Checking method and checker for thin film loading band for encasulating electronic part

A technology for electronic components and inspection devices, applied in the direction of using optical devices, measuring devices, electrical components, etc., can solve the problems of easy leakage, deviation in judgment, and leakage of film carrier tape for packaging of defective electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments (examples) of the present invention will be described with reference to the drawings.

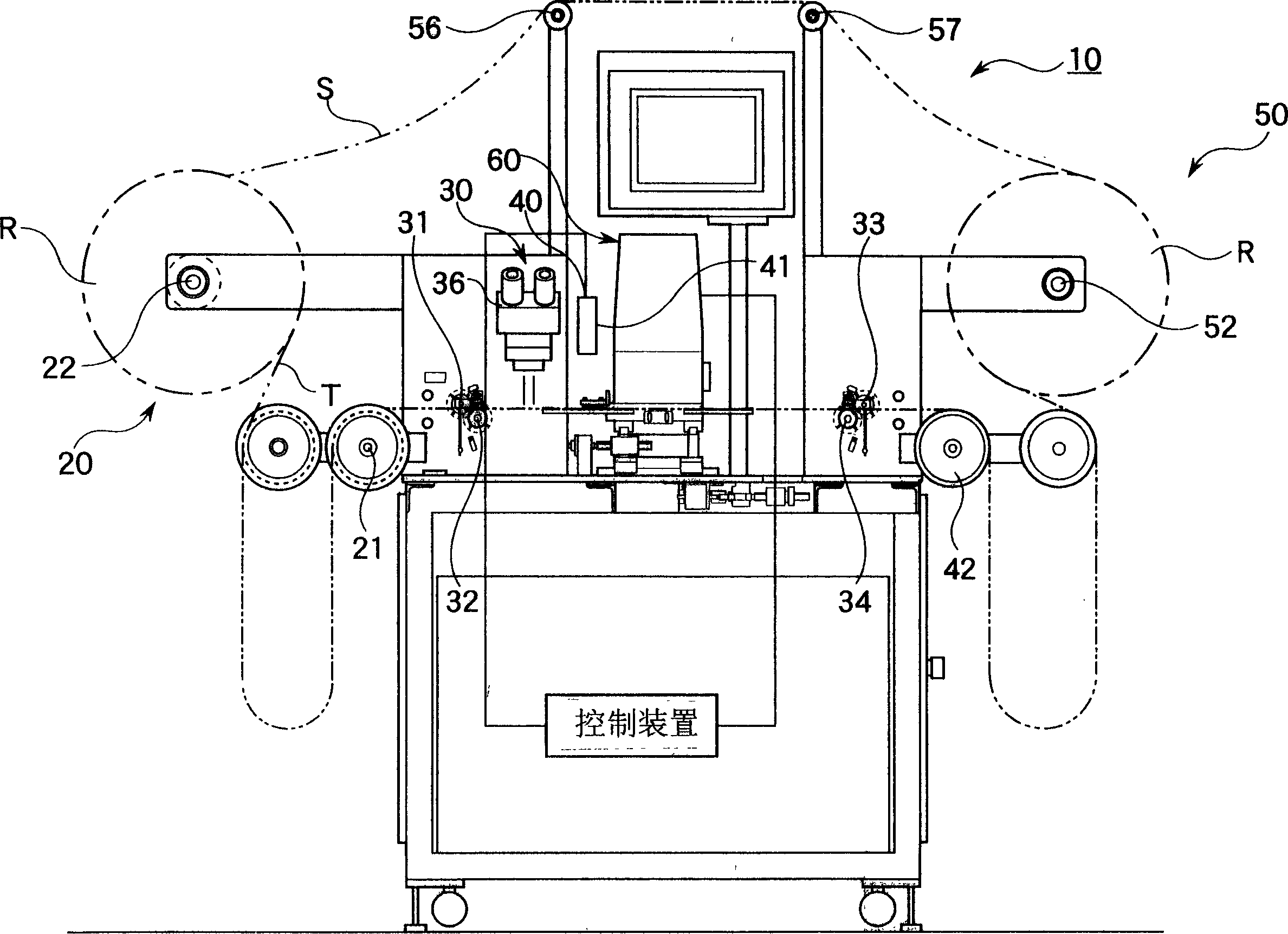

[0020] figure 1 It is a front view of the inspection apparatus of the film carrier tape for electronic component packaging of this invention.

[0021] Such as figure 1 As shown, 10 represents the whole inspection apparatus of the film carrier tape for electronic component packaging of this invention.

[0022] Such as figure 1 As shown, an inspection device 10 (hereinafter simply referred to as 'inspection device 10') of a film carrier tape for packaging electronic components includes a feeding device 20, an inspection unit 30, a marking unit 60, and a winding device 50. In the delivery device 20, there is a film carrier tape for electronic component packaging (hereinafter referred to as "film carrier tape"), and the roll R of the film carrier tape T that has completed the manufacturing process is wound up through the separator S and is attached to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com