Production method of paper pulp with waterproofness

A production method and pulp technology, which are applied in pulp beating method, anti-biological reagent addition, paper and other directions, can solve the problems of cumbersome process flow and low degree of automation, and achieve the effect of reducing cost, improving waterproof ability and saving process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

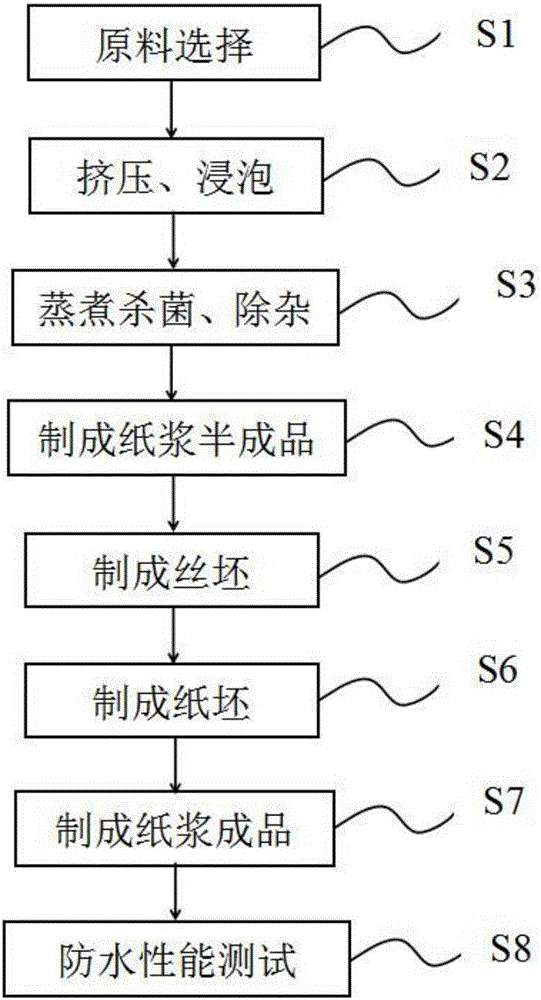

[0035] Such as figure 1 As shown, a kind of production method with waterproof characteristic pulp provided by the present embodiment, described method comprises the following steps:

[0036] Step S1: Raw material selection

[0037] The raw material is recycled waste paper, and the recycled waste paper is shredded;

[0038] Step S2: Squeeze, Soak

[0039] Put the shredded waste paper into the extruder, or crush the shredded waste paper into shredded paper; put the squeezed or crushed waste paper into the soaking tank, add water and stir evenly, so that the shredded paper becomes paste stop;

[0040] Step S3: Cooking and sterilization, removal of impurities

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com