Production process for printing whole-cotton transfer printing paper using copper-plate press

A gravure printing machine and transfer printing technology, which is applied in the field of textile printing and dyeing, can solve the problems of inability to produce catalytic transfer printing paper, etc., and achieve the effects of high authenticity rate, simple method, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

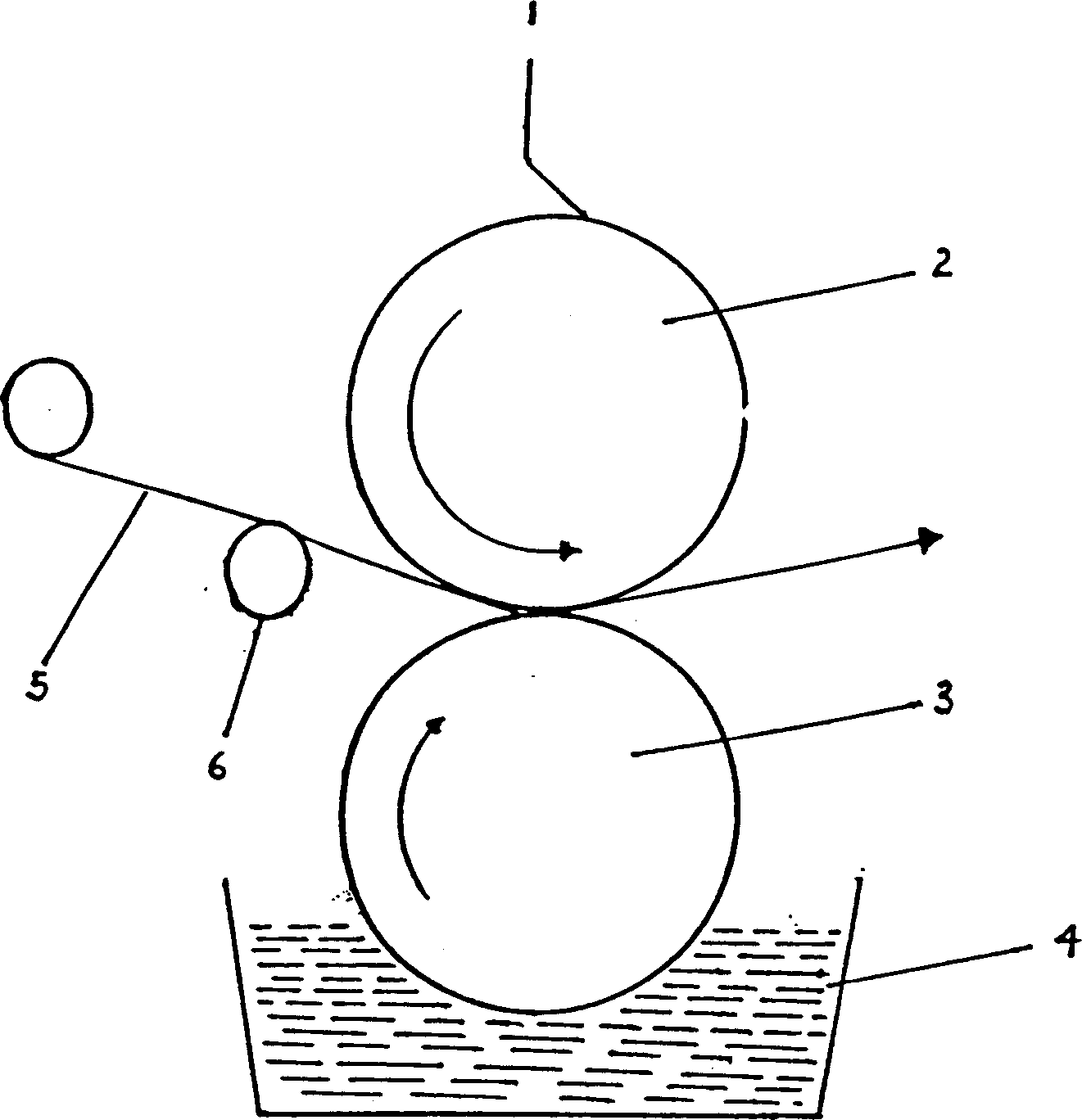

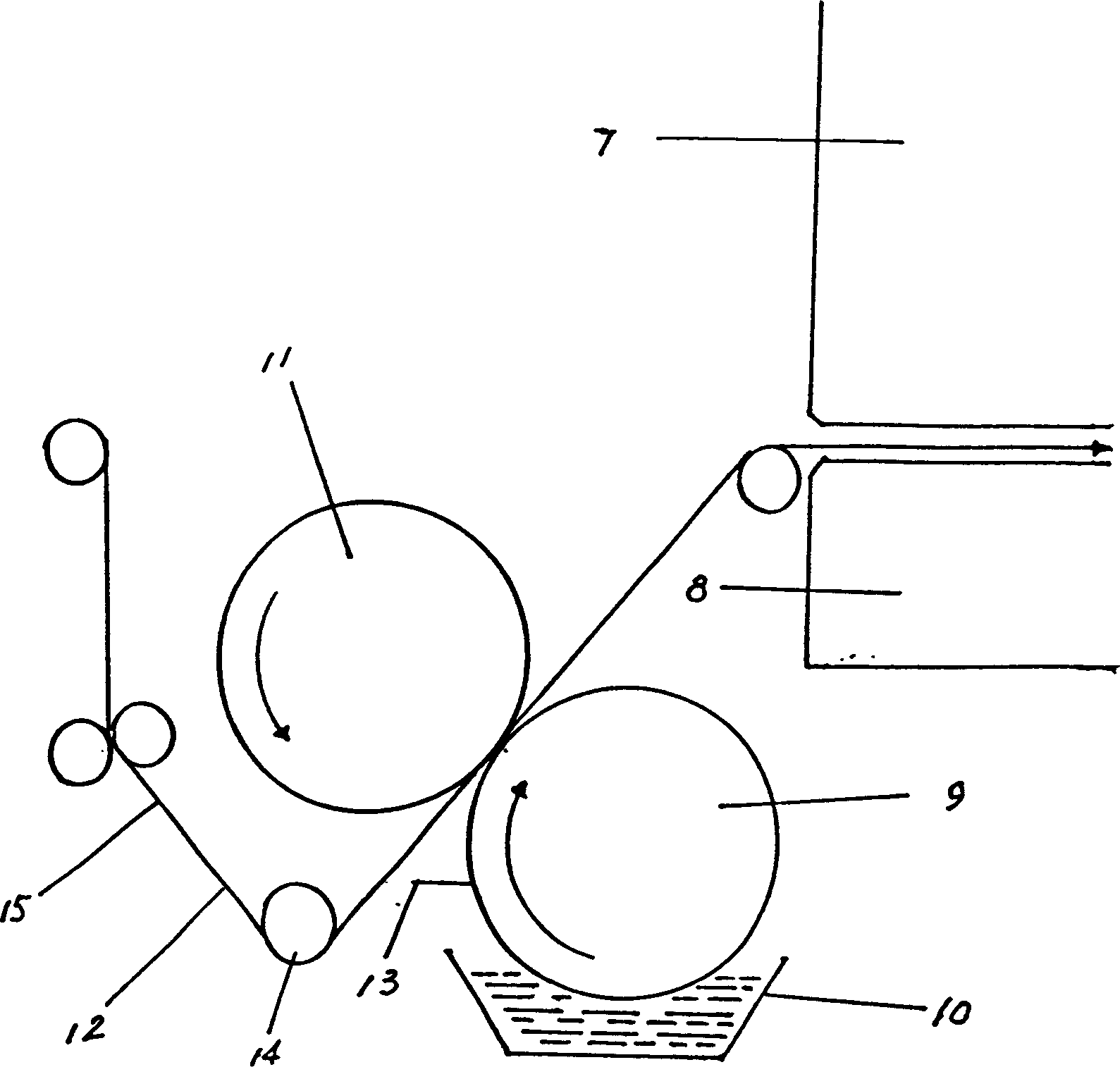

[0027] A gravure printing machine for printing cotton transfer printing paper

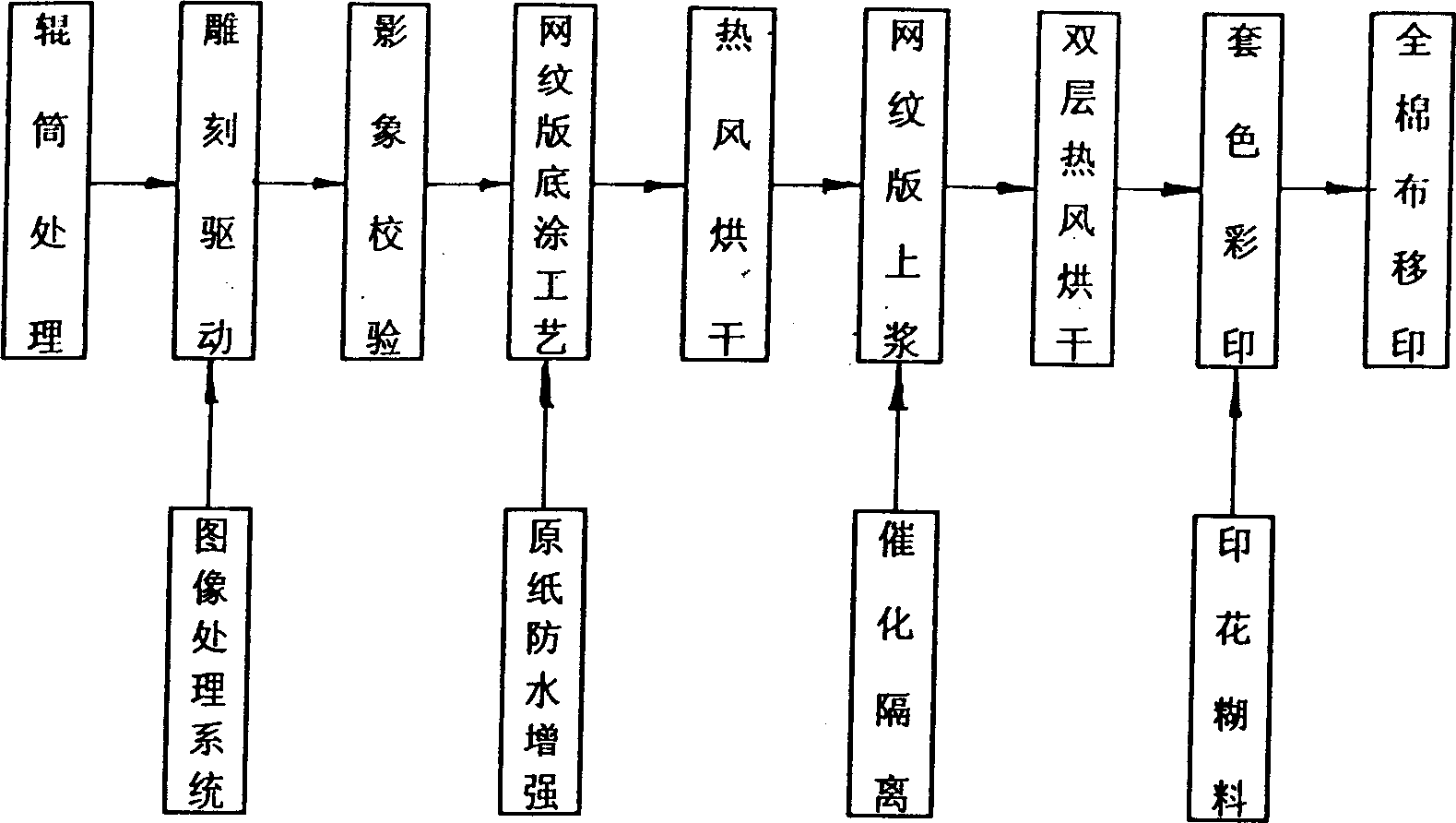

[0028] The production process of cotton transfer printing paper is as follows: figure 1 As shown, it is composed of many parts, which need to be processed by rollers, engraved and driven according to the signal of the image processing system, image verification, base paper anilox plate bottom coating process waterproof enhancement, hot air drying, anilox plate sizing catalytic isolation layer, Double-layer hot air drying, printing paste cover color printing, cotton pad printing paper. Among them, the base coating process of the base paper anilox plate is waterproof and enhanced, the anilox plate sizing catalytic isolation layer, double-layer hot air drying and printing paste cover color printing are all processes that are not available in the traditional gravure printing machine production heat transfer printing paper process. Therefore, it is necessary to add anilox plate bottom coating equipment...

Embodiment 2

[0033] Cotton transfer paper for printing rough fabrics such as khaki and denim.

[0034] Production process and equipment see figure 1 As shown in Example 1: roller processing, engraving drive according to the image processing system signal, image verification, base paper anilox plate bottom coating process waterproof enhancement, hot air drying, anilox plate sizing catalytic isolation layer, double-layer hot air drying Dry, printing paste cover color printing, cotton cloth pad printing.

[0035] Production process parameters:

[0036]Anilox base coating process, steel roller anilox plate line number 50 lines / in, thin stainless steel elastic scraper 0.7mm; slurry is composed of polyvinyl acetate resin, butadiene and styrene copolymer solution, of which polyacetic acid Vinyl alcohol accounts for 40% (weight ratio), butadiene and styrene copolymer accounts for 35% (weight ratio), and the rest is water and auxiliary agents. Its ph value is 7, and the amount of sizing on the b...

Embodiment 3

[0042] Cotton transfer printing paper for printing smooth cotton plain weave fabrics.

[0043] Production process and equipment see figure 1 As shown in Example 1: roller processing, engraving drive according to the image processing system signal, image verification, base paper anilox plate bottom coating process waterproof enhancement, hot air drying, anilox plate sizing catalytic isolation layer, double-layer hot air drying Dry, printing paste cover color printing, cotton cloth pad printing. ,

[0044] Production process parameters:

[0045] Anilox base coating process, steel roller anilox plate line number is 100 lines / in; thin stainless steel elastic scraper is 0.6mm; slurry is composed of polyvinyl acetate resin, butadiene and styrene copolymer solution, of which Polyvinyl acetate accounts for 30% (by weight), butadiene and styrene copolymer accounts for 30%, and the rest is water and auxiliary agents. The pH value of the solution is 7.5, and the sizing amount of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com