes 1 to 30 parts by weight of polyurethane polymer, 0.1 to 10 parts by weight of water dispersible particles, and the balance water. The polarizing plate is arranged between the optical film and the priming coating formed by the priming coating compound. The method includes the steps of coating the priming coating compound on at least one side of the optical film and drying the optical film coated with the priming coating compound. The priming coating compound has excellent bonding performance, and can be contained in the polarizing plate without reducing the transparency of the polarizing plate and using additional procedures or devices.

Owner:LG CHEM LTD

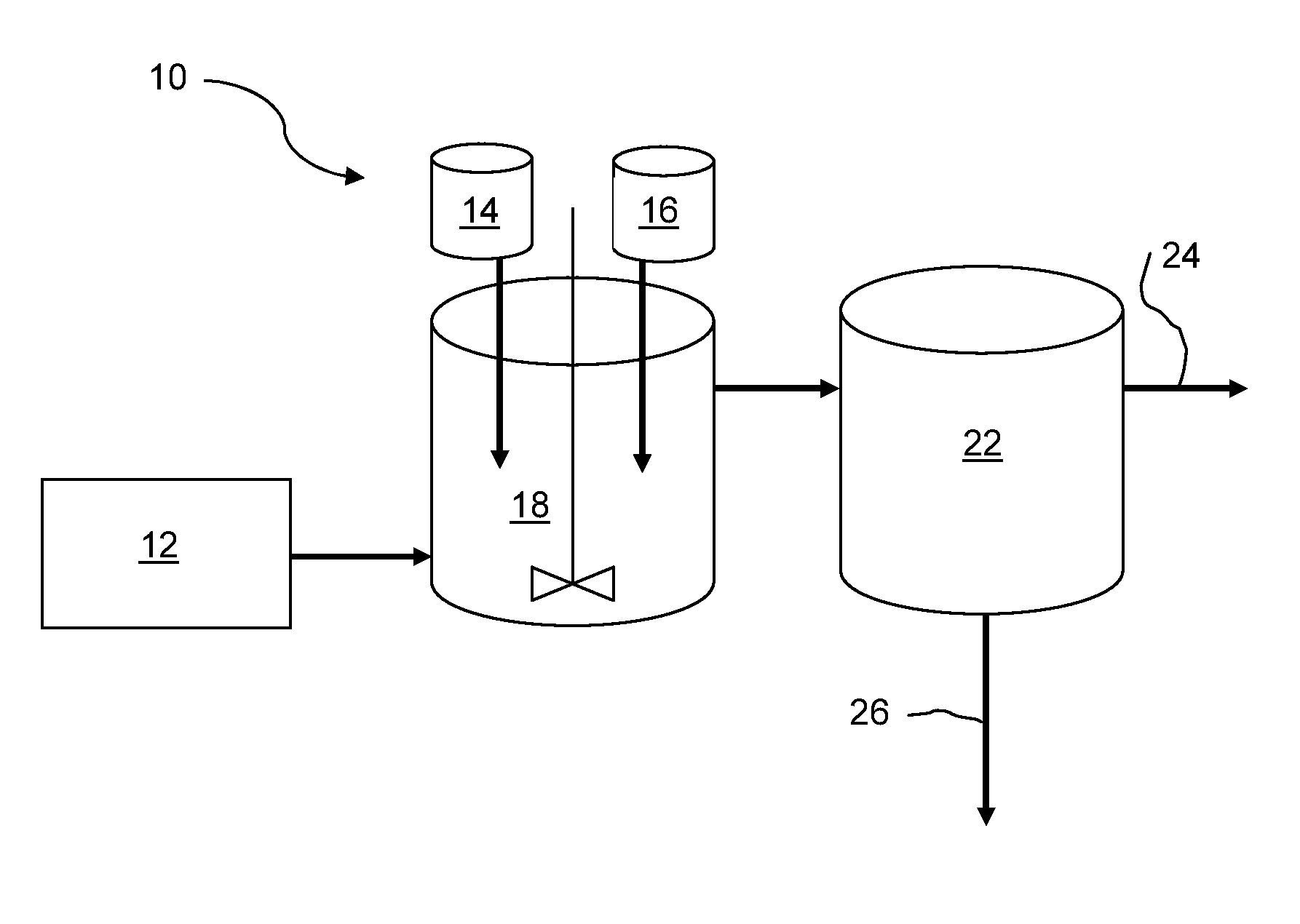

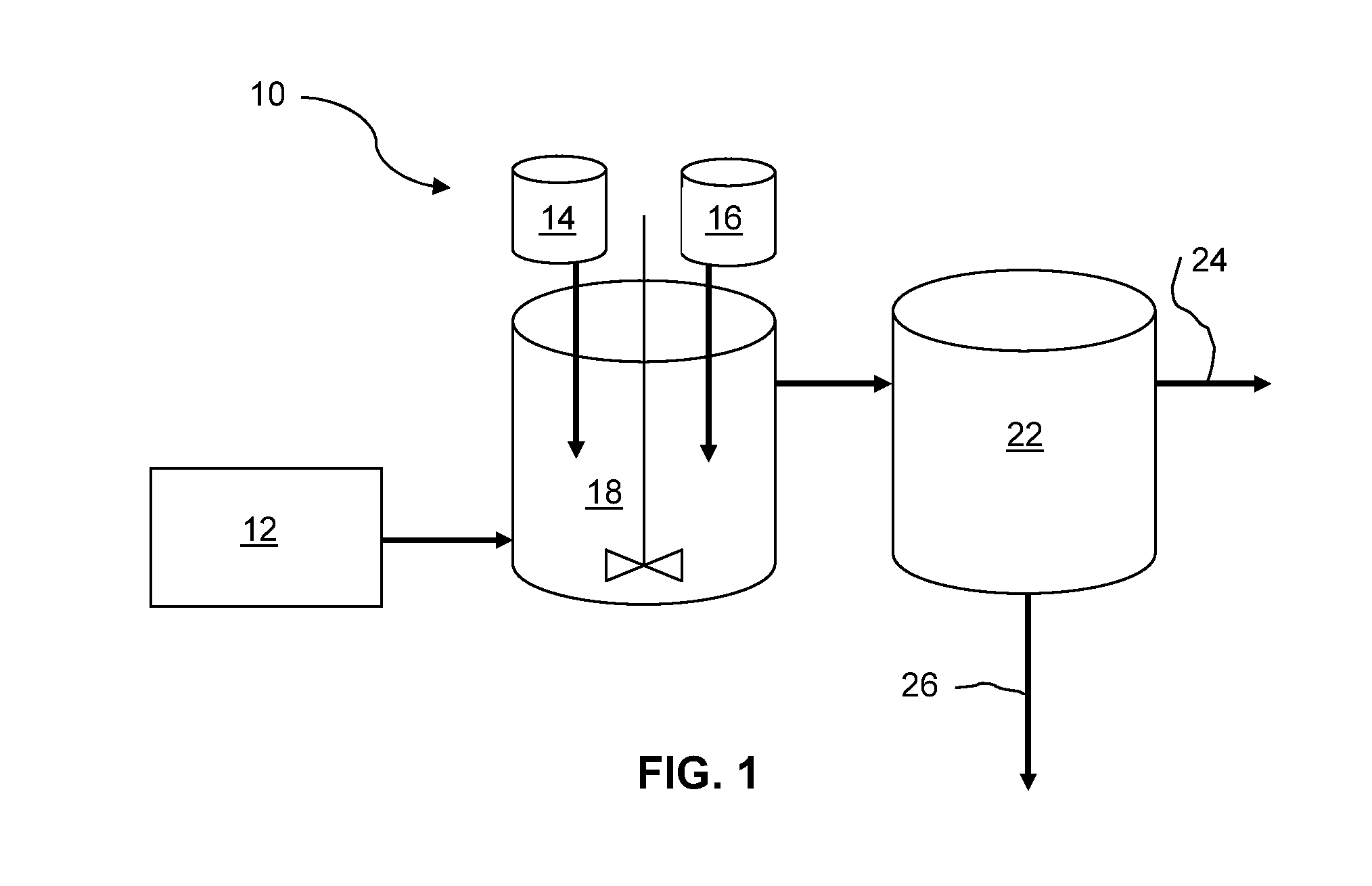

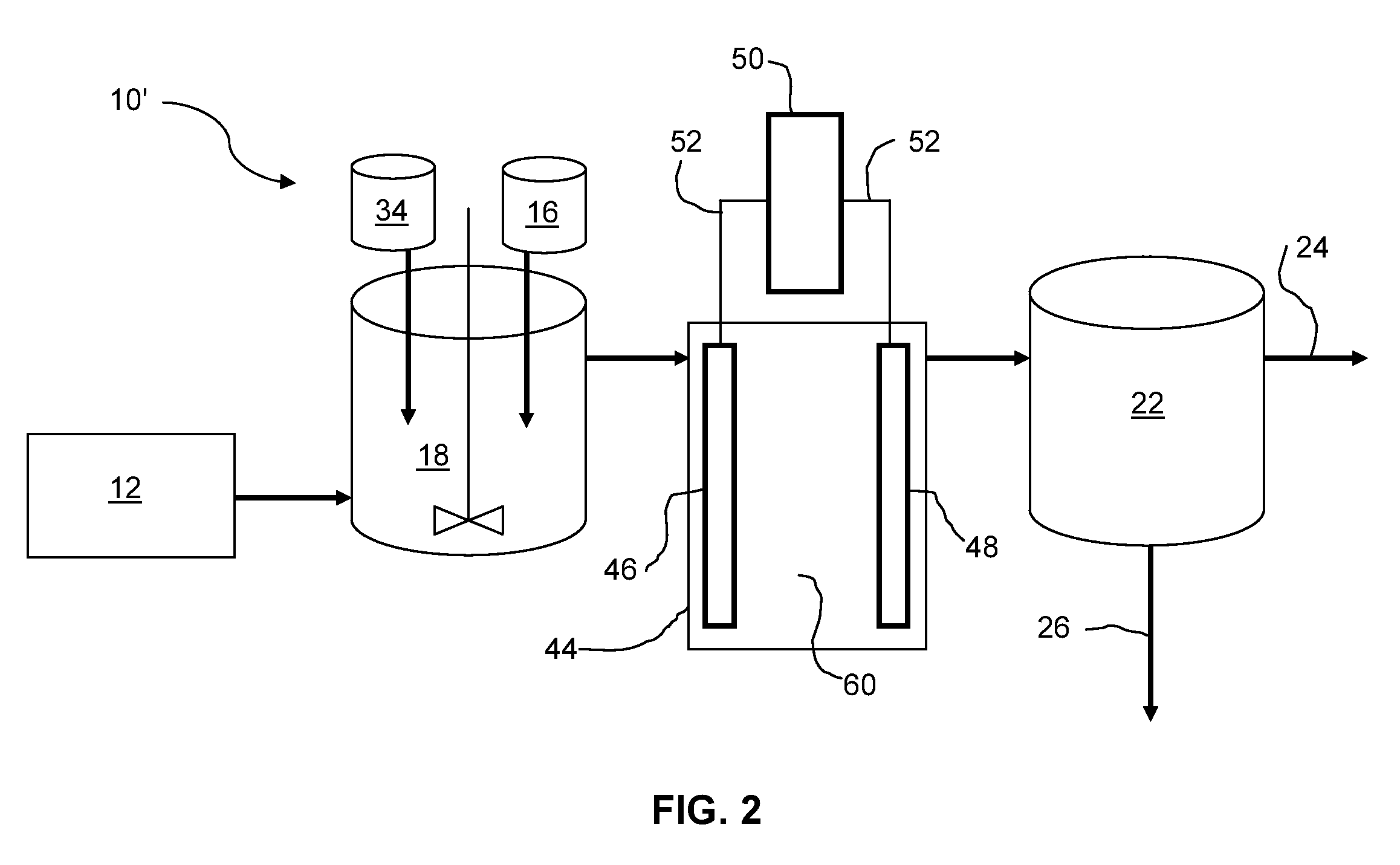

Process for Hardness and Boron Removal

InactiveUS20150053619A1Reduce hardnessEfficient removalSpecific water treatment objectivesWater contaminantsElectrocoagulationAdditional procedure

Both the hardness and boron content of wastewater may be reduced by contacting the wastewater with liquid sodium silicate (LSS) in an effective amount for such reductions followed by one or both of two additional procedures. The additional procedure may be contacting the wastewater with an Al(3+)-containing compound in an amount effective to at least partially remove silicon from the wastewater, where the contacting is before, during or after the wastewater is contacted with LSS. The second additional or alternative procedure involves, subsequent to contacting the wastewater with LSS, treating the untreated water with an electrocoagulation (EC) apparatus for a period of time effective to at least partially remove silicon from the wastewater. The EC procedure may also further remove boron from the wastewater.

Owner:BAKER HUGHES INC

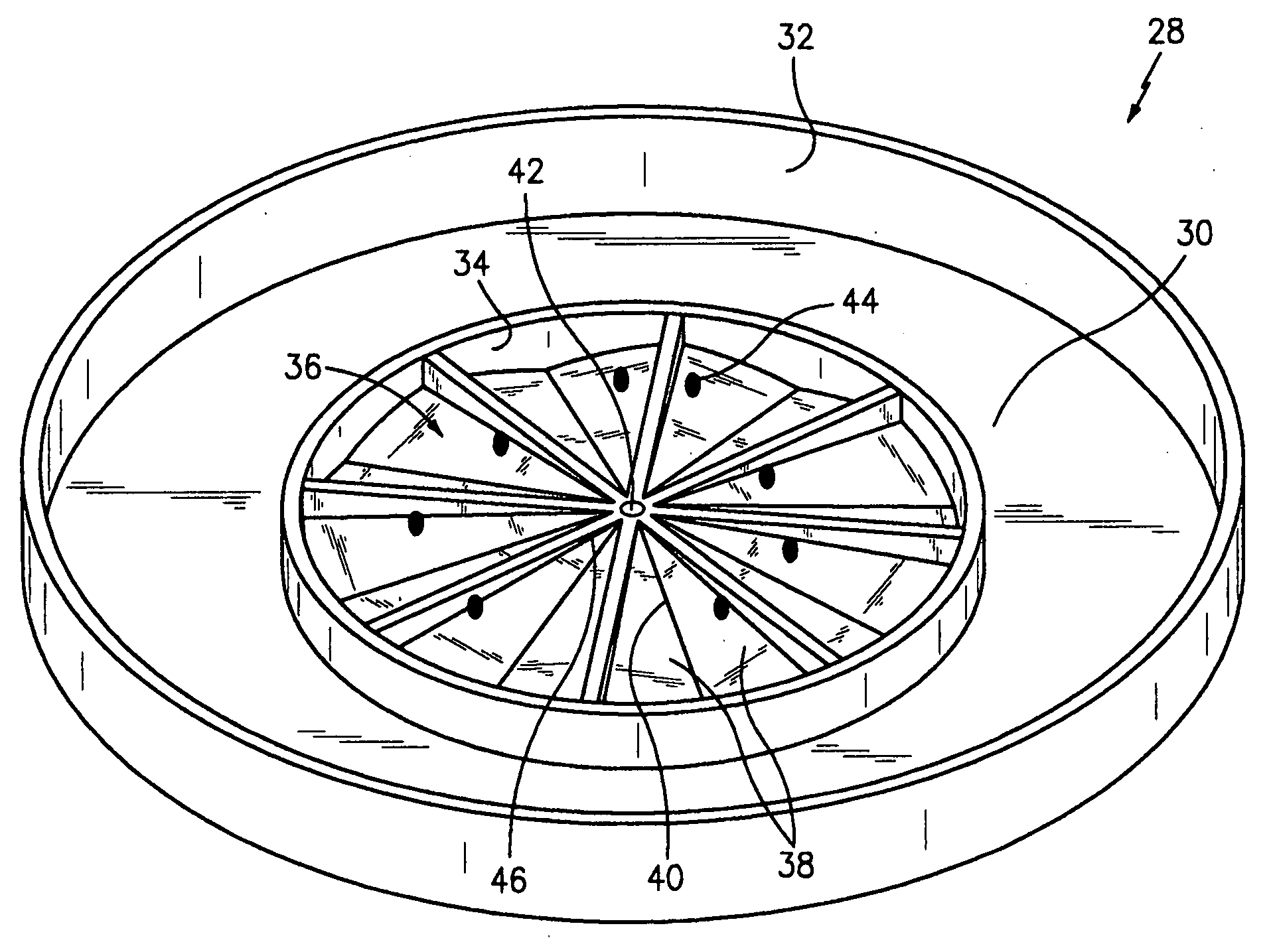

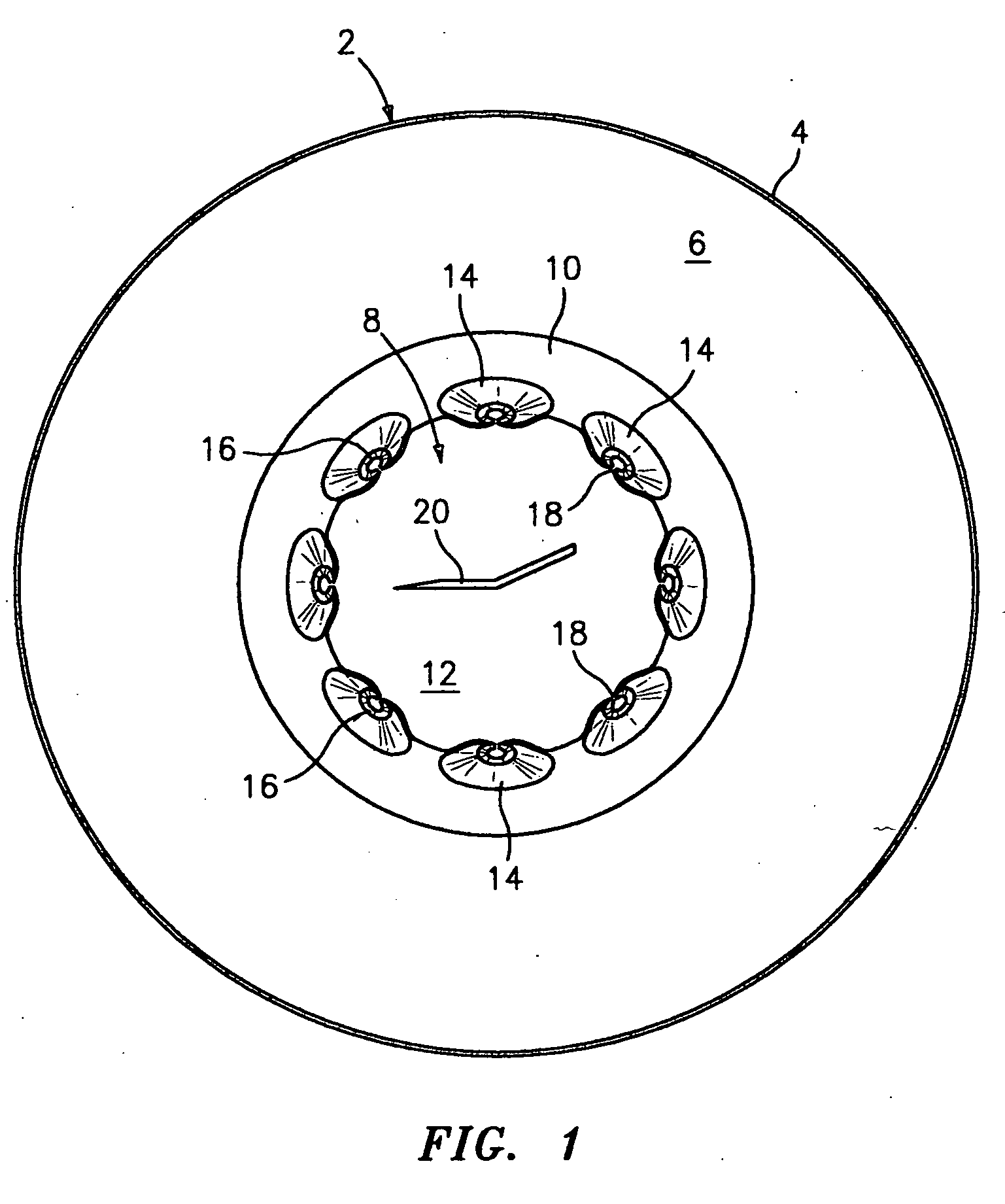

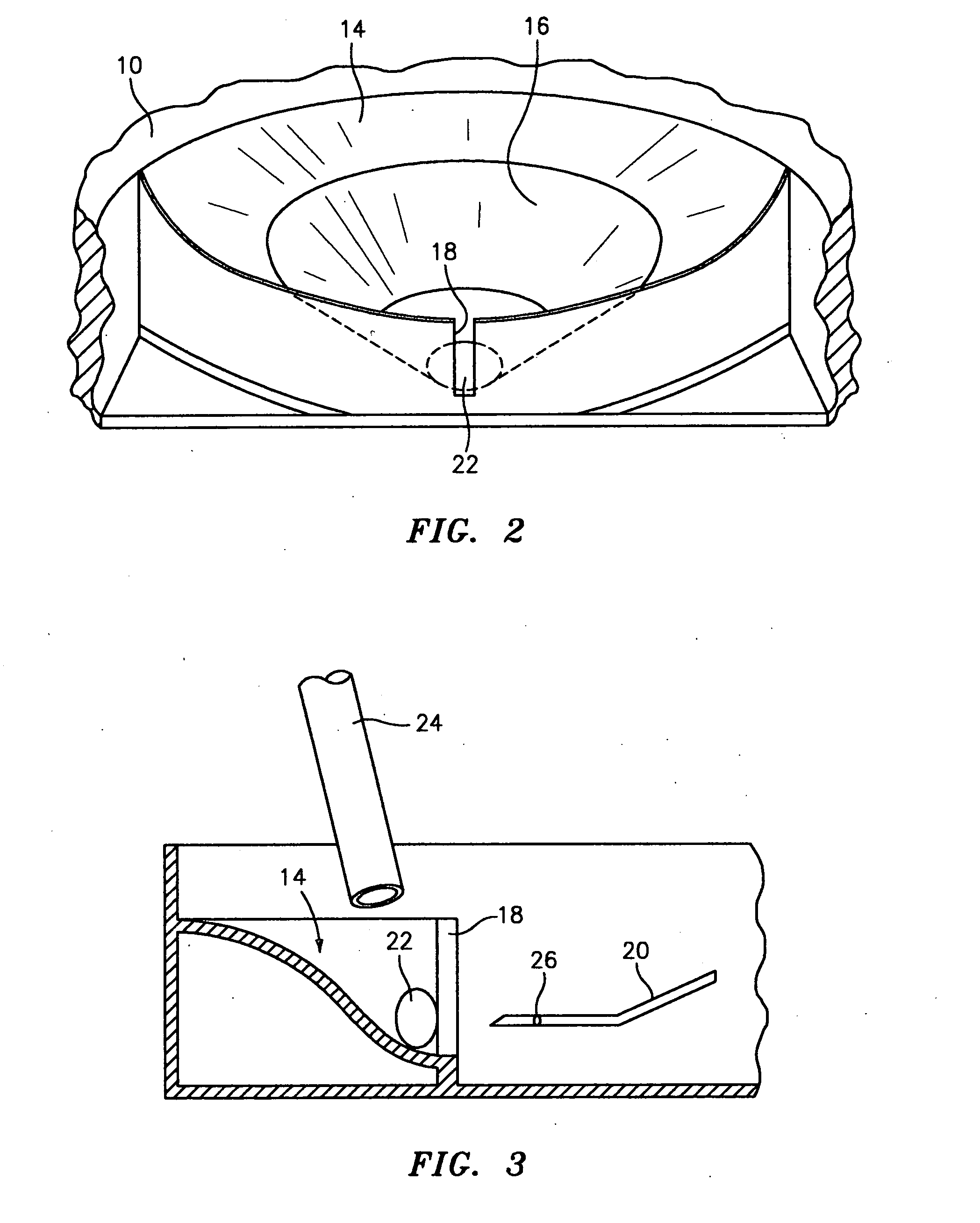

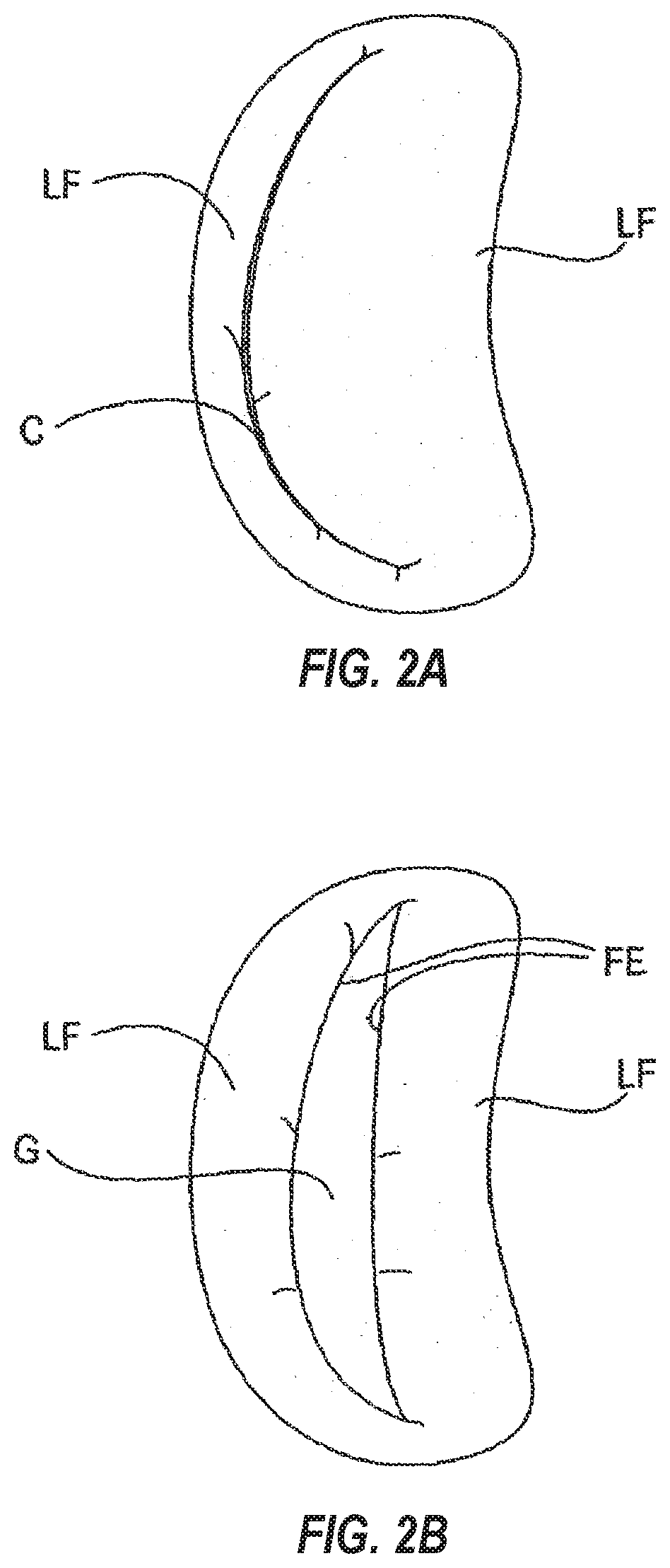

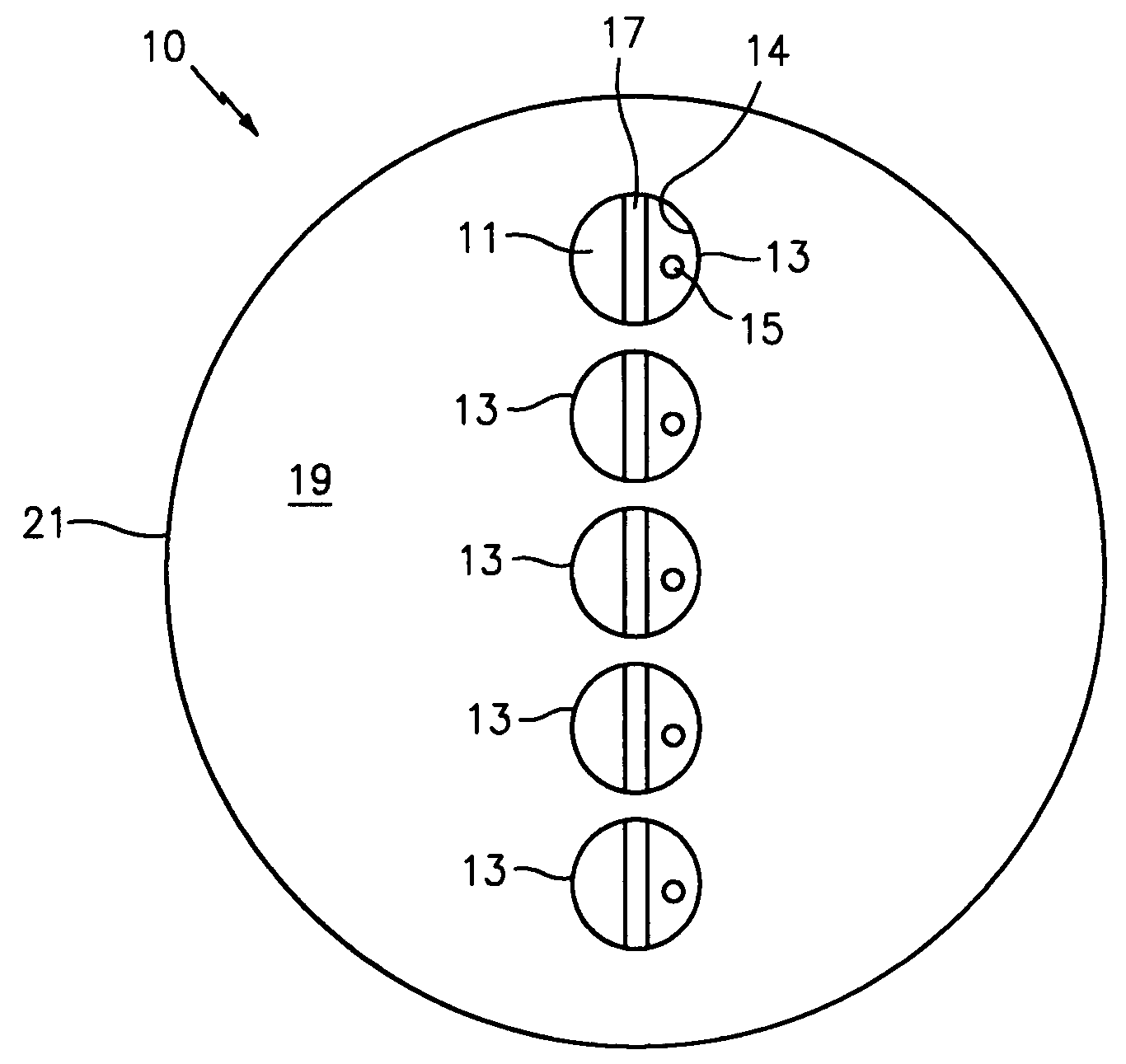

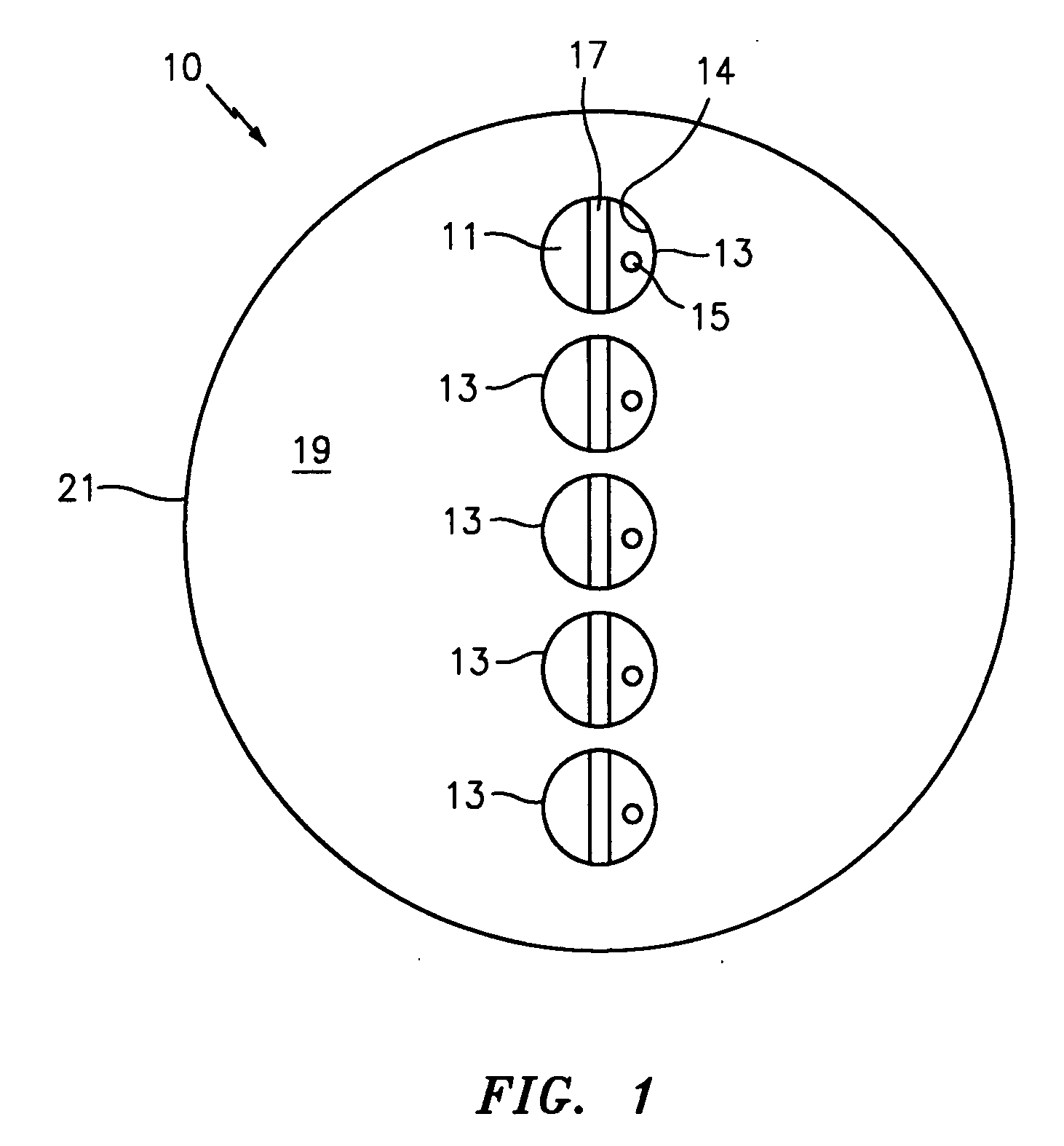

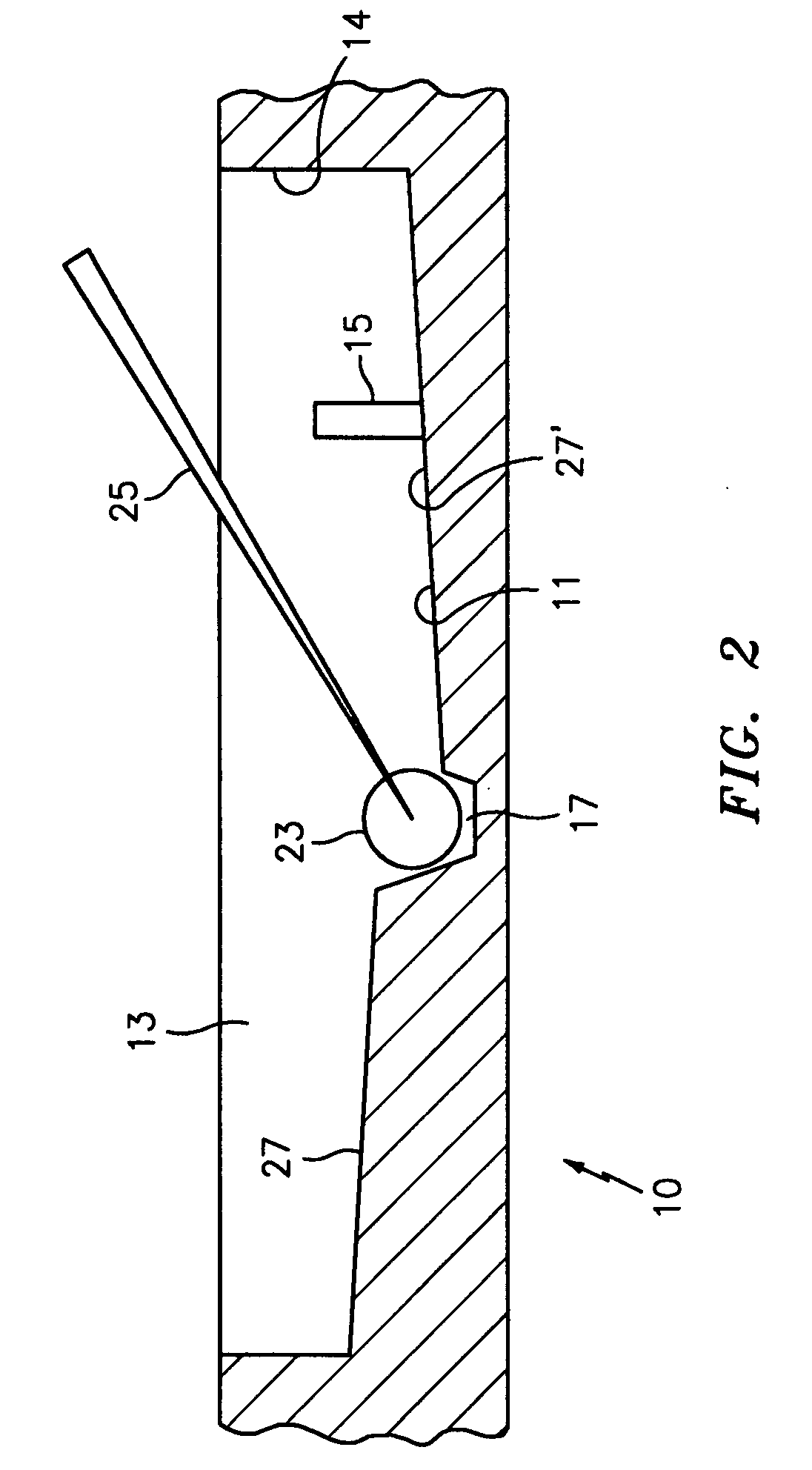

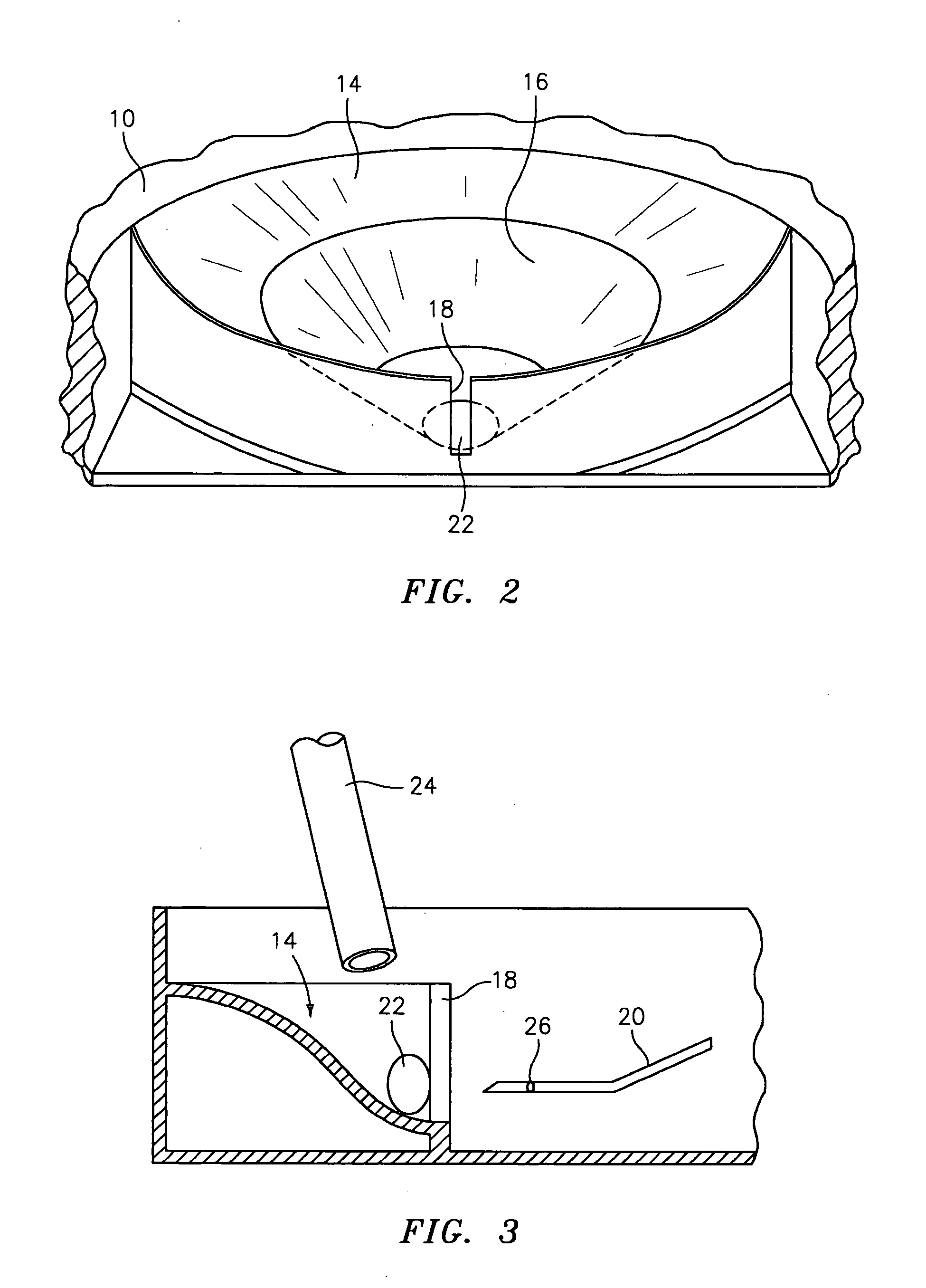

Specimen manipulation device for micro manipulation and biopsy in assisted reproduction and in vitro fertilization

InactiveUS20100075411A1Promote resultsLow costBioreactor/fermenter combinationsBiological substance pretreatmentsAdditional procedureEmbryo

A container or dish used for the micro manipulation, micro injection, biopsy and fertilization of oocyte and embryo culture. The dish allows the user to more readily perform procedures used to fertilize oocyte, such as intracytoplasmic sperm injection (ICSI), biopsy embryos and perform additional procedures in used in assisted reproductive techniques (ART), human reproduction and in vitro fertilization (IVF) techniques. The invention will allow ease in use, the reduction in the number of micro tools used in the procedure, as opposed to conventonal dishes and procedures, and will allow the user to more readily locate the oocytes and embryos to be handled and worked on. The inventon will add repetitiveness, consistency and may result in better results and outcome of the procedures. The invention will also give the user a more ergonomically correct dish for these types of procedures and related protocols.

Owner:COOPERSURGICAL INC

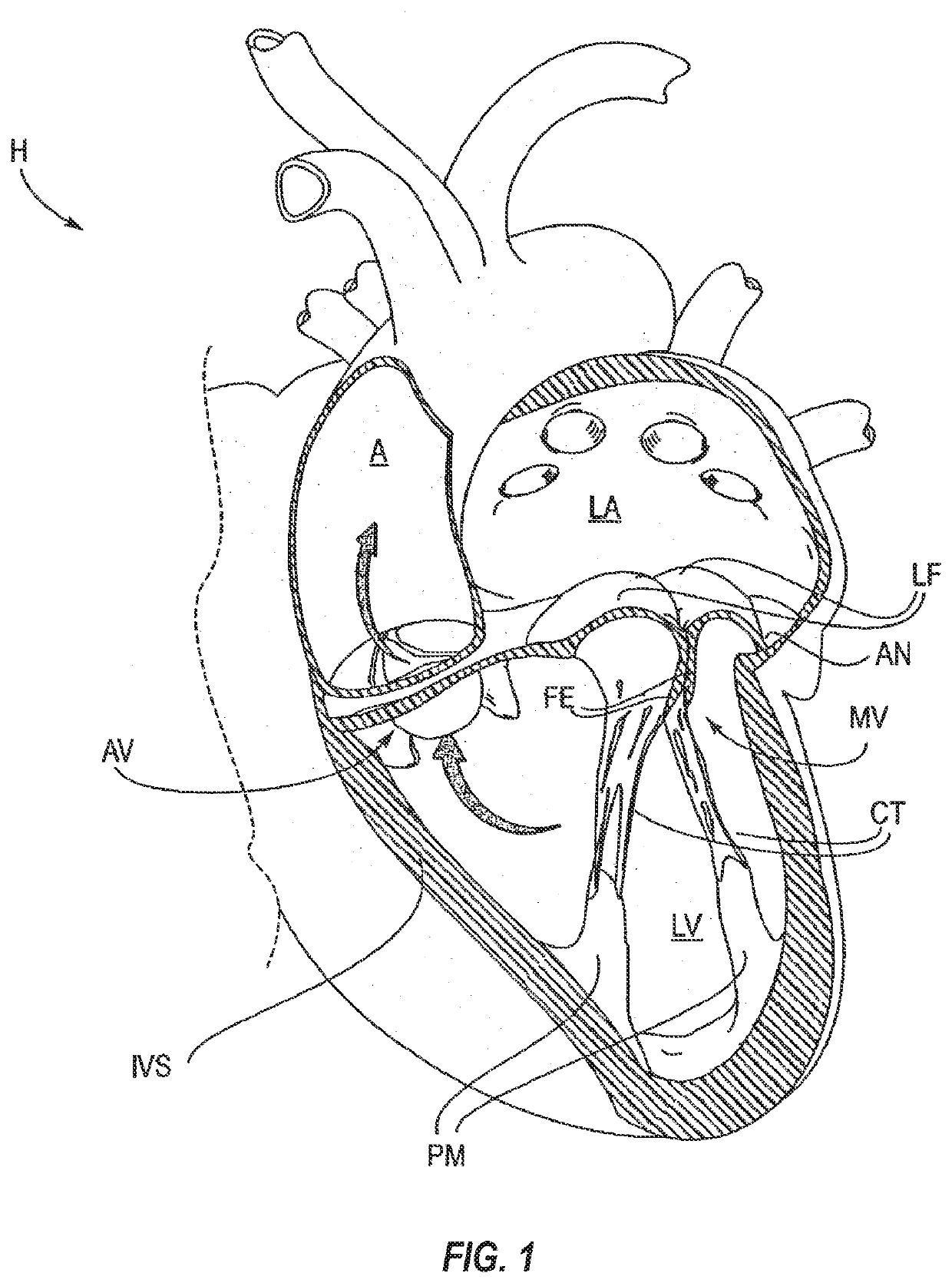

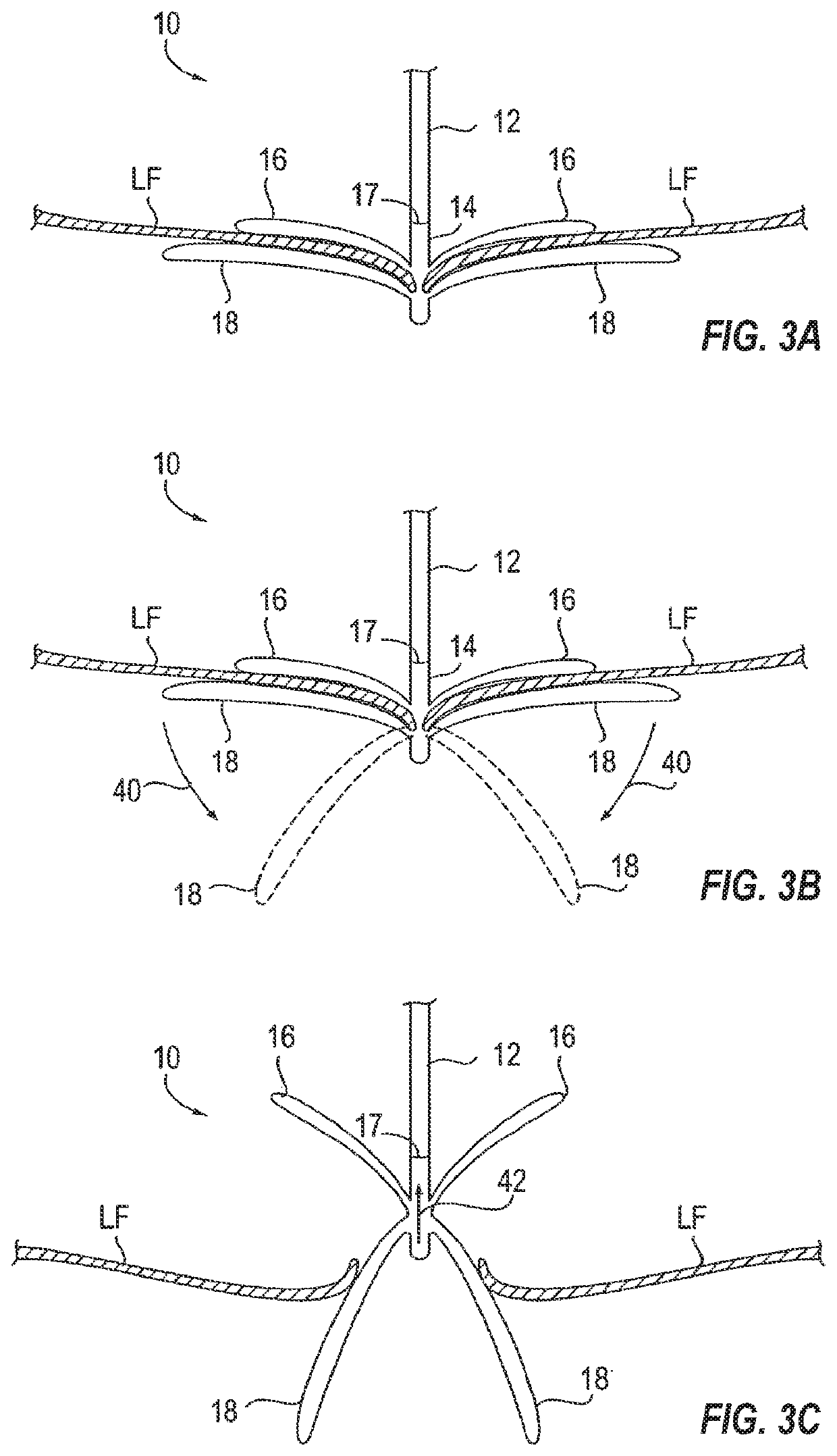

Tissue cutting systems, devices and methods

PendingUS20200121460A1Reduce selection requirementsDiagnosticsAnnuloplasty ringsAdditional procedureMitral valve leaflet

Methods, devices and systems for disabling and / or removing a mitral valve edge-to-edge repair device via minimally invasive, endovascular procedures. Additional procedures on a heart may sometimes become necessary after the installation of a mitral valve edge-to-edge repair device. To prepare for such additional procedures, the edge-to-edge repair device may be removed or disabled in minimally invasive ways (e.g., through an endovascular procedure), without requiring open access to the heart.

Owner:EVALVE

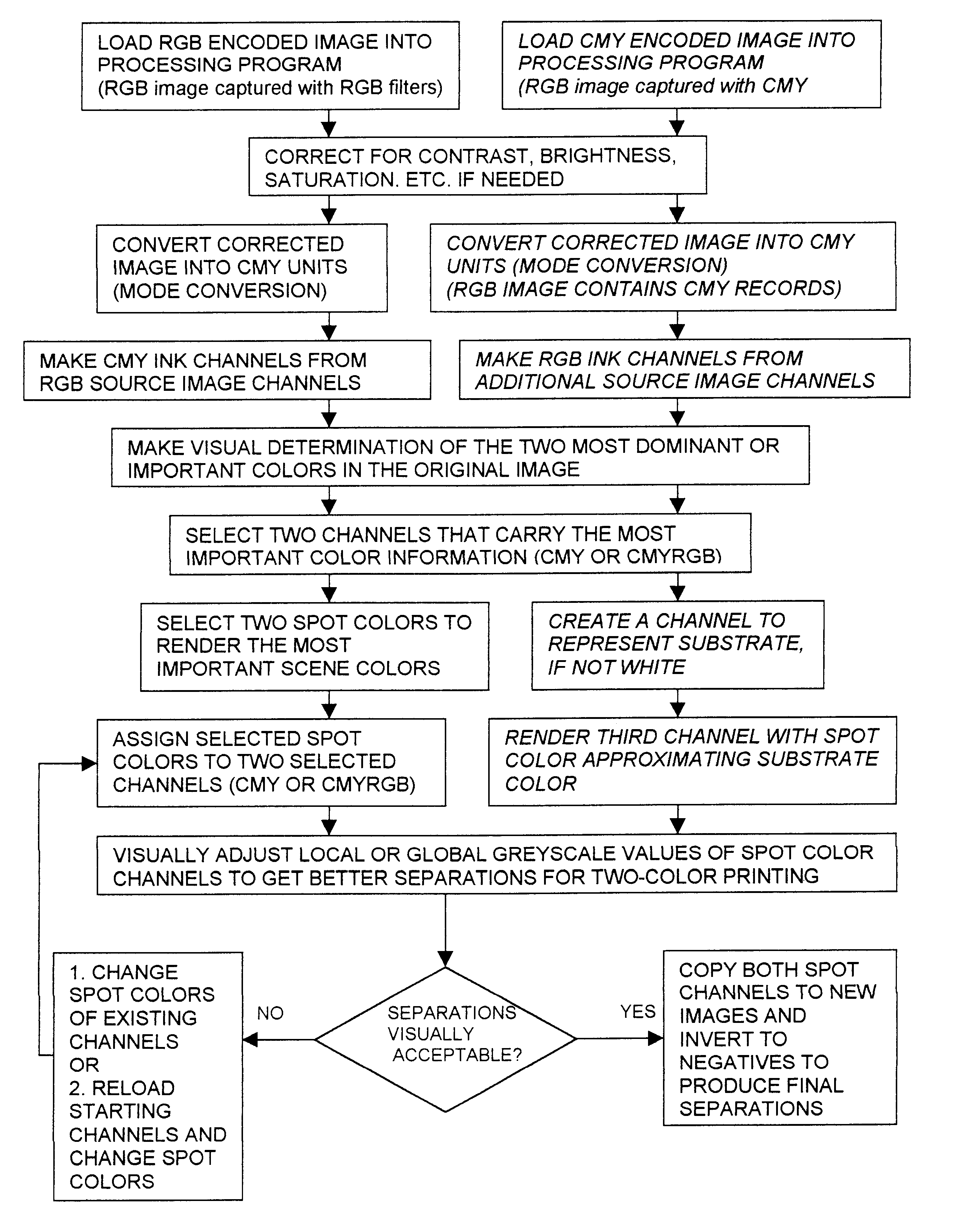

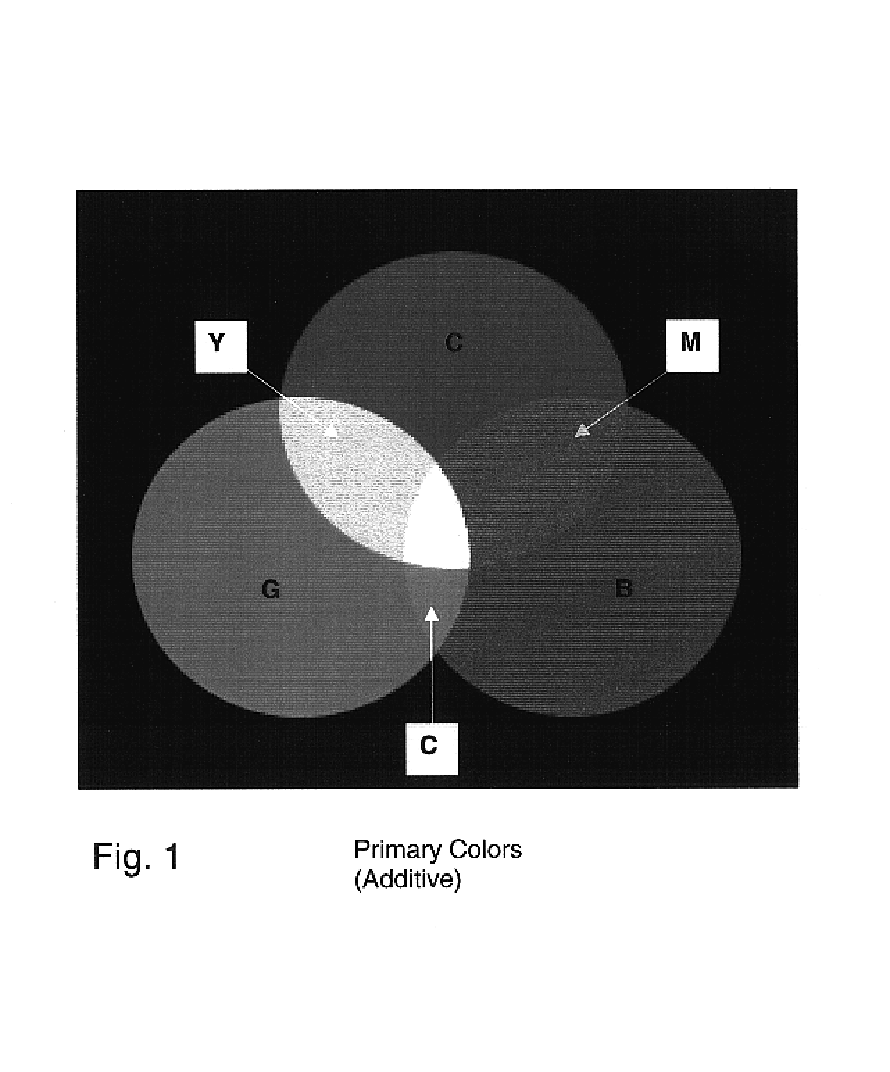

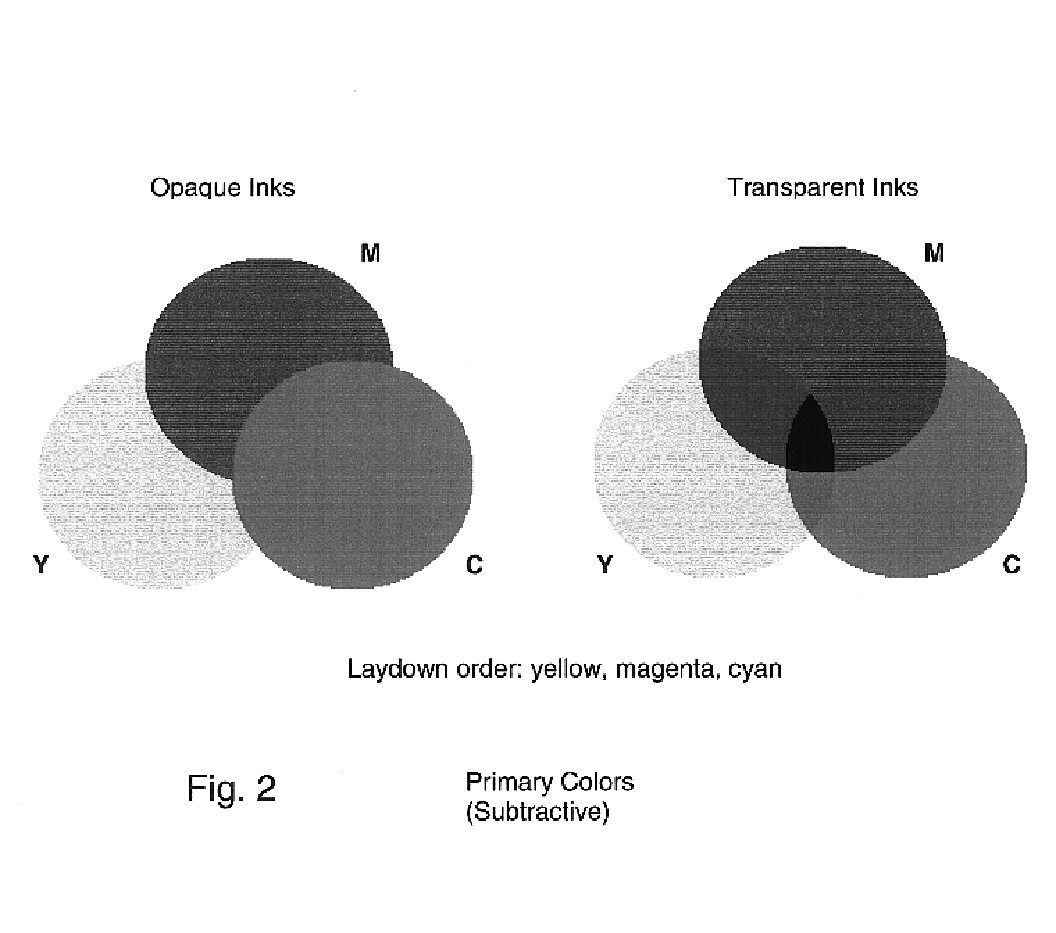

Color reproduction process

ActiveUS7054031B2Attractive colorGood effectDigitally marking record carriersDigital computer detailsColor printingAdditional procedure

A method of color printing is described in which only two transparent inks are used to reproduce a source image The original digitally encoded image in red, green and blue colors may be initially adjusted for contrast, brightness, color balance, and tonal value. This is then converted to cyan, magenta and yellow encoding. The two of these channels which best represent the dominant colors of original image are then selected. The critical colors of the original image to be reproduced with reasonable accuracy are determined and spot colors that best represent these are selected from an ink palette The spot colors are assigned to the selected channels to which they have the closest color relationship. These two channels are next superimposed to form a composite image and their greyscale values are adjusted to produce an image most closely resembling the desired final image. New positive separations are then made and inverted to negative images from which printing plates can be prepared. A third channel may be introduced approximating the color of a colored substrate before the final greyscale adjustment. This channel is not printed, however. An additional procedure useful with colored substrates is to prepare a masking channel which will deposit an opaque ink, usually white, to underlie the two transparent inks and further help control substrate color. Under this implementation, the third channel is printed. The method is capable of rendering very attractive color images on substrates such as the unbleached kraft paper used for corrugated shipping containers.

Owner:INT PAPER CO

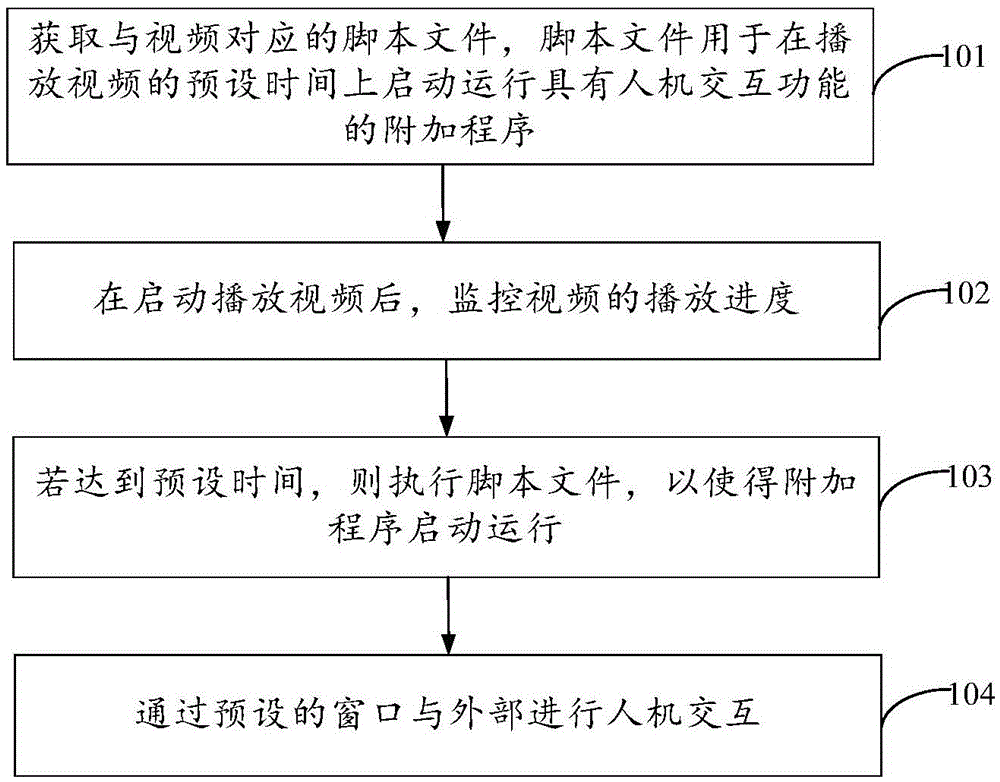

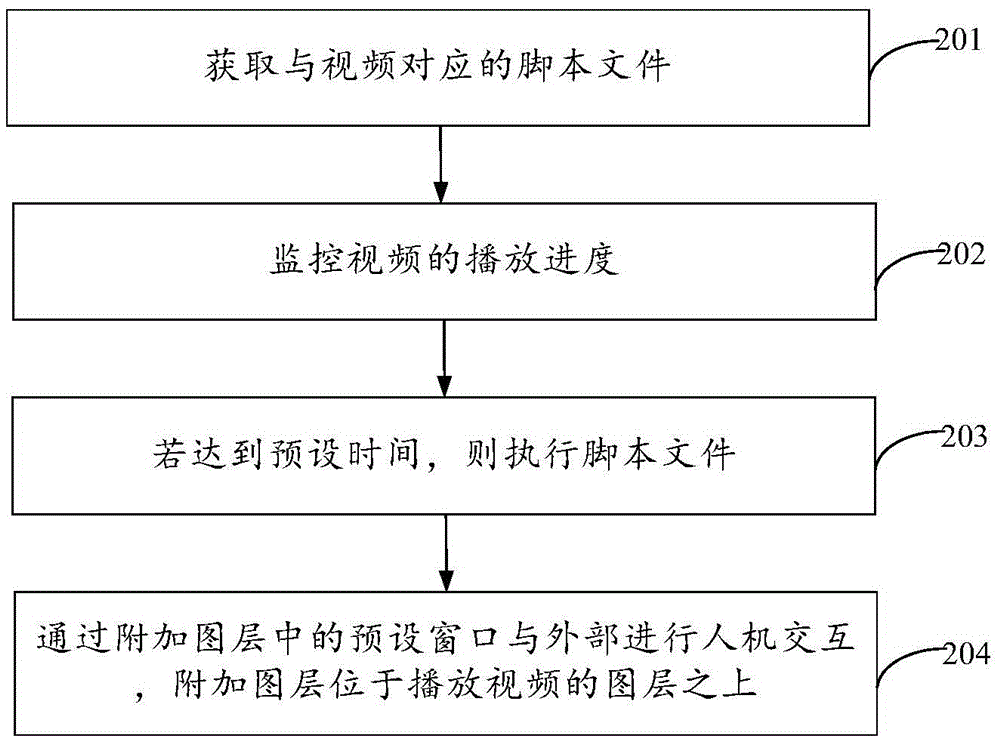

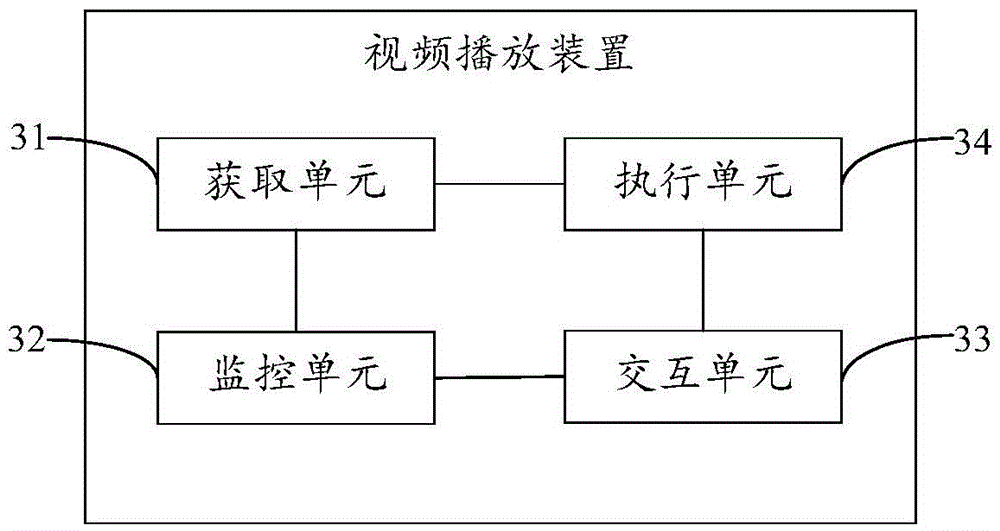

Video play method and apparatus

InactiveCN105657545ASingle solutionRealize human-computer interactionSelective content distributionAdditional procedureHuman–robot interaction

Embodiments of the present invention provide a video play method and apparatus. The method mainly comprises the steps of acquiring a script file corresponding to a video, wherein the scrip file is used for starting and running an additional procedure with a human-computer interaction function in a preset time during which the video is played; after starting playing the video, monitoring the play progress of the video; if a preset time is reached, executing the script file, so as to start and run the additional procedure; and performing human-computer interaction with external world by using a preset window. Compared with the prior art, human-computer interaction with the user can be increased in video play.

Owner:LETV CLOUD COMPUTING CO LTD

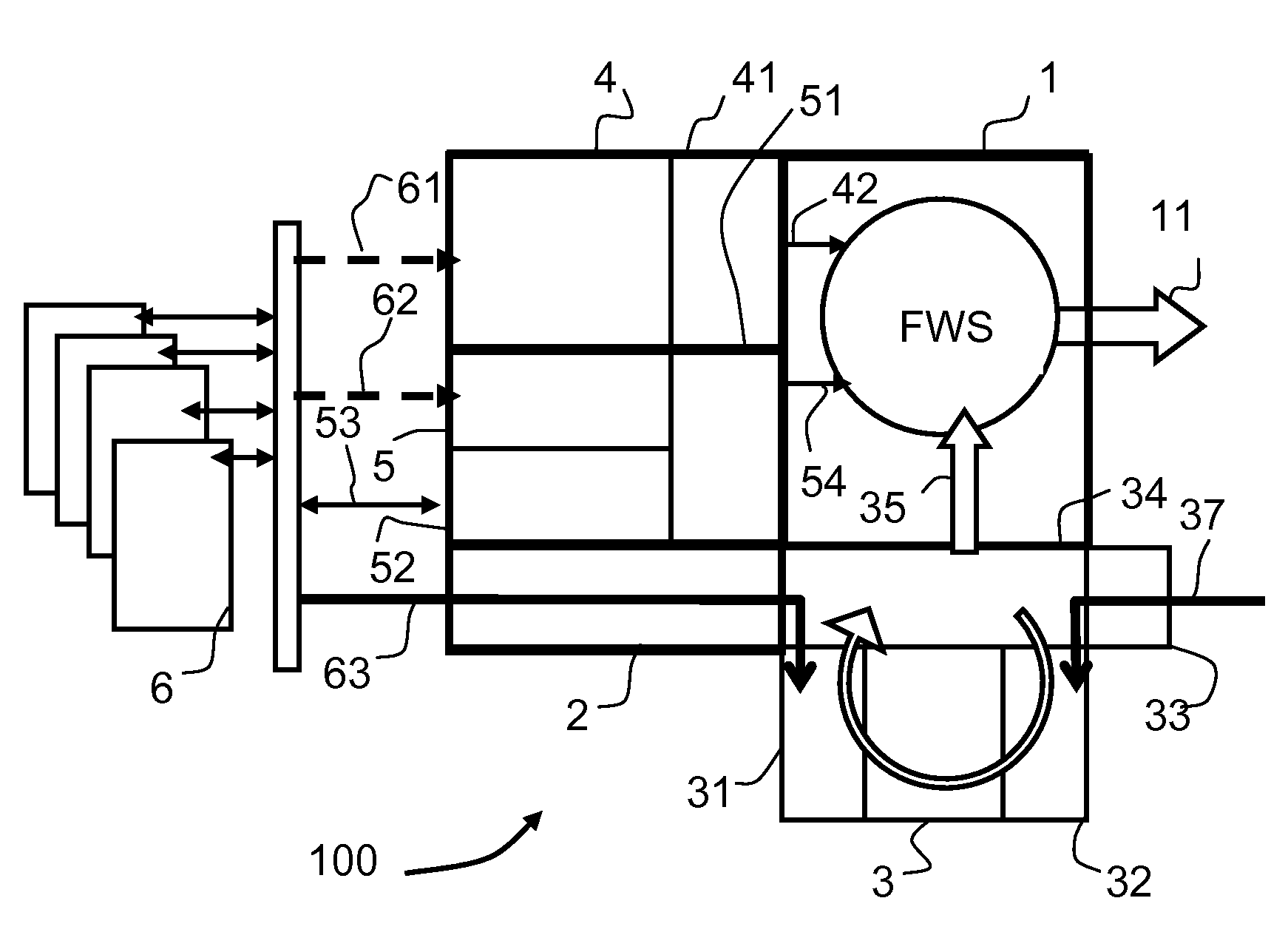

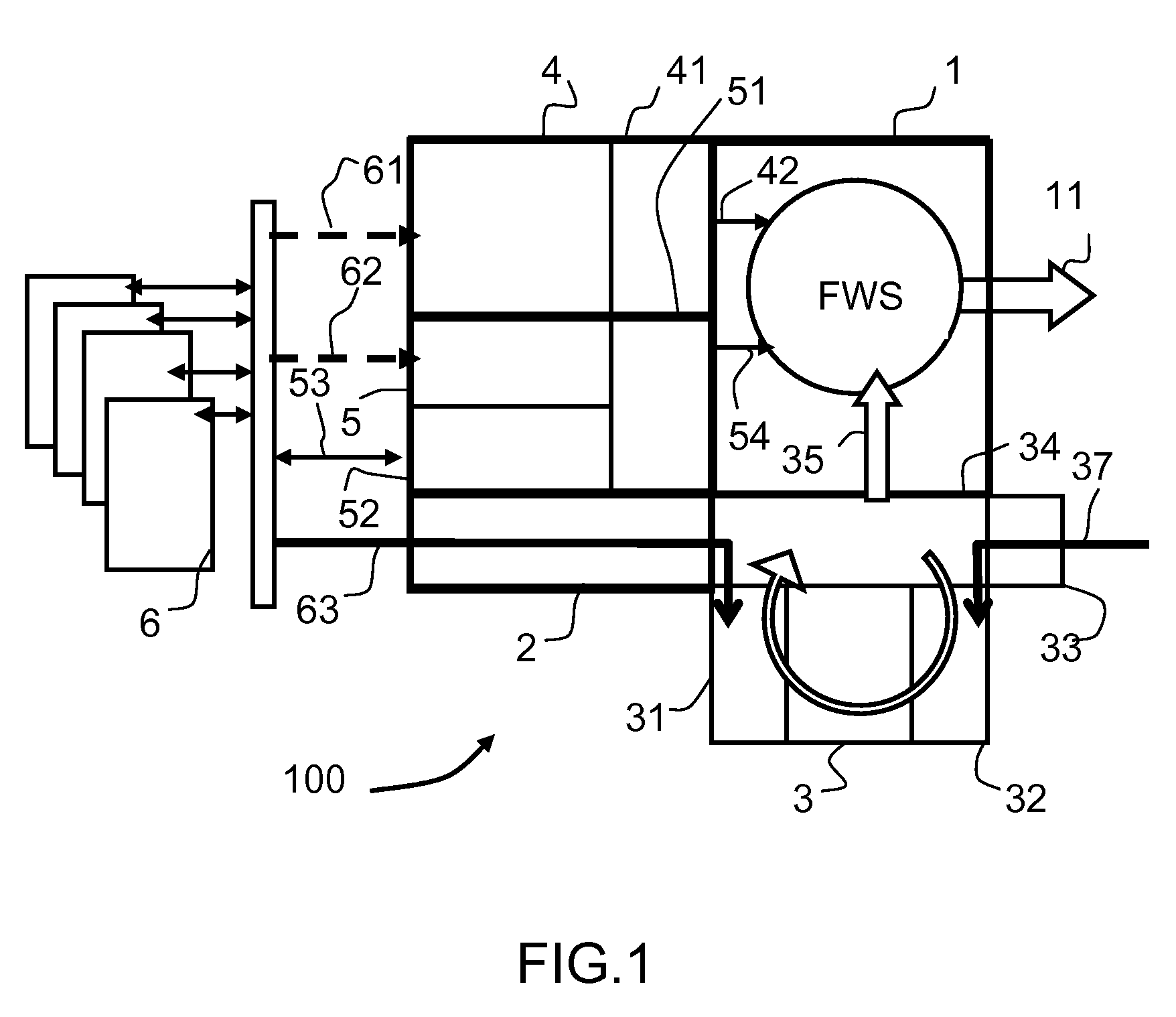

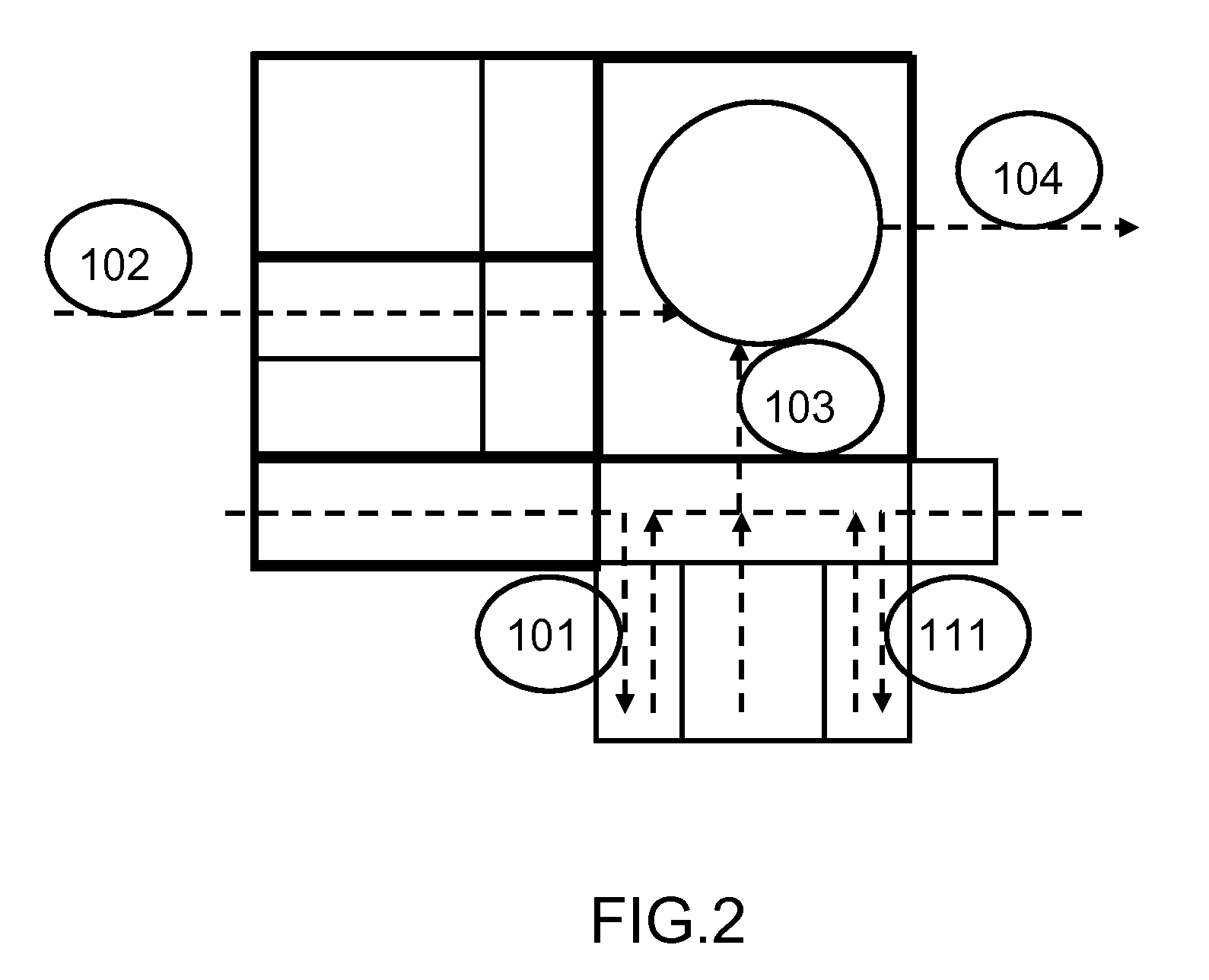

Device and Method for Task Management for Piloting an Aircraft

InactiveUS20120004794A1Easy to detectImprove responseAnalogue computers for trafficComputations using stochastic pulse trainsAlert managementAdditional procedure

A device and method for managing tasks for the piloting of an aircraft includes a means for detecting alerts of the flight systems and an alerts management means for presenting the alerts and the tasks of the resolution procedures to the crew. The device includes means for recording additional procedures and tasks and modifications of attributes of tasks with respect to the tasks recorded in the first recording means, a means for triggering the additional tasks able to order the alerts management means to present the additional tasks, the triggering means operating according to a mode of asynchronous acquisition of trigger data originating from the flight systems and a means for selecting the recorded additional procedures and additional tasks so as to transmit the modified procedures and the modified attributes of the tasks to the alerts management means.

Owner:THALES SA

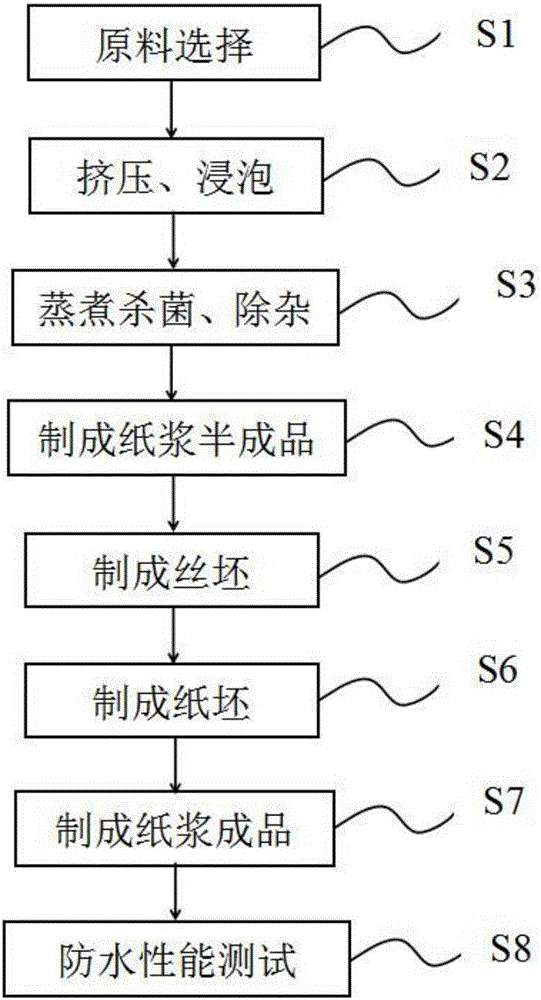

Production method of paper pulp with waterproofness

InactiveCN106638078AImprove waterproof performanceProcess SectionPulp beating methodsDigestersAdhesiveCarton

The invention discloses a production method of paper pulp with waterproofness, and belongs to the technical field of paper pulp production. The method includes the following steps of raw material selection, extrusion, soaking, cooking sterilization, impurity removal, preparation of a paper pulp semi-finished product, preparation of a filament blank, preparation of ground paper, preparation of a paper pulp finished product, and waterproofness testing. According to the method, a new technology is adopted to make the waterproof paper pulp, it can be avoided that an additional procedure is needed in carton processing, a composite dampproof adhesive and YF-921 cationic starch are added directly in the paper pulp processing process to form the waterproof paper pulp, the outward processing of waterproof layer coating is not needed in the midway of the carton manufacturing process, the procedures are simplified, and the cost is reduced; according to the paper pulp produced through the method, the outward processing of waterproof layer coating is not needed, it is only needed to make the waterproof paper pulp with the needed model and specification, and corresponding waterproof cartons can be made as needed; the waterproof capability of the paper pulp is effectively improved.

Owner:中山市天鹏包装制品有限公司

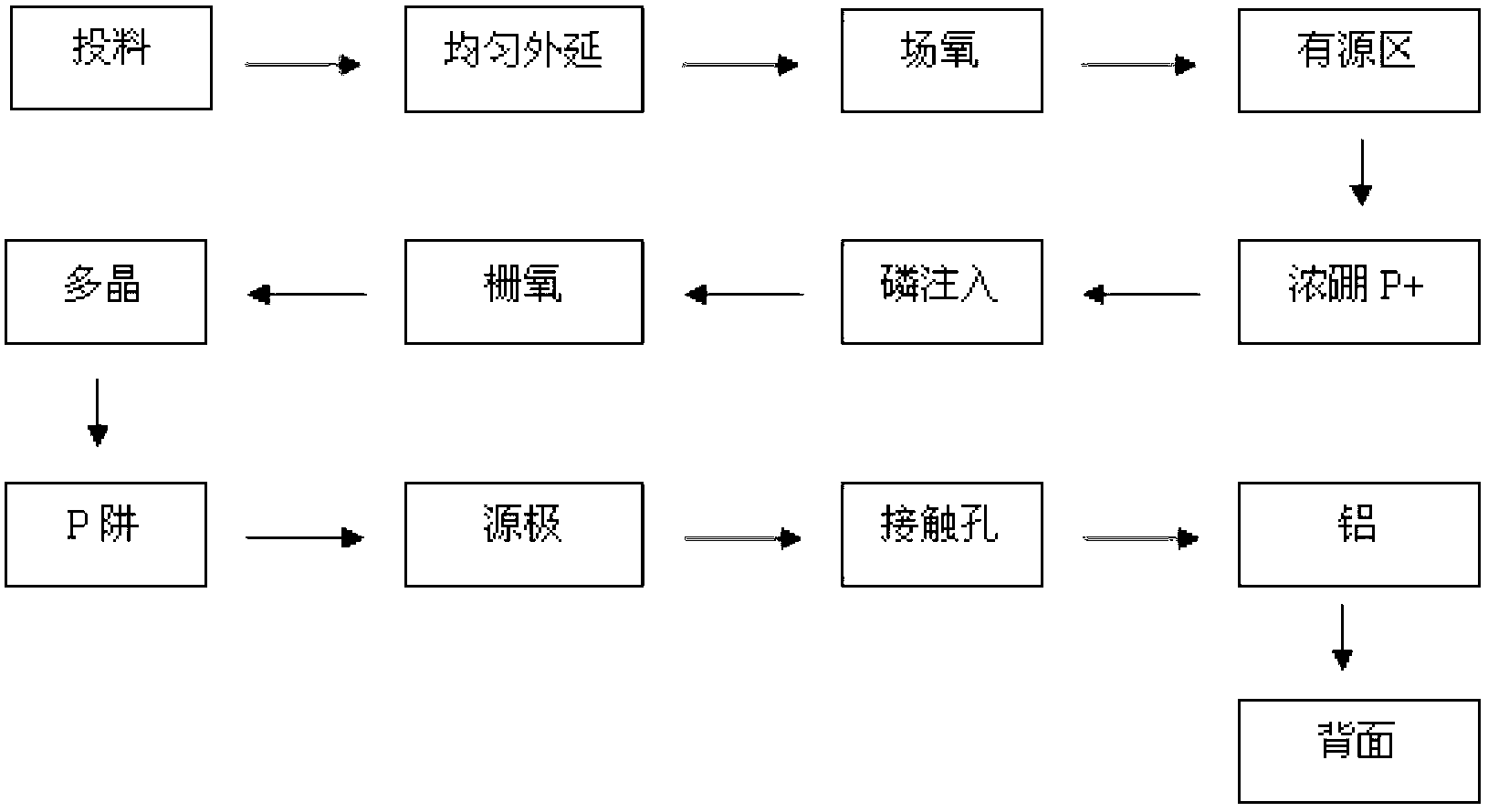

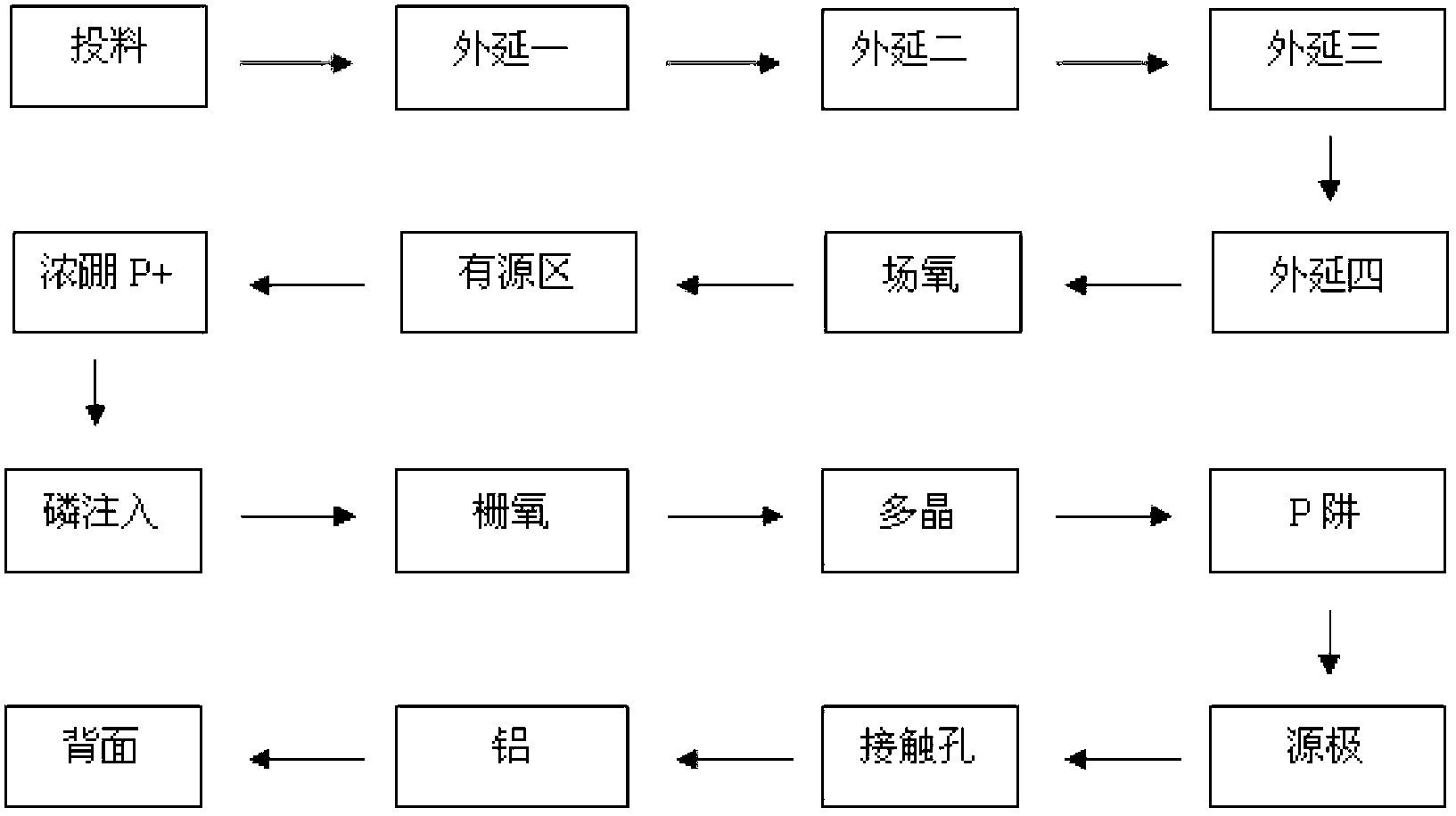

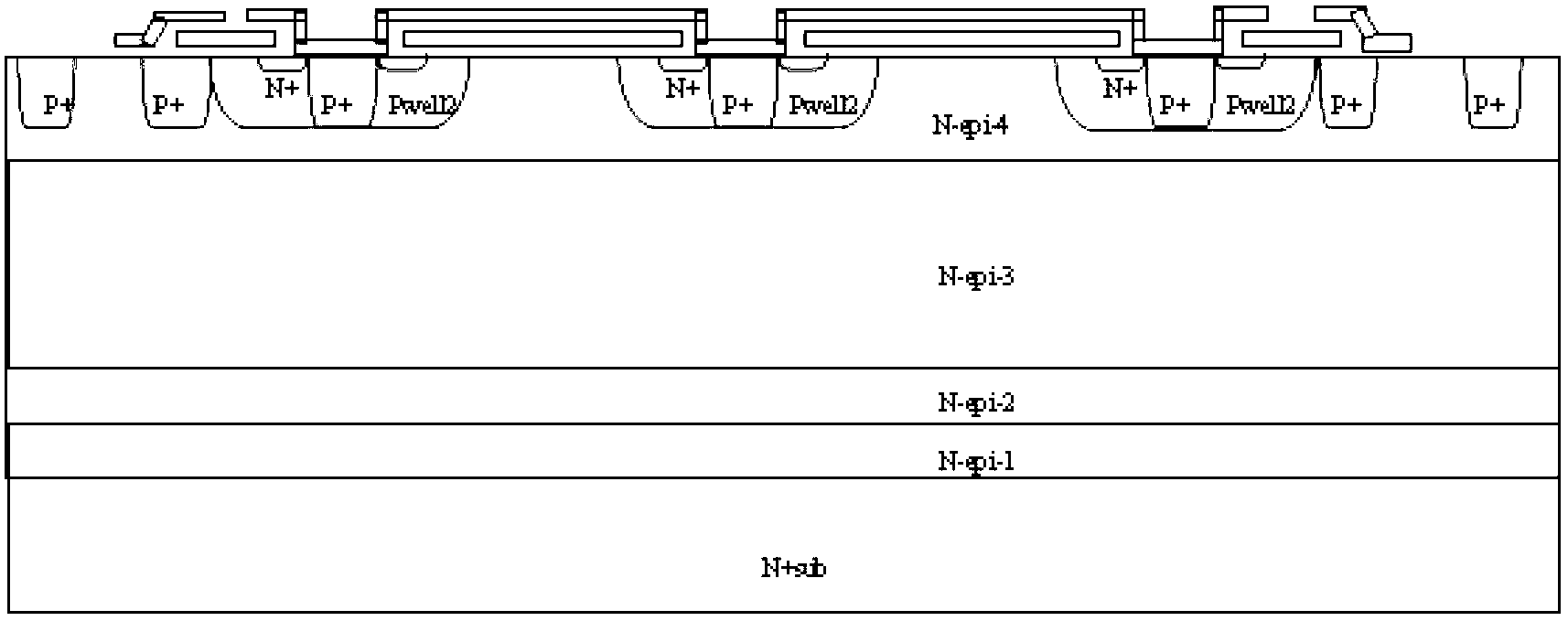

Process for manufacturing series of intermediate-voltage N-type vertical conduction double-diffused metal oxide semiconductor transistors by using composite epitaxy

InactiveCN102709191AImprove safe work areaImprove reliabilitySemiconductor/solid-state device manufacturingHigh concentrationEtching

The invention discloses a process for manufacturing series of intermediate-voltage N-type vertical conduction double-diffused metal oxide semiconductor (VDMOS) transistors by using composite epitaxy. The process comprises the steps of: batch feeding, first-step epitaxy, second-step epitaxy, third-step epitaxy, fourth-step epitaxy, field oxidation, etching of an active area, high-concentration boron injection and junction depth increasing, phosphorus injection and junction depth increasing, gate oxidation, polycrystalline silicon gate deposition and doping, PWELL boron injection and junction depth increasing, source N+ arsenic injection and junction depth increasing, contact hole etching, aluminum evaporation and corrosion, back thinning evaporation and the like. By a process platform, any additional procedure and operation is avoided, and on-resistance can be lowered by 10 percent on the basis of ensuring withstand voltage; by the VDMOS transistor manufactured by the process, a high-current intense-electric field effect can be effectively suppressed, and the safety working area of a device is enlarged to a certain extent; and the on-resistance is lowered, so that power consumption is greatly reduced, energy sources are saved, and the reliability of a circuit is greatly improved.

Owner:WUXI CRYSTAL SOURCE MICROELECTRONICS CO LTD

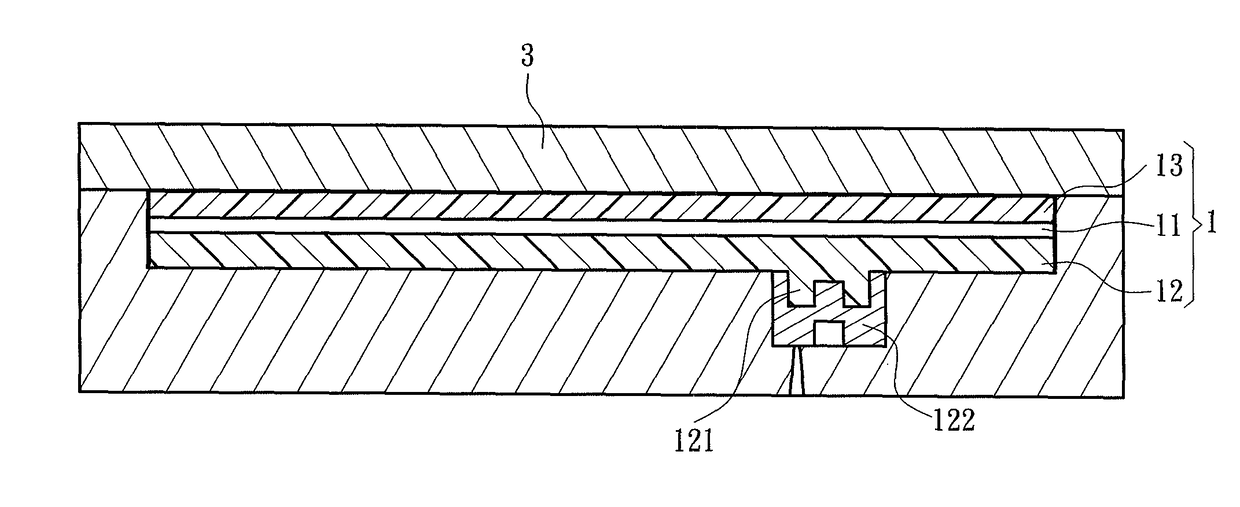

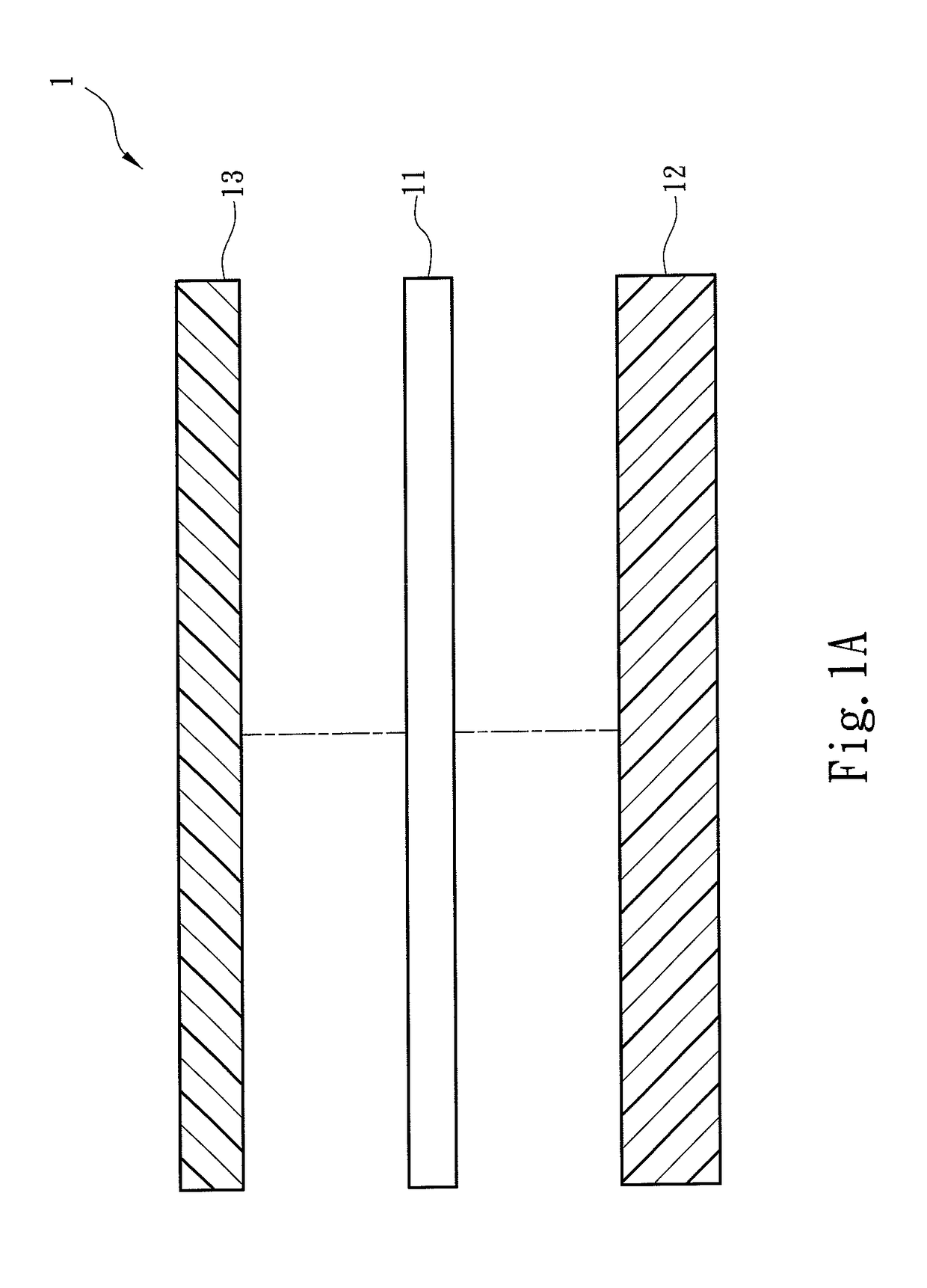

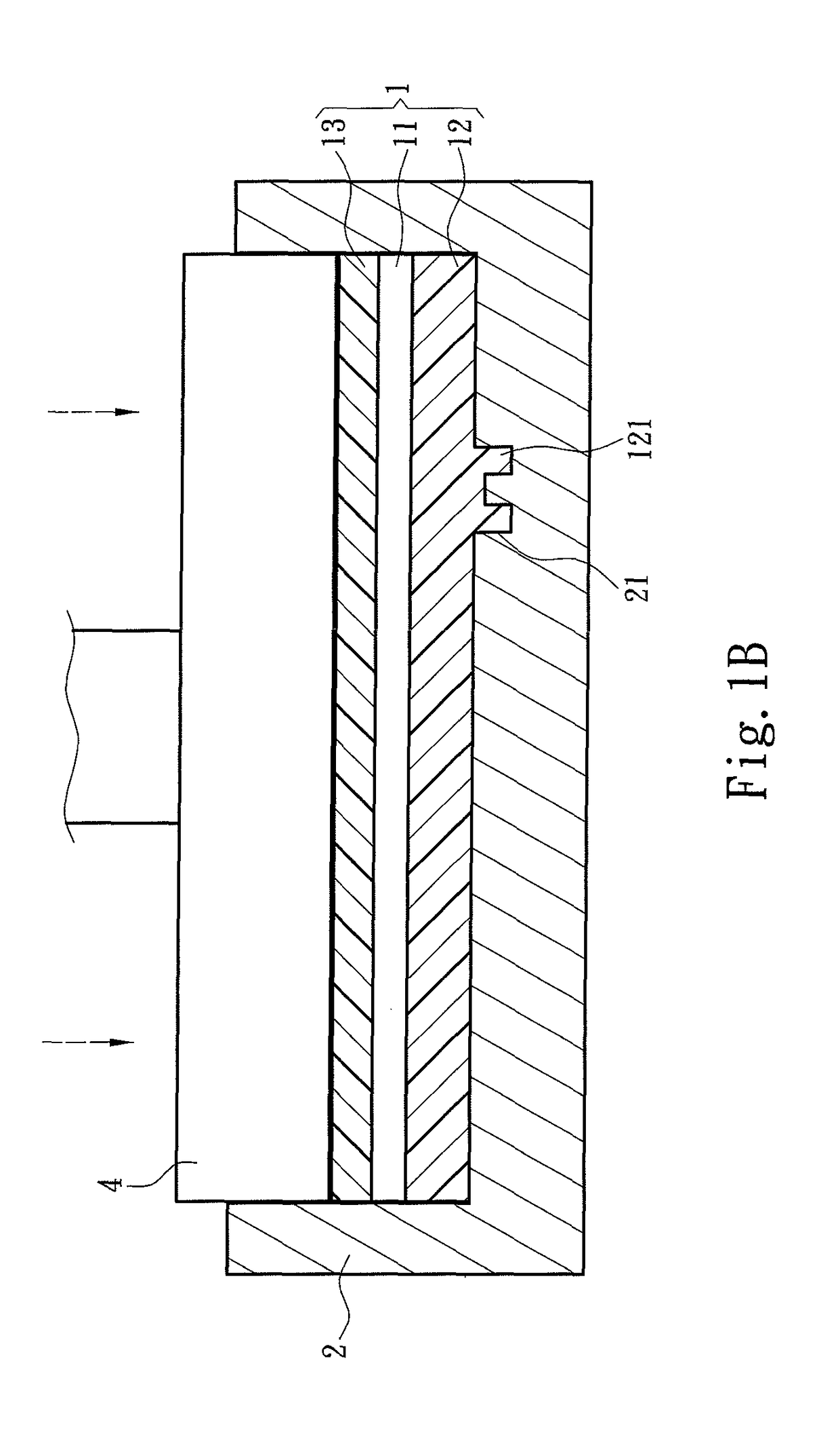

Electronic device casing including coupling structure and method of manufacturing same

InactiveUS9801294B2Simple manufacturing processShorten production timeCasings/cabinets/drawers detailsCeramic shaping apparatusShell moldingPlastic materials

A method for manufacturing an electronic device casing having a coupling structure is provided. The electronic device casing is made of a casing material including a supportive substrate and a first thermoplastic substrate. A preliminary connecting section is formed on the first thermoplastic substrate by a hot-pressing molding process, and a molding plastic material is injected onto the preliminary connecting section by an in-mold injection process. After being cooled, the molding plastic material engages with the preliminary connecting section to form a secondary connecting section for a coupling element to couple with. Thus, the coupling structure of the electronic device casing can be directly formed during a manufacturing process without any additional procedures, thereby overall manufacturing time and costs are reduced.

Owner:SUNTENG NEW TECH

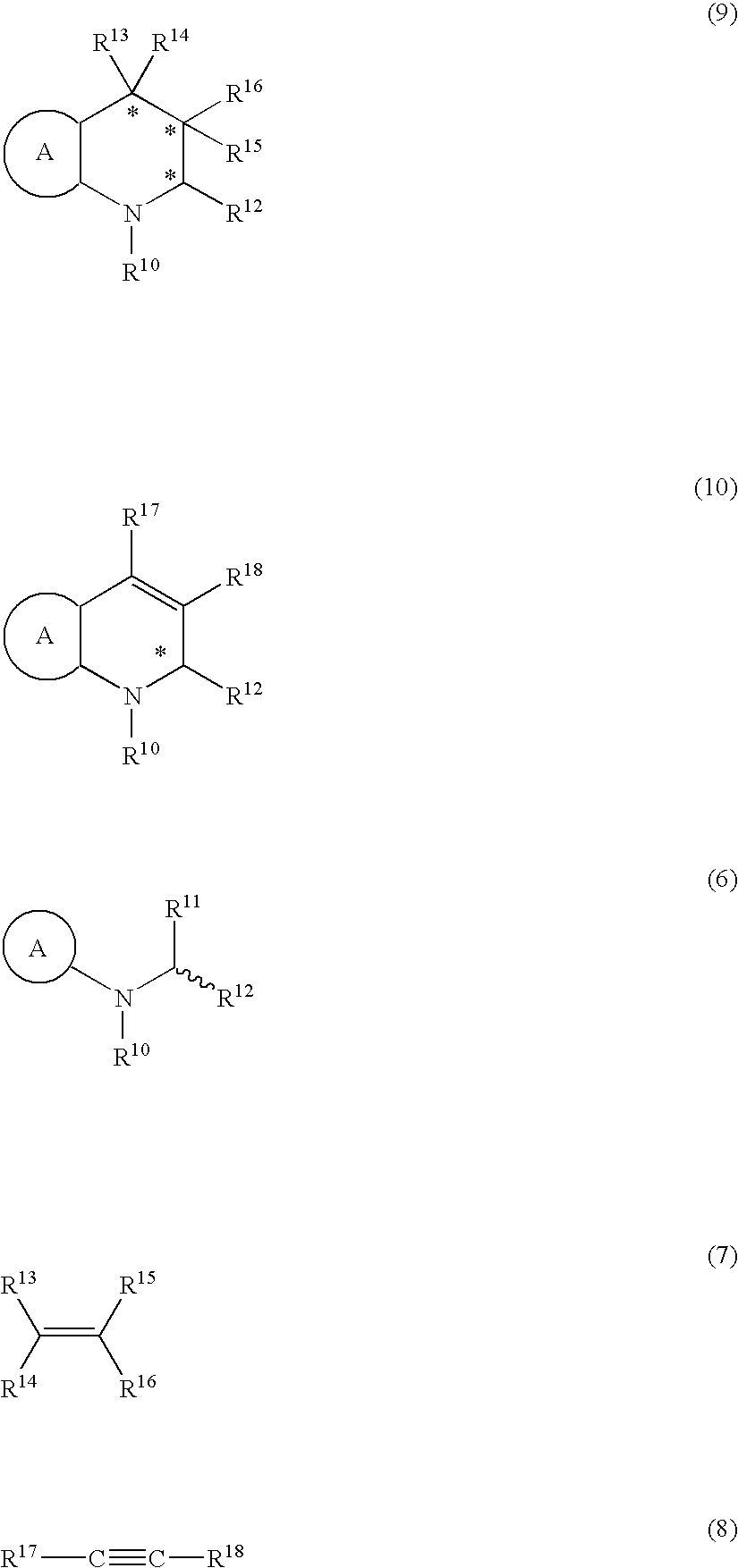

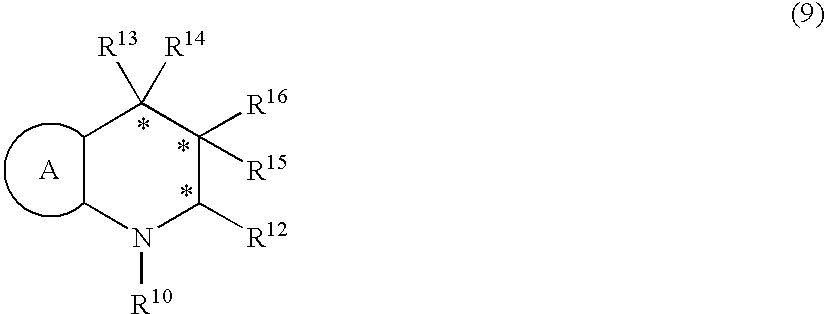

Method for producing optically active amines

InactiveUS20060100239A1Short stepsHigh optical purityBiocideSilicon organic compoundsAdditional procedureAlkyne

The present invention provides a method for producing optically active amines of formula (9) or (10): which comprises reacting an imine equivalent of formula (6): with an alkene of formula (7) or an alkyne of formula (8): in the presence of a chiral catalyst, which method does not require additional procedures such as introduction and removal of protecting groups and gives said amines with high purity and high operability. The optically active amines are useful as synthetic 15 intermediates for pharmaceuticals, agrochemicals, etc.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Polyimide porous film and preparation method thereof

The invention discloses a polyimide porous film and a preparation method thereof, belonging to the field of polymeric dielectric materials. The polyimide porous film has a dense surface layer and an internal porous structure which are integrally formed, and has a pore diameter of 400 to 4000 nm and a porosity of 60% or more. The preparation method comprises the following steps: coating a substratewith a mixture containing polyamic acid, a pore-forming agent and a solvent so as to form a polyamic acid liquid film; drying the polyamic acid liquid film, wherein the temperature at one side of thesubstrate of the polyamic acid liquid film is controlled to be lower than the temperature of the surface of the polyamic acid liquid film during drying; and subjecting the dried polyamic acid film toimidization. According to the invention, the polyimide porous film with a dense smooth skin layer on the surface is integrally formed without additional procedures; and the polyimide porous film hashigh porosity, uniform pore diameter, extremely low dielectric constant and good mechanical properties. Moreover, the preparation method is shortened in process flow, low in cost and easy for mass production.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

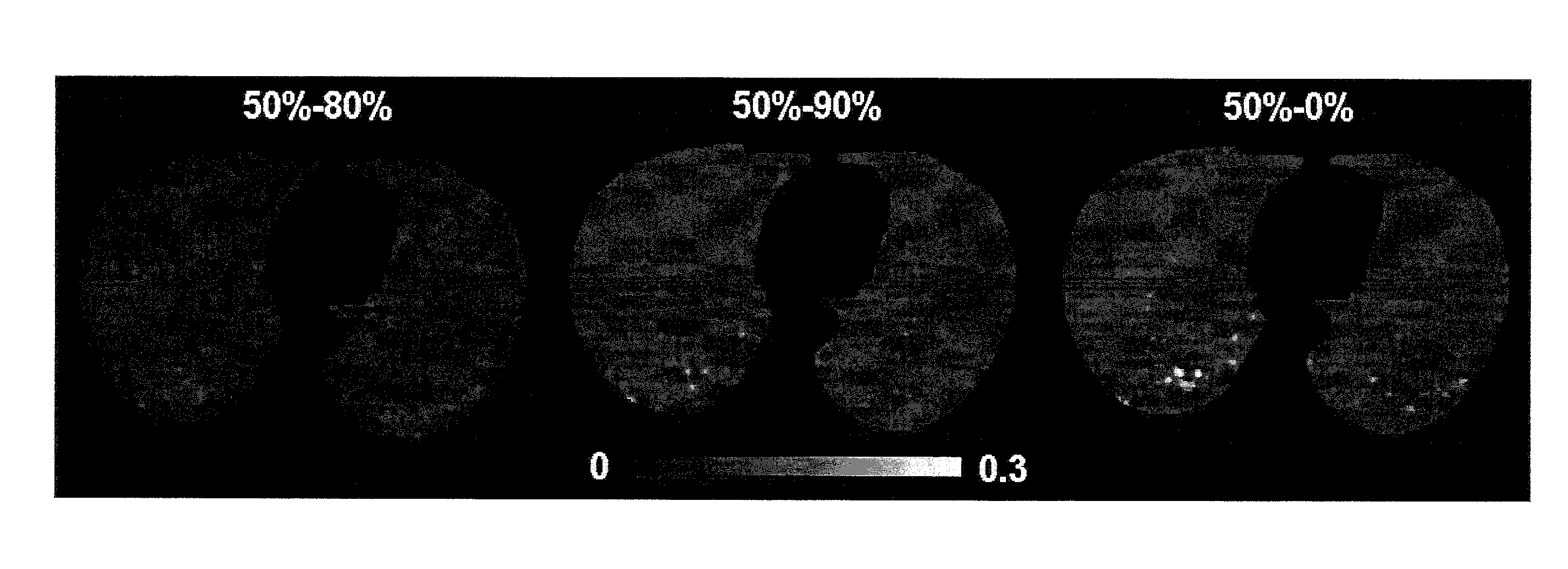

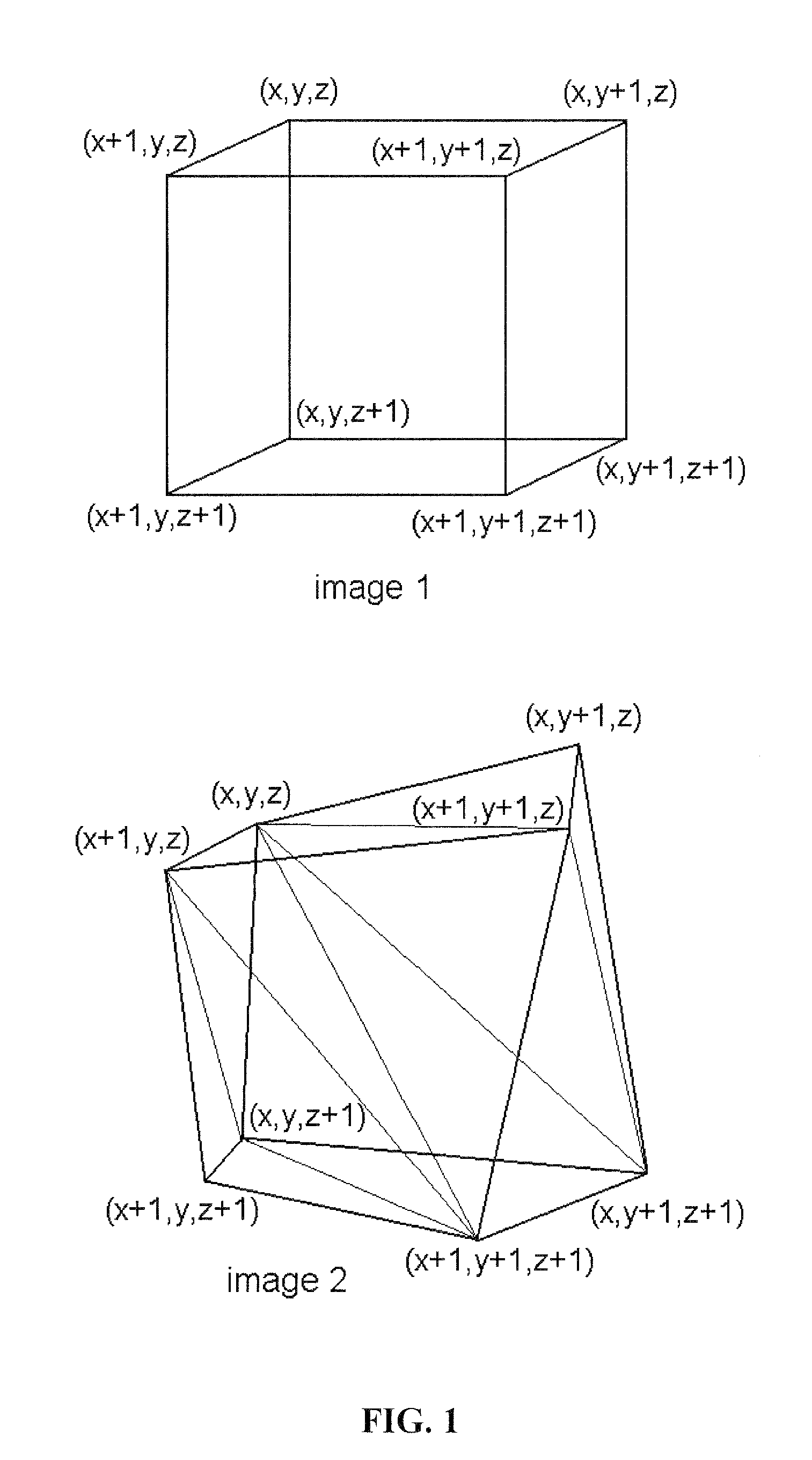

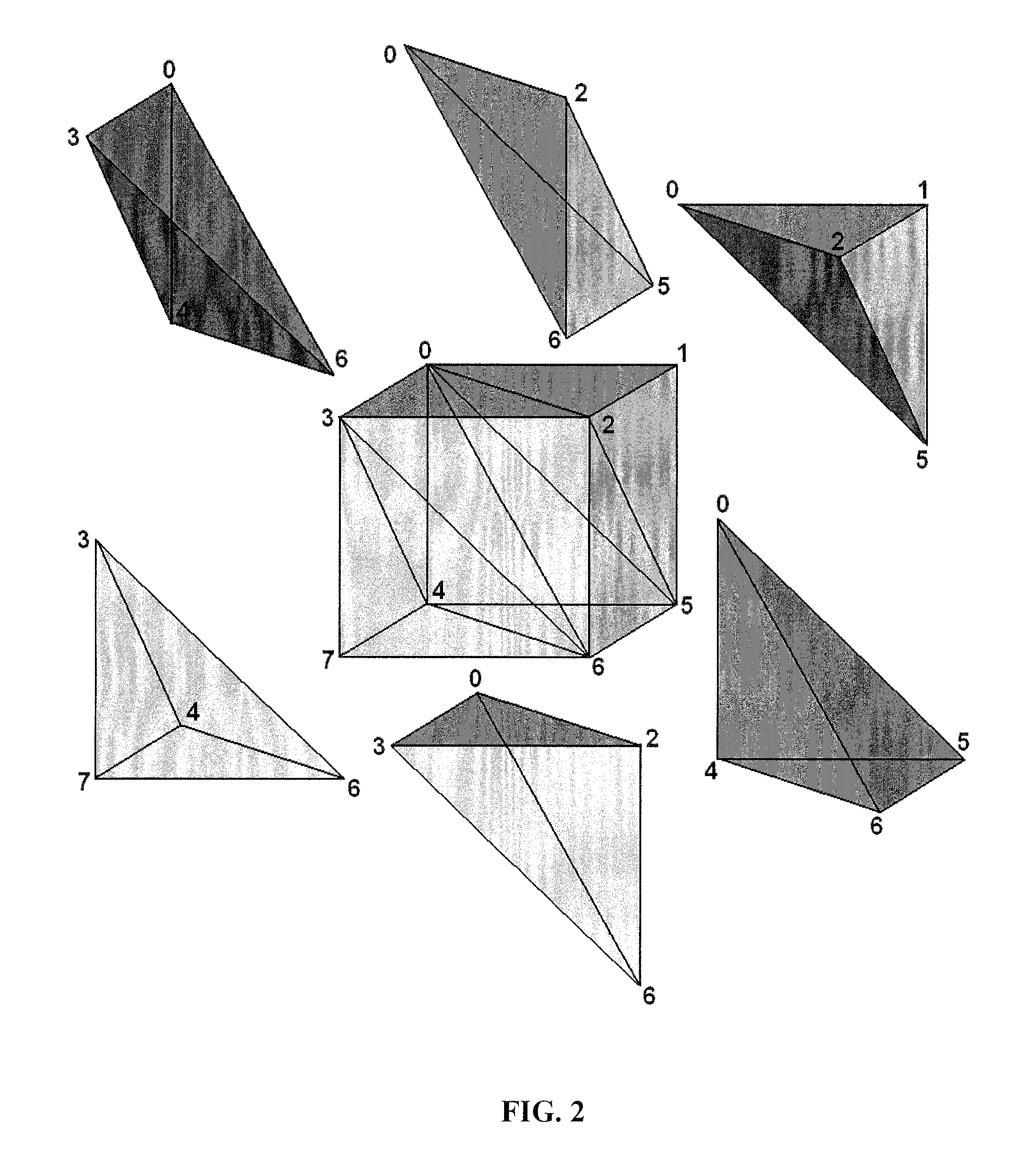

Method and apparatus for pulmonary ventilation imaging using local volume changes

The invention provides a novel method of high-resolution quantifiable pulmonary regional ventilation imaging using a package of computer programs, including deformable image registration and local volume change calculation on 4-D or breath-hold CT images. High resolution 3D ventilation images have been generated using this technique with superior quality. The deformation matrices between different respiration phases are calculated using deformable image registration and applied to calculate local volume change ΔV between respiration phases. The invention provides less image-noise and mismatch sensitivity than other techniques based on CT images, and is less expensive than nuclear medicine imaging. Implemented clinically, the method can derive a patient's pulmonary ventilation information from the same set of 4-D CT images, providing a cheaper but more accurate method to generate clinical lung ventilation image. Such information can be utilized in treatment planning sparing functional lung volumes without additional procedure and cost for lung functional imaging.

Owner:UNIV OF SOUTH FLORIDA

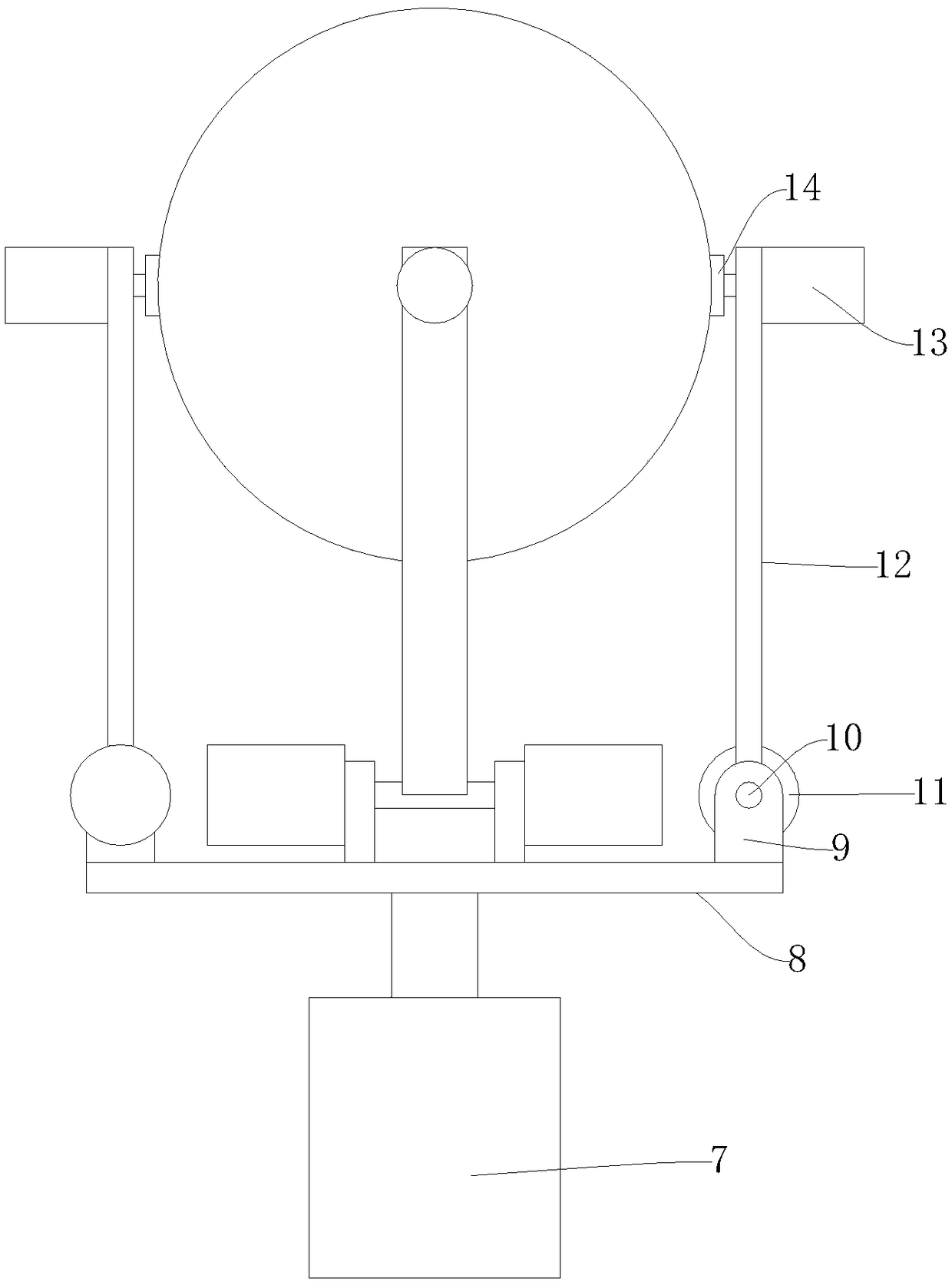

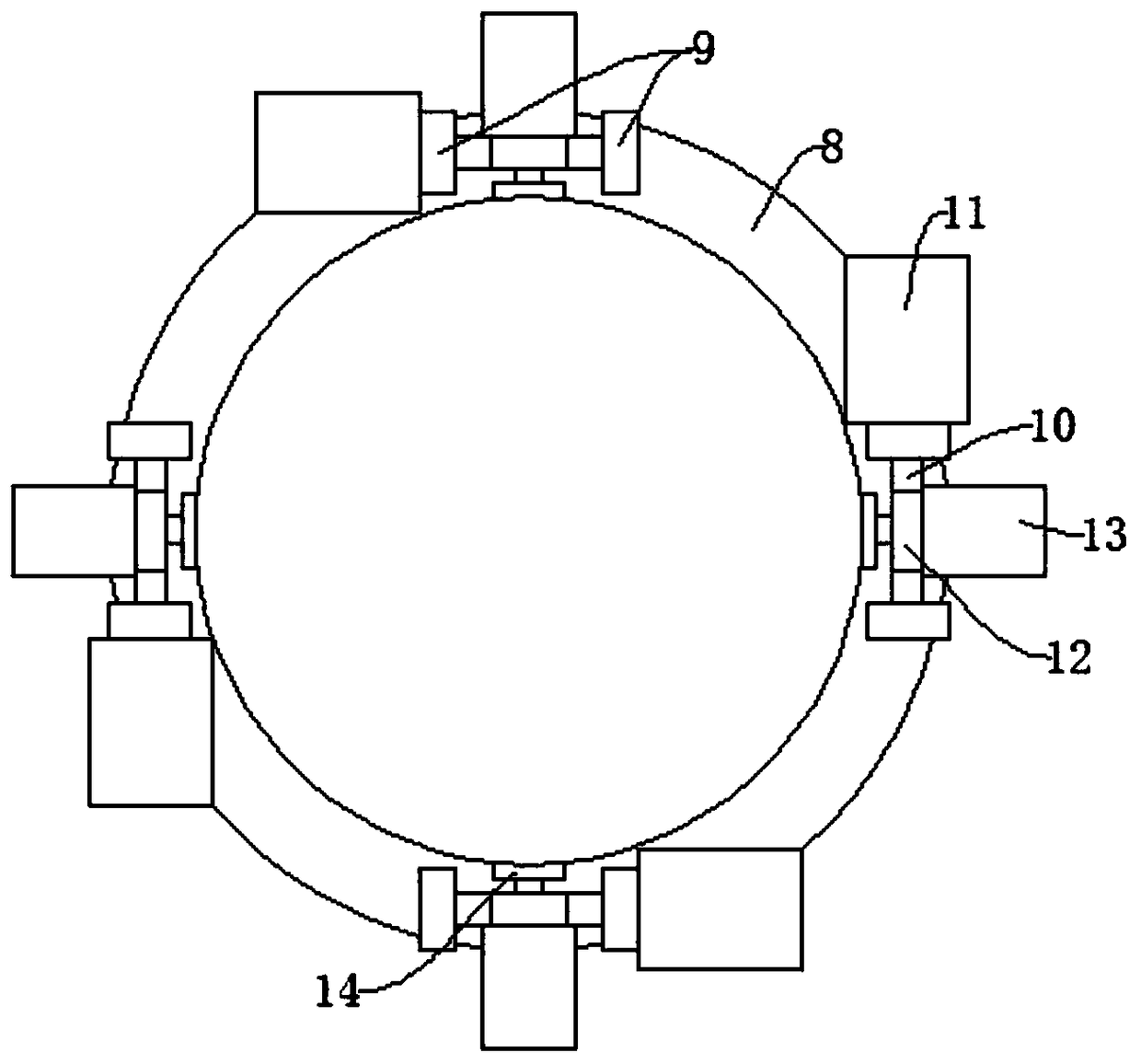

Staggered-distance extrusion forming device and method for bending component

ActiveCN107649529AAdjustable curvatureBreaking through a single shape featureExtrusion diesRelative displacementAdditional procedure

The invention discloses a staggered-distance extrusion forming device and method for a bending component, and relates to a extrusion forming device and method for the bending component. The device andthe method aim to solve a series of problems that in a traditional bending component manufacturing process, the number of required procedures is large, the flexibility of the component is poor, the production efficiency is low, and quality control is difficult to achieve. According to the method, a conventional integral punch for extruding is divided into two or more than two split structures; the split punches are arranged in a staggered manner according to a certain relative displacement amount and fixed; then integral loading forming of blanks is carried out; and the curvature change of the bending component subjected to extrusion forming can be regulated. The single shape feature that conventional extrusion products are mostly long straight lines is broken through, the variety range of the products capable of being formed is enriched, and the application field also tends to be diversified. According to the method, the double effects that extruding and bend and forming are integrated are achieved in a single-pass extrusion technology process, additional procedures are not needed, the required bending component can be machined at one time, the machining process is shortened, theproduction efficiency is improved, and the manufacturing cost is reduced. The staggered-distance extrusion forming device and method for the bending component is used for extrusion and machining forming of the bending component.

Owner:福建祥鑫股份有限公司

Method for producing an optically active beta-amino acid

InactiveUS7015348B2Improve performanceHigh enantiomeric excessOrganic compound preparationOrganic chemistry methodsSynthesis methodsAsymmetric hydrogenation

To provide a producing method of an optically active β-amino acid useful as intermediate for the production of medicines, agricultural chemicals and physiologically active substances, by means of a catalytic and asymmetric synthesis method of high performance and a high enantiomeric excess, without requiring additional procedures such as introduction and removal of protecting group and so on.A producing method of an optically active β-amino acids which comprises subjecting an enamine to an asymmetric hydrogenation.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Array substrate and manufacturing method thereof, and liquid crystal display device

ActiveCN102402090AAppropriate line widthImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayAdditional procedure

The invention discloses an array substrate and a manufacturing method thereof, and a liquid crystal display device. The array substrate comprises a scanning line and a data line, wherein the width of the data line at the joint of the data line and the scanning line is greater than that of the other part of the data line. The invention has the advantages that: the yield of the liquid crystal display device can be improved on the premise of not increasing additional procedures; the process is simple; and the cost is low.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Specimen container for the micro manipulation and biopsy in in-vitro fertilization

InactiveUS20080248563A1Increase speedImprove efficacyBioreactor/fermenter combinationsBiological substance pretreatmentsAdditional procedureEmbryo

A container or dish is useful for the micro manipulation, micro injection, biopsy and fertilization in oocyte and embryo manipulation and culturing. The dish allows the user to more readily perform procedures used to fertilize oocytes by Intracytoplasmic sperm injection (ICSI) or other procedures, biopsy embryos and perform additional procedures for use in assisted reproductive techniques (ART), human reproduction and in-vitro fertilization (IVF). The invention allows ease in use, the reduction in the number of micro tools used in the procedure, as opposed to conventional dishes and procedures, and will allow the user to more readily locate the oocytes and embryos to be handled and worked on. The invention will add repetitiveness, consistency, improve efficacy and ease of procedure and may improve outcomes. The invention will also give the user a more ergonomically practical dish for these types of procedures and related protocols. Specimens other than oocytes and embryos can be treated in the container by means of micro manipulation.

Owner:COOPERSURGICAL INC

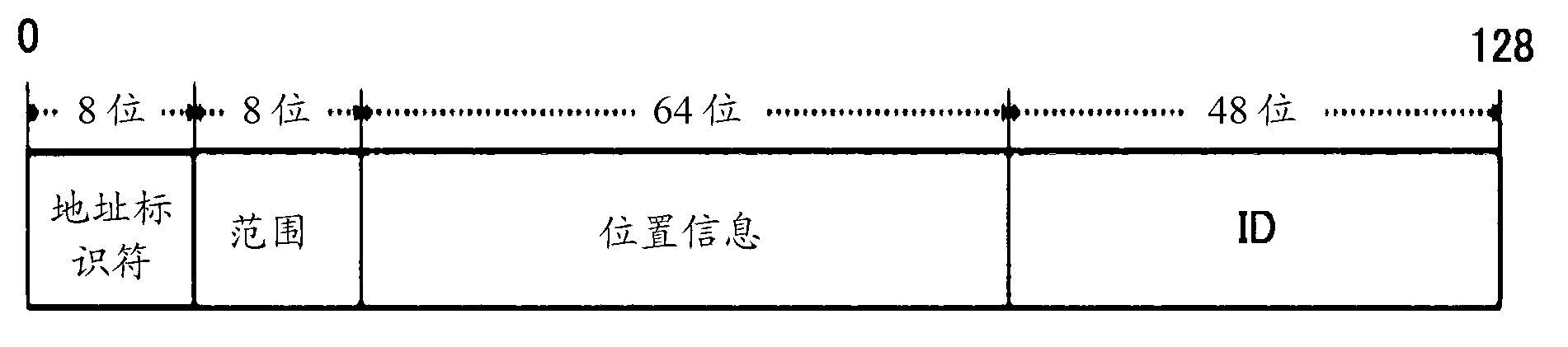

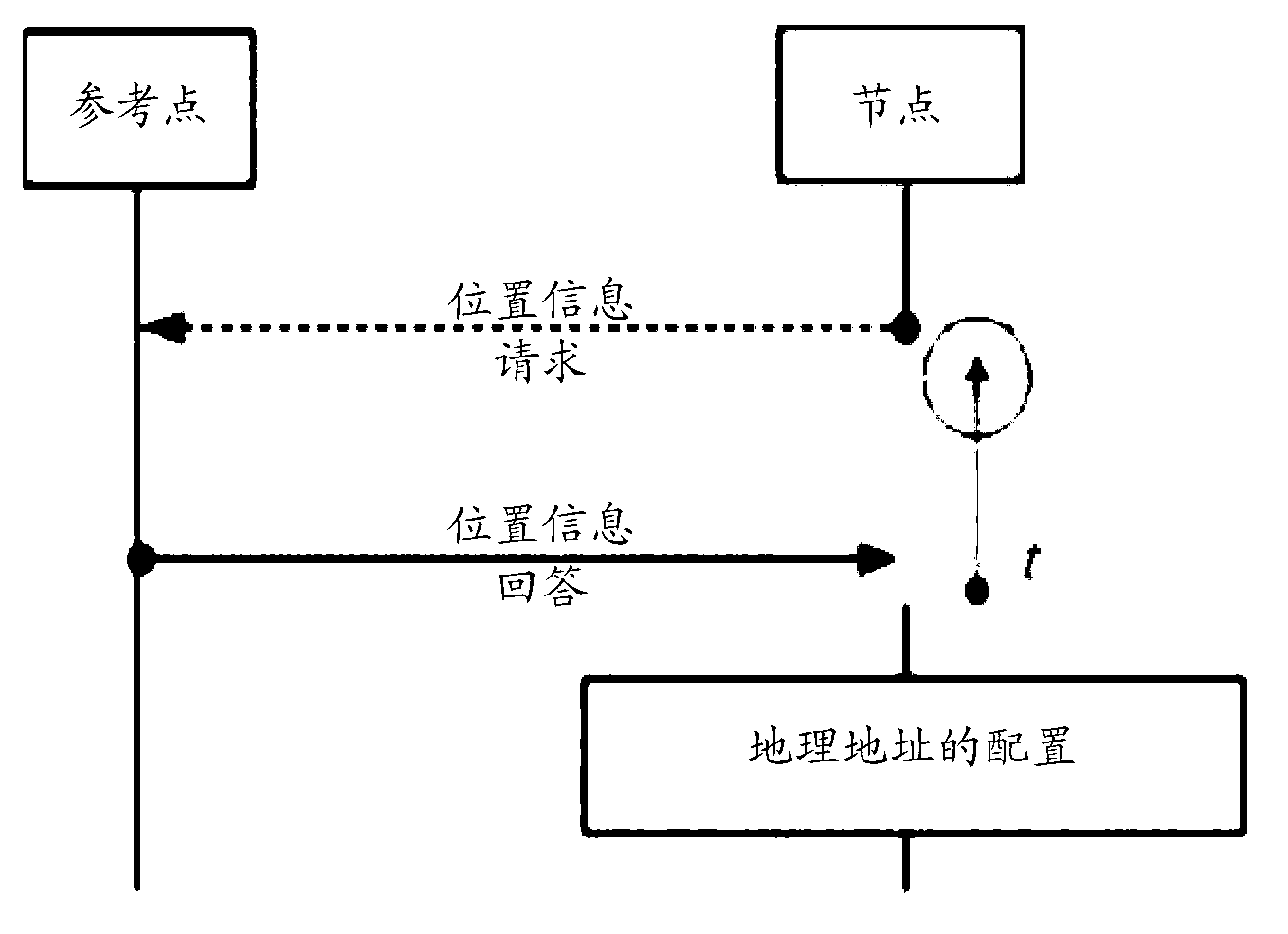

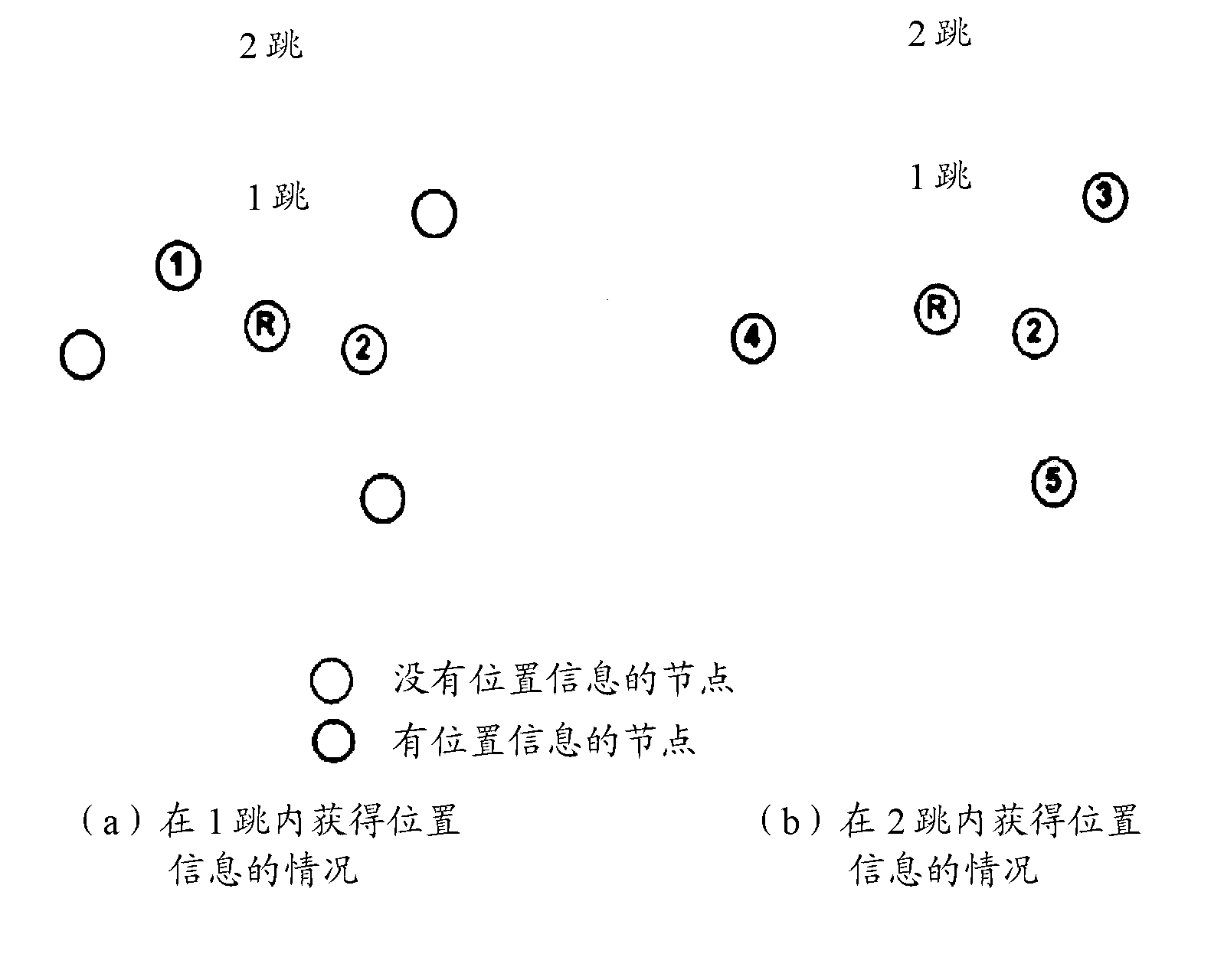

Network system

InactiveCN103053186AReduction procedureImprove routing efficiencyParticular environment based servicesRadio transmission for post communicationTransport systemNetworked system

The present invention relates to a method for setting and transmitting the geographical address of a terminal in a packet transmission system, and more particularly relates to a method for setting and transmitting the geographical address of a terminal in a packet transmission system, whereby additional procedures for providing a positioning service are reduced and routing efficiency can be increased by means of a position-based routing method in which an address is generated that takes into account a geographical concept based on terminal position data and in which position data is used that includes a target address in a router responsible for packet transmission.

Owner:INTELLECTUAL DISCOVERY CO LTD

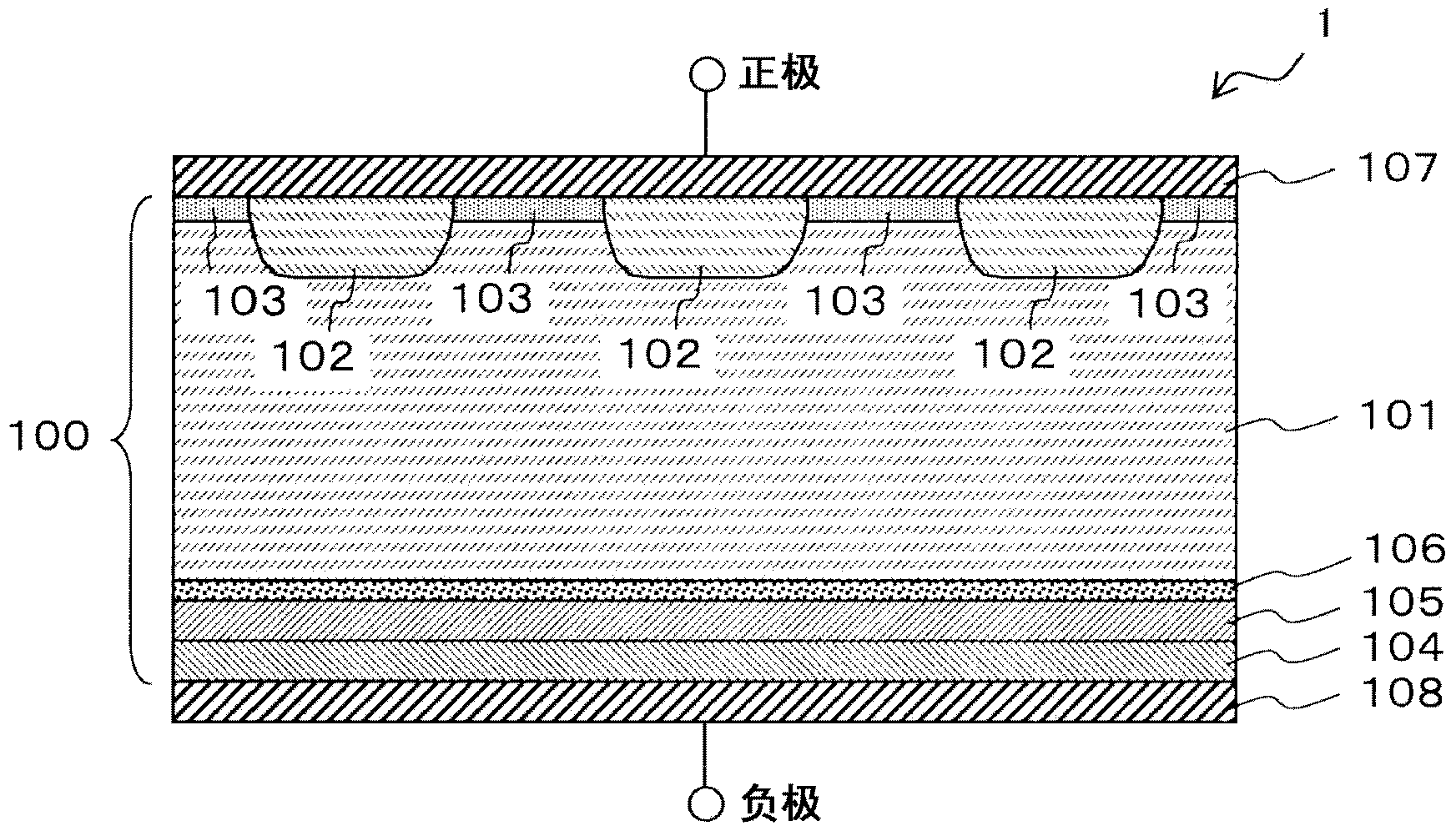

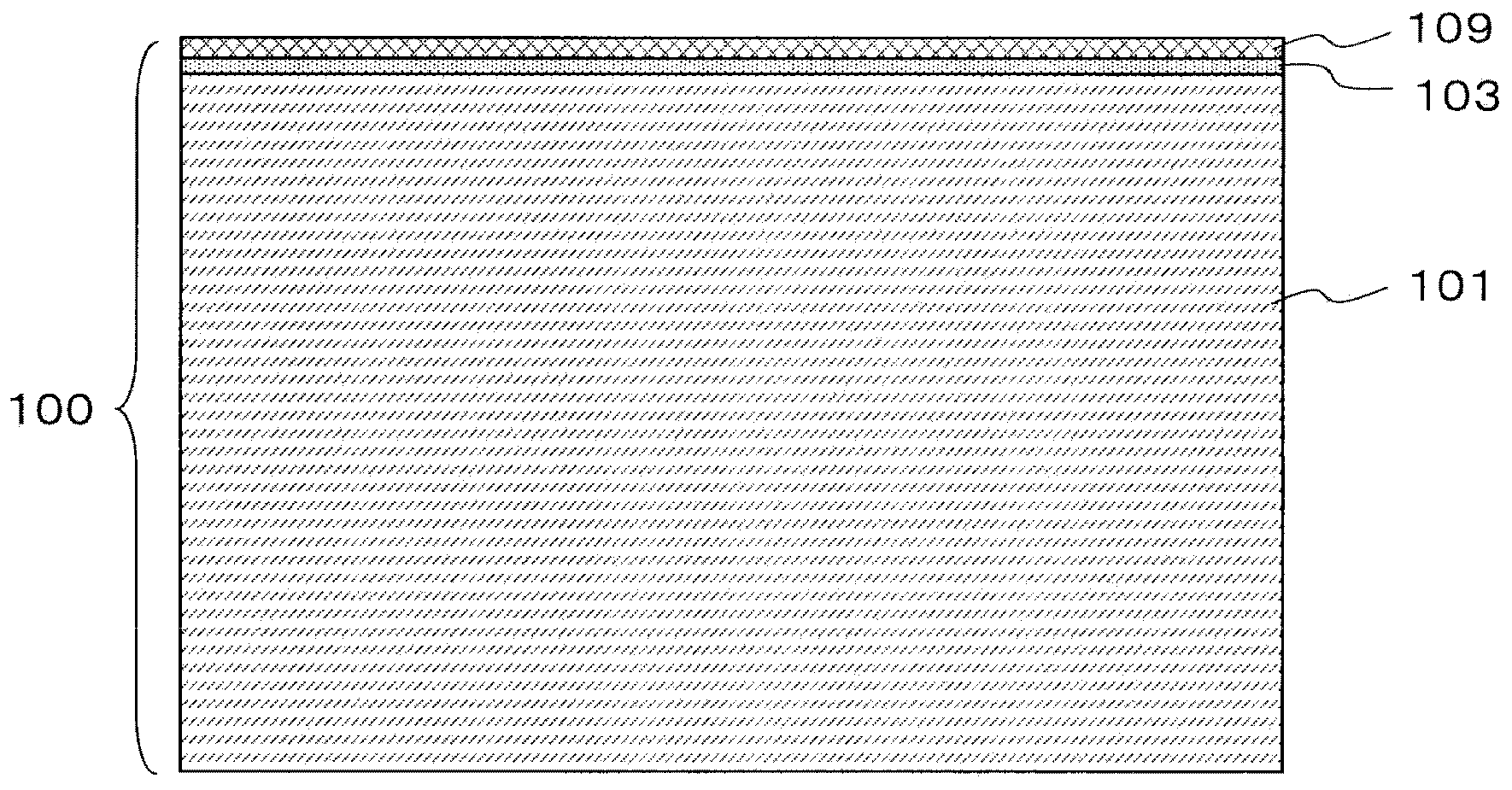

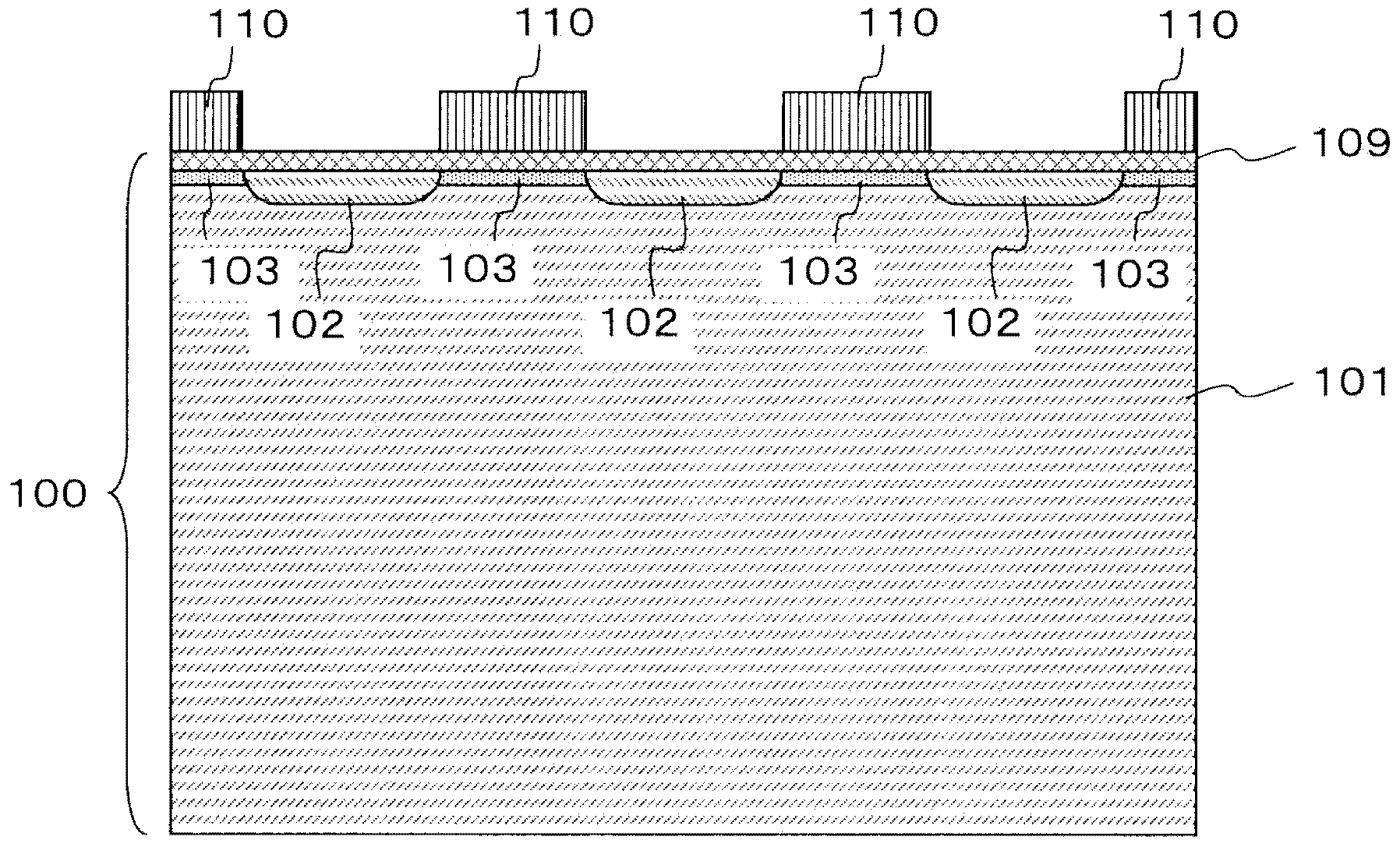

Diode and power conversion system

Owner:HITACHI POWER SEMICON DEVICE

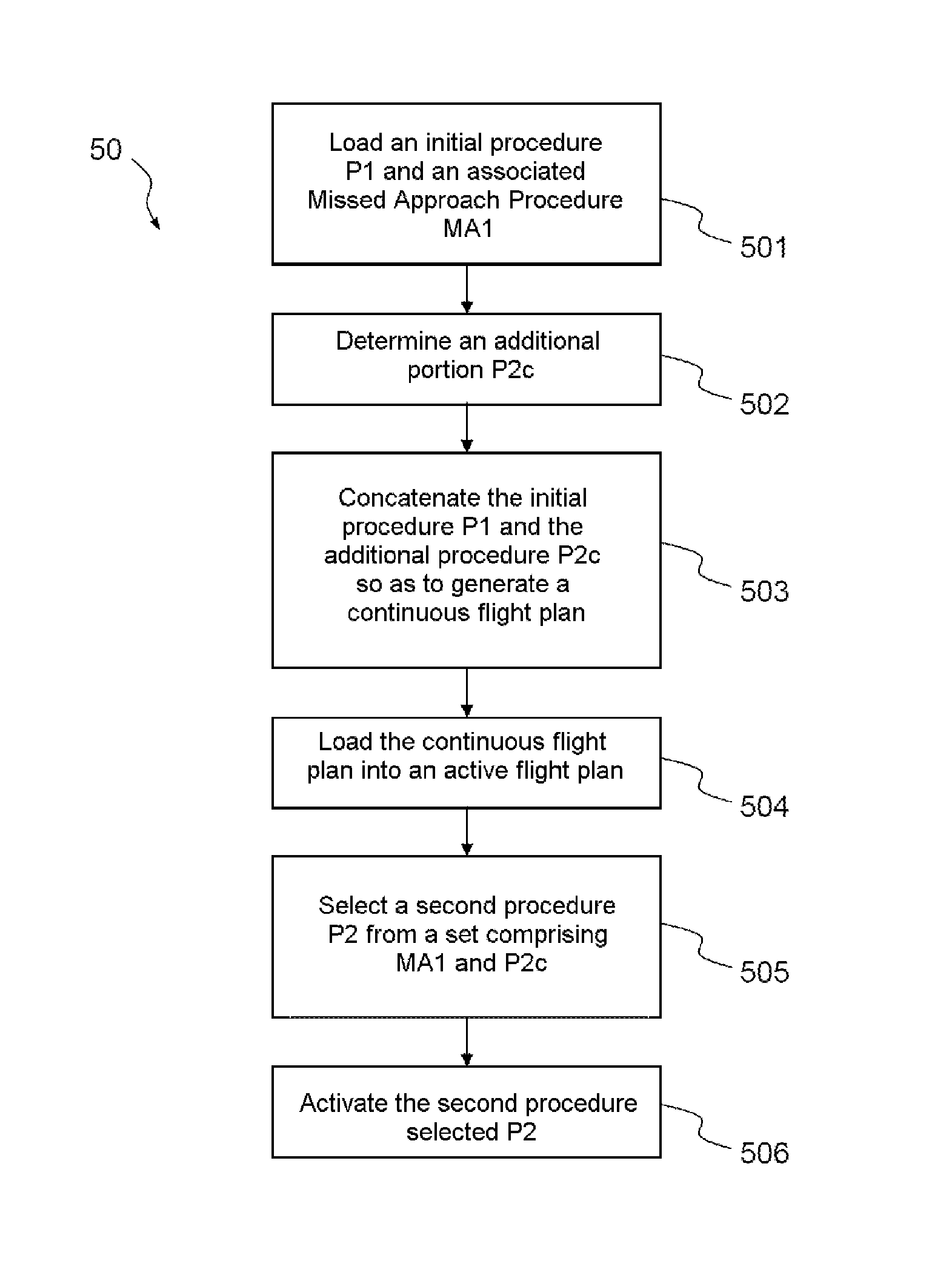

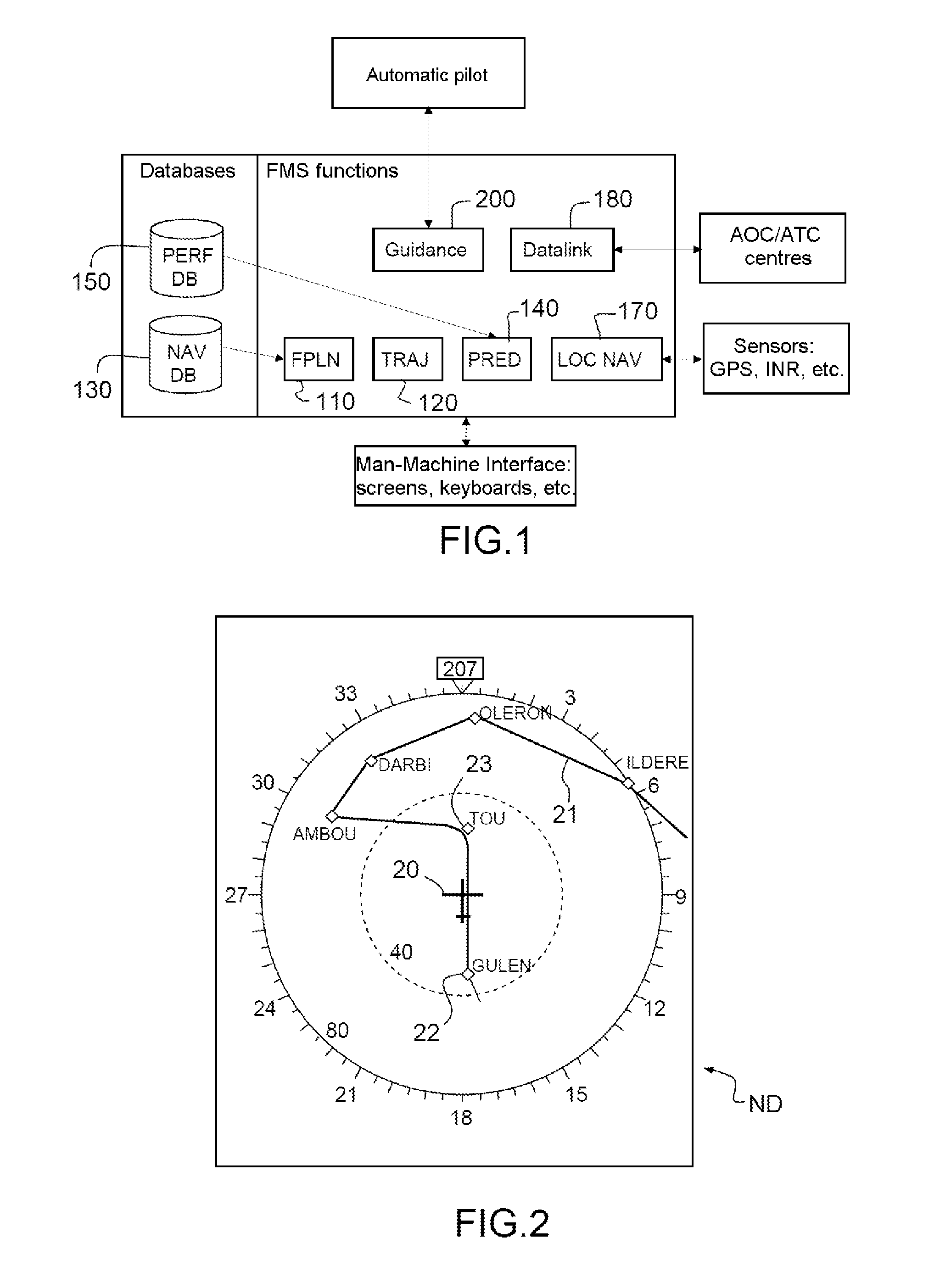

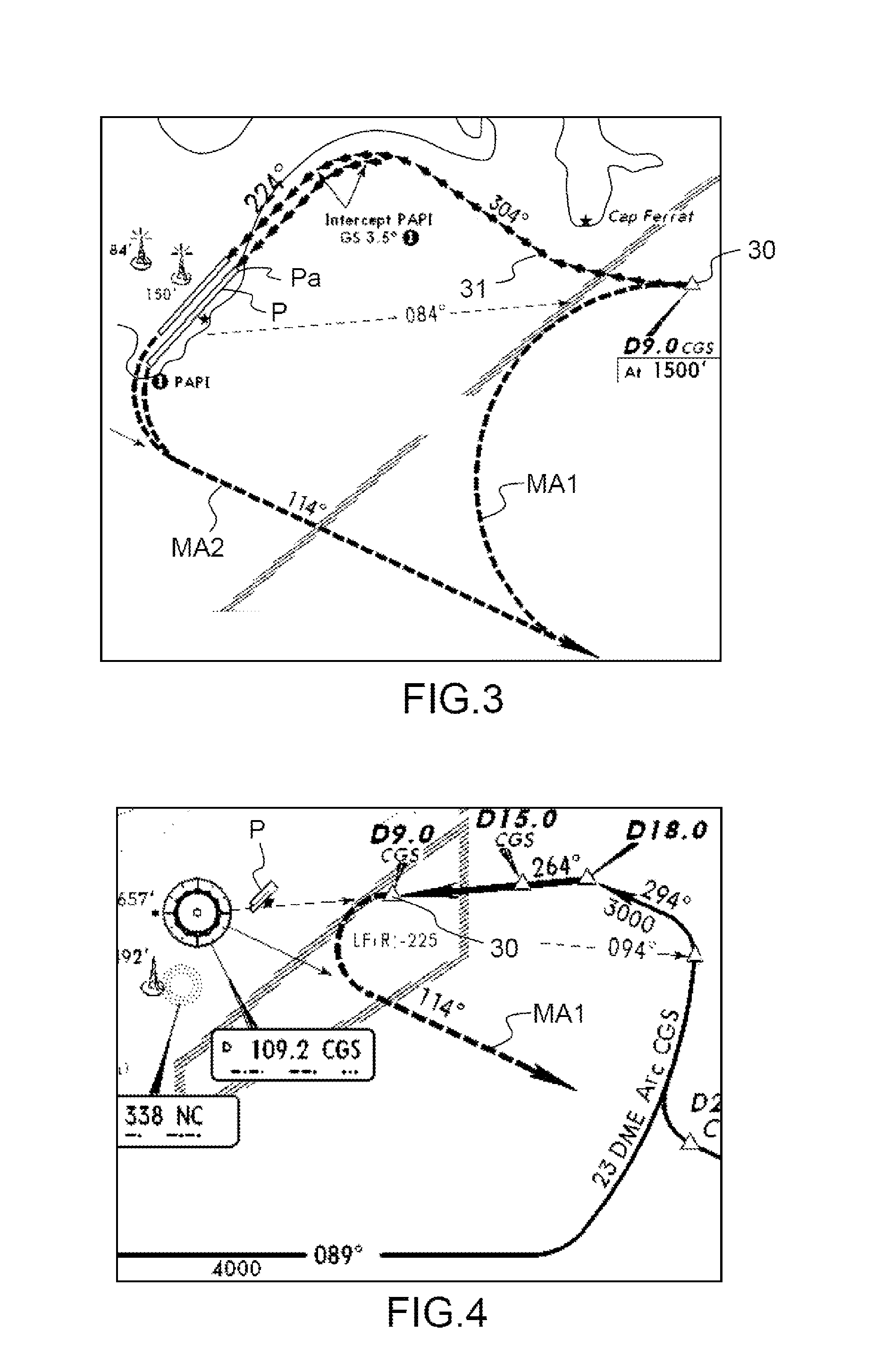

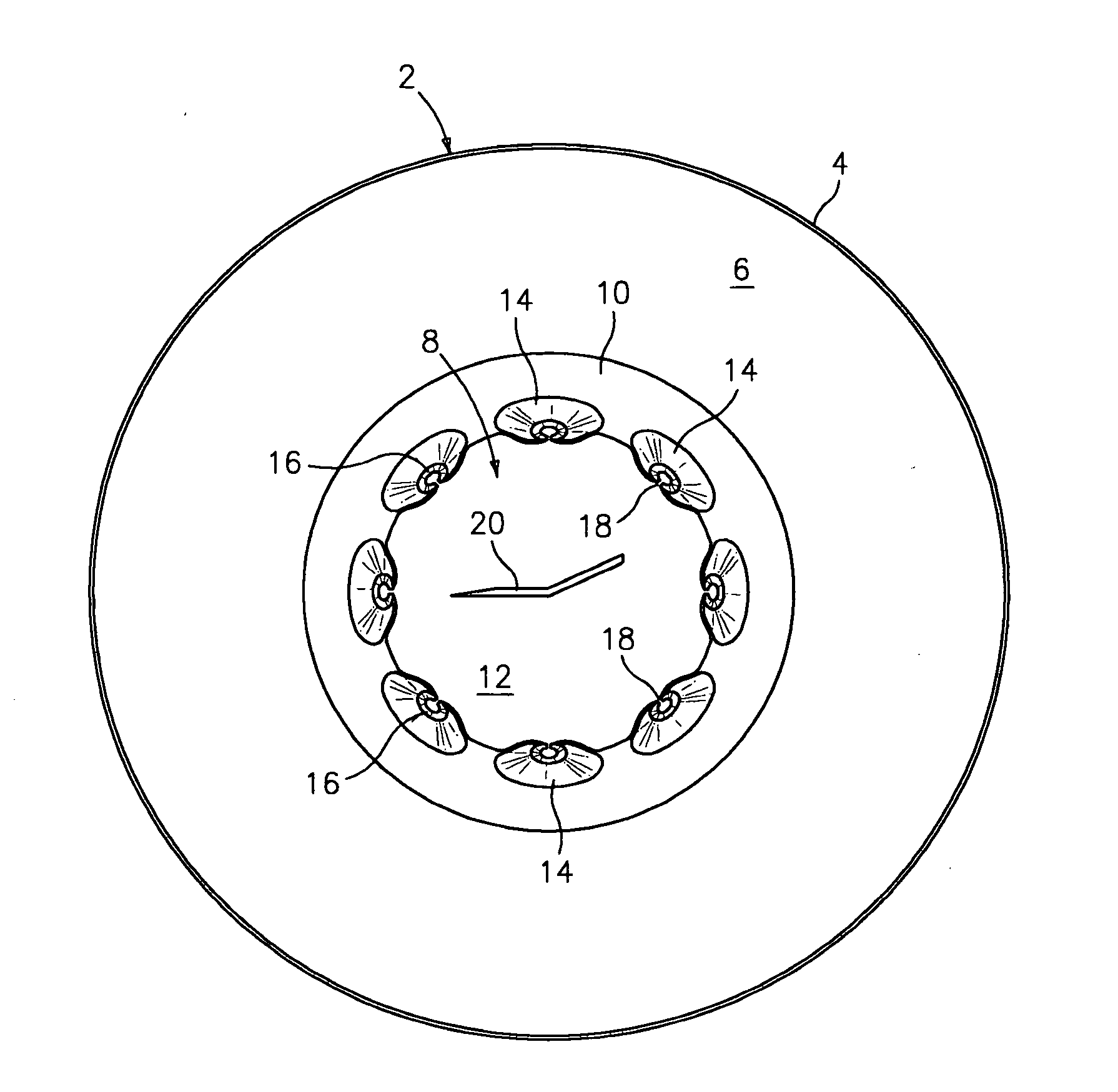

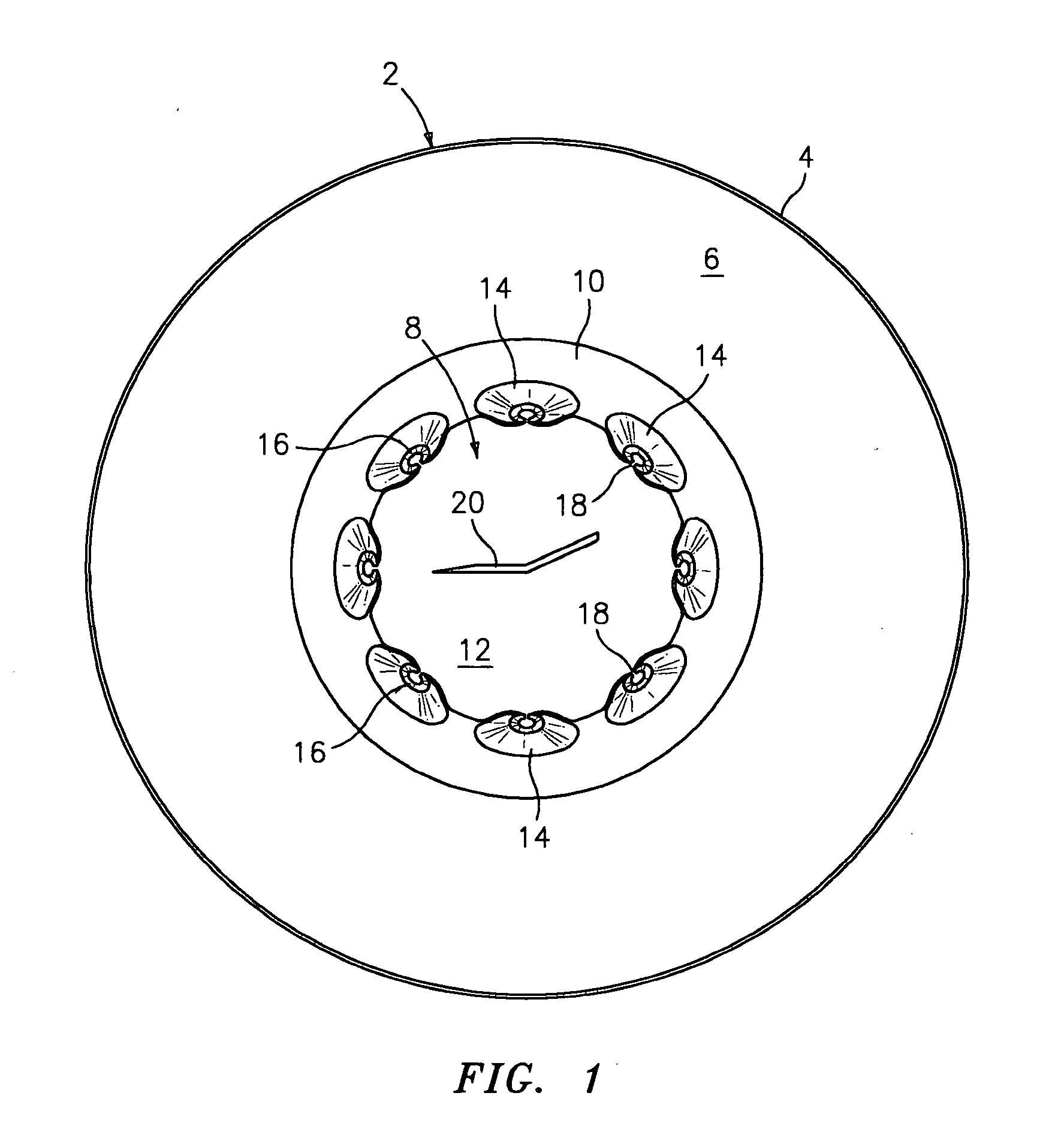

Method and device for calculating a flight plan of an aircraft in a runway approach phase

ActiveUS9368036B2Automatic aircraft landing aidsAltitude or depth controlMissed approachFlight vehicle

A method for calculating a flight plan used by a flight management system of an aircraft in a runway approach phase comprises: loading an initial procedure ending at a first end point not corresponding to a threshold of the runway and a first associated missed approach procedure; determining an additional procedure and a second associated missed approach procedure; concatenating the initial procedure and the additional procedure in order to generate a continuous concatenated flight plan comprising the initial procedure, the first missed approach procedure, the additional procedure and the second missed approach procedure; loading the concatenated flight plan into an active flight plan; selecting a second procedure from a set comprising the first missed approach procedure and the additional procedure; activating the selected second procedure.

Owner:THALES SA

Specimen manipulation device for micro manipulation and biopsy in assisted reproduction and in vitro fertilization

InactiveUS20110218390A1Precise positioningEasy to moveBioreactor/fermenter combinationsBiological substance pretreatmentsAdditional procedureEmbryo

A container or dish used for the micro manipulation, micro injection, biopsy and fertilization of oocyte and embryo culture. The dish allows the user to more readily perform procedures used to fertilize oocyte, such as intracytoplasmic sperm injection (ICSI), biopsy embryos and perform additional procedures in used in assisted reproductive techniques (ART), human reproduction and in vitro fertilization (IVF) techniques. The invention will allow ease in use, the reduction in the number of micro tools used in the procedure, as opposed to conventional dishes and procedures, and will allow the user to more readily locate the oocytes and embryos to be handled and worked on. The invention will add repetitiveness, consistency and may result in better results and outcome of the procedures. The invention will also give the user a more ergonomically correct dish for these types of procedures and related protocols.

Owner:COOPERSURGICAL INC

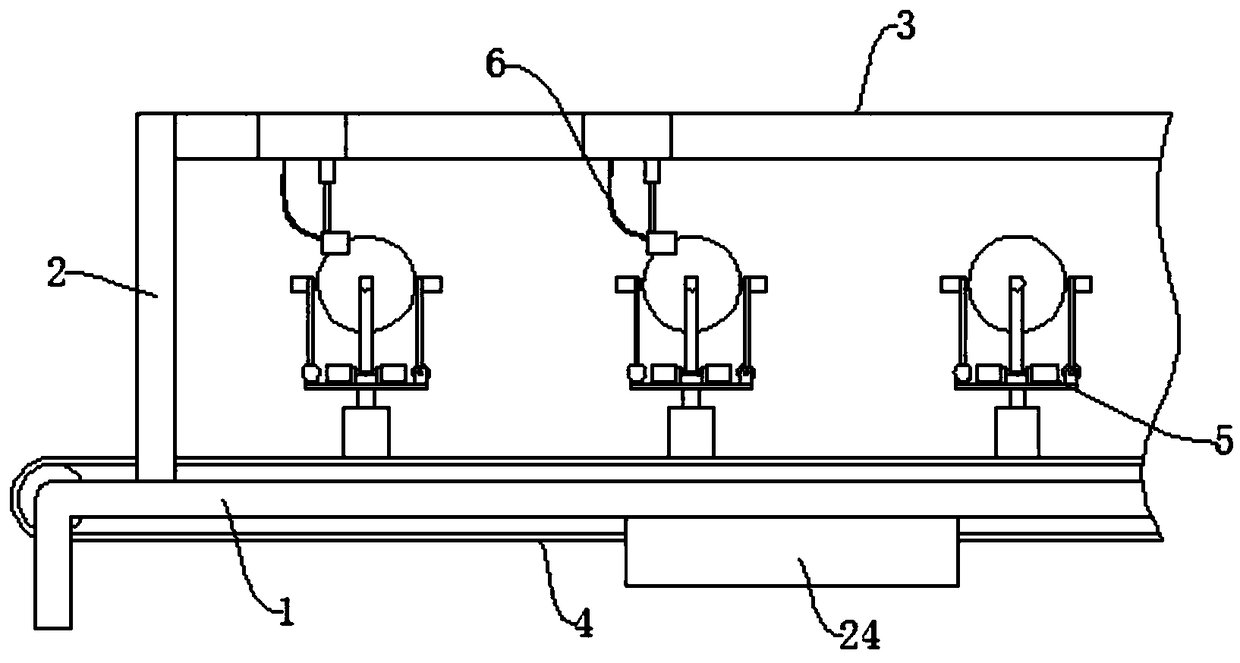

Waxing device for lemon processing

ActiveCN109169885AApply evenlyShorten waxing timeFruits/vegetable preservation by coatingElectricityWax

The invention discloses a waxing device for lemon processing. The waxing device for lemon processing comprises a conveyor, wherein waxing equipment, a wax conveying device and a PLC (Program Logic Controller) are mounted on the conveyor; the PLC is electrically connected with the waxing equipment and the wax conveying device. The waxing device for lemon processing has the beneficial effects that wax layers are uniformly applied to the surfaces of lemons in a short time, and the additional procedures including polishing and the like are not needed, so that the time and the effort are reduced, the waxing time is effectively shortened, and the practicability is good.

Owner:JIANGXI REEMOON TECH HLDG

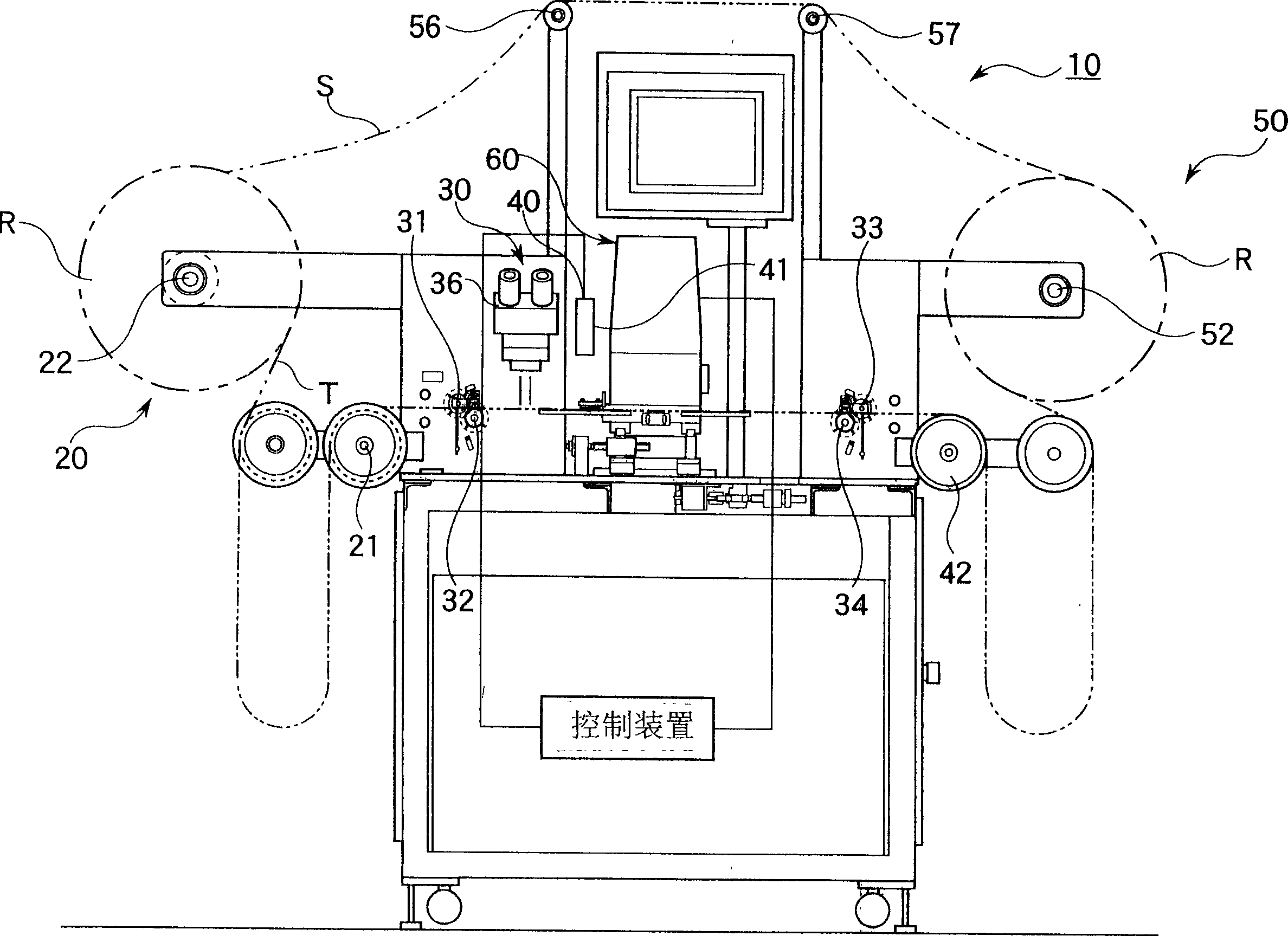

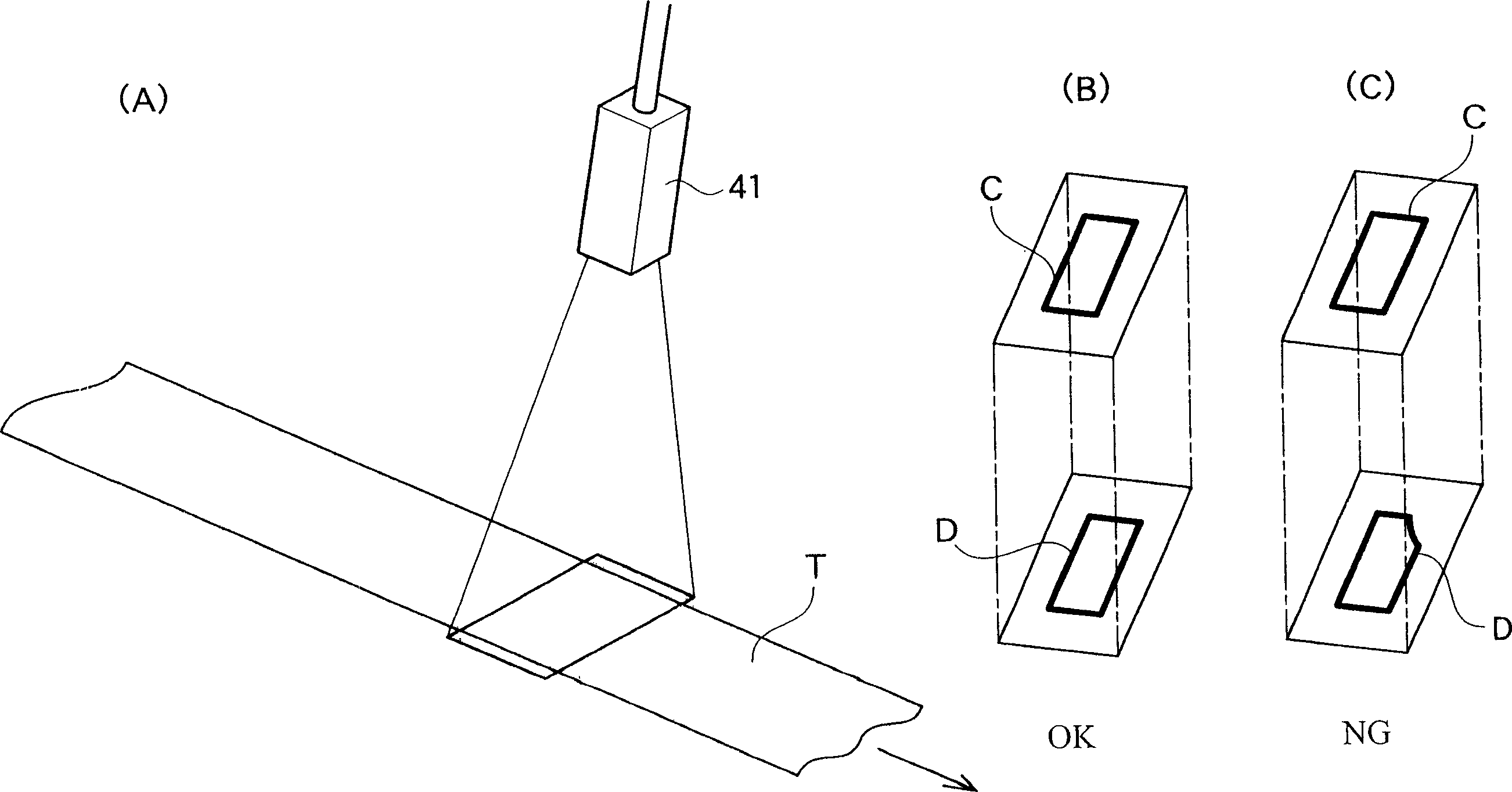

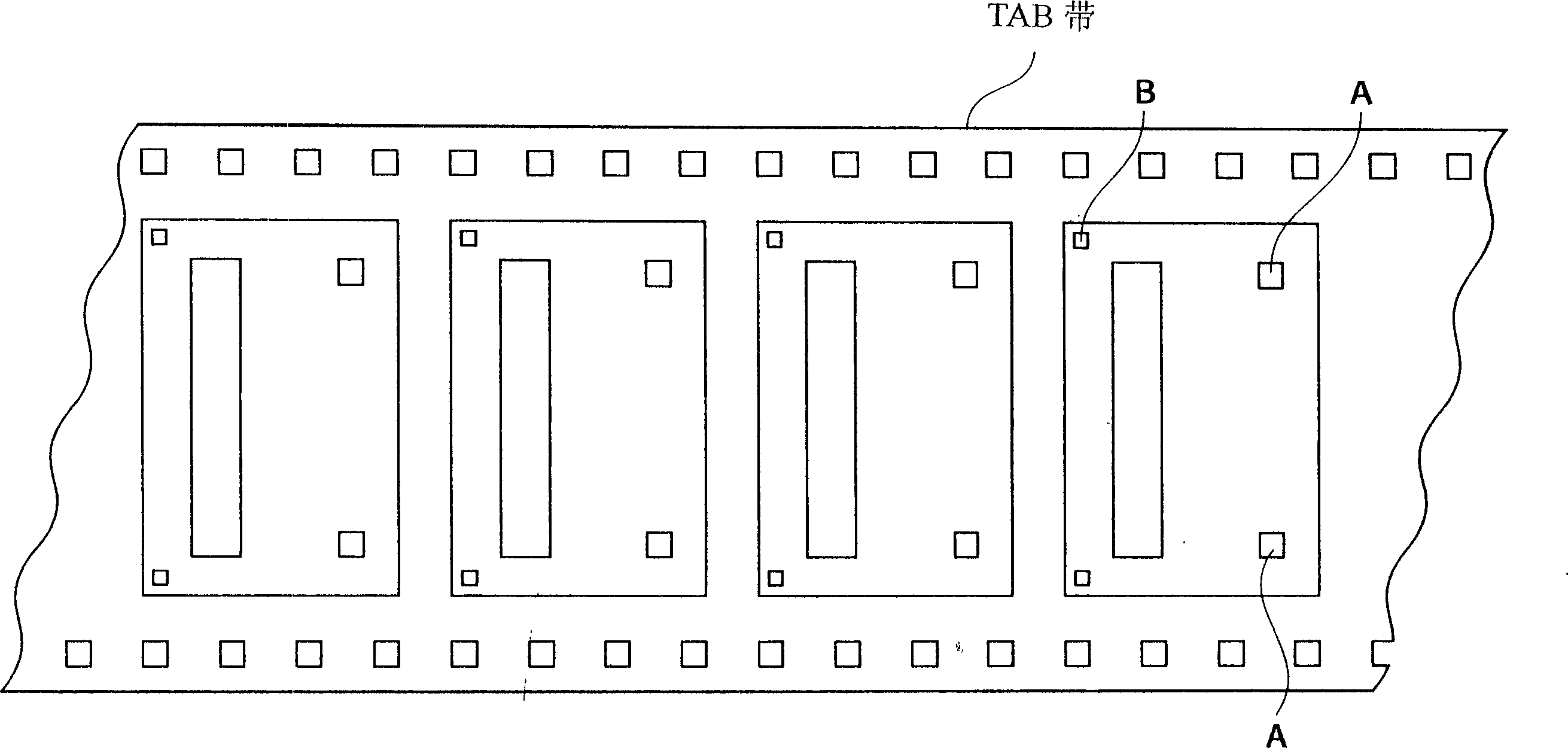

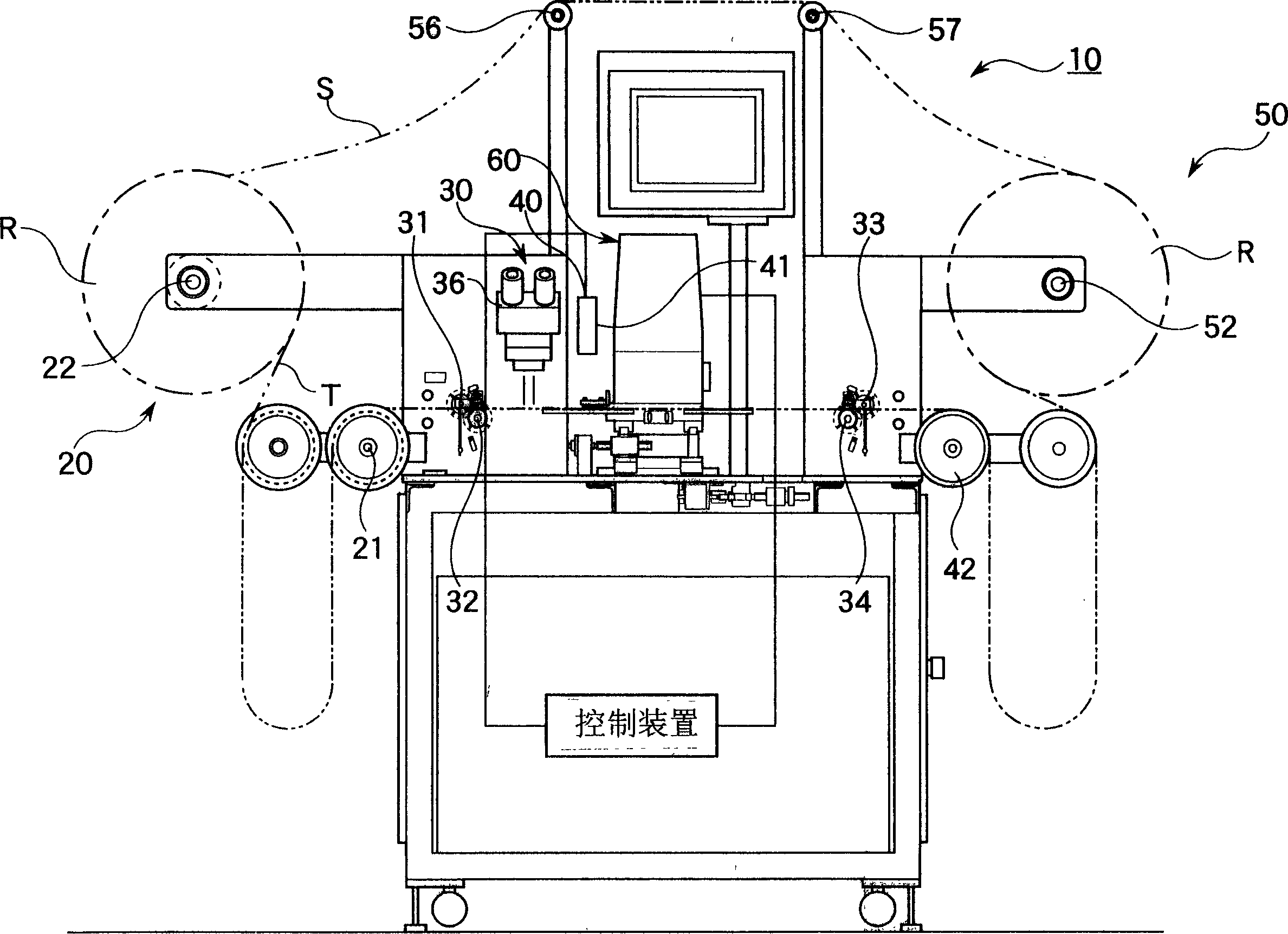

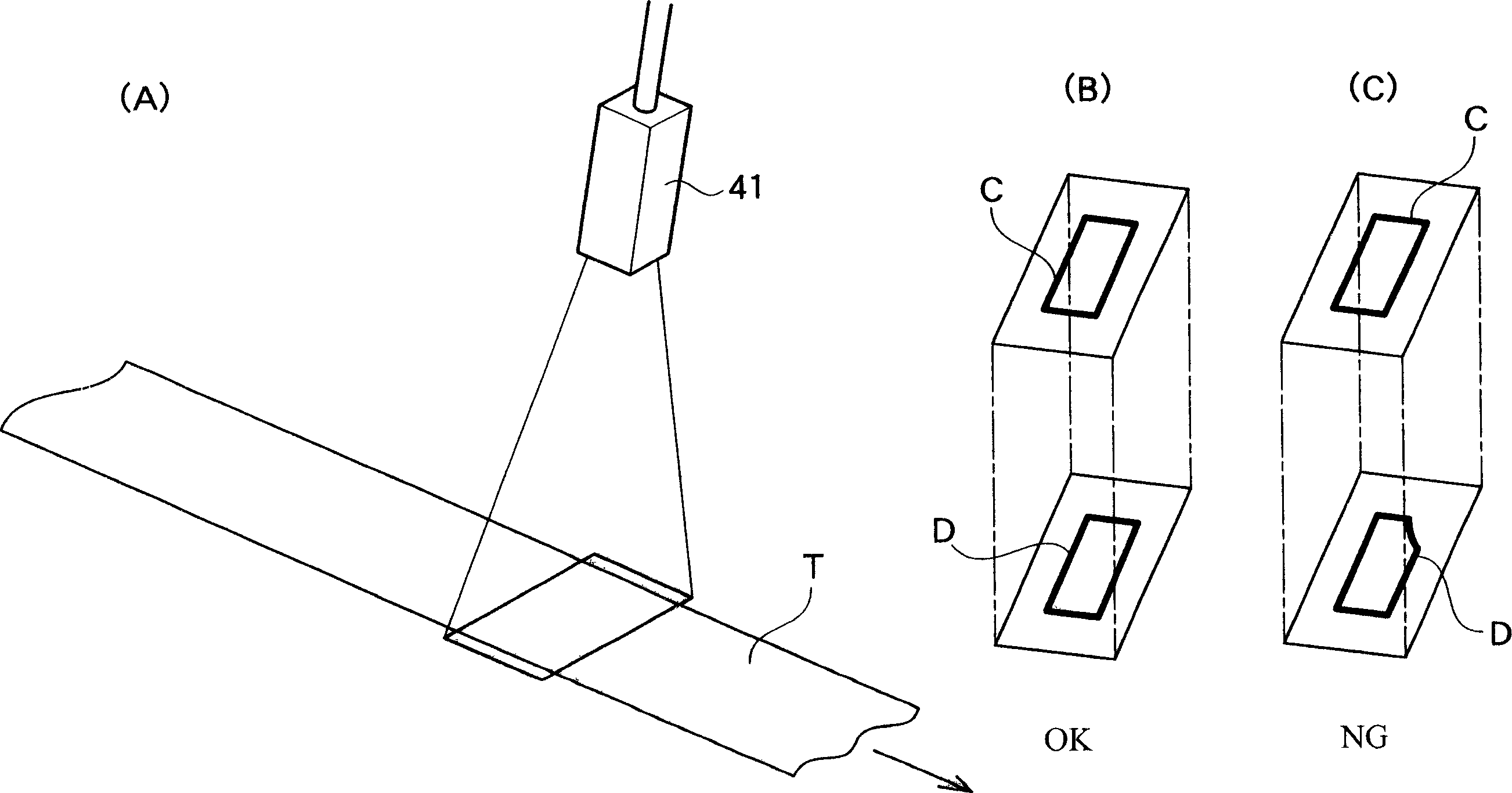

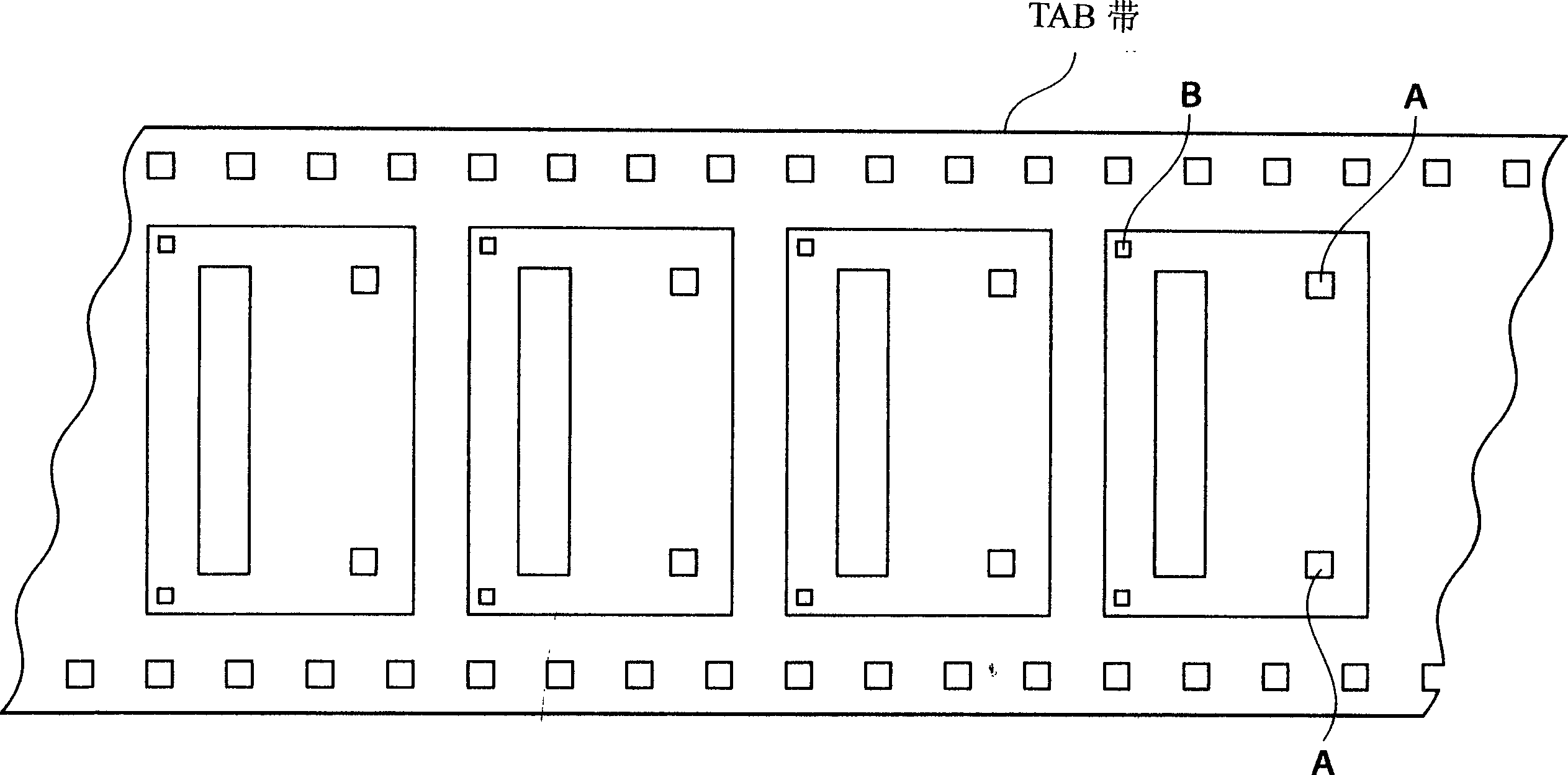

Checking method and checker for thin film loading band for encasulating electronic part

InactiveCN1277298CLow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAdditional procedureElectron

The present invention relates to an inspection method and an apparatus of film carrier tape for mounting electronic parts, which are used for inspecting poor marks such as alignment mark for determining the assembling position in mounting IC electronic parts, a land for holding the tape without additional procedures and labor. The method and the apparatus of the present invention could be carried out at a low cost, in short inspecting time, and in excellent accuracy. The inspection method of film carrier tape for mounting electronic parts of the present invention comprises the steps of comparing a pattern shape of a mark pre-stored in a memory with a pattern shape of a mark input to a sensor, then judging as a poor mark if a consistency between the two pattern shapes is below a predetermined threshold value.

Owner:MITSUI MINING & SMELTING CO LTD

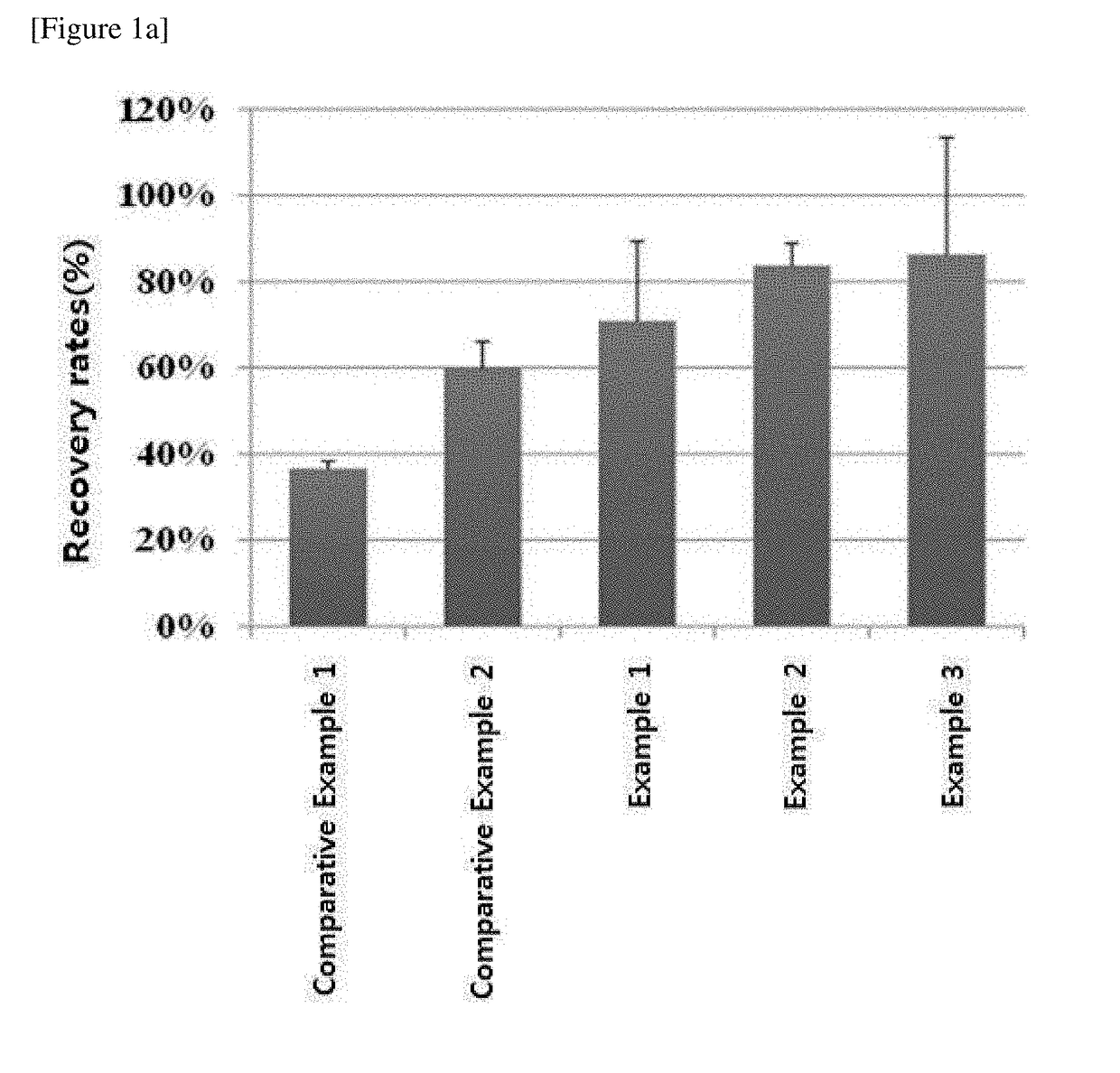

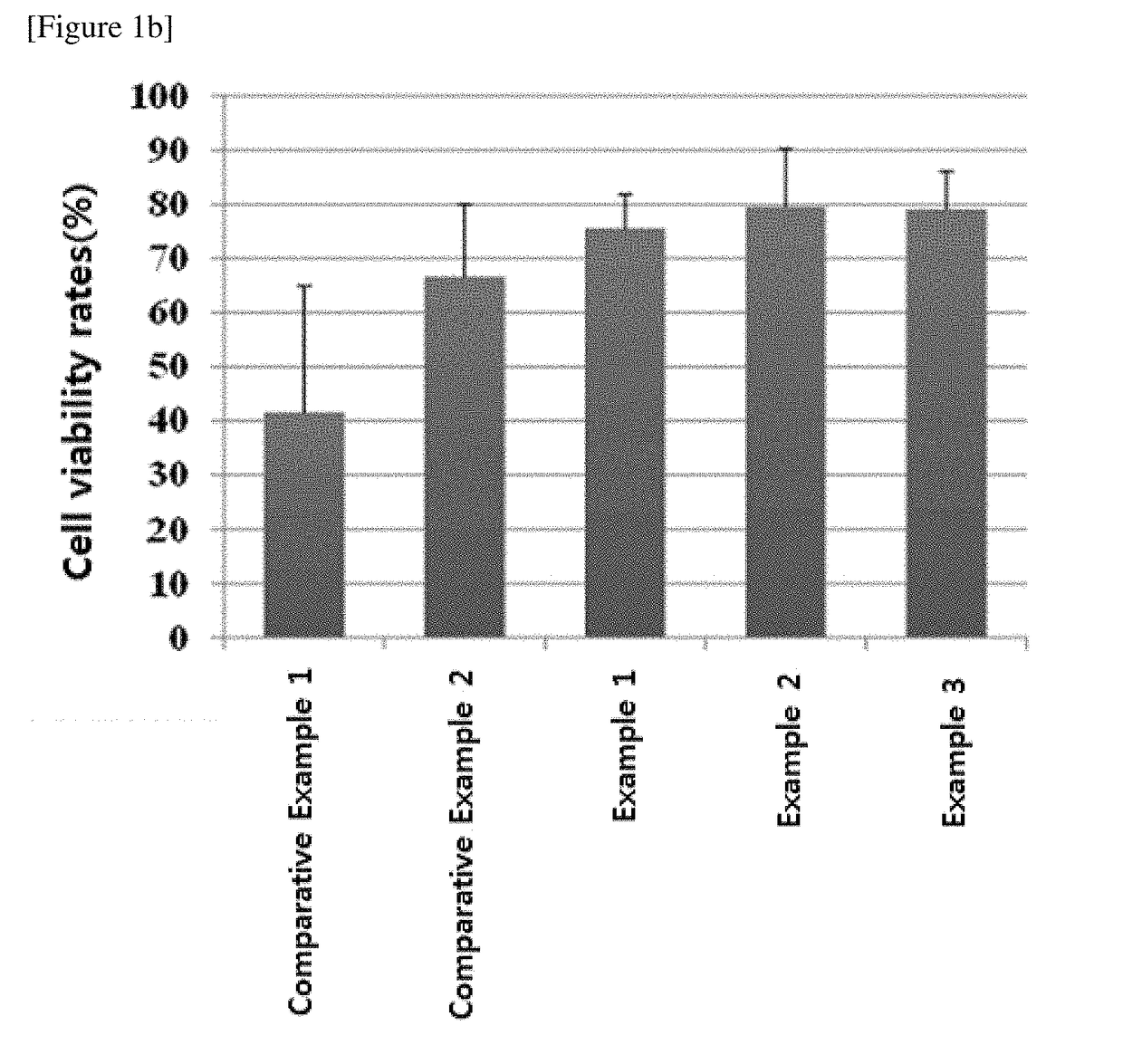

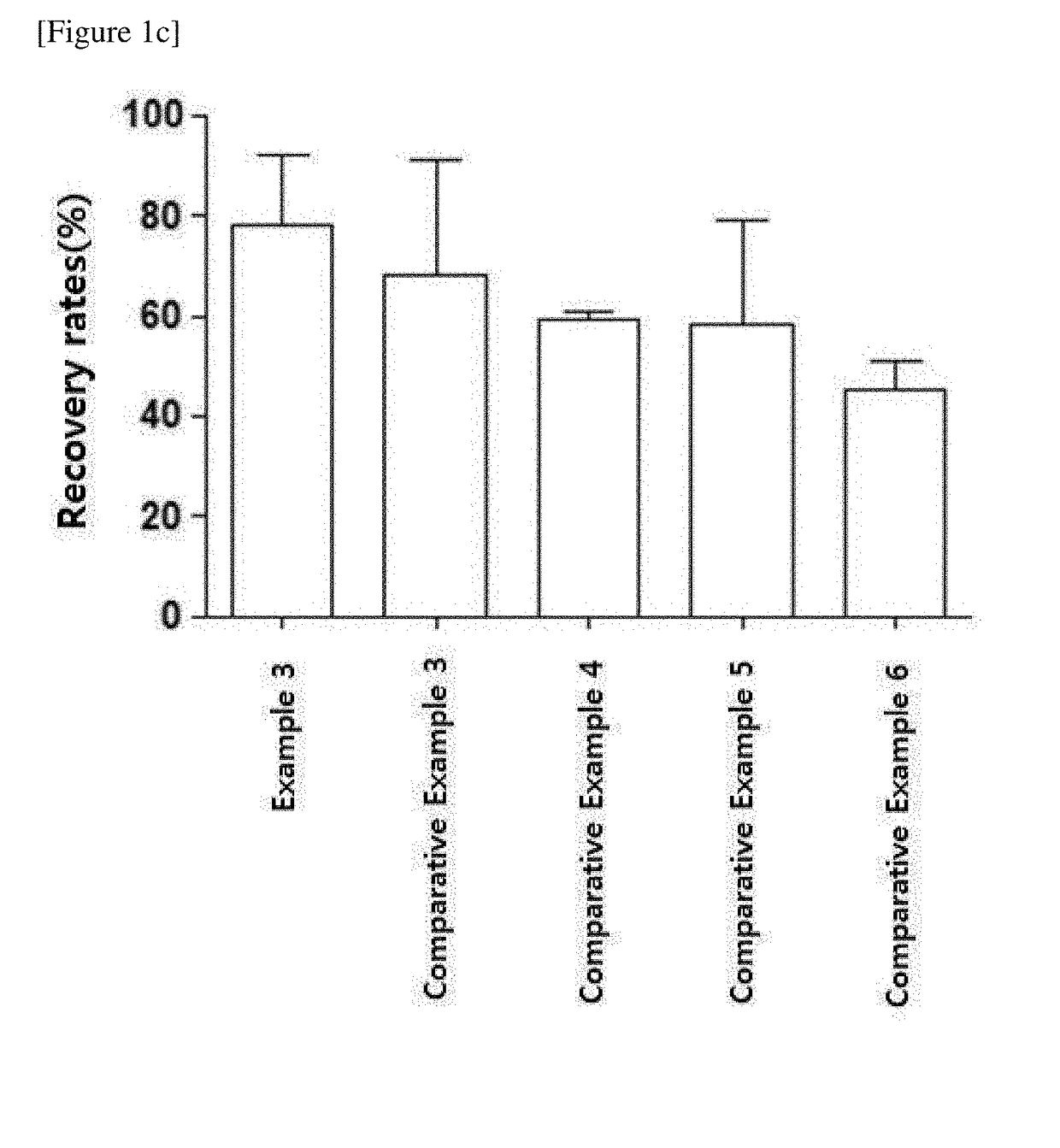

Medium composition for cryopreservation of cell and use thereof

InactiveUS20190037831A1Simple compositionImprove survivabilityCulture processDead animal preservationCell activityAdditional procedure

The present invention relates to a medium composition for the cryopreservation of cells, which exhibits excellent cell recovery rates, cell viability rates and cell activity after thawing, and a pharmaceutical composition comprising the medium composition and therapeutic cells. Also, the medium composition of the present invention allows for readily administering the cryopreserved therapeutic cells to a subject without additional procedures such as washing, separation, etc. Therefore, the composition may be used as an excellent medium composition for cell cryopreservation or as an excellent therapeutic composition.

Owner:GC CELL CORP

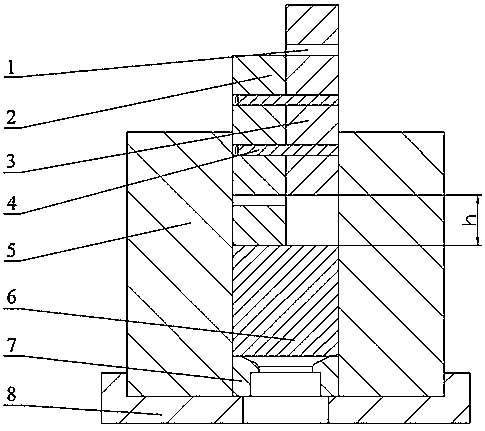

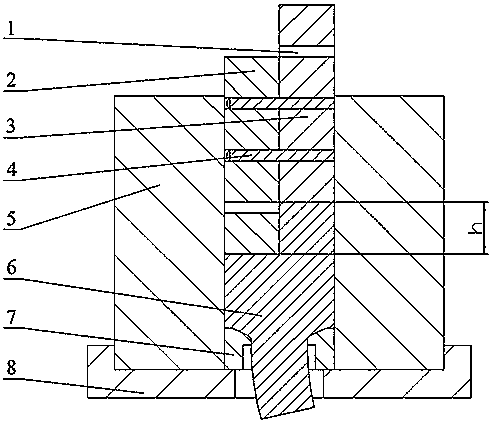

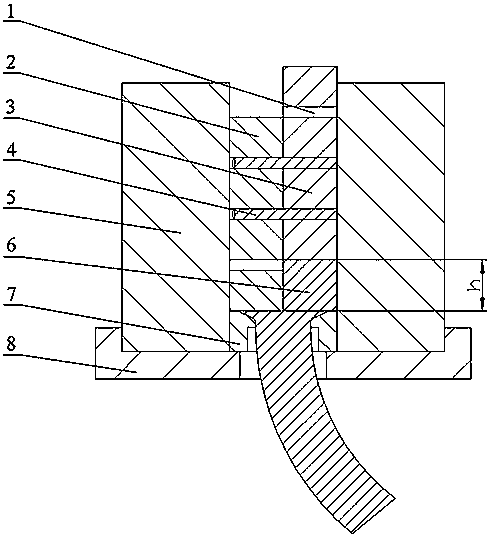

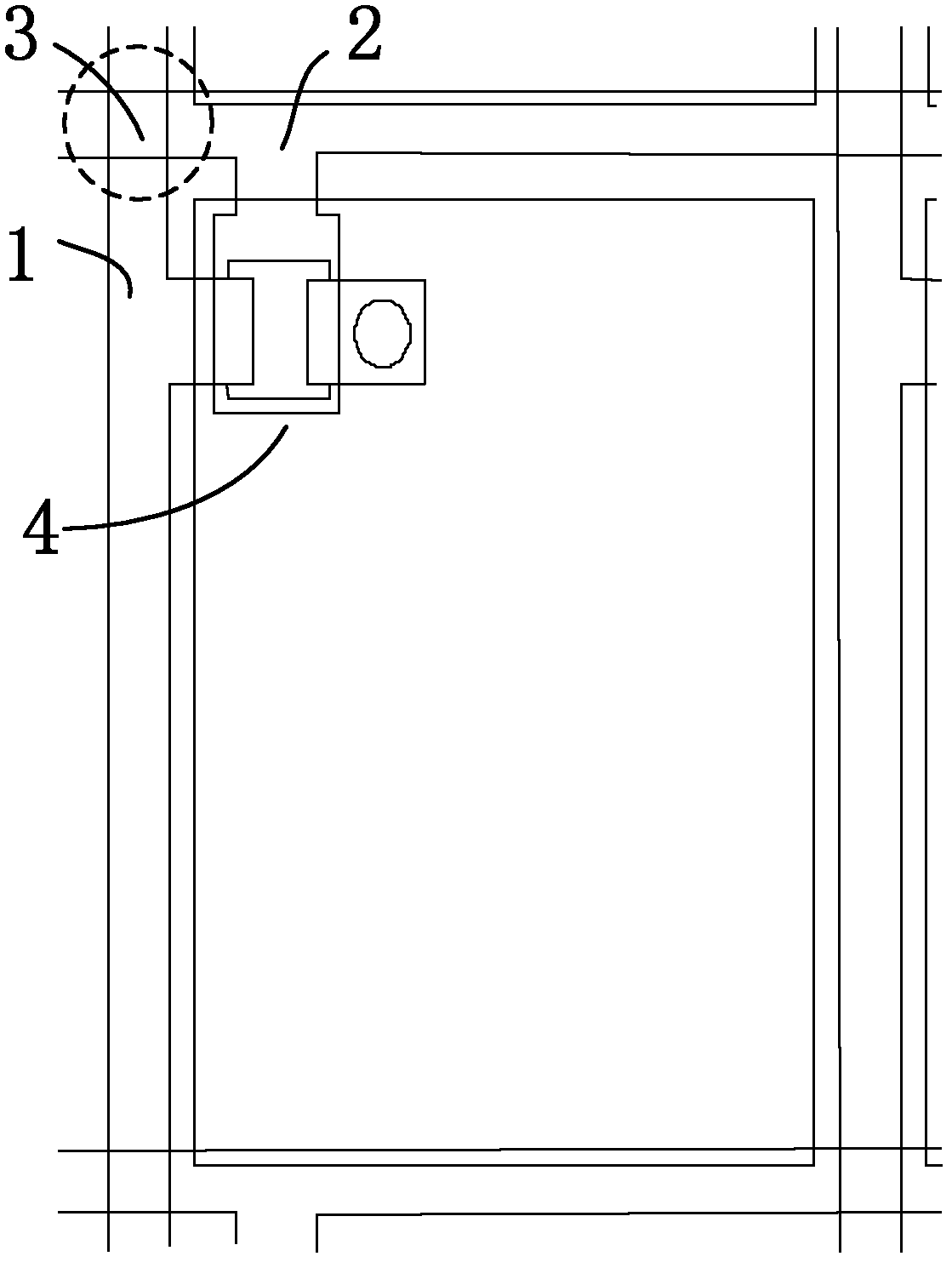

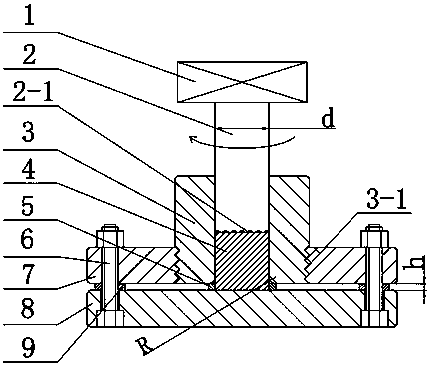

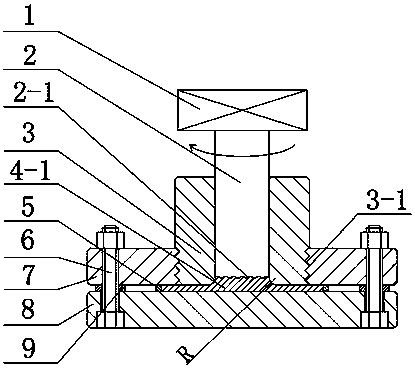

Short process extrusion forming device and method for high-performance metal plate

ActiveCN108380683AEasy for deep processingImprove mechanical propertiesExtrusion profiling toolsAdditional procedureQuality performance

The invention discloses a short process extrusion forming device and method for a high-performance metal plate and relates to an efficient extrusion forming device and method for a metal plate. The series of problems that energy consumption needed by an existing metal plate extrusion forming method is large, the number of procedures is large, the material utilization rate is low, the technologicalflexibility is poor, and quality performance coordination control is difficult can be solved. According to the efficient extrusion forming device, an antiskid structure 2-1 is designed at the end ofa male die 2; a sleeve 3 and a flange 7 are connected with each other through a thread 3-1; and the shape and thickness of the extrusion plate are adjusted and controlled through an annular limiting block 9 or a split limiting block 10 and adjustment of the height h. According to the efficient extrusion forming method, after a blank 4 is put into the sleeve 3, a torsion mechanism 1 drives the maledie 2 to go downwards for loading, and the blank 4 sequentially flows into a bottom cavity till complete extrusion is achieved. According to the efficient extrusion forming method, a fine grain modification effect of strong plastic deformation technology can be achieved without additional procedures, and plate products of different specifications can be customized. The efficient extrusion formingdevice and method are suitable for extrusion forming of high-performance metal plate products.

Owner:福建祥鑫股份有限公司

Method for producing an optically active beta-amino acid

InactiveUS20060122418A1Improve performanceHigh enantiomeric excessOrganic compound preparationOrganic chemistry methodsGreek letter betaSynthesis methods

The Problem to Be Solved: To provide a producing method of an optically active β-amino acid useful as intermediate for the production of medicines, agricultural chemicals and physiologically active substances, by means of a catalytic and asymmetric synthesis method of high performance and a high enantiomeric excess, without requiring additional procedures such as introduction and removal of protecting group and so on. Means to Solve the Problems: A producing method of an optically active β-amino acids which comprises subjecting an enamine to an asymmetric hydrogenation.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Checking method and checker for thin film loading band for encasulating electronic part

InactiveCN1499600ALow costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAdditional procedureEngineering

The present invention relates to an inspection method and an apparatus of film carrier tape for mounting electronic parts, which are used for inspecting poor marks such as alignment mark for determining the assembling position in mounting IC electronic parts, a land for holding the tape without additional procedures and labor. The method and the apparatus of the present invention could be carried out at a low cost, in short inspecting time, and in excellent accuracy. The inspection method of film carrier tape for mounting electronic parts of the present invention comprises the steps of comparing a pattern shape of a mark pre-stored in a memory with a pattern shape of a mark input to a sensor, then judging as a poor mark if a consistency between the two pattern shapes is below a predetermined threshold value.

Owner:MITSUI MINING & SMELTING CO LTD

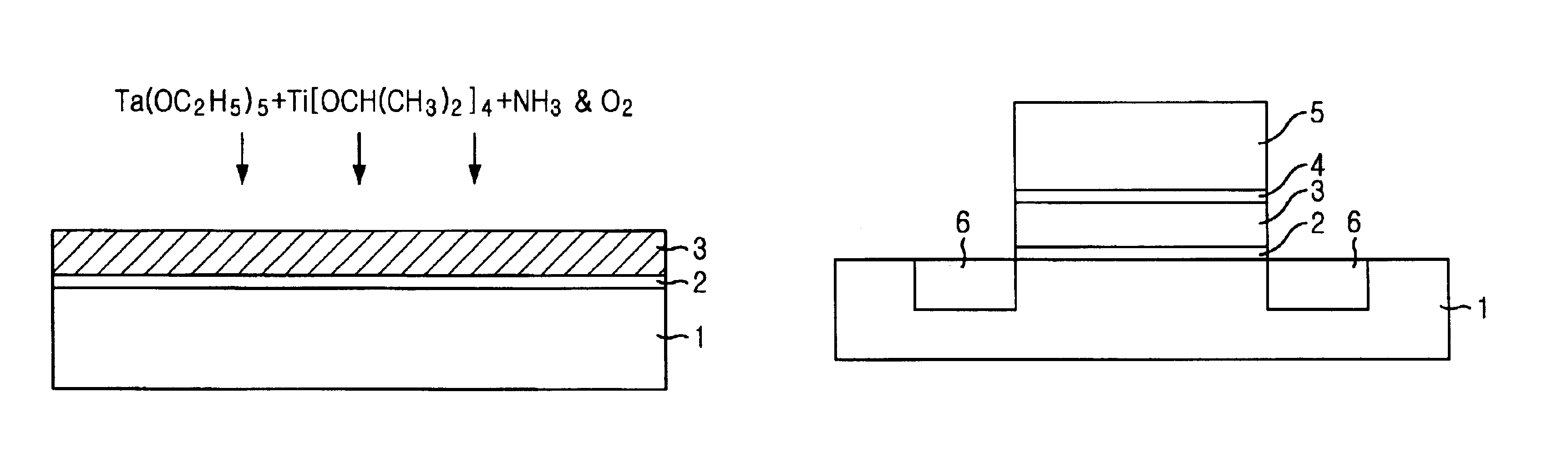

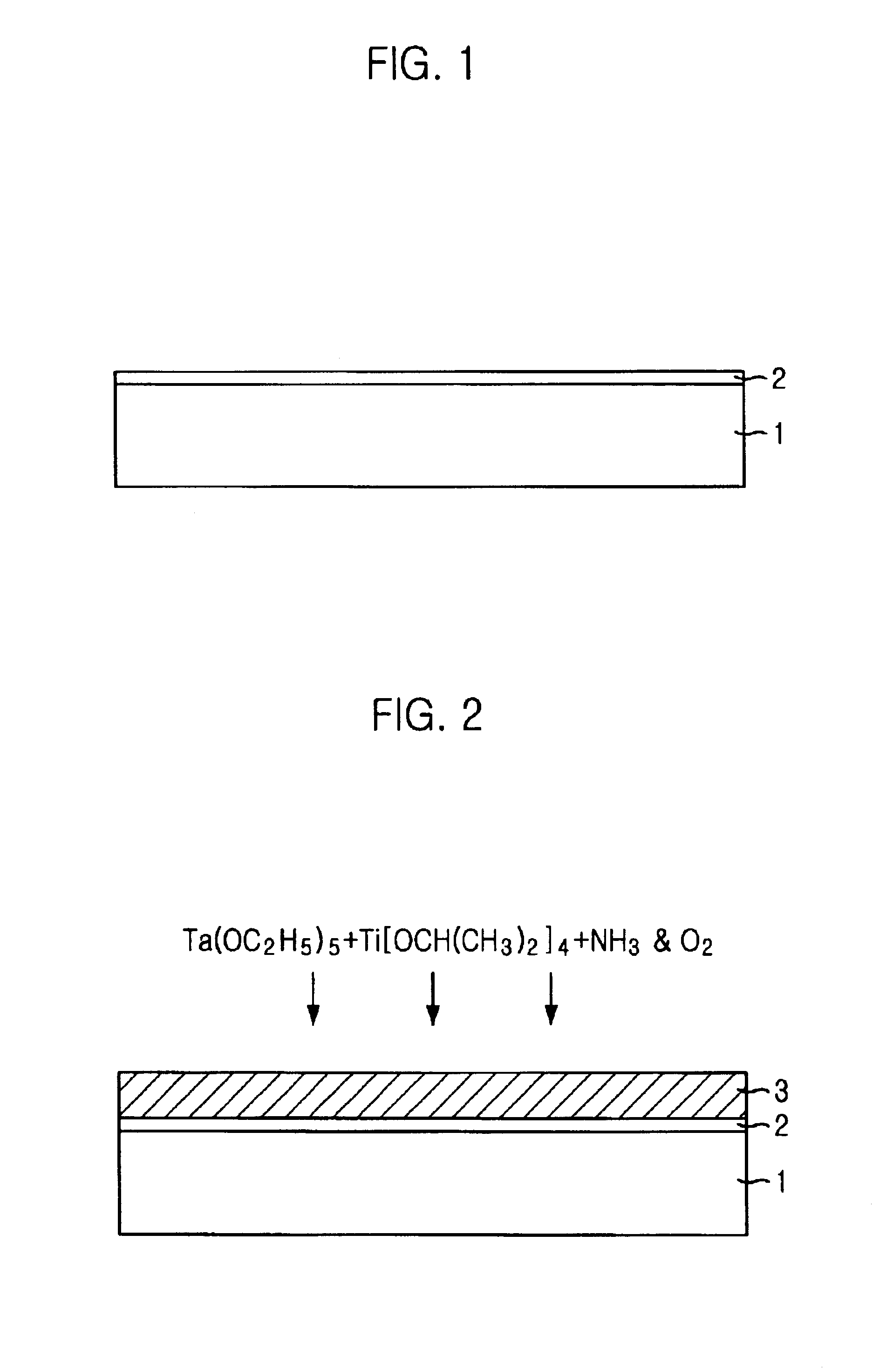

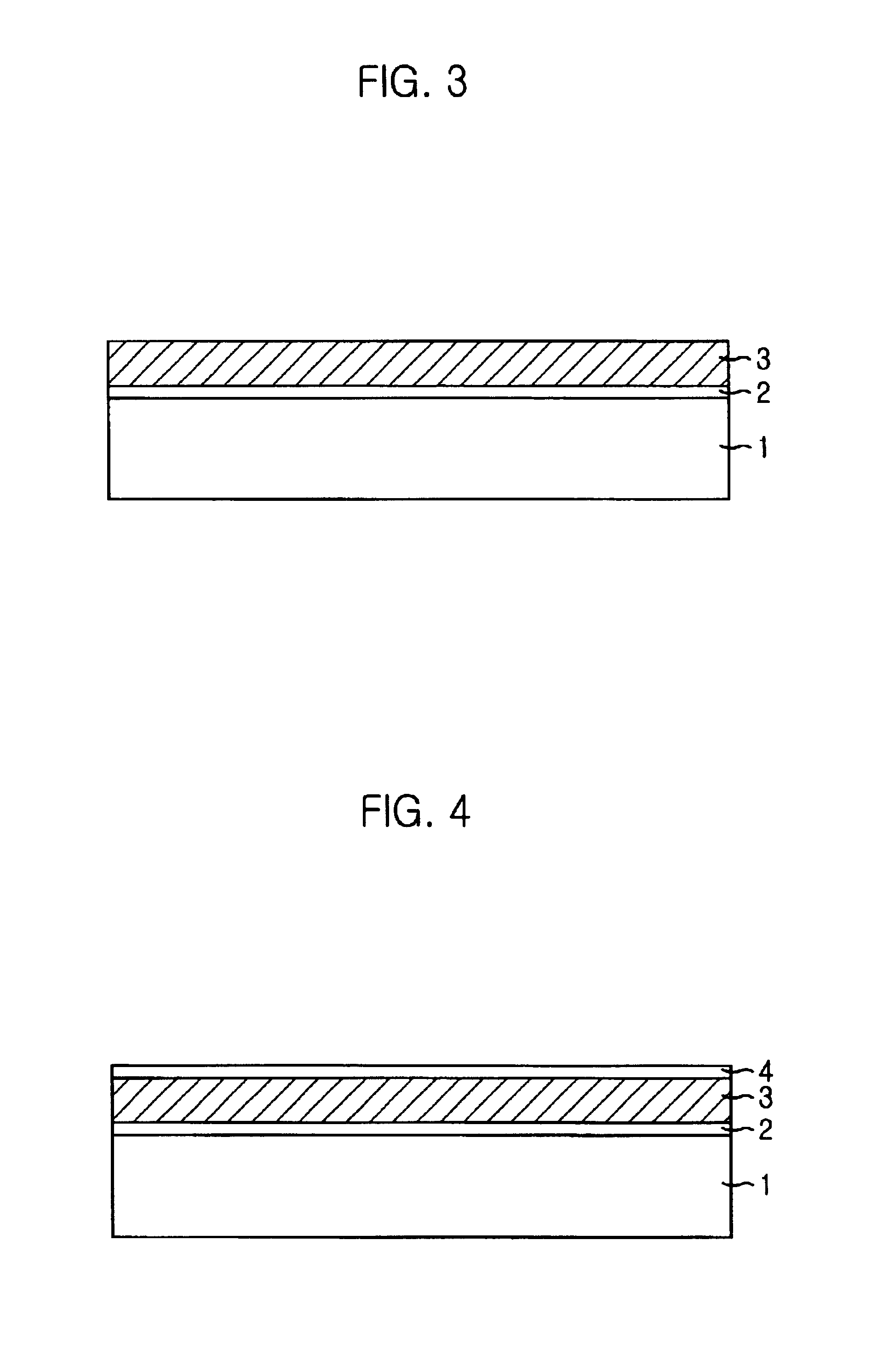

Method for forming a dielectric layer in a semiconductor device

Owner:SK HYNIX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com