Patents

Literature

185results about How to "No relative displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

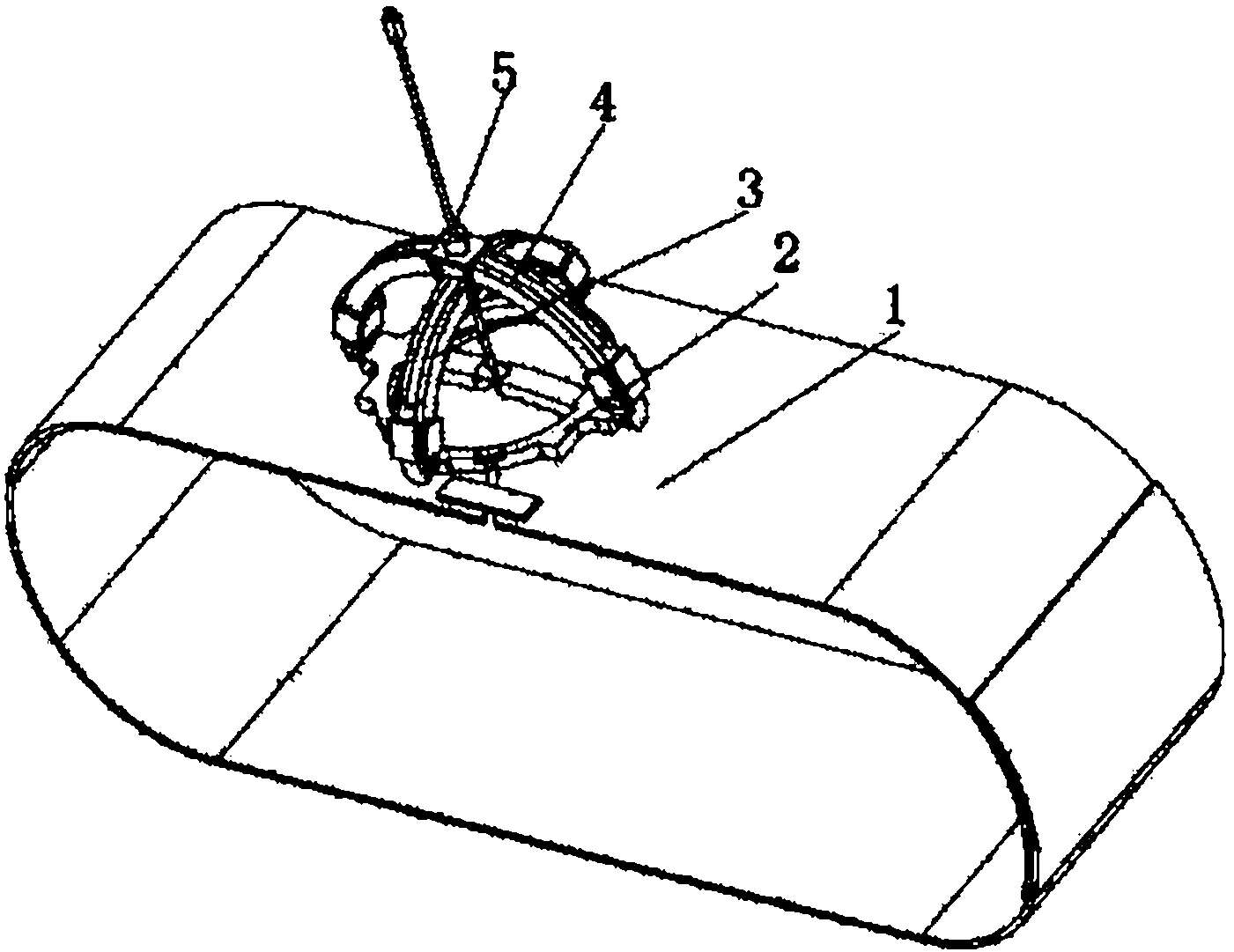

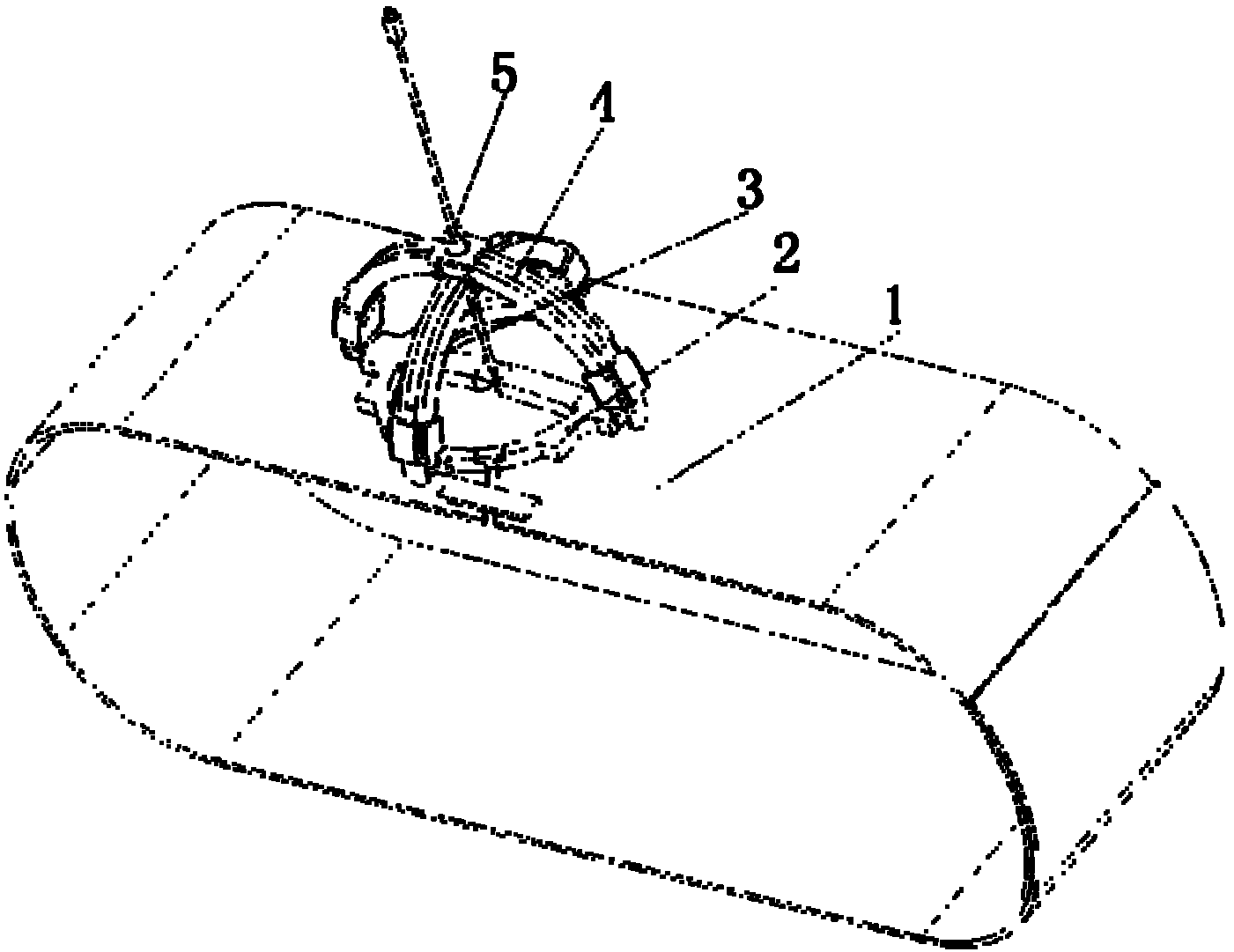

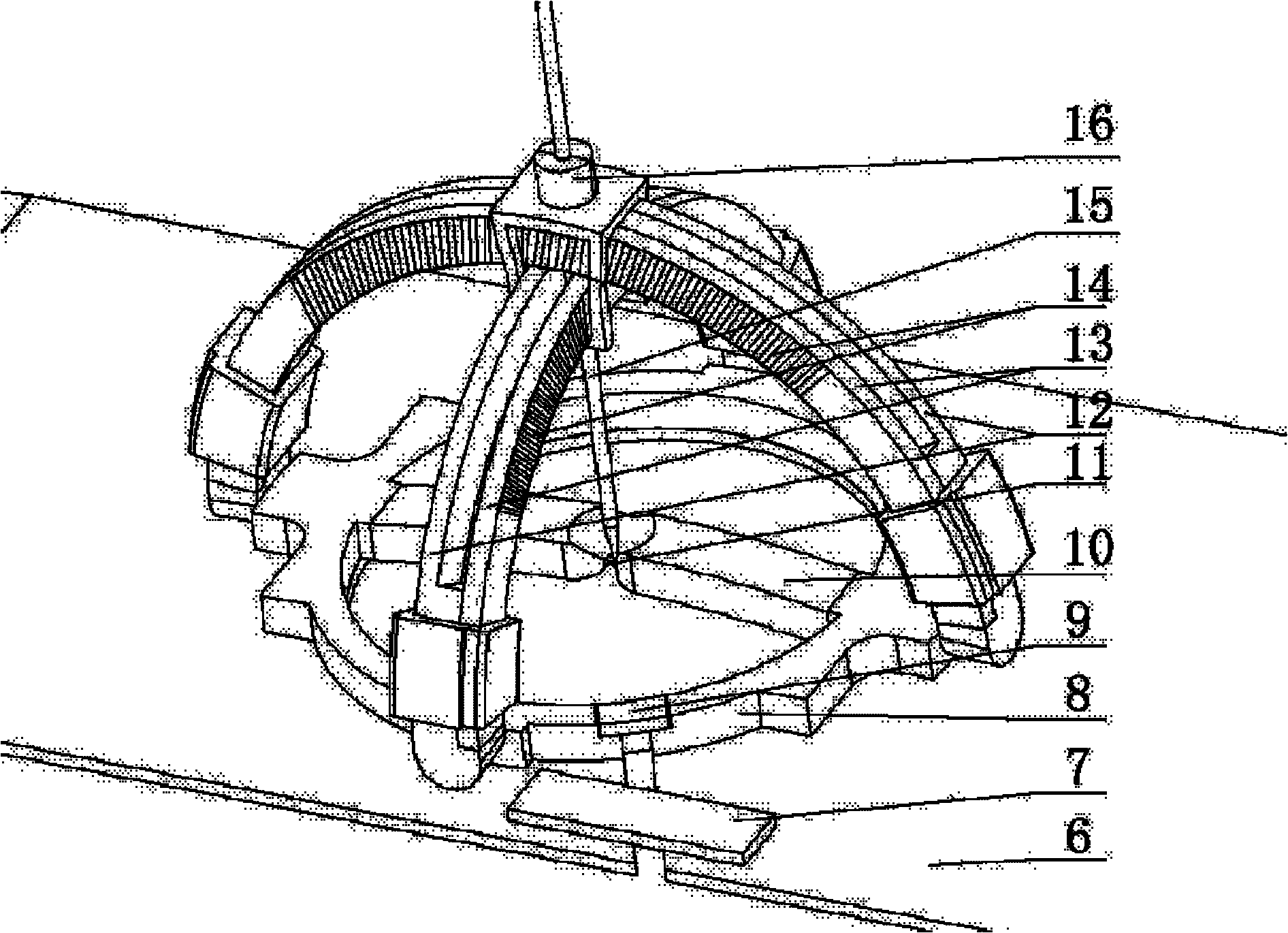

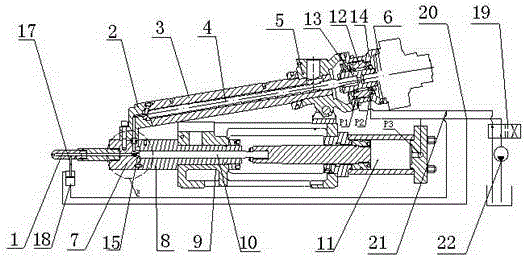

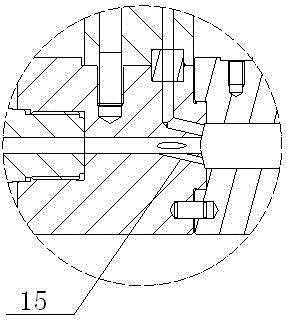

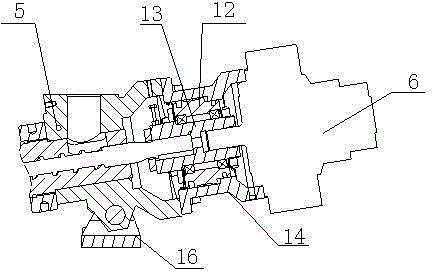

CT guided lung puncture positioning instrument

InactiveCN102090932AImprove securityReduce incidenceDiagnosticsSurgical needlesComputed tomographyThree-dimensional space

The invention discloses a computed tomography (CT) guided lung puncture positioning instrument in the technical field of medicinal instruments, which comprises a fixing mechanism, a chassis mechanism, two motion arm mechanisms and a puncture guide mechanism, wherein the chassis mechanism is fixedly arranged on the fixing mechanism; the two motion arm mechanisms are rotationally connected with thechassis mechanism from top to bottom respectively, and the first motion arm mechanism is mutually vertical to the second motion arm mechanism; and the puncture guide mechanism sequentially passes through the two motion arm mechanisms and the fixing mechanism and is opposite to the circle center of the fixing mechanism. The positioning instrument has small size, simple structure, accurate positioning, three-dimensional spatial free positioning, simple operating method and the like, can be positioned in a three-dimensional space so as to expand the selection of a puncture channel, avoids the influence of operation on the surgery in a two-dimensional space, avoids deviation of the puncture direction due to human hand fluctuation, and can be quickly detached and withdrawn so as not to affect the subsequent complex operation.

Owner:SHANGHAI JIAO TONG UNIV

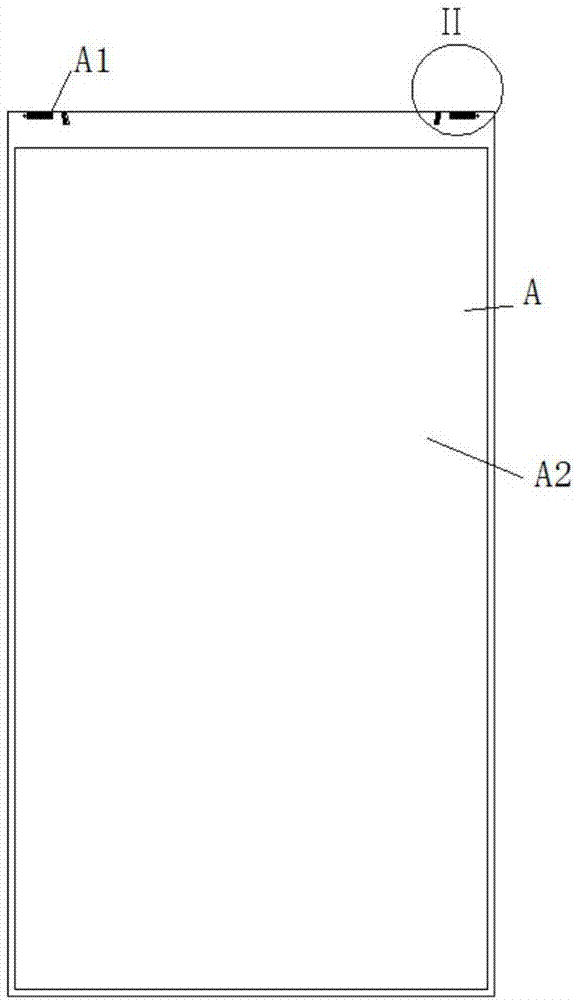

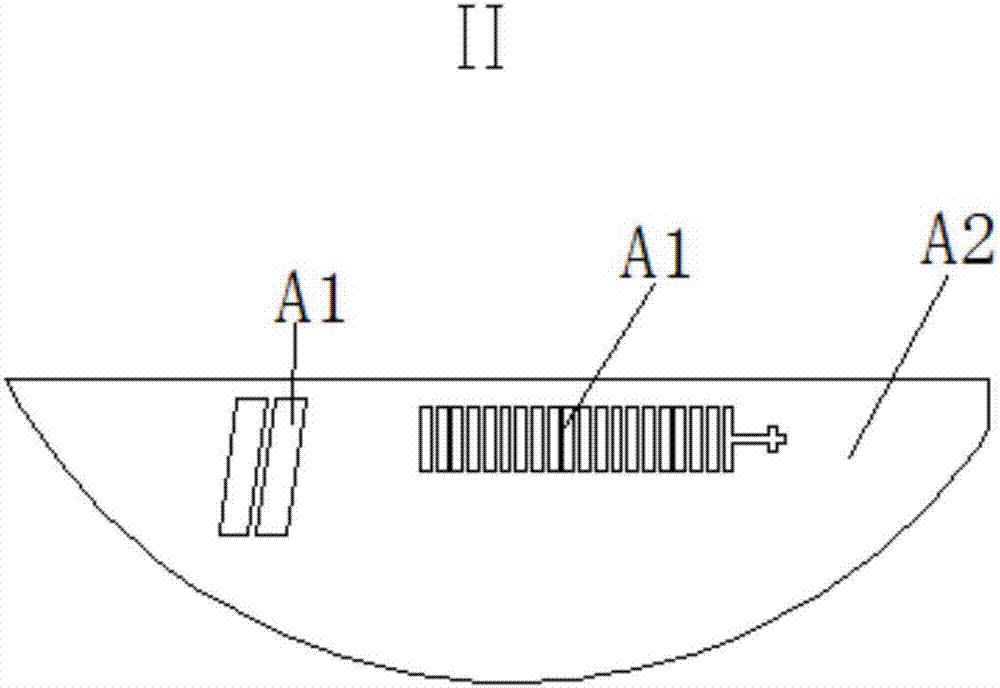

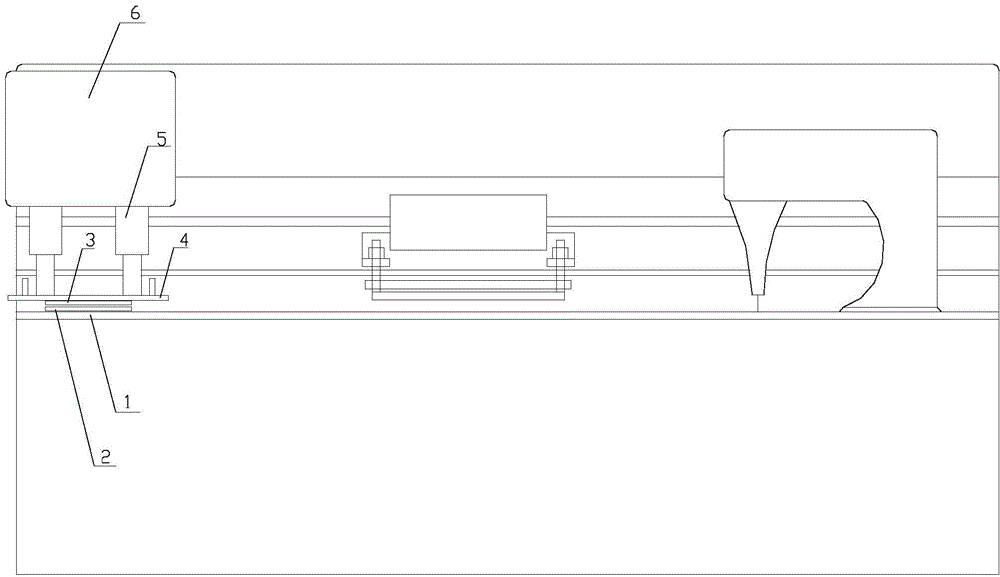

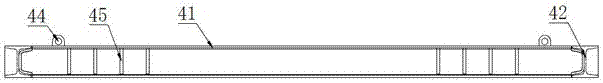

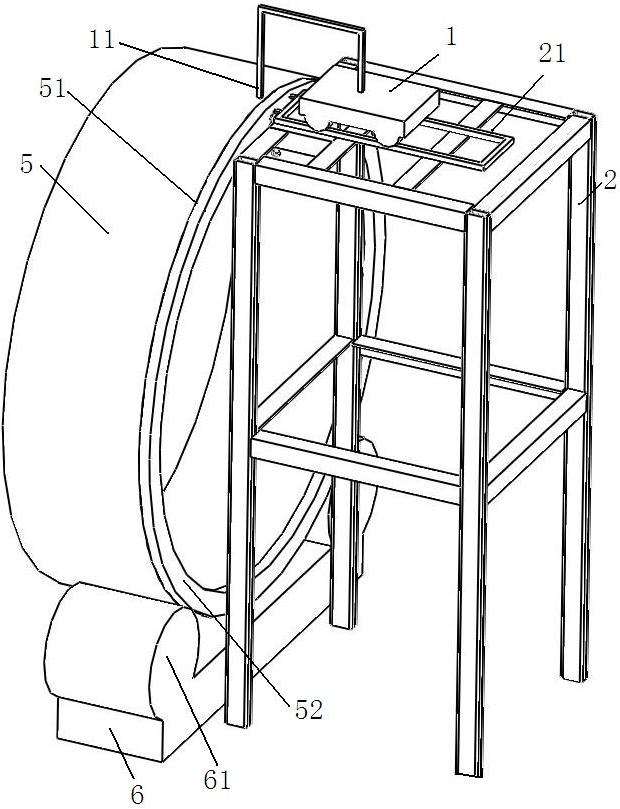

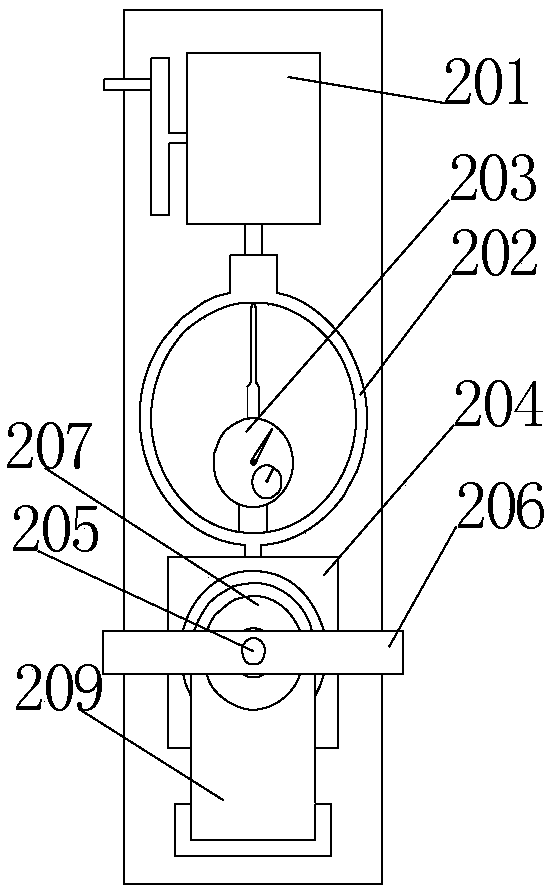

Automatic alignment lighting device for flexible OLED panel and FPC

PendingCN107478871ARealize alignment crimpingAvoid technical problems with excessive offsetsMeasurement instrument housingEngineeringConnection control

The present invention discloses an automatic alignment lighting device for a flexible OLED (Organic Light-Emitting Diode) panel and a FPC (Flexible Printed Circuit). The device comprises a location connection unit, an alignment control unit and a light test unit. The location connection unit comprises a flexible OLED panel vacuum sucker and a FPC location crimping tool, and when the flexible OLED panel vacuum sucker absorbs a flexible OLED panel, the deviation values of the displacement offsets of PINs on the flexible OLED panel are not larger than 5% of the widths of the PINs; the alignment control unit comprises a CCD lens, an automatic alignment platform, a control box and a device operation desk; and the flexible OLED panel vacuum sucker is connected with the automatic alignment platform, the CCD lens is arranged between the flexible OLED panel vacuum sucker and the FPC location crimping tool, the detection operation desk is electrically connected with the control box, and the control box is electrically connected with the automatic alignment platform, the CCD lens and the FPC location crimping tool. The automatic alignment lighting device for the flexible OLED panel and the FPC are simple in structure and convenient to use, can rapidly and accurately realize alignment crimping of PINs of the flexible OLED panel and the PINs of the FPC.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

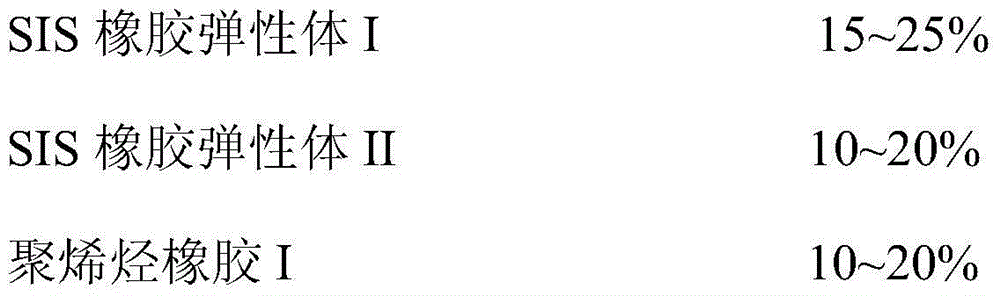

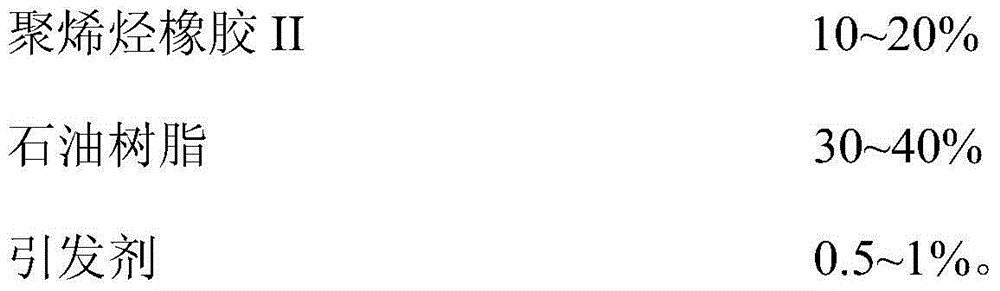

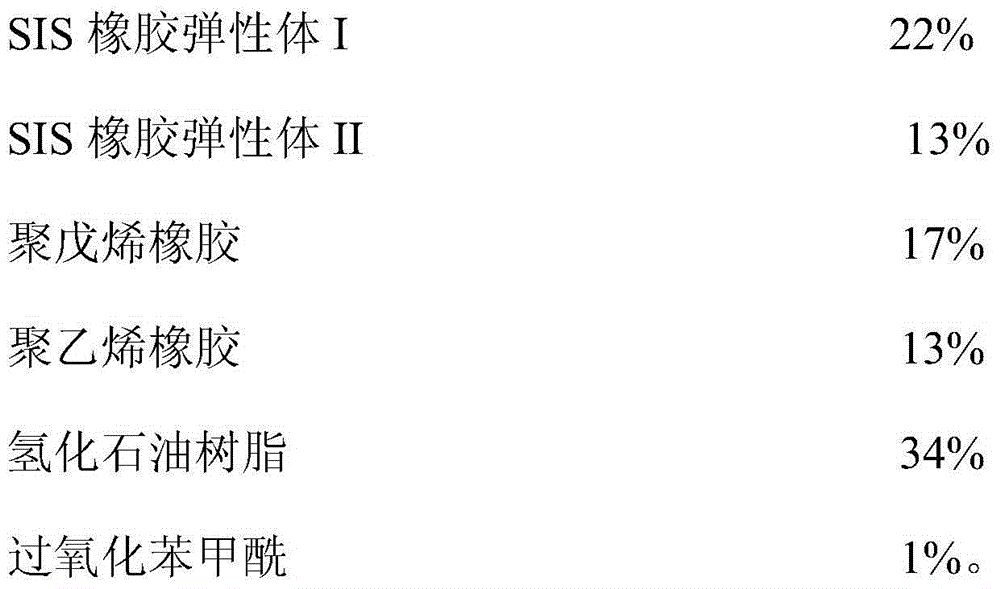

Single-surface adhesive tape for lithium battery and preparation method for single-surface adhesive tape

ActiveCN104559823AGuaranteed performanceQuality improvementMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesRelative displacementChemical reaction

The invention relates to a single-surface adhesive tape for a lithium battery. The single-surface adhesive tape comprises a sealing hot-melt pressure-sensitive adhesive layer and a base film layer, wherein the sealing hot-melt pressure-sensitive adhesive layer and the base film layer are connected with each other. The single-surface adhesive tape is high in adhesiveness, can resist corrosion of electrolyte of the lithium battery without generating chemical reaction with the electrolyte in the lithium battery, and keeps the performance of the lithium battery and the quality of the lithium battery. When the single-surface adhesive tape is used, the adhesive surface is attached to a pole group, and the pole group is wrapped by an external packaging material; furthermore, the relative position between the pole group and the external packaging material is adjusted, and the lithium battery is heated and pressurized; glue can overflow out of the two side surfaces of the single-surface adhesive tape to adhere the pole group and the external packaging material, so that the single-surface adhesive tape is convenient to use and meets the requirement of the production technology of the lithium battery; the pole group of the lithium battery and the external packaging material can be fixed by the single-surface adhesive tape and are firmly adhered, so that no relative displacement is generated; the single-surface adhesive tape is high in anti-falling capacity, high in safety, long in service life and stale in quality.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

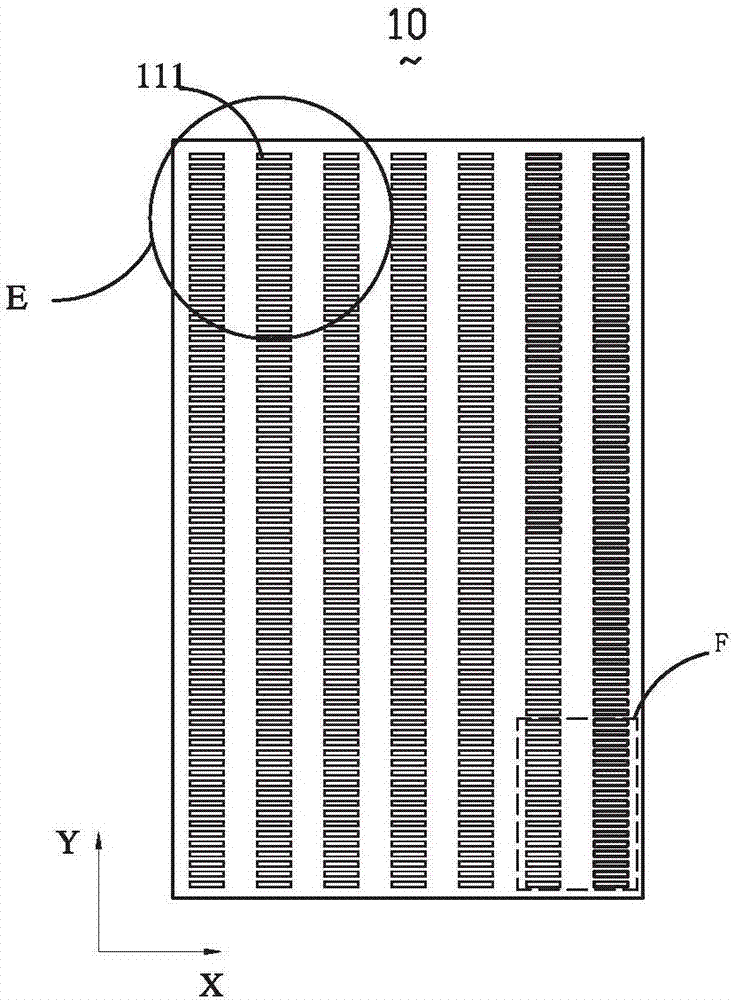

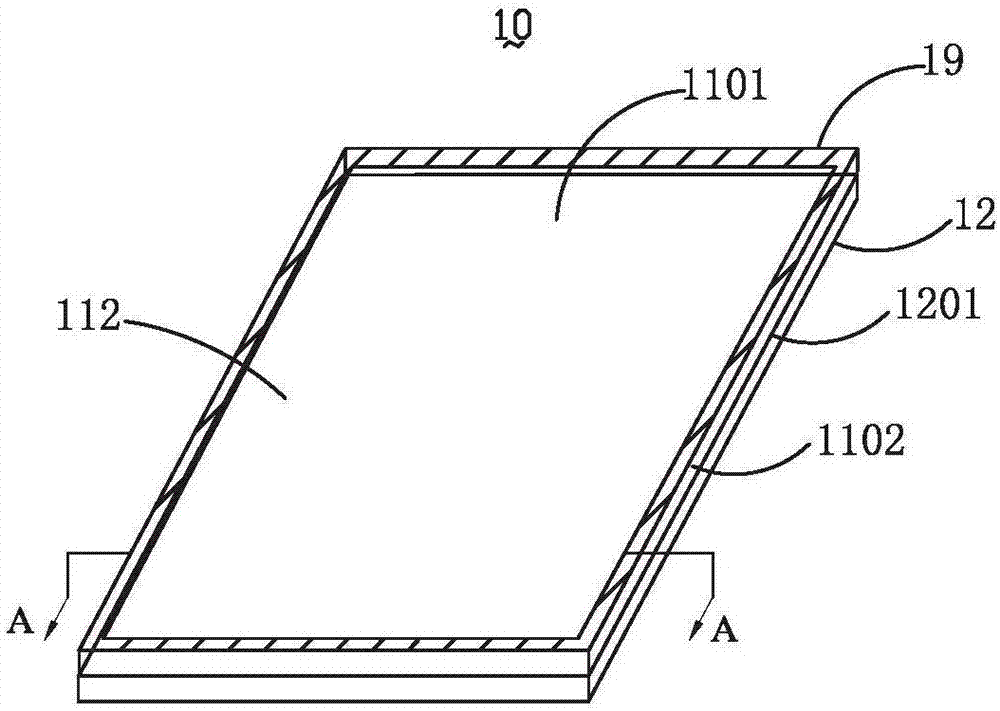

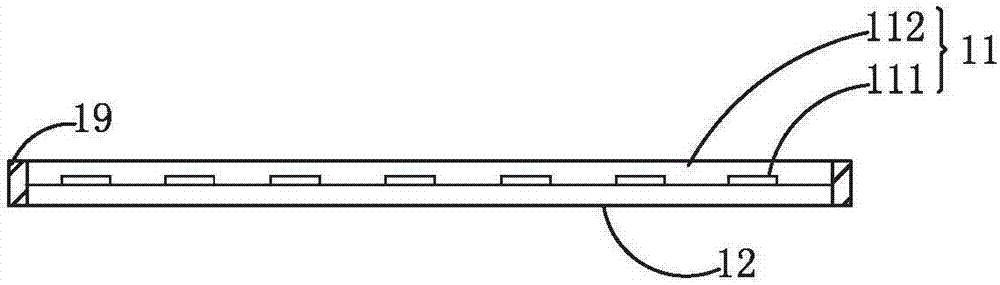

Flexible area light source, manufacturing method therefor, and electronic equipment

ActiveCN107093659AQuality improvementUniformity controllableStatic indicating devicesElectric circuit arrangementsEngineeringFluorescent light

The invention provides a flexible area light source, and the area light source comprises a flexible substrate, a plurality of LED chips, and a fluorescent layer. The plurality of LED chips are arranged on the surface of the flexible substrate in an ordered manner. The fluorescent layer is a prefabricated fluorescent film which covers the surface, equipped with the LED chips, of the flexible substrate. The LED chips are packaged in the fluorescent layer. The invention also provides a method for manufacturing the area light source, and electronic equipment employing the area light source. According to the invention, the area light source provided by the invention, the area light source manufactured through the method and the electronic equipment employing the area light source are good in bending performances, and are good in light emitting effect.

Owner:SHENZHEN LT OPTOELECTRONICS CO LTD

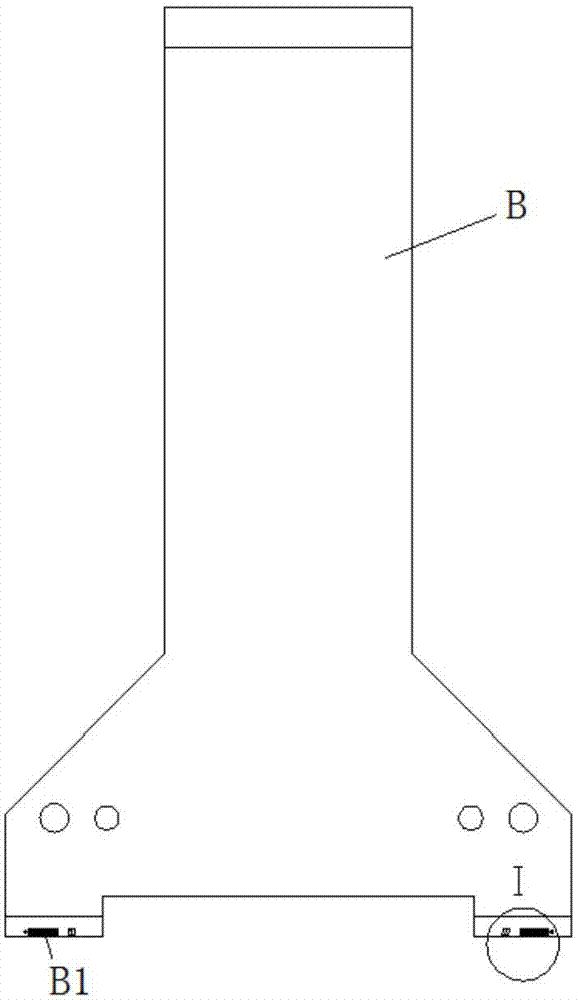

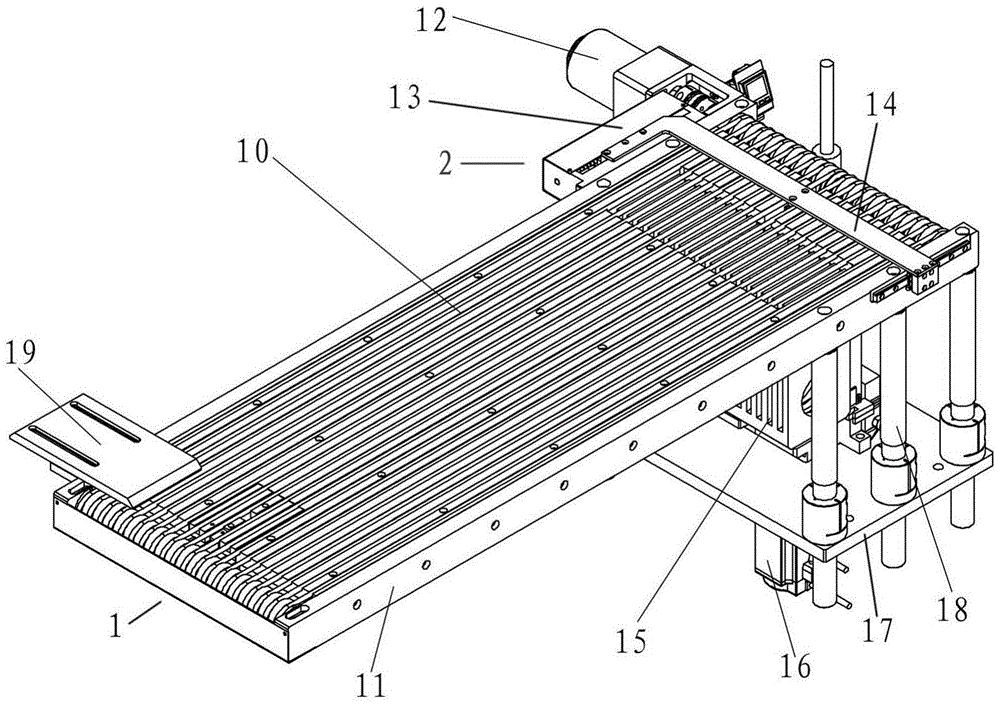

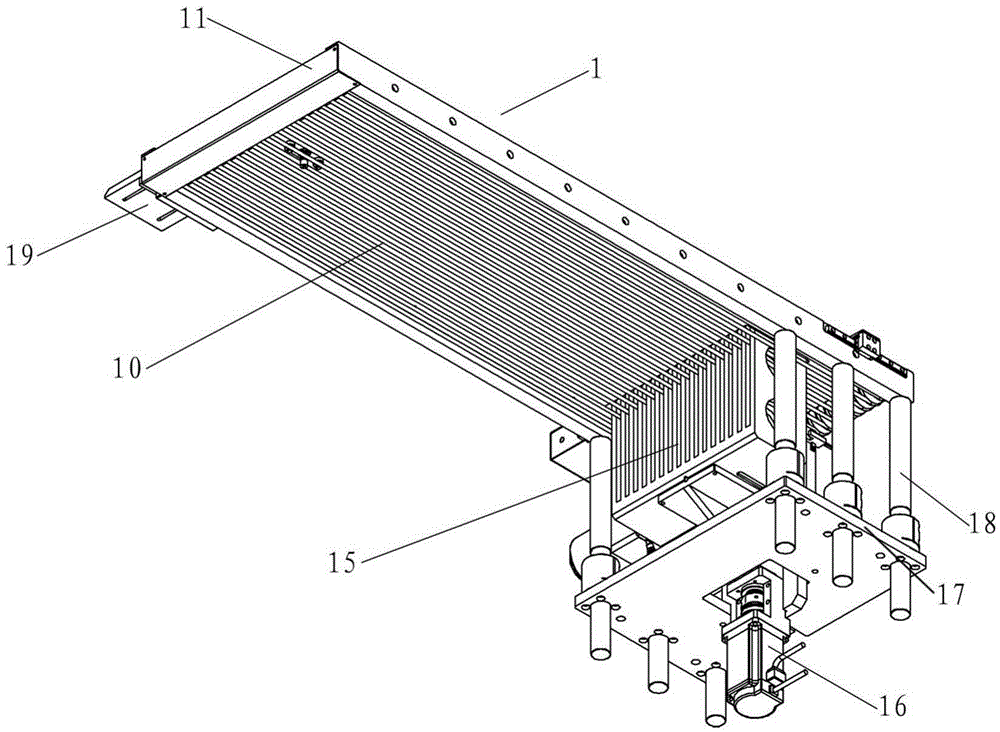

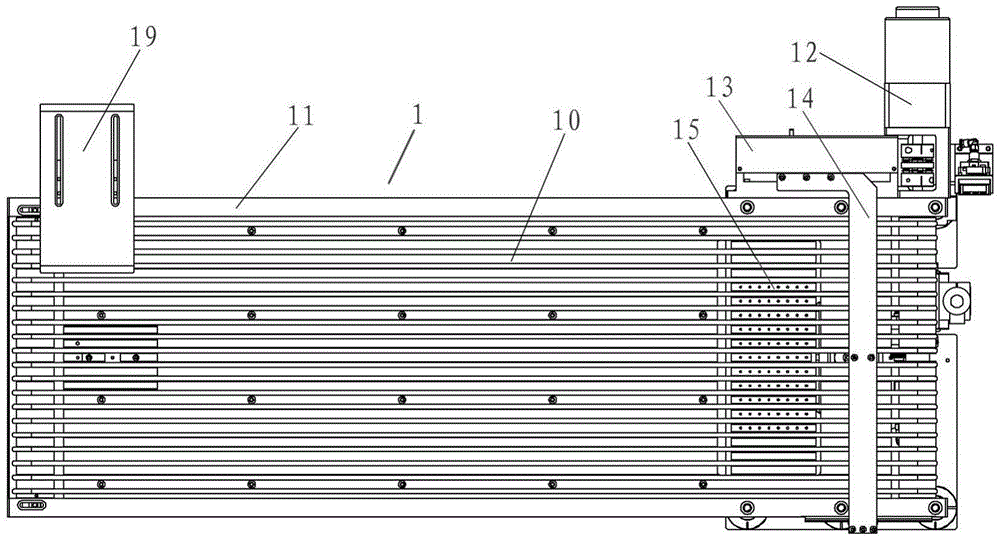

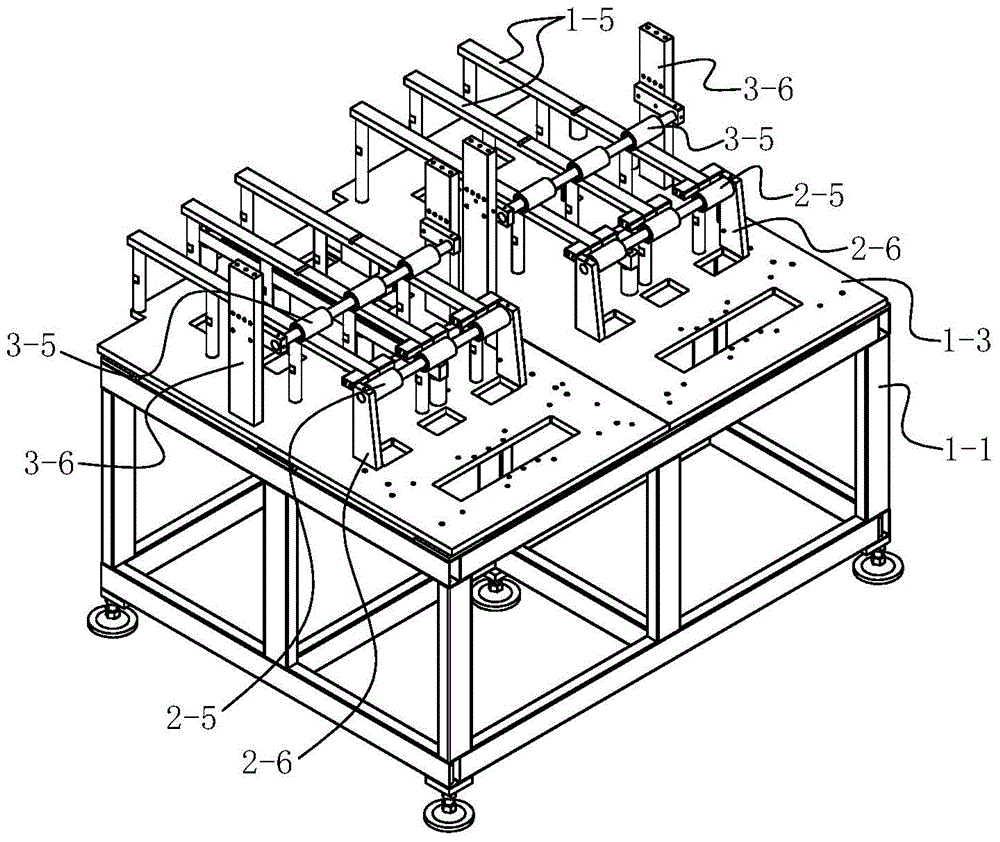

Feeding structure for feeding assembly line

ActiveCN104944103AImprove stabilityAccurate retrievingControl devices for conveyorsMechanical conveyorsStructural stabilityAssembly line

The invention provides a feeding structure for a feeding assembly line. The feeding structure comprises the assembly line, a conveying motor, a lifting motor, a lifting platform, a detection and correction device and a controller. The assembly line is composed of a plurality of belts, a rotating shaft and assembly line baffles. The rotating shaft is provided with fixing grooves matched with all the belts, and all the belts rotate in the fixing grooves. The position, at the tail end of the assembly line, of the rotating shaft is connected with the conveying motor, and the conveying motor drives the belts to rotate circularly through the rotating shaft. The lifting platform is in a multi-row column shape and can be contained in gaps between the belts. The lifting motor controls the lifting platform to ascend and penetrate through the gaps between the belts and utilizes vacuum suction to cooperate with feeding. The controller is connected with and controls the conveying motor, the lifting motor and the detection and correction device. The feeding structure for the feeding assembly line is good in stability, high in material fetching accuracy and capable of improving production efficiency.

Owner:SHENZHEN XINSANLI AUTOMATION EQUIP

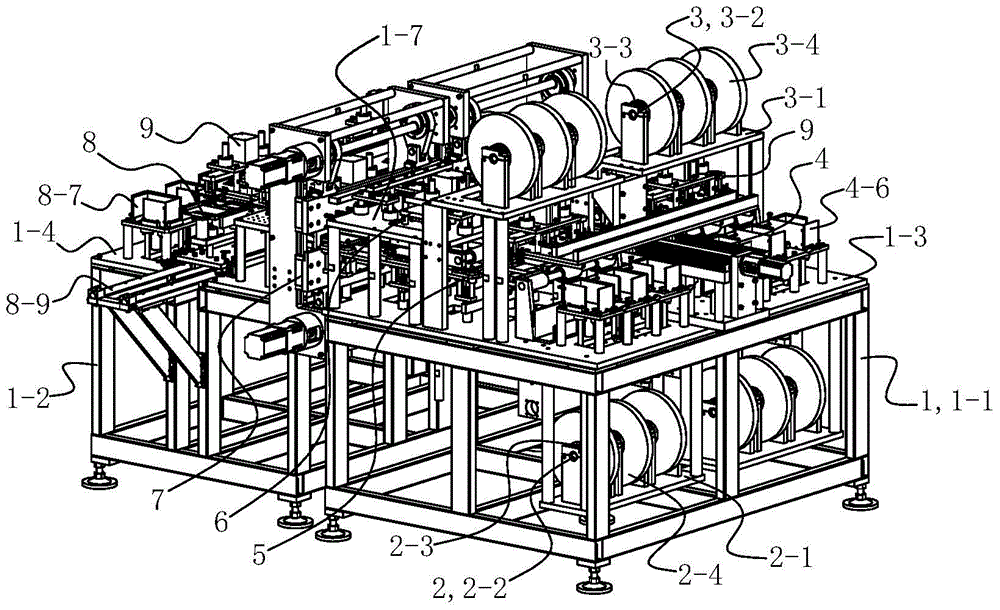

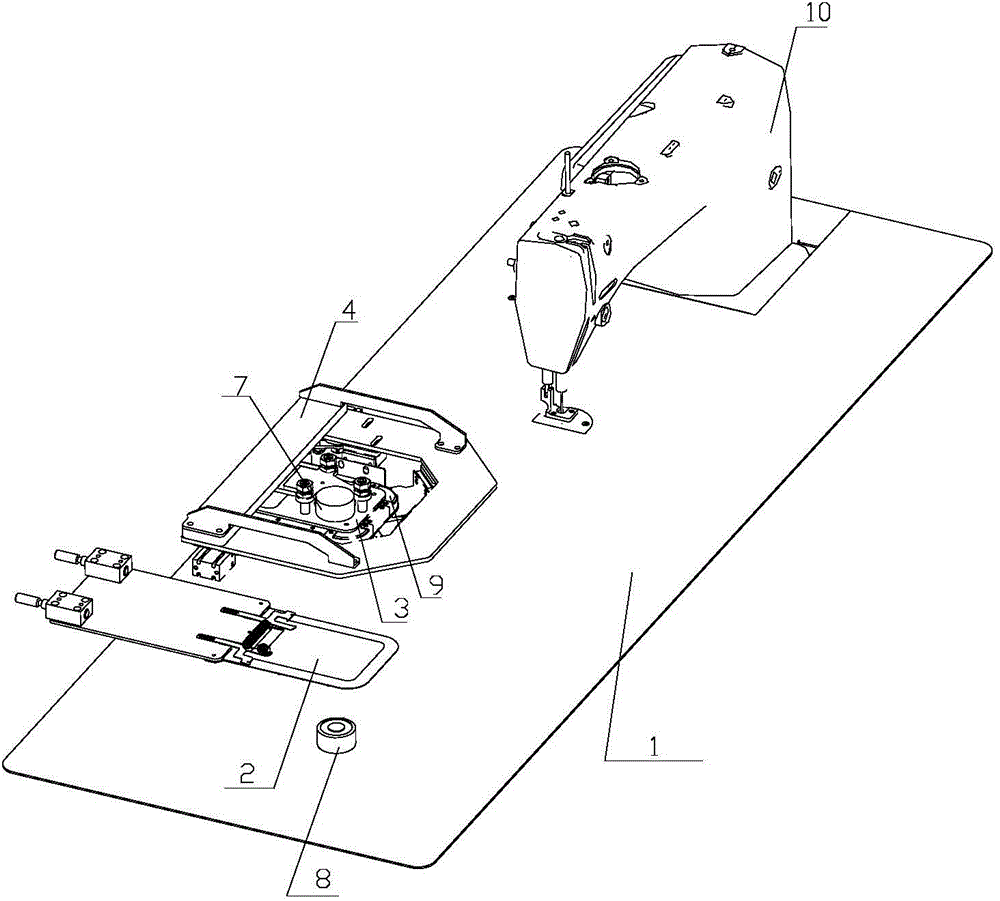

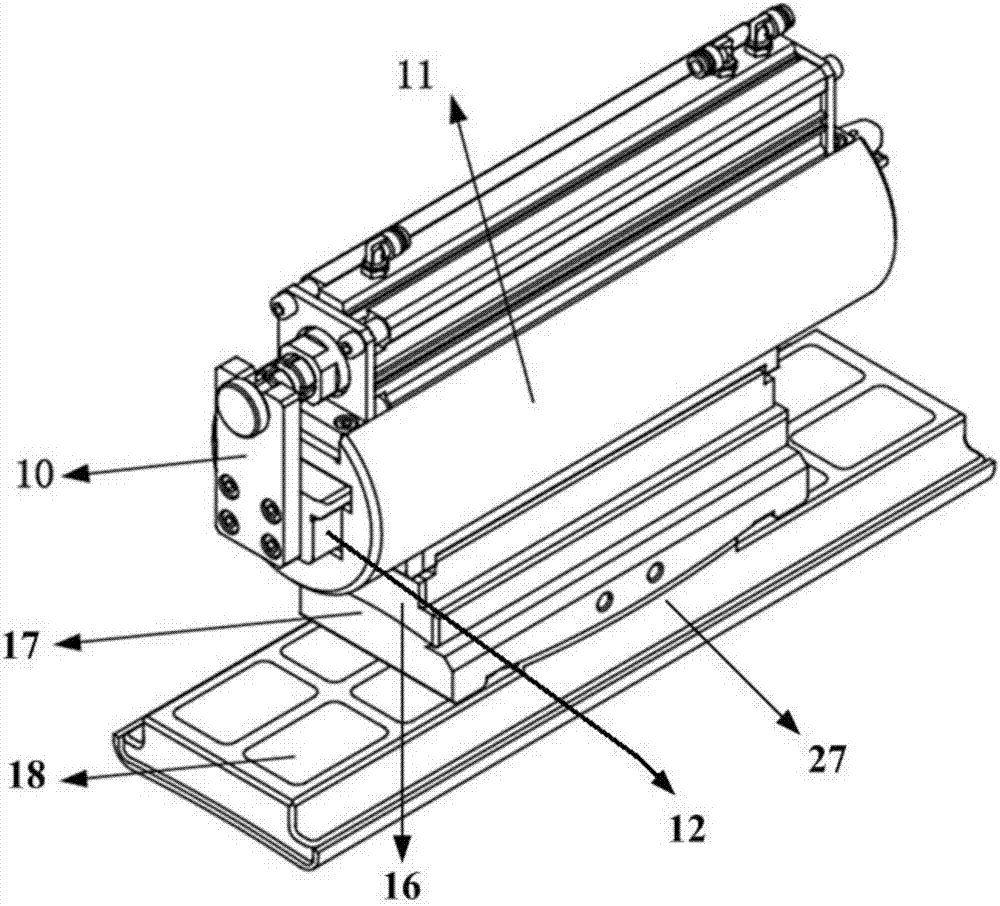

Automatic film-enveloping and piece-laminating machine

ActiveCN104064813ANo relative displacementHigh coating precisionAssembling battery machinesFinal product manufactureEngineeringAutomation

The invention relates to an automatic film-enveloping and piece-laminating machine. The machine comprises a stander, a lower diaphragm unreeling device, an upper diaphragm unreeling device, a piece-feeding device, a piece-moving device, a sealing-pressing device, a shearing device and a piece-laminating device, wherein long-strip-shaped piece-moving platforms are arranged on the stander; the piece-feeding device comprises sucking disc piece-fetching mechanisms and a piece-feeding translation mechanism; the piece-moving device comprises a clamp plate translation mechanism, piece-moving substrates, clamp plate air cylinders, base plates and clamp plates; the sealing-pressing device comprises a heat-seal assembly and a heat-seal lifting mechanism, the heat-seal assembly is located above the piece-moving platforms, and the heat-seal lifting mechanism is used for driving the rising and the falling of the heat-seal assembly; the piece-laminating device comprises sucking disc piece-fetching mechanisms, a piece-laminating translation mechanism and piece-collecting mechanisms, and the piece-laminating translation mechanism is used for driving the sucking disc piece-fetching mechanisms to carry out translational motion. According to the automatic film-enveloping and piece-laminating machine, the full automation is realized during film-enveloping, heat-seal, shearing and piece-laminating processes, the film-enveloping precision is high, the film-enveloping speed is high, and the film-enveloping effect is good.

Owner:上海恒动新能源有限公司

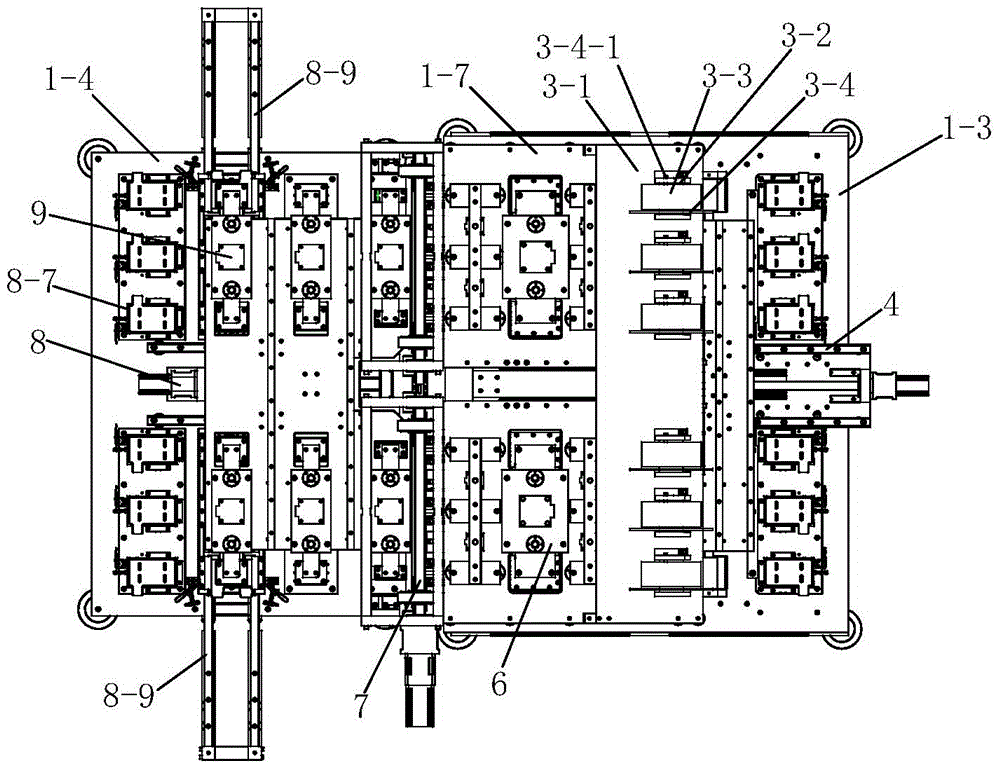

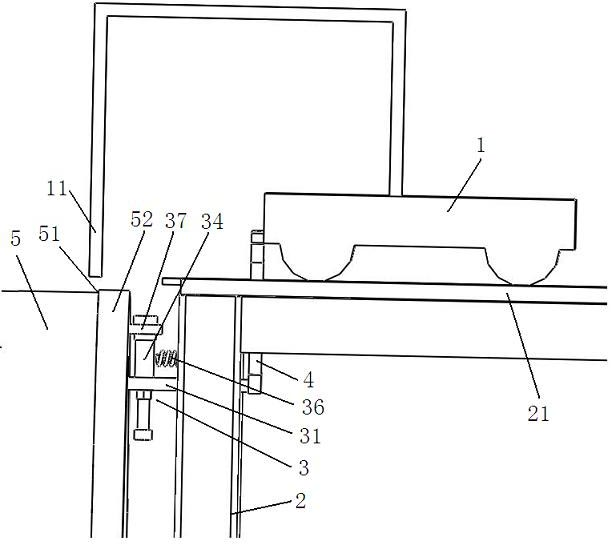

Patch pocket machine folding feeding mechanism

ActiveCN104630994APatch pocket precisionNo relative displacementWork-feeding meansFixed frameMechanical equipment

The invention relates to a patch pocket machine folding feeding mechanism and belongs to the field of sewing mechanical equipment. The patch pocket machine folding feeding mechanism comprises a working platform, a horizontal beam, a lower die plate and an upper die pocket folding device. The upper die pocket folding device is fixed at one end of the horizontal beam. A motor is fixed on the horizontal beam. A guiding column is arranged vertically. One end of the guiding column is connected with the output end of a fixing motor. The other end of the guiding column is hinged to an upper die plate fixing frame. An upper die plate is fixed in the middle of the upper die plate fixing frame. The face, opposite to the working platform, of the upper die plate is the front face. An electromagnet is arranged on the back face of the upper die plate. Pocket bending inserting plates are arranged on the three side faces of the upper die plate fixing frame. The lower die plate is arranged under an upper die piece and is fixed on one guiding track of the horizontal beam. An electromagnet is arranged at the center of a projection zone of the working platform of the lower die plate. According to the patch pocket machine folding feeding mechanism, accurate patch pocket operation can be achieved, and deforming and dislocation of pockets can be avoided.

Owner:SHANGHAI WEISHI MACHINERY

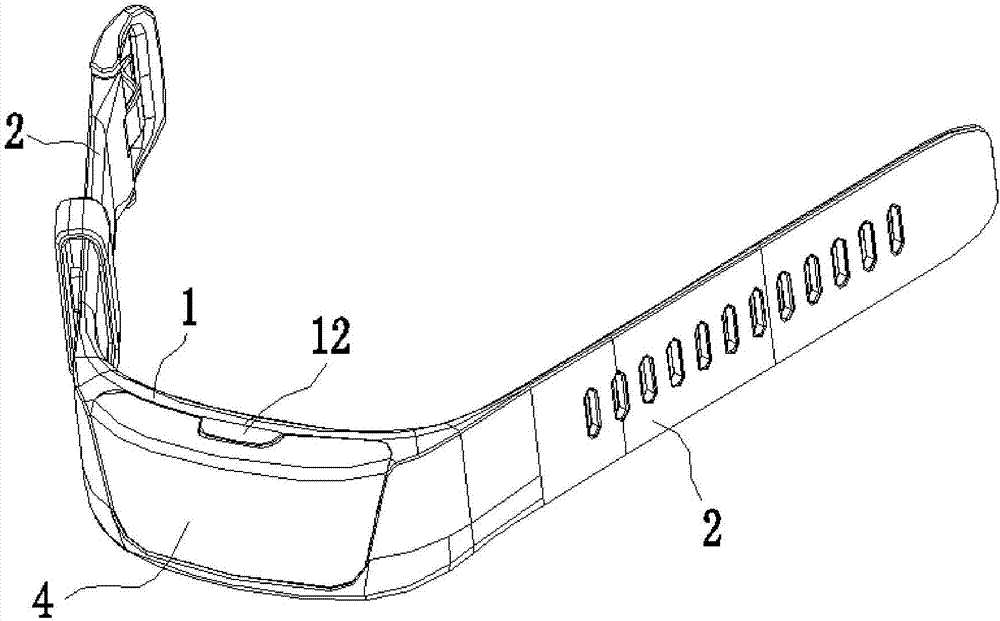

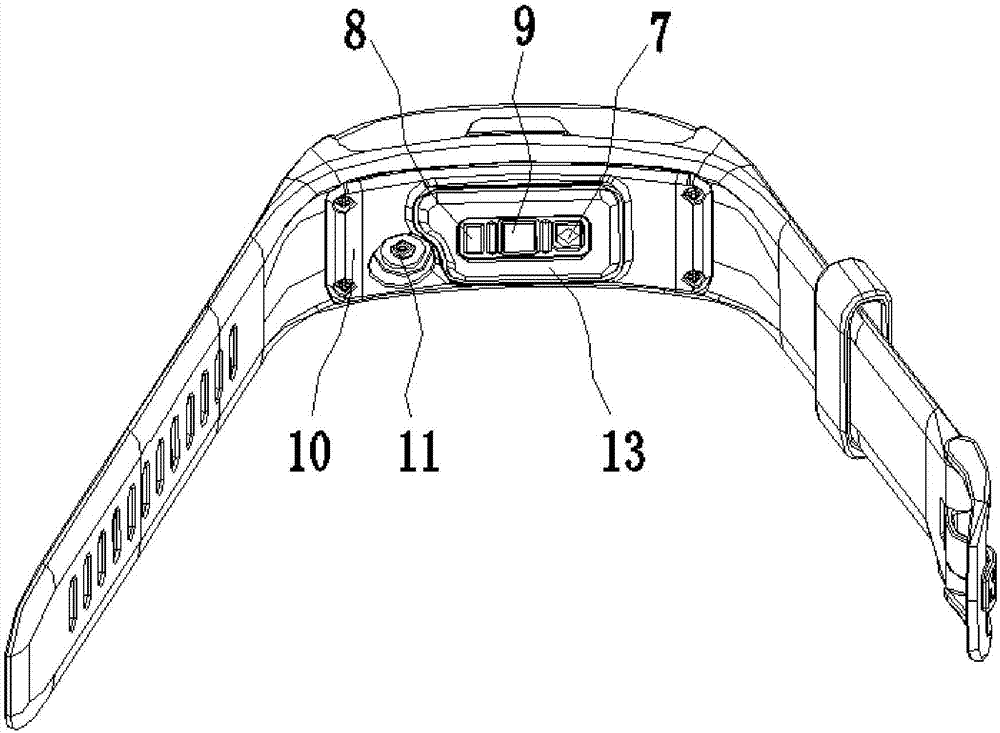

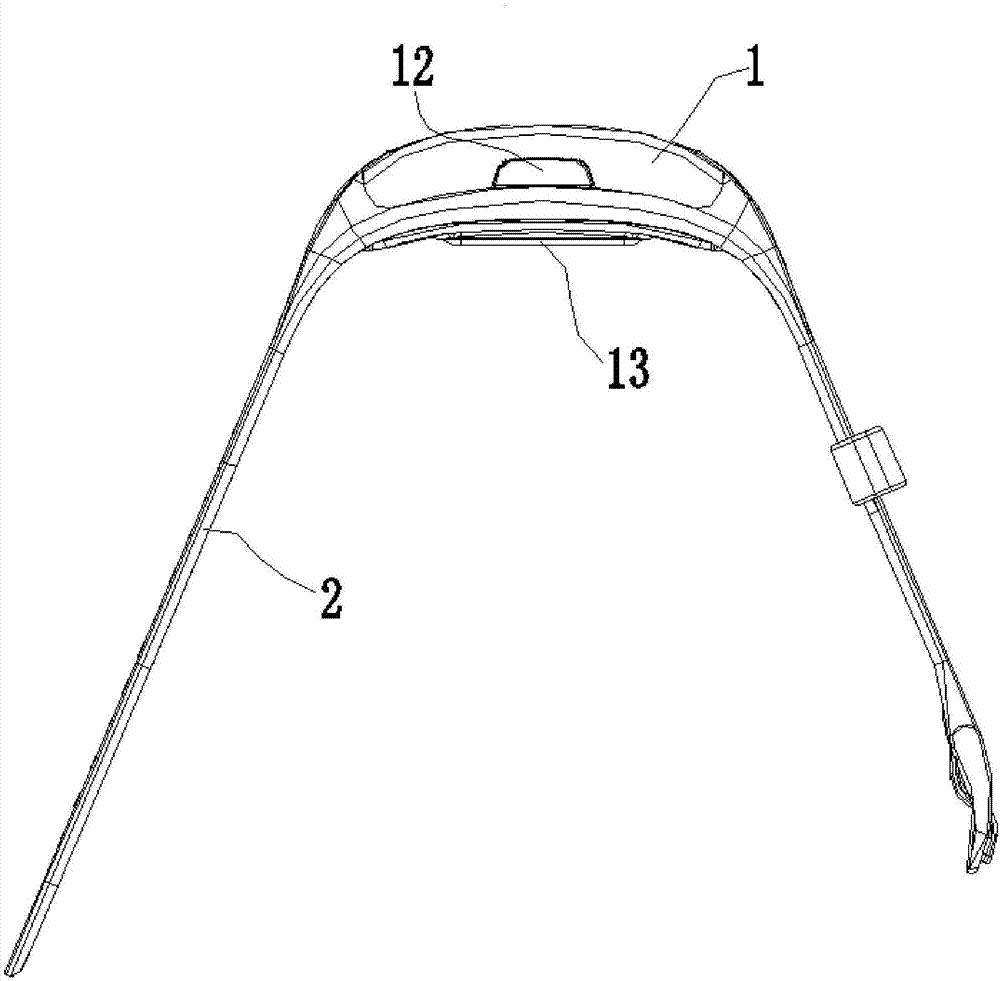

Medical wristband with self-compensation function and self-compensation method

ActiveCN107874765AFilter out distracting factorsGuaranteed not to moveSensorsMeasuring/recording heart/pulse rateObservational errorInterference factor

The invention relates to the technical field of medical electronics and in particular relates to a medical wristband with a self-compensation function and capable of offsetting blood oxygen measurement interference due to movements of a user when the user wears the wristband. Movement compensation is realized via gravitational acceleration, and interference factors produced during the daily use ofthe wristband can be eliminated; accurate and reliable blood oxygen saturation measurement can be achieved; a boss, mounted on the bottom of a wristband body, is keen to skin, so a temperature sensor, a photosensitive sensor and a light source projection window can be well applied to the wrist skin, and position of the wristband during the movement of the user can be positioned; and relative displacement between the temperature sensor and the photosensitive sensor and the wrist skin can be prevented, so measurement error during the movement can be reduced or eliminated.

Owner:SHENZHEN CHENG FONG DIGITAL TECH LTD

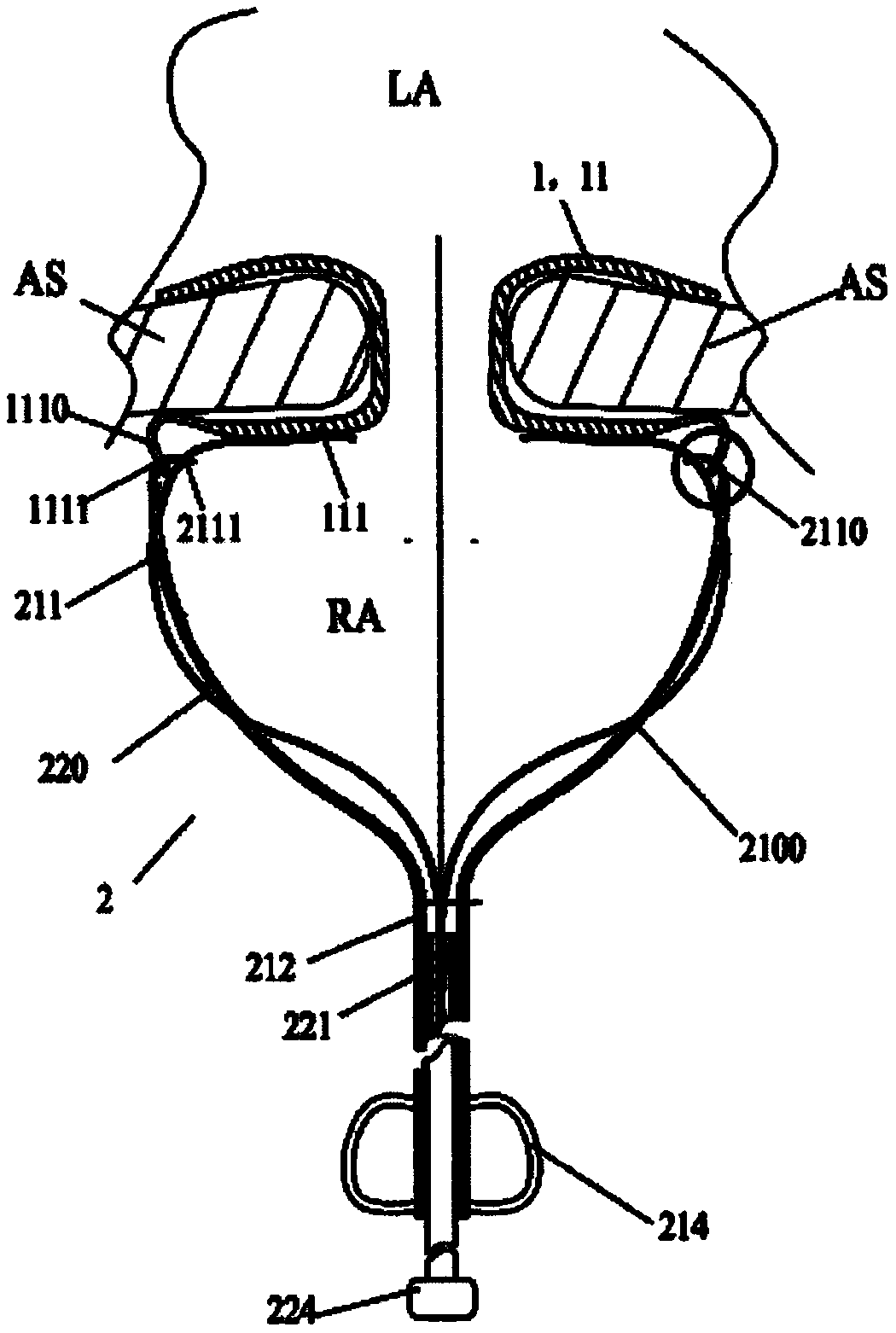

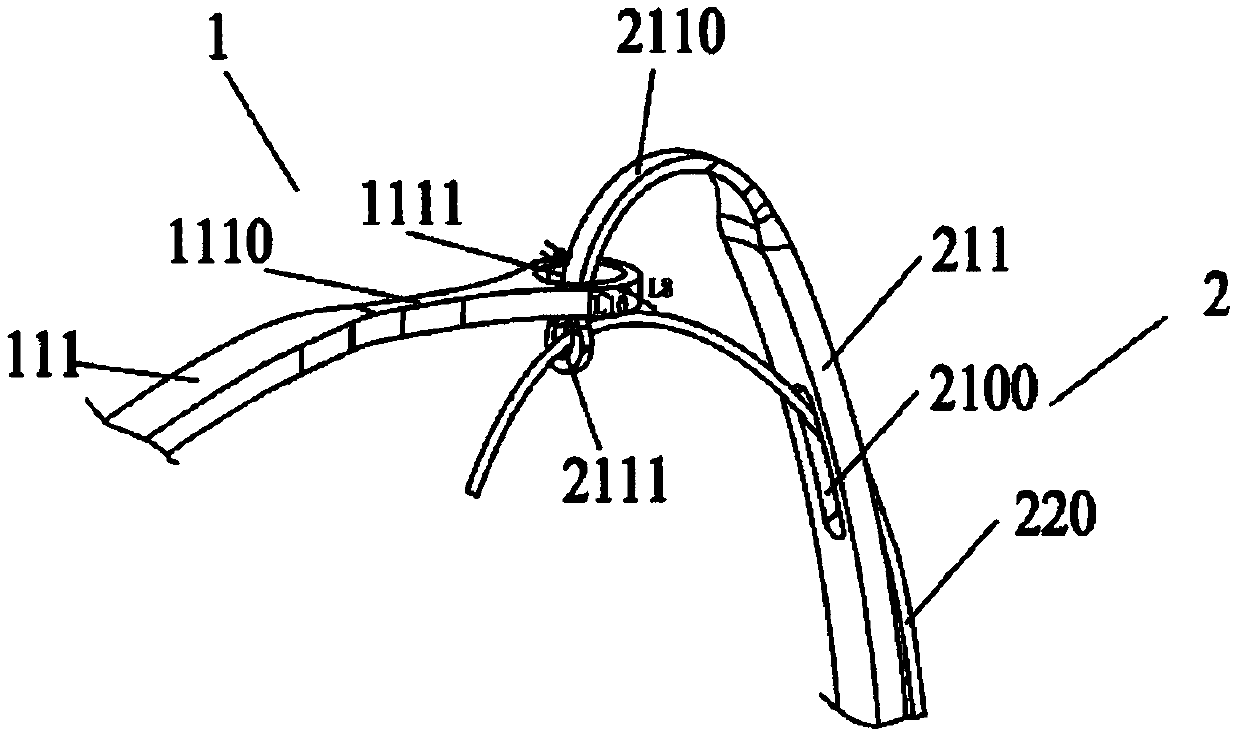

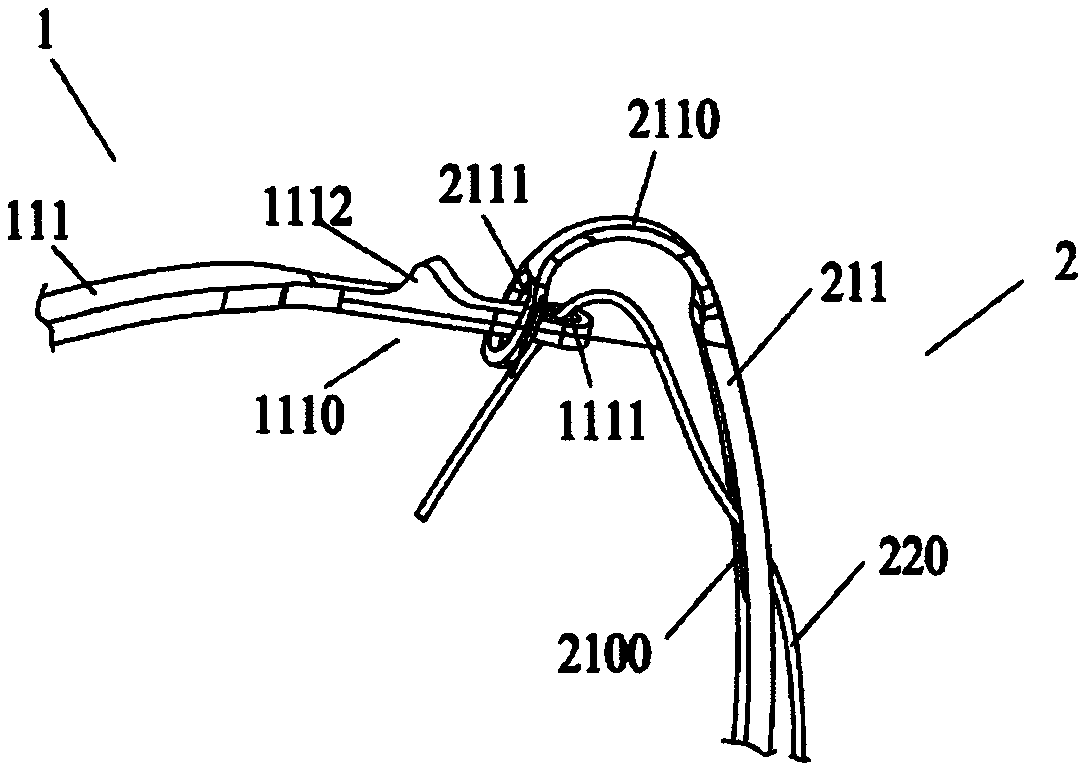

Controllable release system

The application relates to a controllable release system comprising an implantation instrument and a conveying system. A plurality of first holes are formed in the near-end area of the implantation instrument. The conveying system includes a plurality of traction rods and a plurality of release wires; the plurality of release wires, the plurality of traction rods and the plurality of first holes are in one-to-one correspondence in number and position; each traction rod is provided with a second hole and a constraint part; the second holes are formed in the far ends of the traction rods; the release wires penetrate the constraint parts and the first holes or the second holes to realize connection between the implantation instrument and the conveying system. During the conveying process, theconstraint parts can limit movement of the release wires; and when the implantation instrument is released, the release wires can move relative to the traction rods. According to the system, the implantation instrument is convenient to repeatedly recover timely before dismounting of the implantation instrument; and during the releasing process, the implantation instrument can slowly stretch to anoptimal form from a sheath tube, detachable connection can be realized by withdrawing the release wires to realize the controllable release function. The system is simple in overall structure, convenient to operate, safe and reliable.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

Marine platform equipment installation system

PendingCN107499453AShorten the construction periodDoes not affect constructionVessel designingMarine engineeringPower equipment

The invention relates to a marine platform equipment installation system used for conveying power equipment to an equipment fixing base on the upper surface of a deck of an engine compartment. The marine platform equipment installation system is characterized by including a suspended base, a first linear guide rail, a second linear guide rail, a second linear guide rail bracket, a mobile platform and a mobile platform driving mechanism, wherein a first locating assembly is arranged between the second linear guide rail bracket and the equipment fixing base, a second locating assembly is arranged between the second linear guide rail bracket and the suspended base, and a third locating assembly is arranged between the second linear guide rail and the first linear guide rail. The marine platform equipment installation system has the advantages that equipment can be directly conveyed from an inlet in one side of the engine compartment into the engine compartment without installing the power equipment before the segmented upper-layer deck of the marine platform engine compartment is closed, segmented construction of other large-scale steel-structure platforms can not be influenced, and therefore the construction cycle of marine platforms can be shortened.

Owner:RUGAO CITY SHUANGYA ENVIRONMENTAL PROTECTION TECH CO LTD

Fixing clamp for automobile brake caliper

PendingCN110385596AGuaranteed positioning accuracyAchieve preloadPositioning apparatusMetal-working holdersEngineeringCalipers

The invention provides a fixing clamp for an automobile brake caliper. The fixing clamp comprises a fixing plate structure, a pre-tightening mechanism and a clamping mechanism; the fixing plate structure comprises a fixing plate and a positioning plate; the positioning plate is vertically arranged on the left end surface of the fixing plate; the fixing plate is fixedly connected with the positioning plate; the positioning plate is provided with two oblong holes formed side by side; the pre-tensioning mechanism comprises a positioning block, an arc-shaped positioning plate and four elastic mechanisms; each oblong hole is internally and slidably provided with two corresponding elastic mechanisms; the end portions, away from the oblong holes, of all the elastic mechanisms are connected with the positioning block; the arc-shaped positioning plate is hinged to the positioning block; the clamping mechanism comprises a driving mechanism and a clamping block; the driving mechanism is arrangedon the right end surface of the fixing plate; the extension end of the driving mechanism is connected with the clamping block; and the clamping block directly faces the two oblong holes. Through the fixing clamp for the automobile brake caliper, the technical problem that conventional automobile brake caliper clamps cannot hold workpieces stably is solved.

Owner:中联精工(天津)有限公司

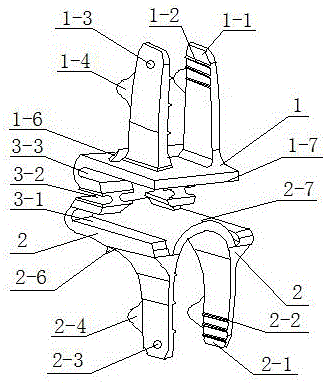

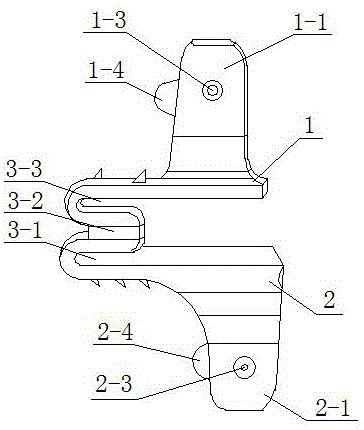

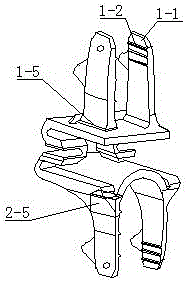

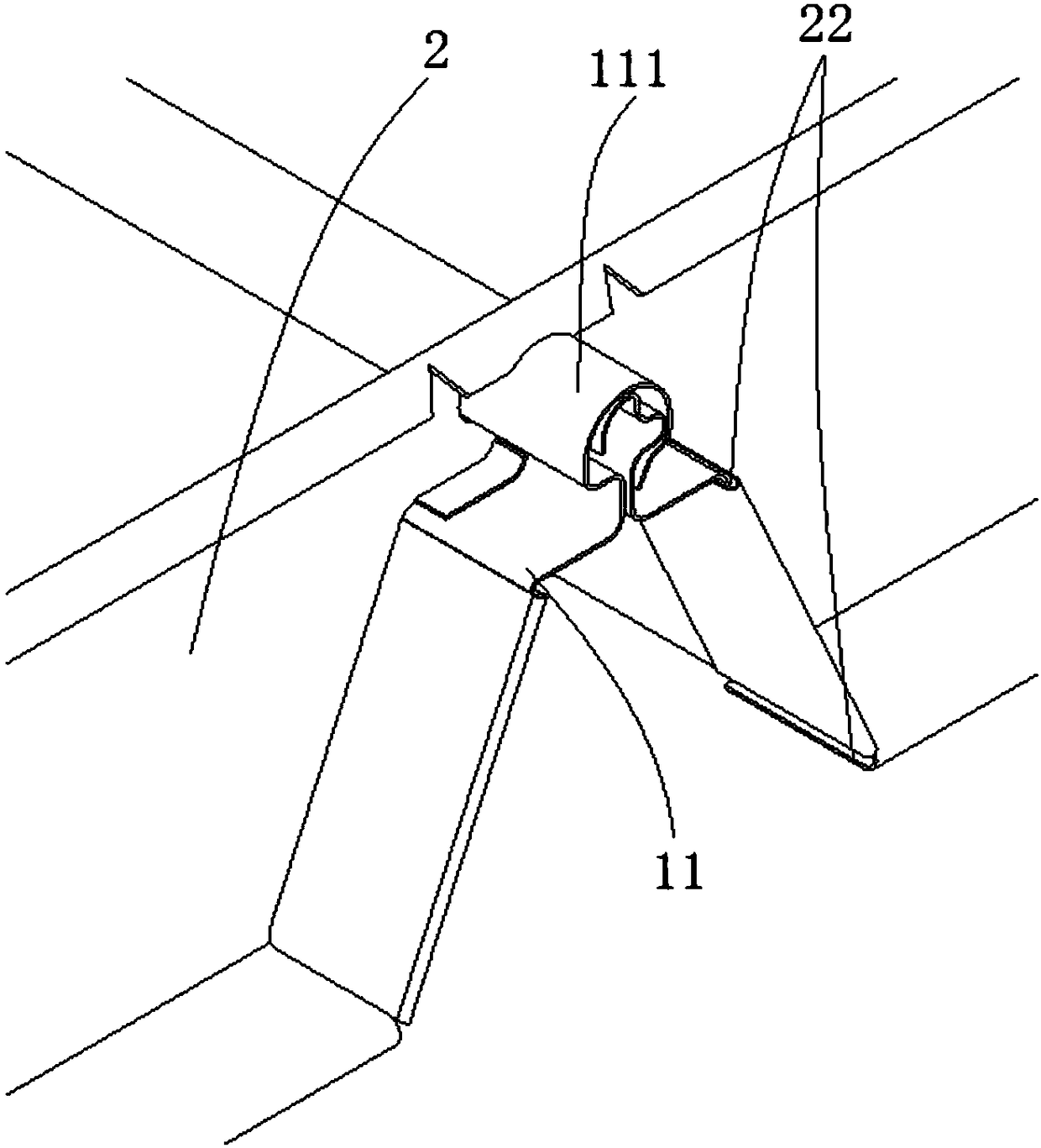

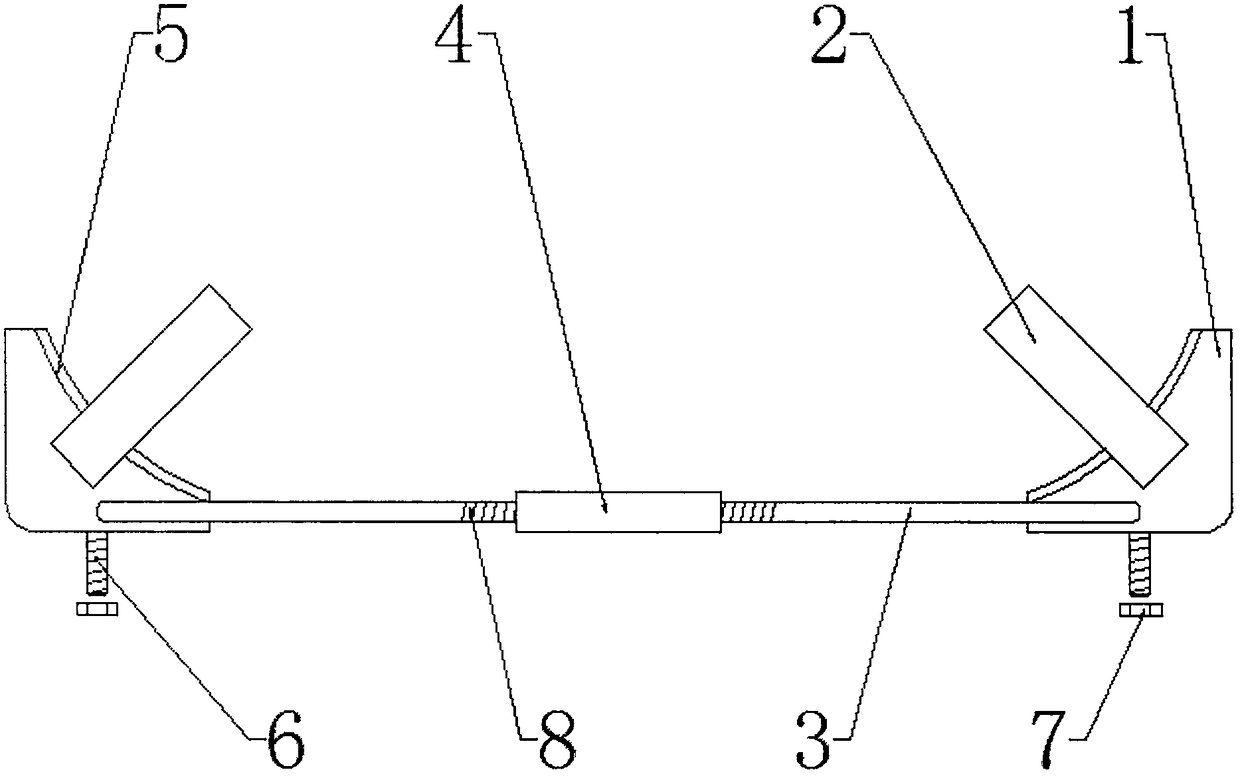

Spinous process and vertebral plate stabilizer

The invention relates to a spinous process and vertebral plate stabilizer, and belongs to the technical field of an elastomer for vertebral plate dynamic fixation. The spinous process and vertebral plate stabilizer includes a first fixing portion, a second fixing portion, and an elastic device; the first fixing portion is connected to the second fixing portion through the elastic device; a first fixing portion is of a clamp-shaped structure formed by two side wings a and a bottom plate; the second fixing portion is of a clamp-shaped structure formed by two side wings b and an arc bottom plate; and the elastic device consists of a first elastic structure, a second elastic structure and a third elastic structure. The spinous process and vertebral plate stabilizer fully considers the demands of physiological actions of a human body, can achieve maximum matching with the activity in all the directions, is reasonable in structure, is strong in vertical support force, is small in size, is reliable in fixation, and is high in elasticity attenuation resistance ability and can be used for the human body in a long term; rotation centers of a coronal view and a sagittal view of a prosthesis are close to rotation centers of a coronal view and a sagittal view of a spine of the human body after the stabilizer is implanted; and the spinous process and vertebral plate stabilizer is conductive to postoperative recovery of a patient, is easy to operate, and can lower the difficulty and risks of an operation.

Owner:李照文

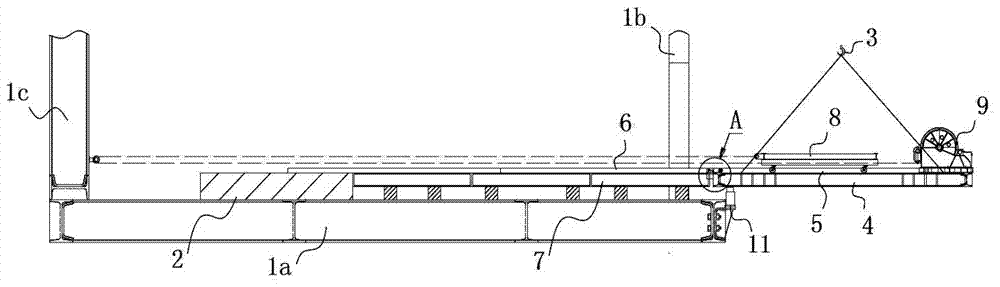

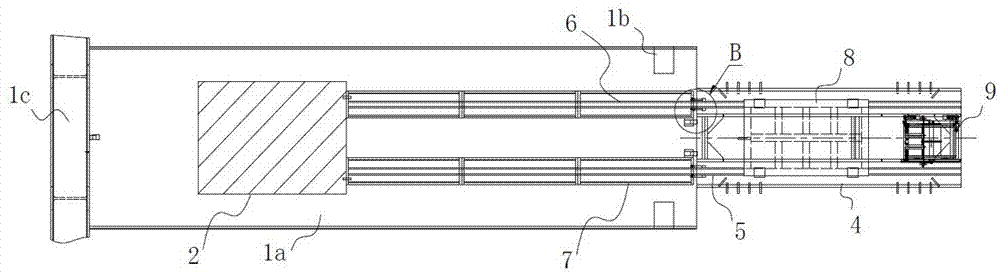

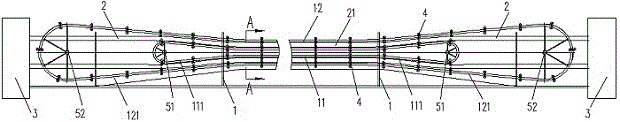

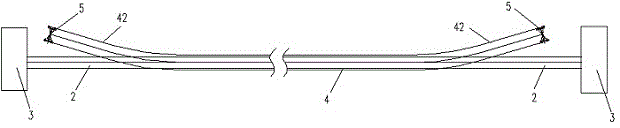

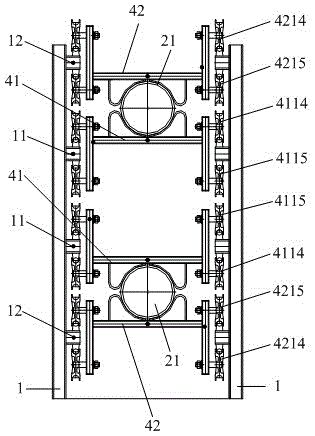

Sidesway separation movable bracket type tubular belt conveyor

The invention relates to a sidesway separation movable bracket type tubular belt conveyor. The sidesway separation movable bracket type tubular belt conveyor comprises machine frames, annular adhesive tapes, driving components, annular supporting and clamping components and guide rail bend wheels, wherein the annular adhesive tapes can bear materials; the driving components of the adhesive tapes are respectively arranged at machine heads and machine tails; the annular supporting and clamping components can support and clamp the adhesive tapes; the annular adhesive taps are hung and wound on the driving components in a sleeving manner; the supporting and clamping components are movably supported and clamped between the adhesive tapes and the machine frames; the support clamping components near the machine heads and the machine tails are separated from the adhesive tapes. The sidesway separation movable bracket type belt conveyor disclosed by the invention has the beneficial effects that the support components are used to replace carrier rollers in the prior art, and resistance between the carrier rollers and the adhesive tapes is changed into rigid rolling friction between the support components and guide rails; through the change of a mechanical structure, transport resistance is obviously reduced, and the dissipation power of the conveyor is greatly reduced.

Owner:NINGXIA TIANDI NORTHWEST COAL MACHINERY

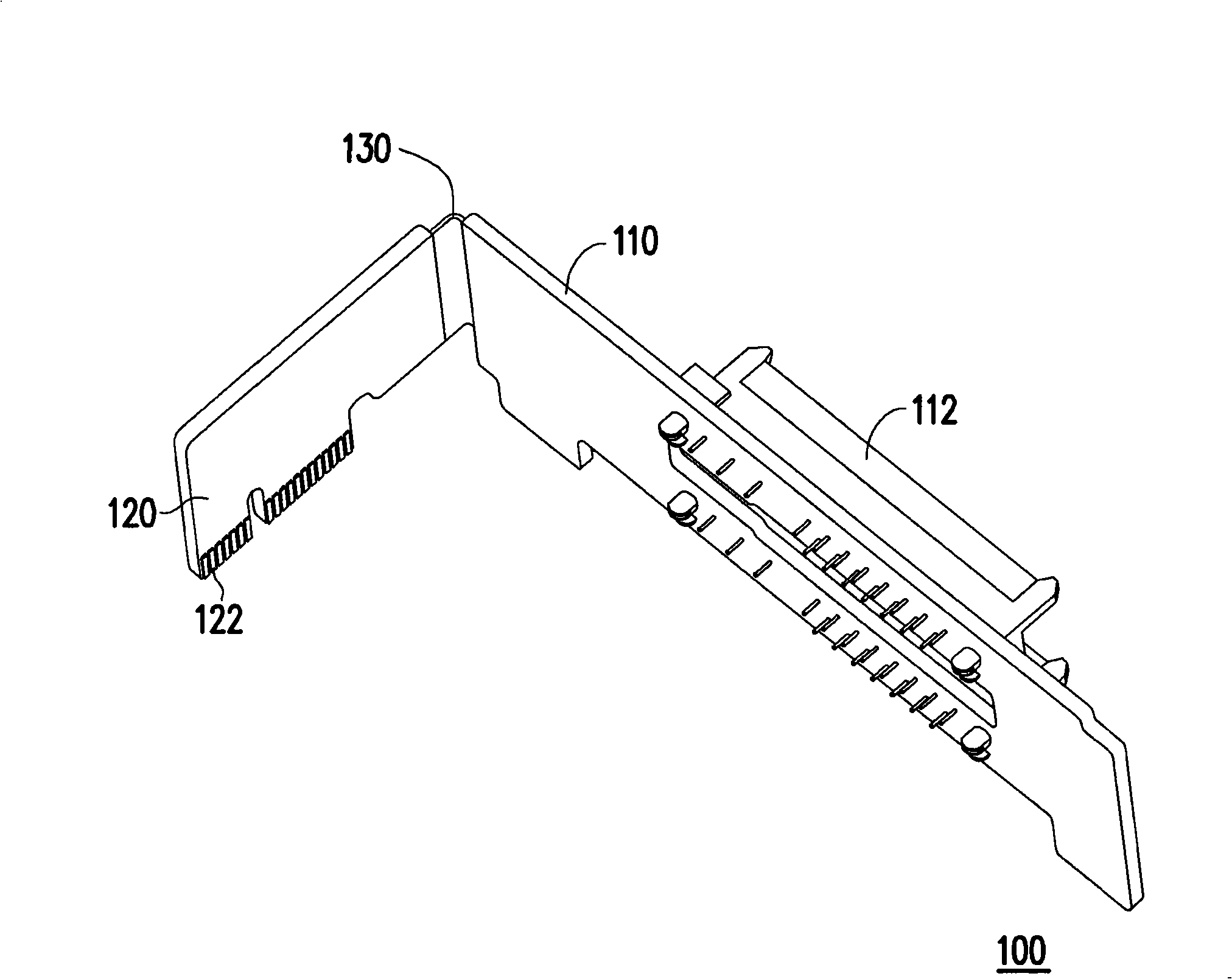

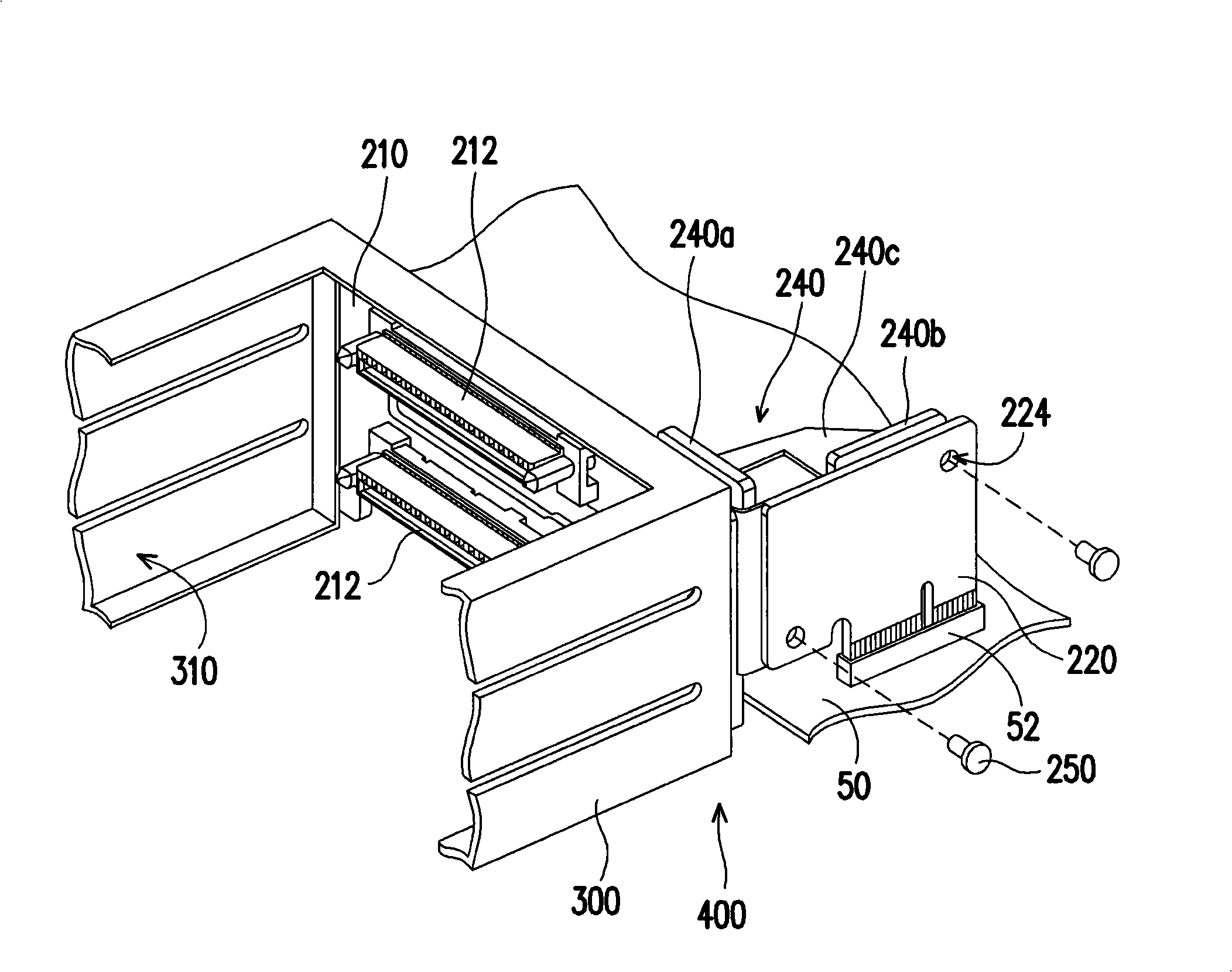

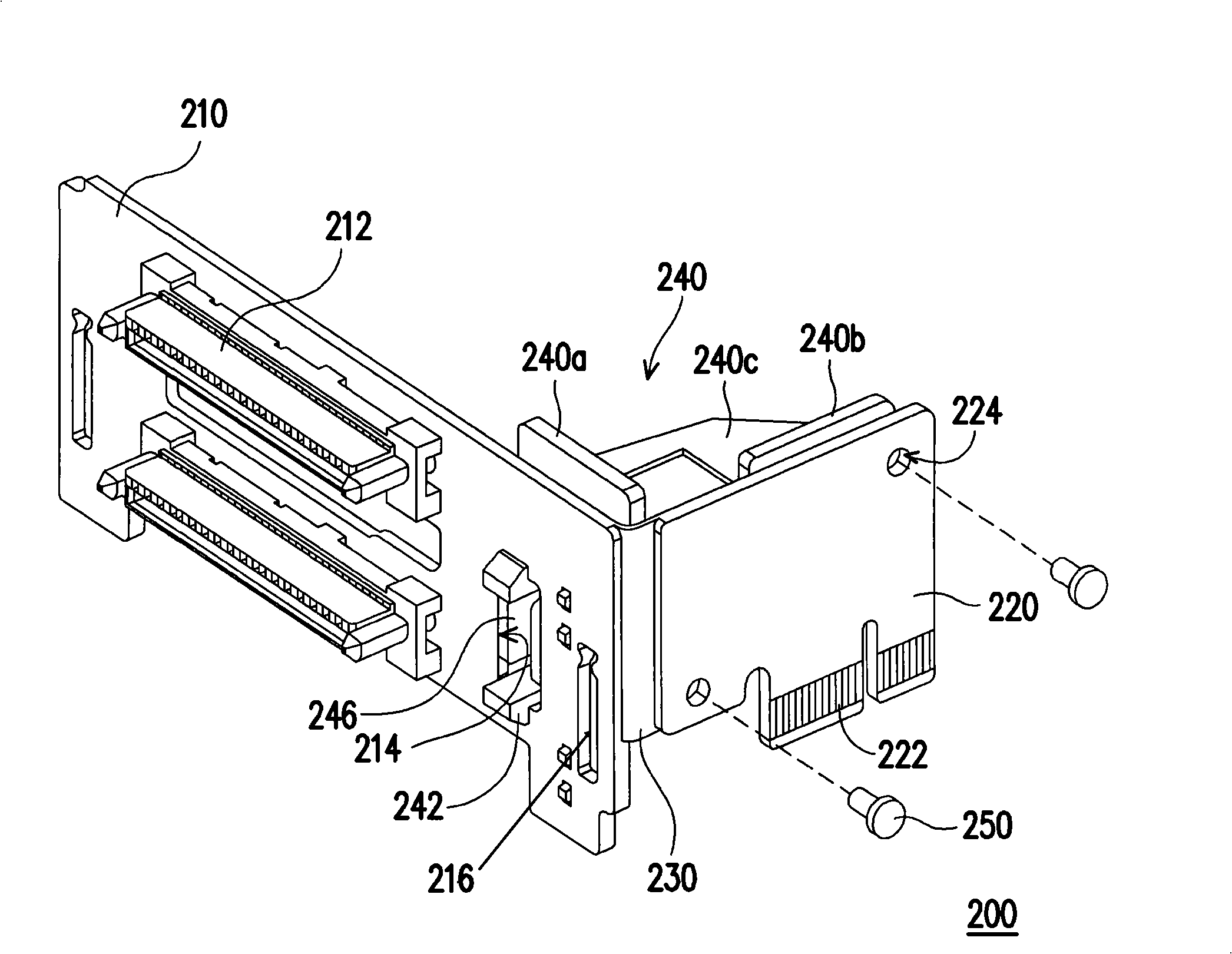

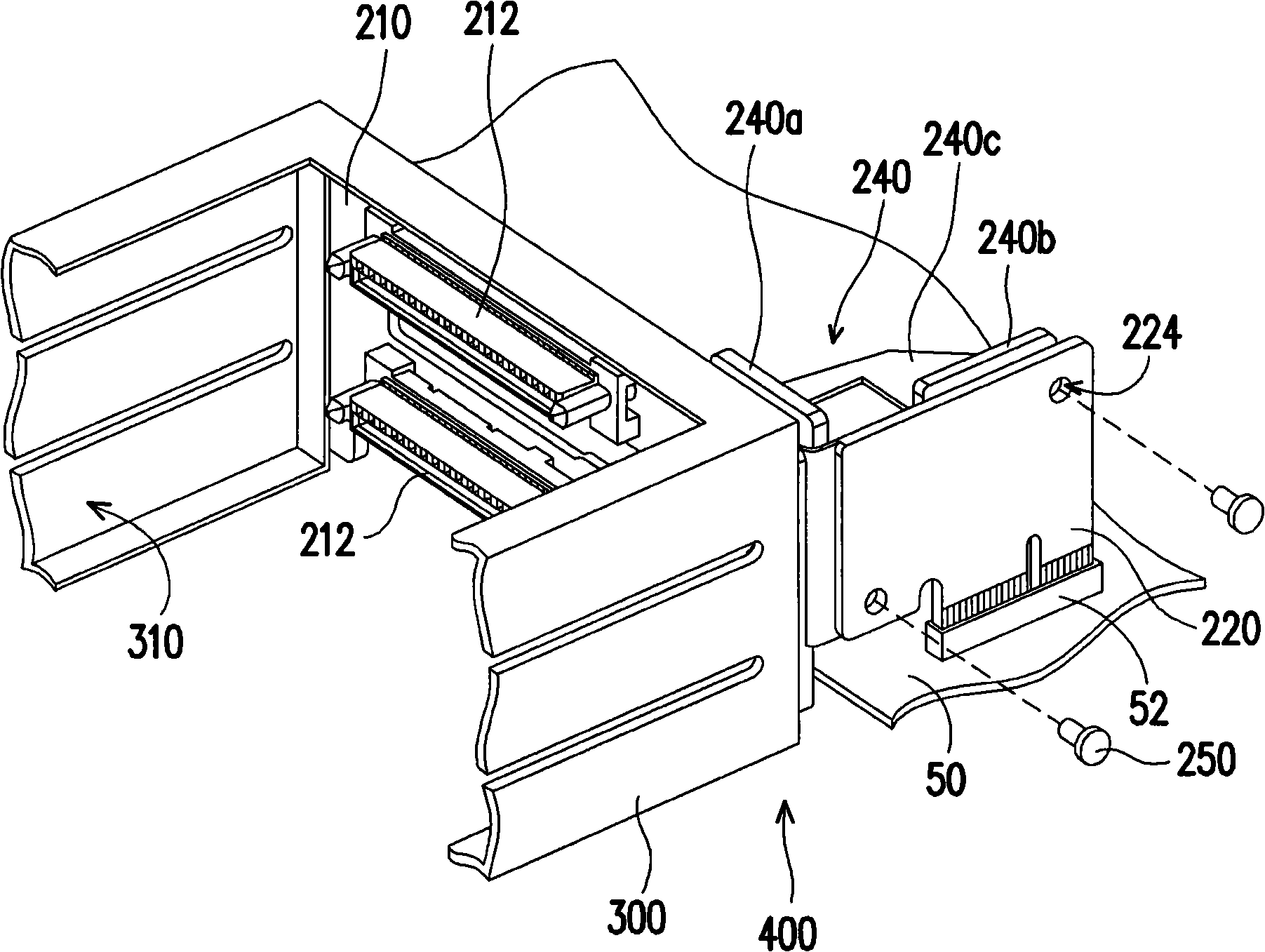

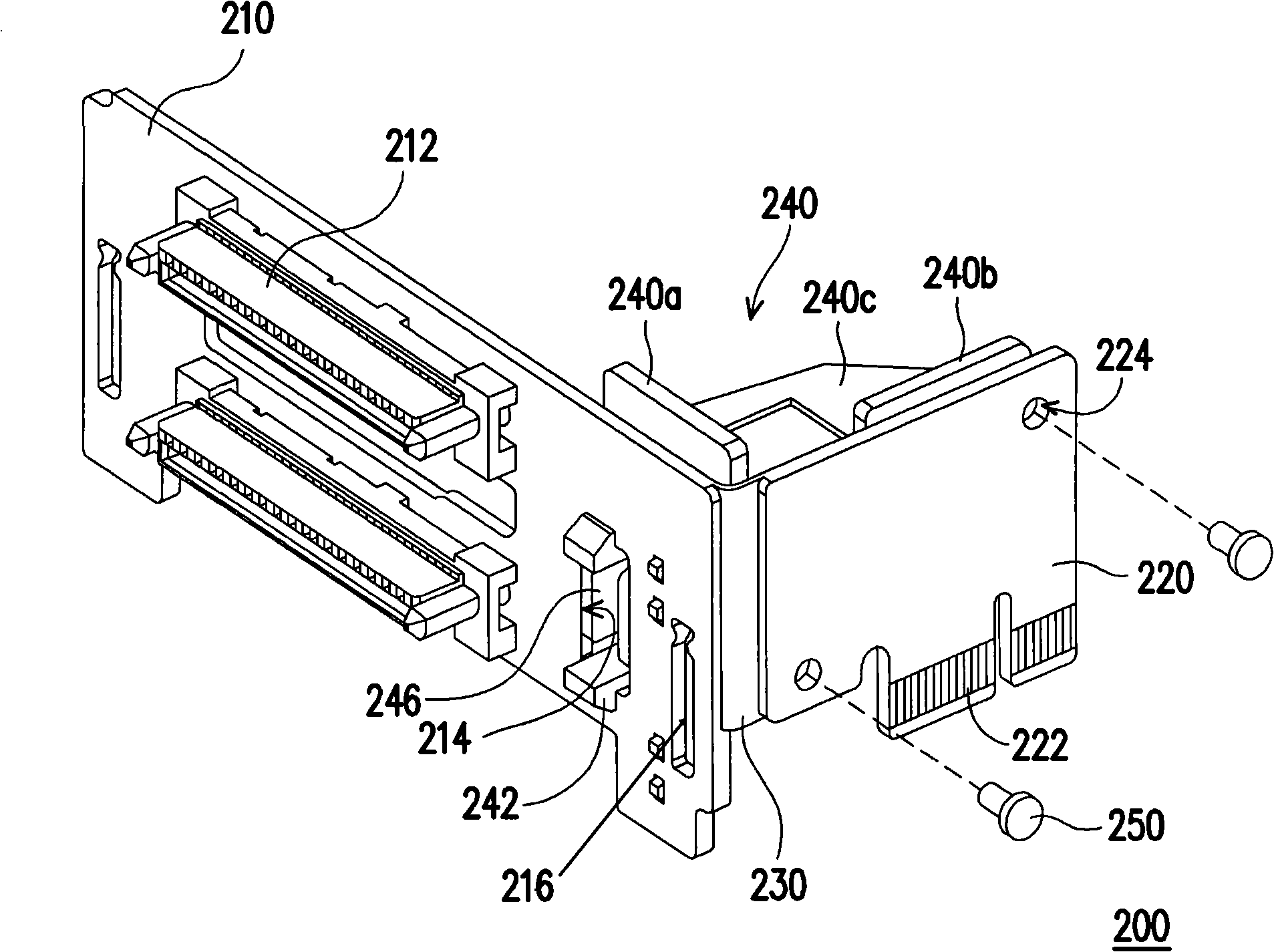

Expansion board and expansion board fixing structure thereof

InactiveCN101349935ANo relative displacementImprove reliabilityDigital processing power distributionSupport structure mountingElectrical and Electronics engineering

Owner:INVENTEC CORP

Partial mixed lamination board dislocation prevention method

ActiveCN104519674AEmbedded positioning implementationChimeric positioning is accuratePrinted circuit assemblingStacked PCBsRelative displacementPre treatment

The invention provides a partial mixed lamination board dislocation prevention method comprising daughter and mother board preprocessing steps and a daughter board and mother board mixed lamination step. The following step is performed after the daughter board preprocessing step: multiple grooves are formed on at least one edge of a daughter board; the following step is performed after the mother board preprocessing step: convex blocks, which are matched and inserted into the grooves, are formed on the corresponding edges of the cavity, which is suitable for embedding of the daughter board, of a mother board; the following step is performed before the daughter board and mother board mixed lamination step: the daughter board and mother board are positioned in an embedded way via mutual plugging and matching of the grooves and the convex blocks; and the daughter board is fixed and adhered on the mother board via lamination gel. According to the method, the daughter board and mother board are positioned in the embedded way via mutual matching of the grooves and the convex blocks so that the daughter board and mother board can be accurately positioned, relative displacement is not generated in the lamination process due to accurate positioning, and thus manufacturing quality of the mixed lamination board manufactured by using the method is high and rejection rate is low.

Owner:NEW FOUNDER HLDG DEV LLC +1

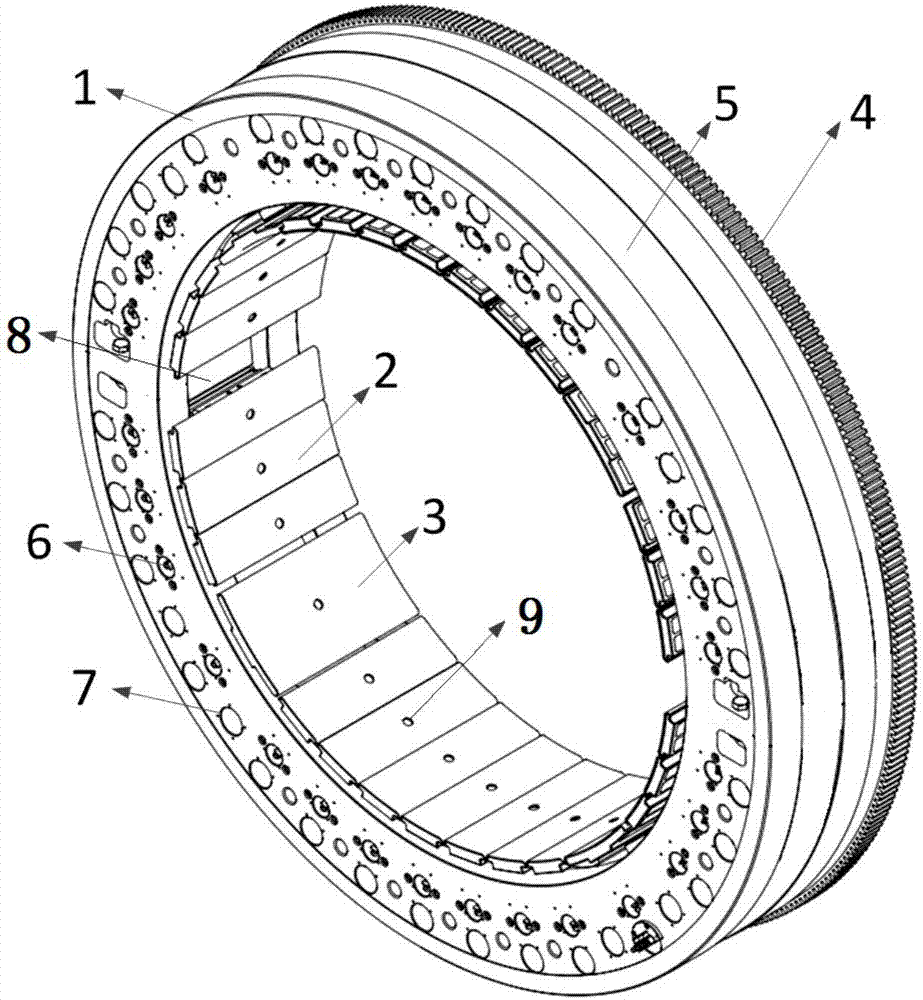

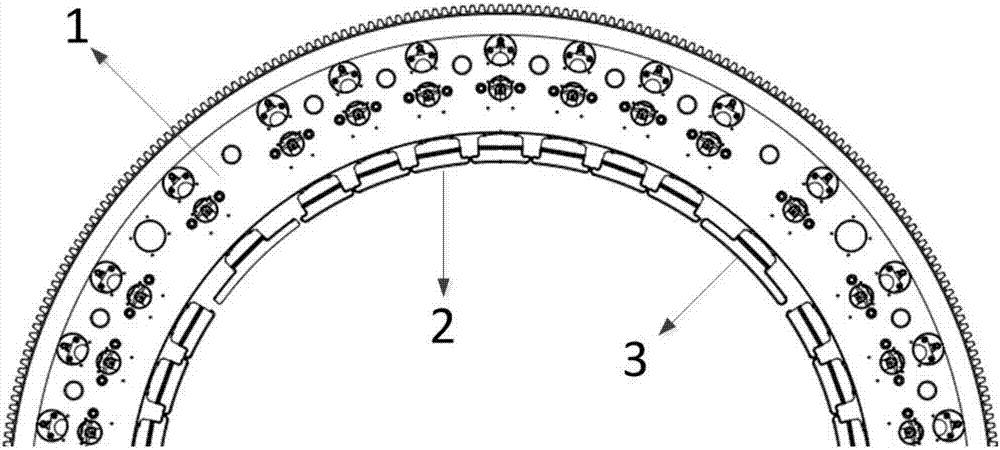

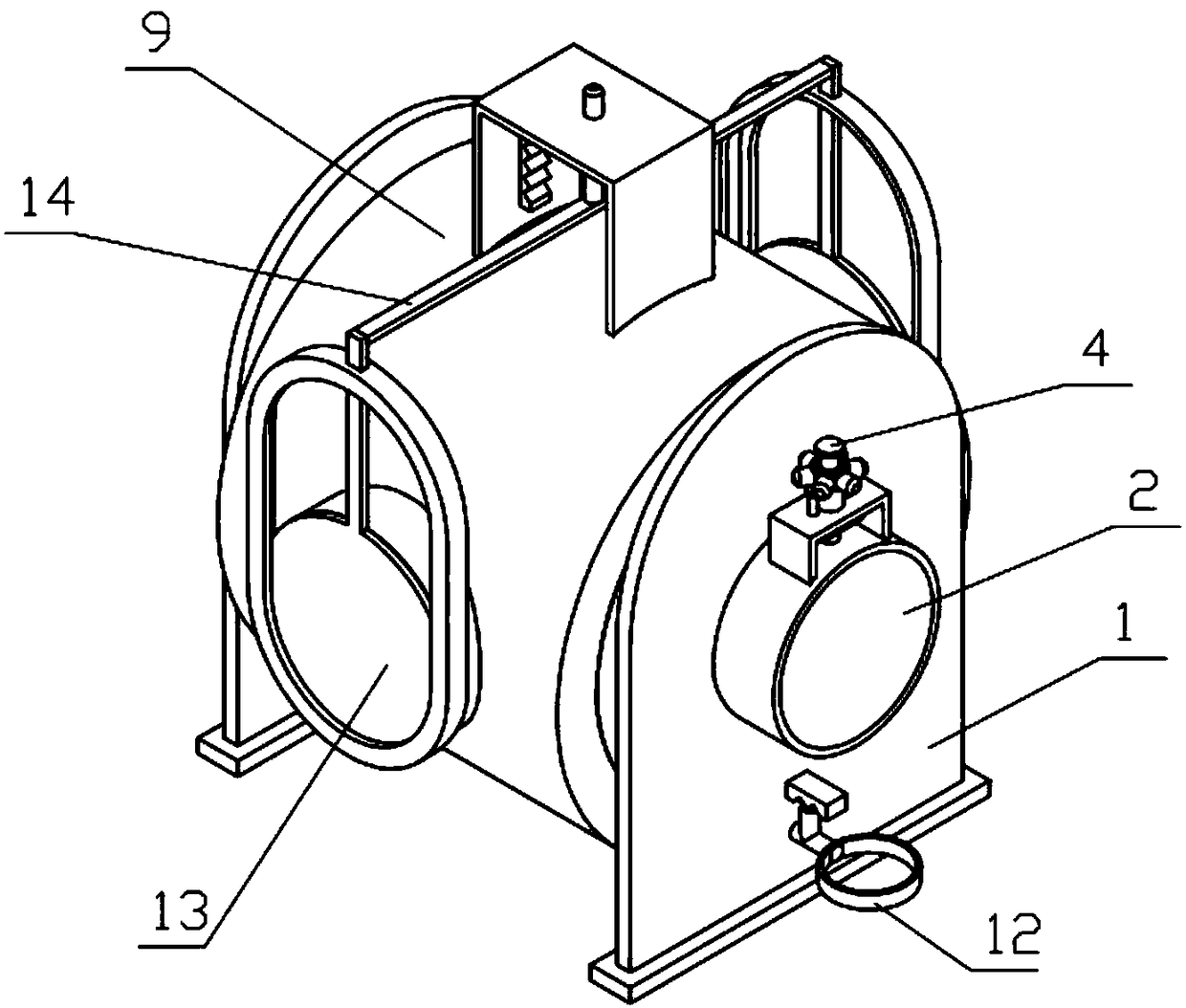

Large workpiece clamping device and clamping system

ActiveCN107309686AIncrease the effective contact areaClamping state effectPositioning apparatusMetal-working holdersRadial motionEngineering

The invention provides a large workpiece clamping device. The large workpiece clamping device comprises a circular clamp body. A mounting groove is formed in the inner ring of the clamp body so that multiple detachable clamping units can be mounted. Each clamping unit comprises a clamping execution device and a clamping drive device. Each clamping drive device is connected with the corresponding clamping execution device and used for driving the corresponding clamping execution device to move in the axial direction and / or the radial direction of a ring of the clamp body. The clamping execution devices are circumferentially distributed along the inner ring of the clamp body. Each clamping drive device comprises a drive device connecting portion fixedly connected with the clamp body. The invention further provides a large workpiece clamping system which comprises the large workpiece clamping device and a bearing platform. Supporting bases are arranged on the bearing platform in parallel. The supporting bases are provided with rolling bearing grooves matched with the outer edge of the clamp body. The large workpiece clamping device and the large workpiece clamping system have the beneficial effects that floating clamping is achieved; the center position of a workpiece does not need to be adjusted repeatedly when the workpiece is clamped; an extra auxiliary supporting structure is not needed; and the clamping efficiency is improved.

Owner:重庆真测科技股份有限公司 +2

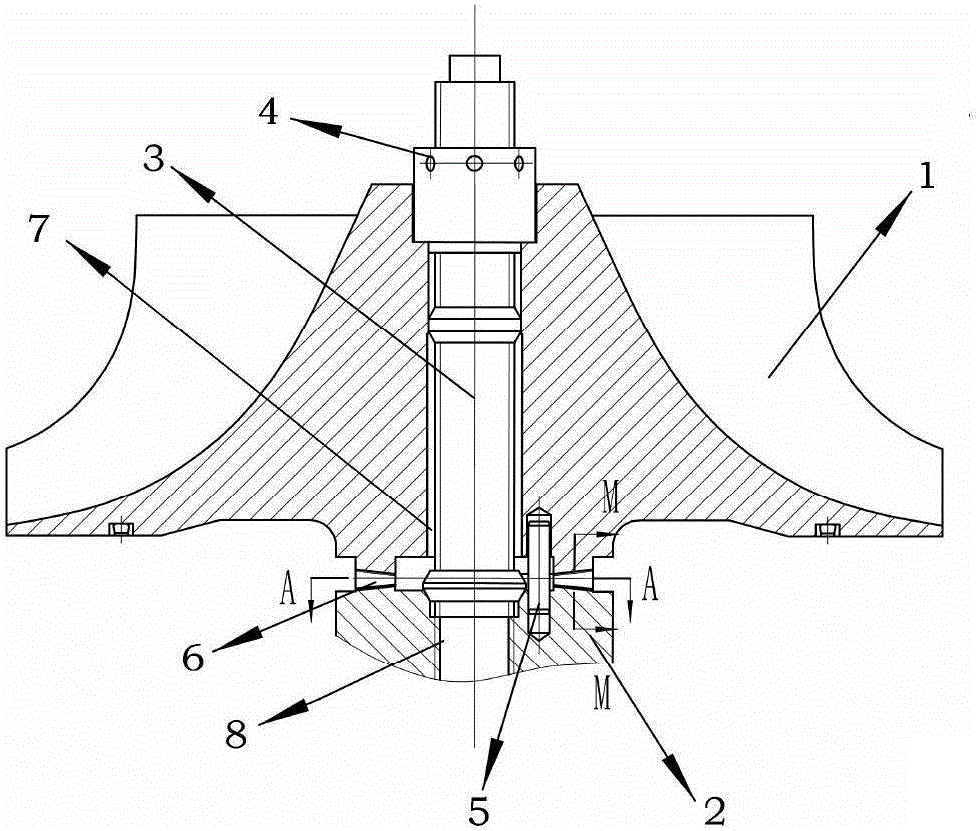

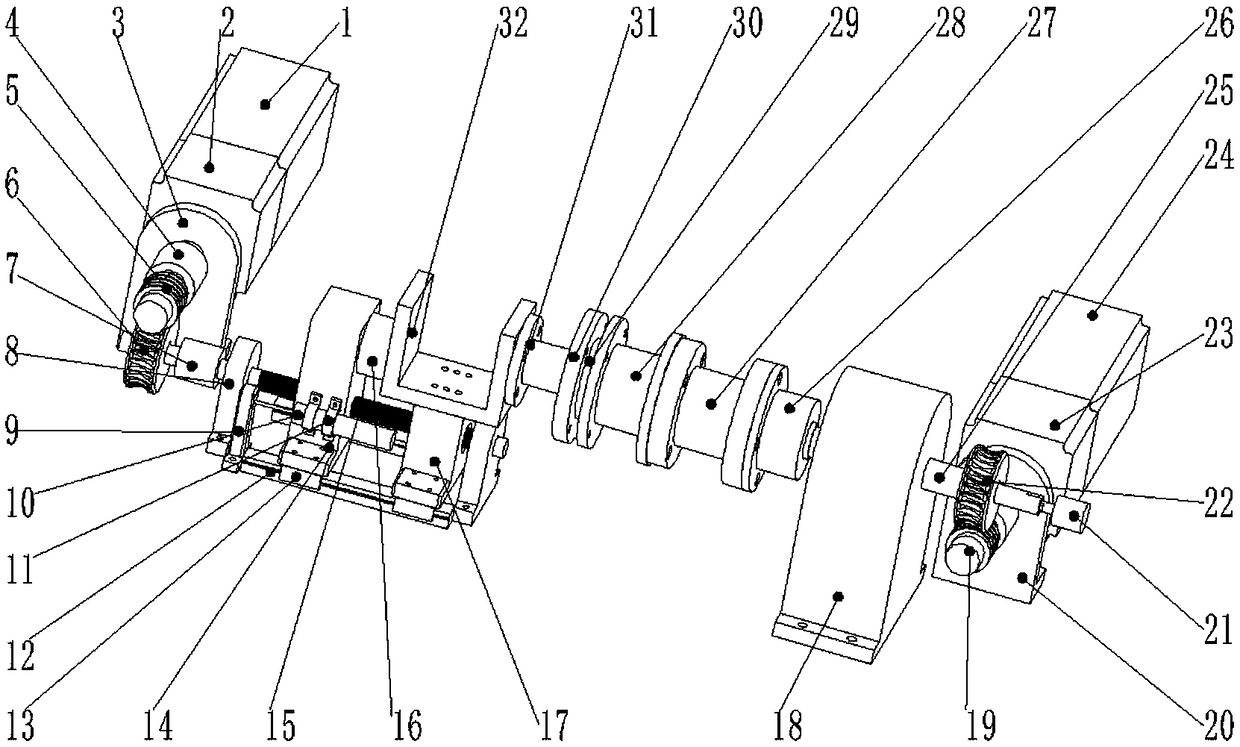

Compressor impeller and pinion shaft connecting structure and machining method thereof

InactiveCN106545520ASimplify the assembly processImprove assembly accuracyPump componentsCouplings for rigid shaftsImpellerRelative displacement

The invention discloses a compressor impeller and pinion shaft connecting structure. The compressor impeller and pinion shaft connecting structure comprises an impeller and a pinion shaft. The tail end of an impeller disc of the impeller and the end face, matched with the impeller, of a shaft head of the pinion shaft are provided with end teeth matched with each other. A through hole is formed in the center line of the impeller. A threaded hole is formed in the center line of the pinion shaft. A stretching bolt penetrates the through hole and is connected into the threaded hole for connecting the impeller and the pinion shaft. The compressor impeller and pinion shaft connecting structure is easy to assemble, high in assembly precision and free of relative displacement.

Owner:SHENYANG BLOWER WORKS GROUP CORP

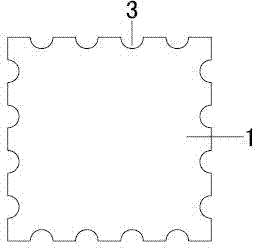

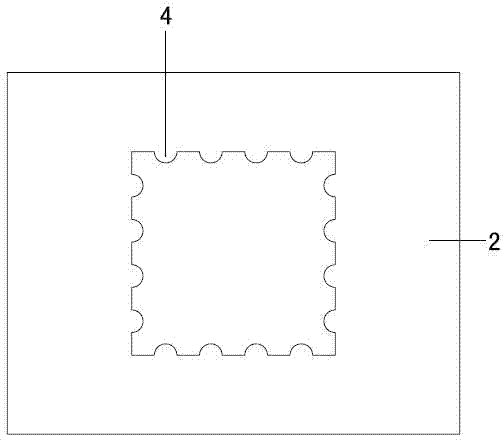

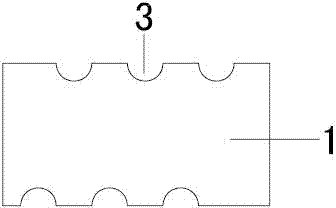

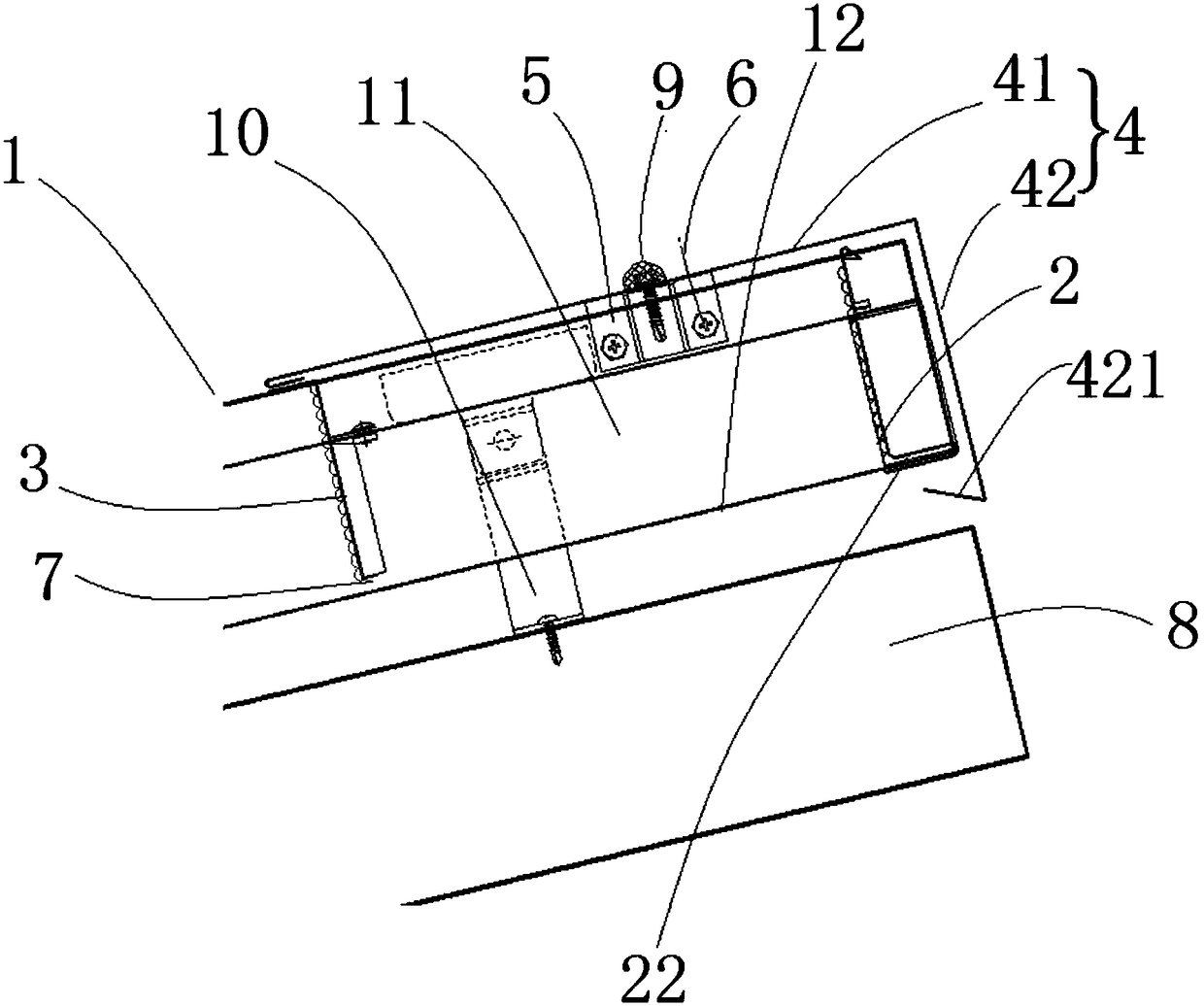

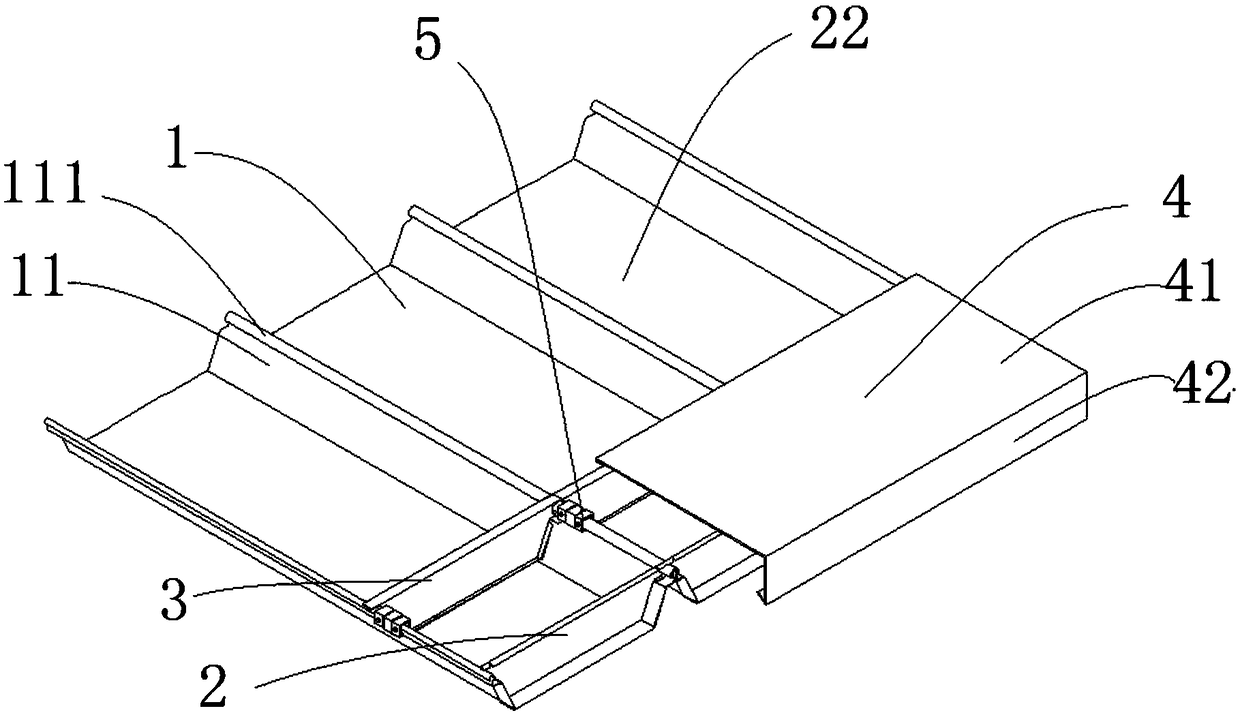

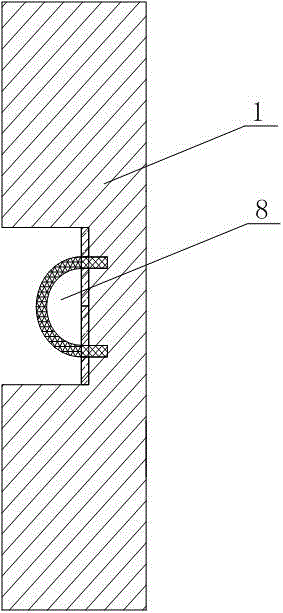

Integral roof ridge sealing structure for metal roof system

PendingCN108316568ASolve the problem of not being able to seal effectively for a long timeGuaranteed tightnessRoof covering using slabs/sheetsRoof covering insulationsEngineeringMechanical engineering

The invention discloses an integral roof ridge sealing structure for a metal roof system. The integral roof ridge sealing structure is arranged on a roof plate of the metal roof system, and comprisesa roof ridge inner sealing element (2) and a roof ridge outer sealing element, wherein the roof ridge inner sealing element (2) and the roof ridge outer sealing element (3) are in interval arrangementin the roof ridge positions of the roof plate (1), and maintain the same cross-section shape as the upper end surface of the roof plate (1); the roof ridge outer sealing element (3) and the roof ridge inner sealing element (2) form attachment sealing with two side plate ribs (11) and a bottom plate (12) of the roof plate (1). The integral roof ridge sealing structure has the advantages that the inner and outer roof ridge sealing elements are arranged in the roof ridge positions; the roof ridge sealing elements are processed into a notch structure with the same cross section as the roof plate;the problem that the roof ridge position of a traditional metal roof system cannot be effectively sealed for a long time is solved; through the roof ridge connecting structure provided by the invention, the sealing performance and the windproof and waterproof performance of the position are ensured.

Owner:CENT INT GROUP

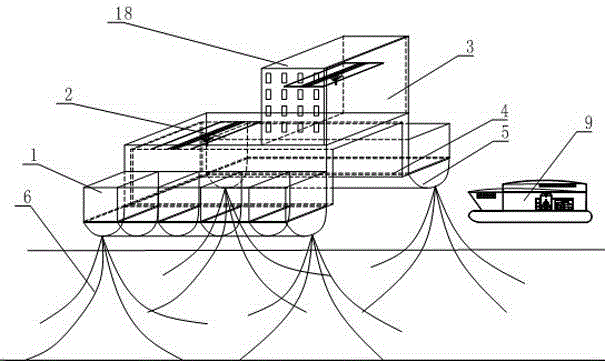

Maintenance support base station and achievement method applicable to offshore floating nuclear power plant

ActiveCN104810070AShorten the timeIncrease profitNuclear energy generationFloating buildingsNuclear powerNuclear engineering

The invention discloses a maintenance support base station and an achievement method applicable to an offshore floating nuclear power plant. The maintenance support base station applicable to the offshore floating nuclear power plant comprises floating platforms which are fixed on a sea bed through an anchor chain; a power positioning system is arranged on the floating platforms; tops of the two floating platforms are connected through a high-order platform; a channel is formed between the high-order platform and the two floating platforms; one end of the channel is closed; the other end is provided with a flexible closed separation plate; bottoms of the floating platforms are provided with slidable bottom separation plates; the two bottom separation plates extend out to be spliced into an integral. According to the maintenance support base station and the achievement method applicable to the offshore floating nuclear power plant, the utilization time of conventional energy is compressed possibly, the maintenance support base station platform of the floating power plant is close to the platforms, time for material change and heavy repair of the floating power plant is saved, heavy repair and material change of the floating nuclear power plant can be achieved within relative short time, and the use ratio and the economy of the nuclear energy of the floating nuclear power plant are improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Double-step precision injection molding device

InactiveCN104441403ARealize self-locking sealNot prone to material stagnationHydraulic motorThrust bearing

The invention relates to the field of injection molding machines, in particular to a double-step precision injection molding device. The invention discloses the double-step precision injection molding device with the following structure, the device comprises a pre-injection storing mechanism, an injection mechanism, a hydraulic system and a spray nozzle, wherein the pre-injection storing mechanism comprises a front premolding material barrel, a premolding material barrel, a screw rod, a feeding seat and a hydraulic motor, and the hydraulic motor is used for driving the screw rod to rotate; the injection mechanism comprises a front material barrel, a material barrel, an injection seat, a plunger rod and an injection electro-hydraulic system; a double-acting cylinder is arranged between a thrust bearing and a sealed groove, and movements of the pre-injection storing mechanism, the injection mechanism and the spray nozzle are coordinated and controlled by the hydraulic system. The double-step precision injection molding device has the advantages that the flow channel is short, the stagnation of materials is avoided, and the injection precision is high.

Owner:浙江泰瑞重型机械有限公司

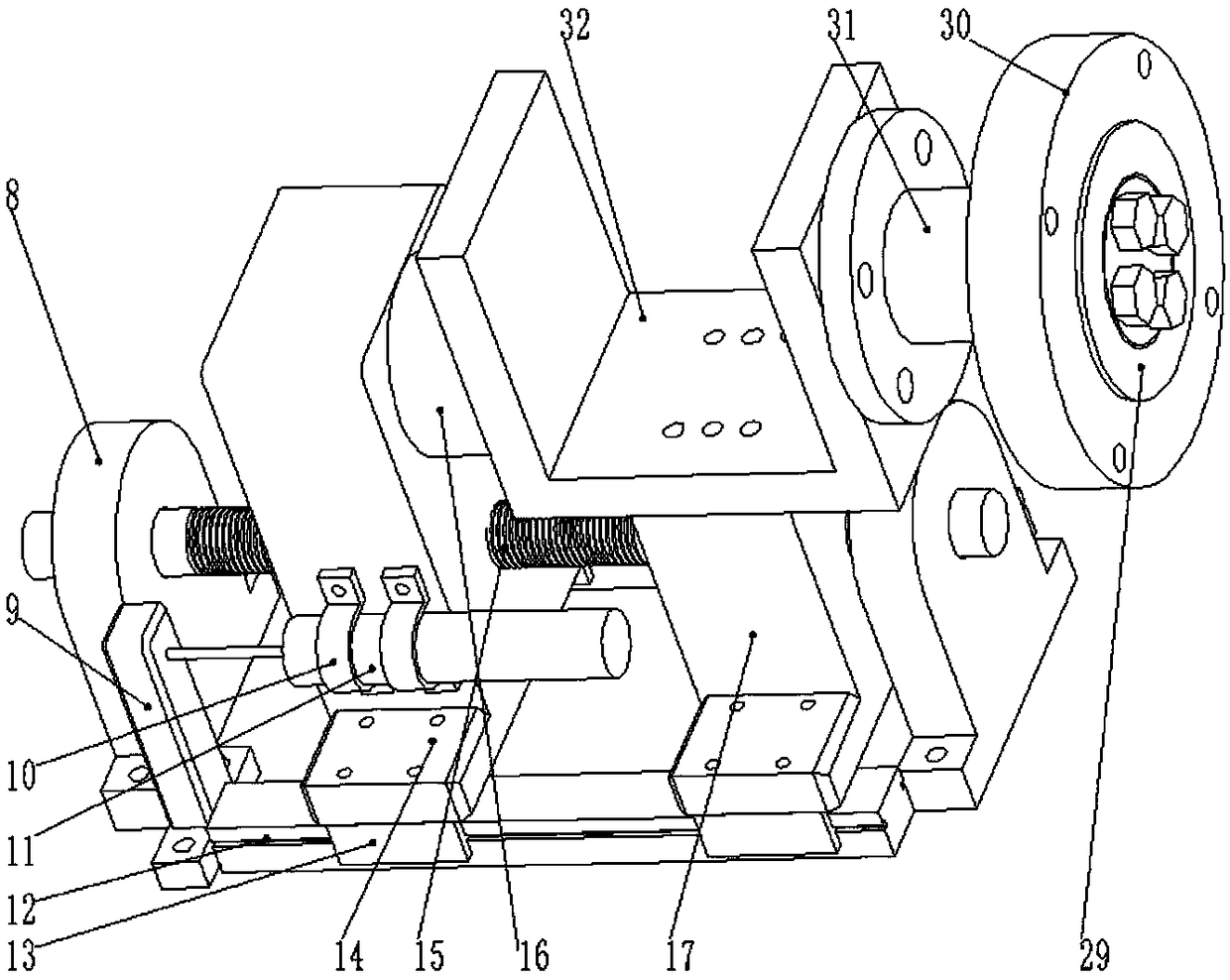

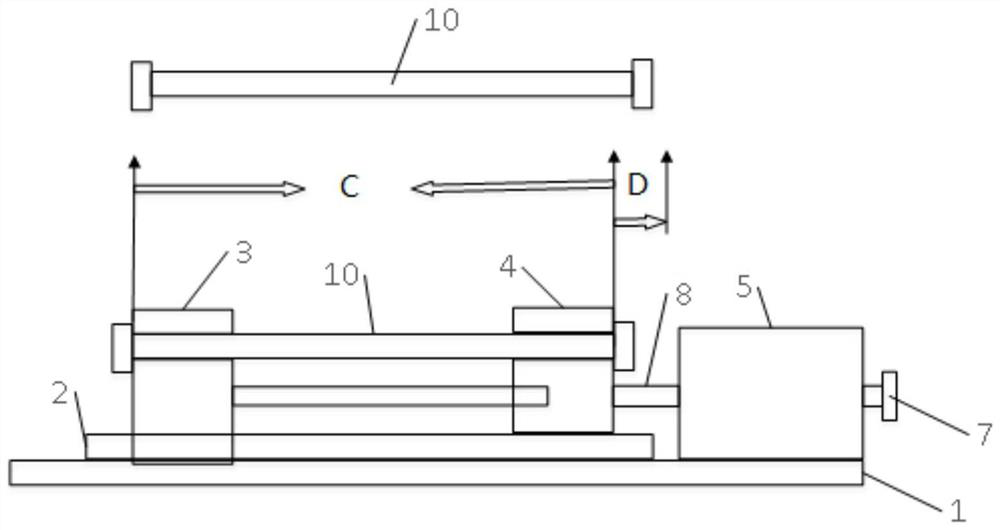

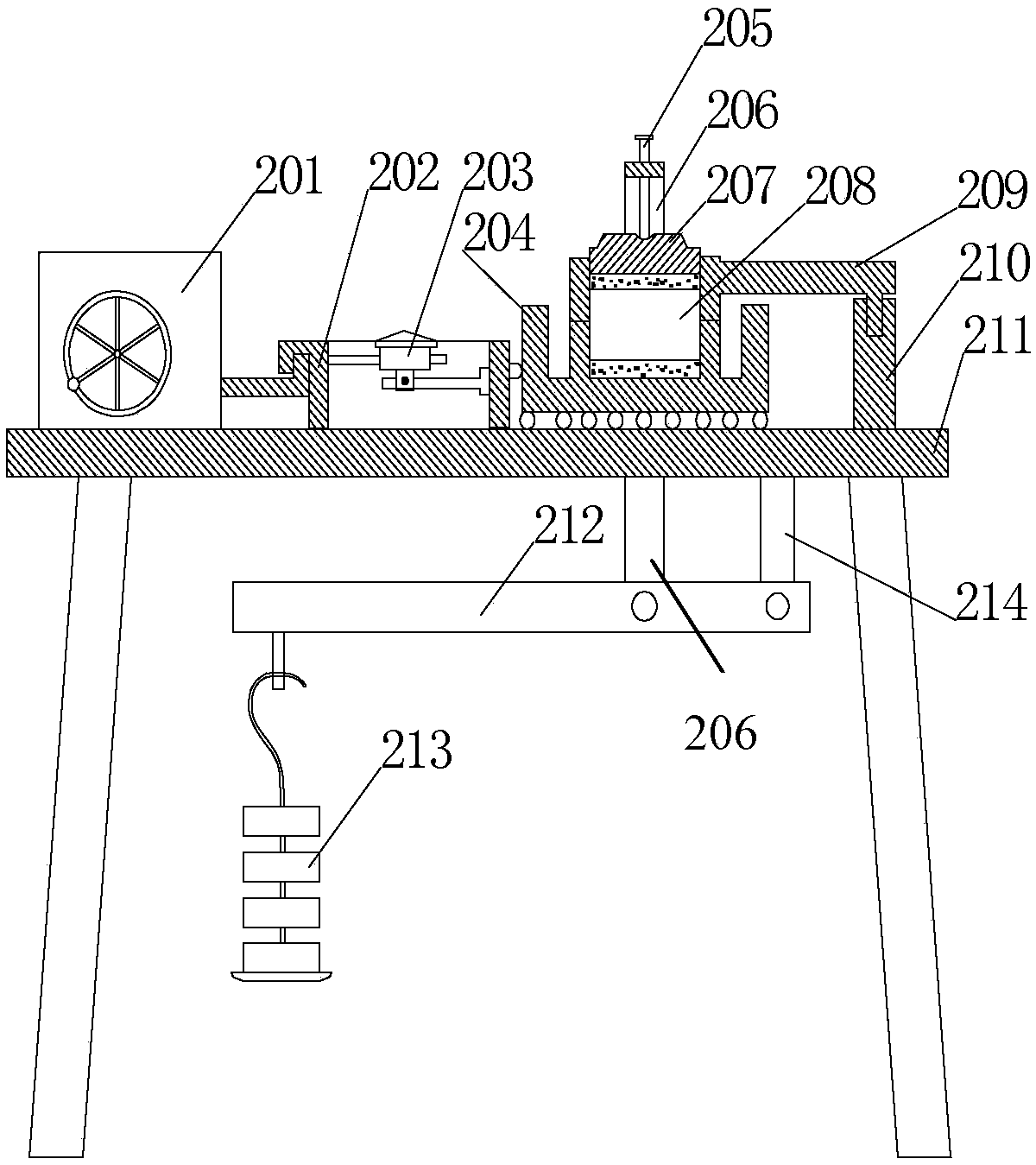

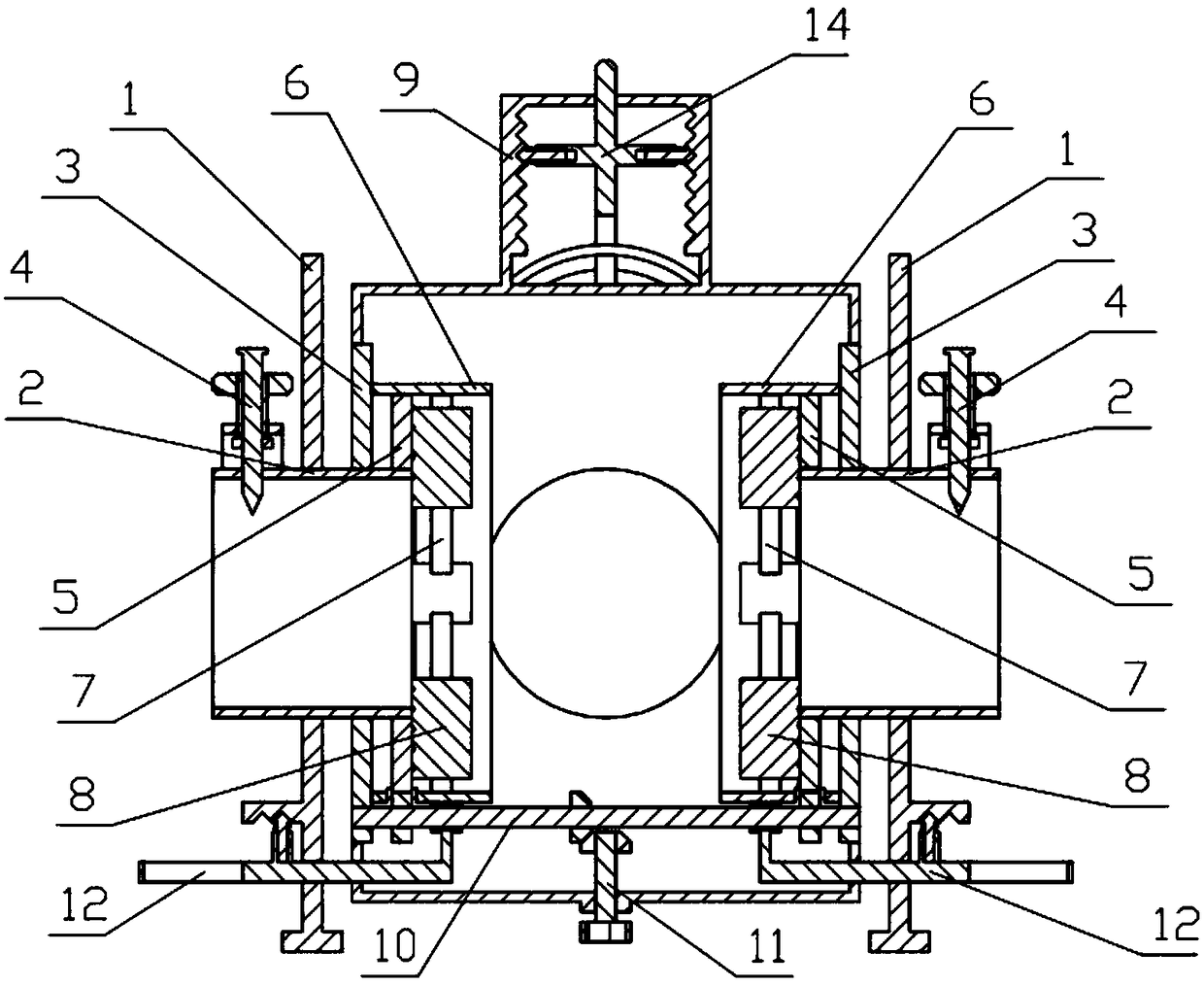

Bidirectional shear test device for metal plates

ActiveCN109283067AEasy to testConstant ratioMaterial strength using steady shearing forcesMotor driveLow speed

The invention discloses a bidirectional shear test device for metal plates, comprising a servo motor, a speed reduction mechanism, a measuring instrument, a tension and compression shearing mechanismand a rotary shearing mechanism, wherein the servo motor supplies power to the whole device to drive the operation of the whole device; the speed reduction mechanism is configured to convert the high-speed motor rotation into low-speed shearing motion; the measuring instrument is configured to measure the force and deformation generated during the test; and the tension and compression shearing mechanism and the rotary shearing mechanism are the actuators of the entire test device in order to achieve shear deformation in both directions of the bidirectional shear test piece. The motor drive canrealize the constant tension, compression shear deformation and rotational shear deformation at any ratio during bidirectional shearing, and improve the reliability of the test results. The forward and reverse shearing of the metal plates can be realized by the forward and reverse rotation of the drive system to obtain a more comprehensive study of material properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Vehicle wheel fixator

InactiveCN108407837AEasy to fixEasy to installItem transportation vehiclesCargo supporting/securing componentsRelative displacementAutomotive engineering

The invention discloses a vehicle wheel fixator and relates to the field of vehicle service equipment. When the vehicle wheel fixator is used, firstly, a threaded tube can be rotated on two connectingrods to adjust the distance between two vehicle wheel support frames, then the two vehicle wheel support frames are inserted from the side surfaces of vehicle wheels, and flexible pads are underlaidon both sides of the vehicle wheels. Vehicle wheel clamping boards are inserted into the vehicle wheels to fix the vehicle wheels, then threaded columns are inserted into a support frame for transporting a vehicle, nuts are screwed onto the threaded columns, the vehicle wheel support frames are fixed, and therefore the vehicle wheels are fixed. The vehicle wheel fixator can be conveniently installed on the support frame for transporting the vehicle, can stably fix the vehicle wheels, and maintains a stable and fixed state after being stressed, and it is ensured that the vehicle does not have relative displacement during transportation.

Owner:ANHUI SANLIAN UNIV

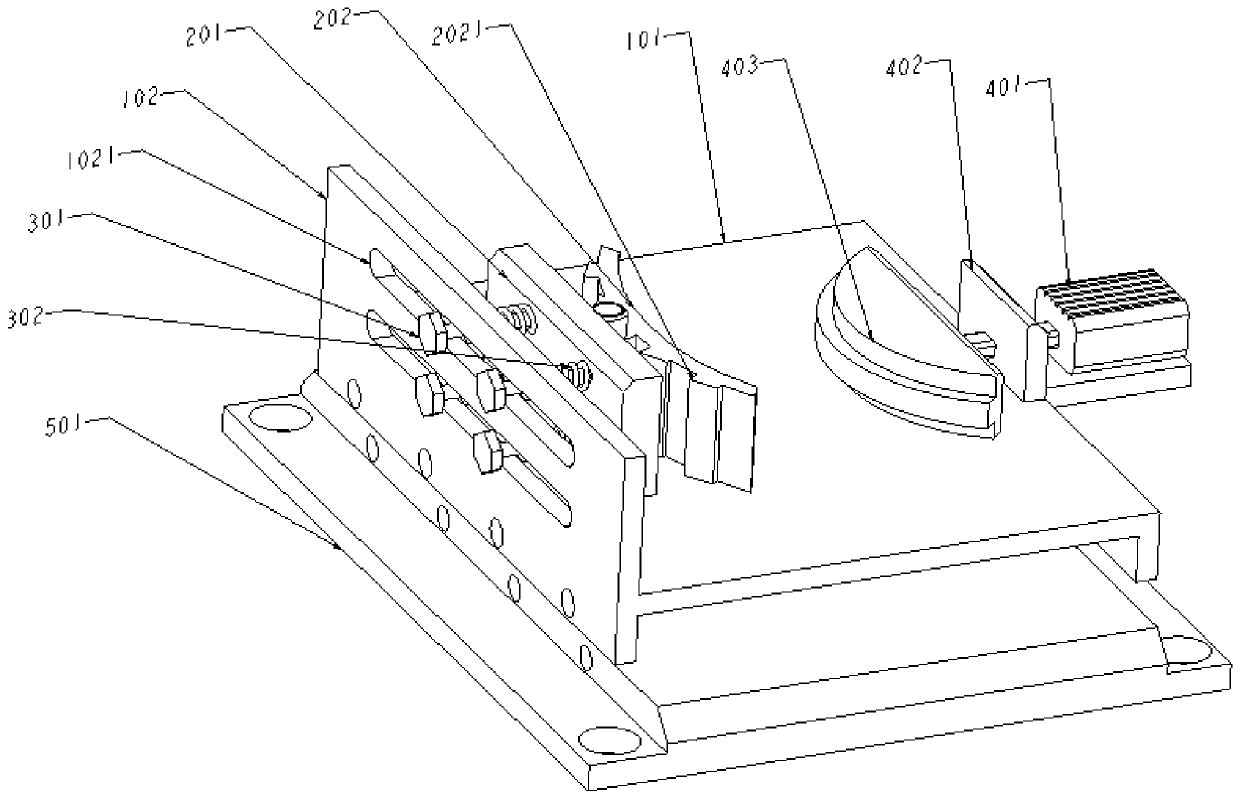

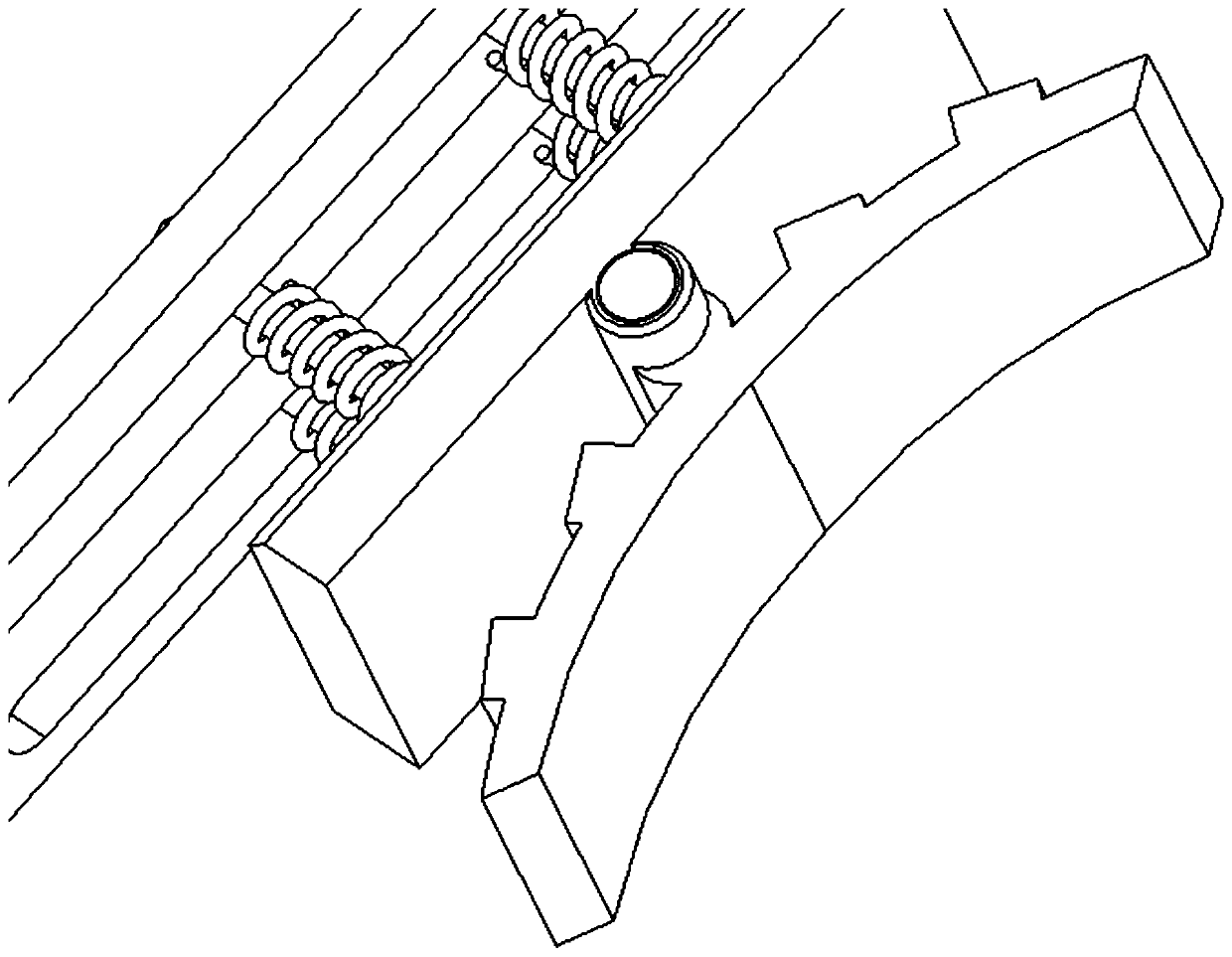

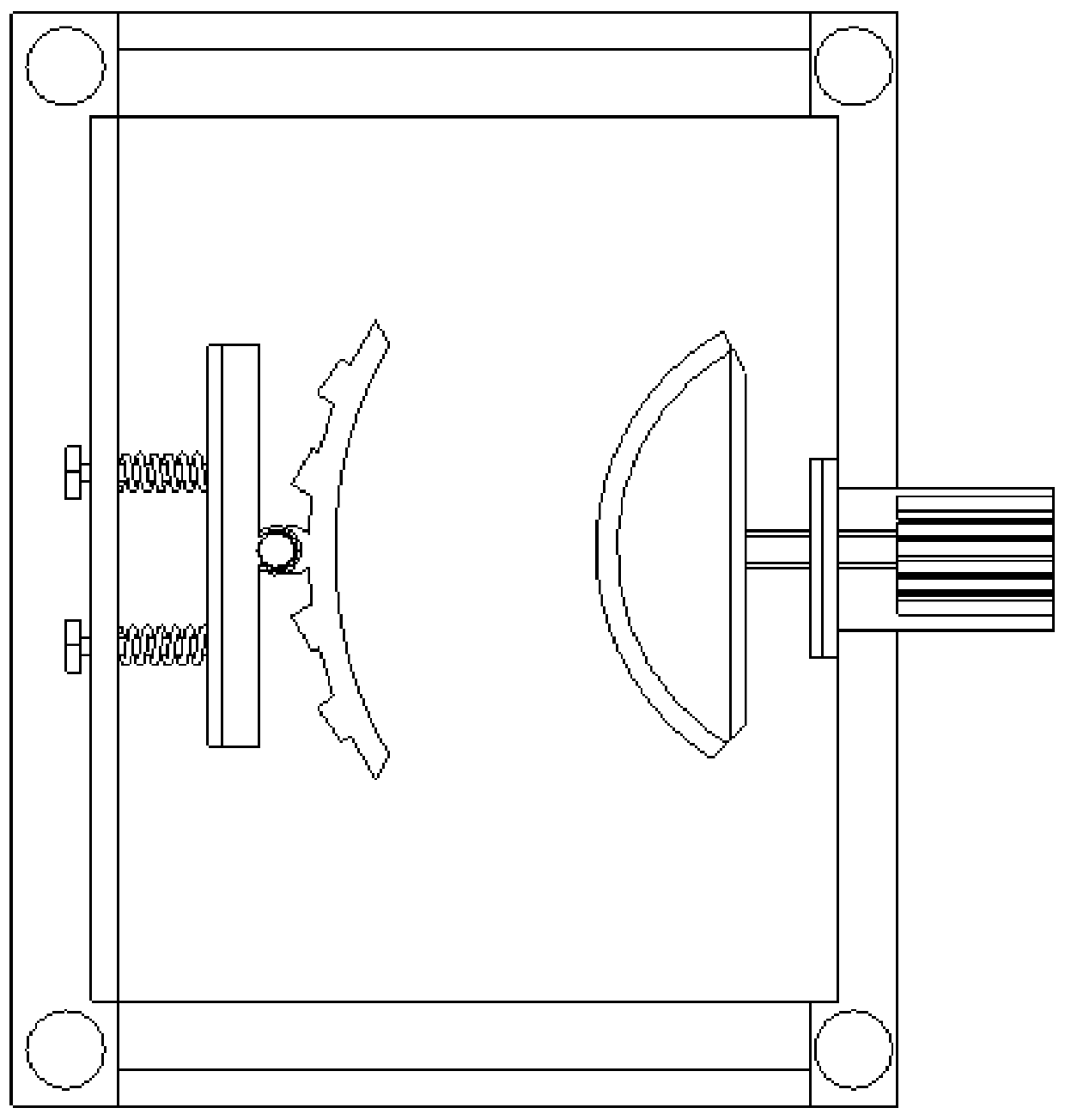

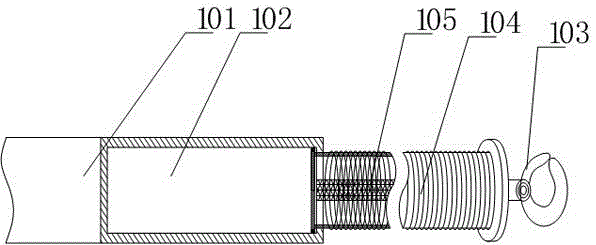

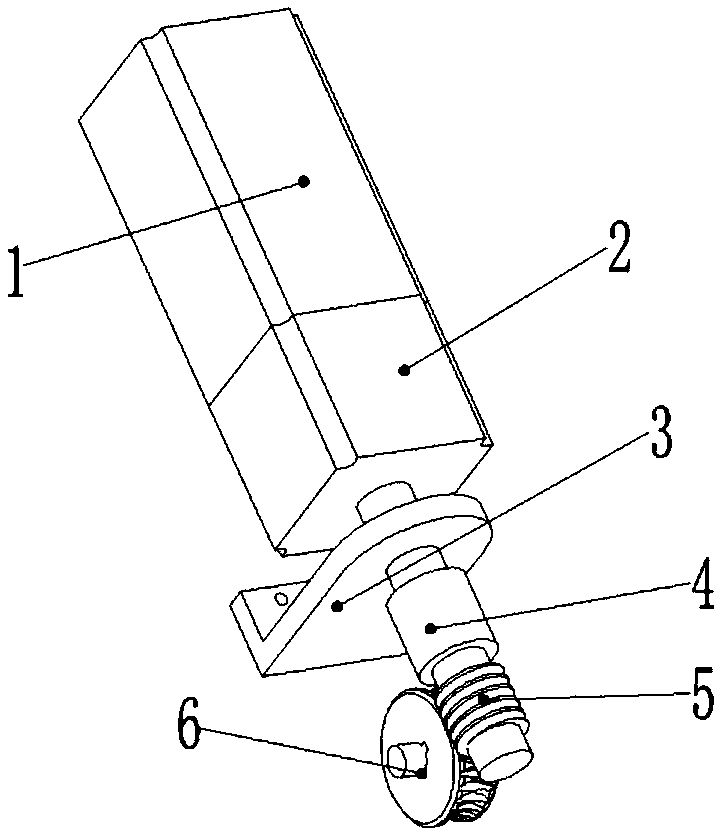

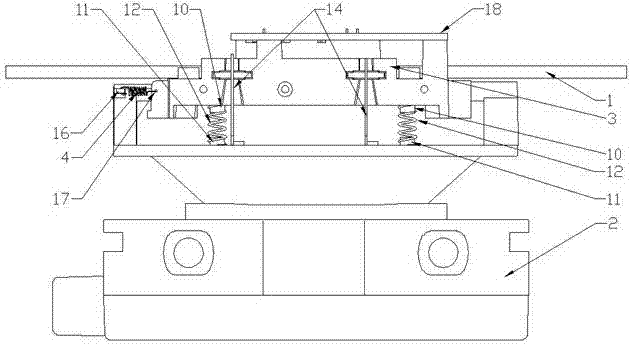

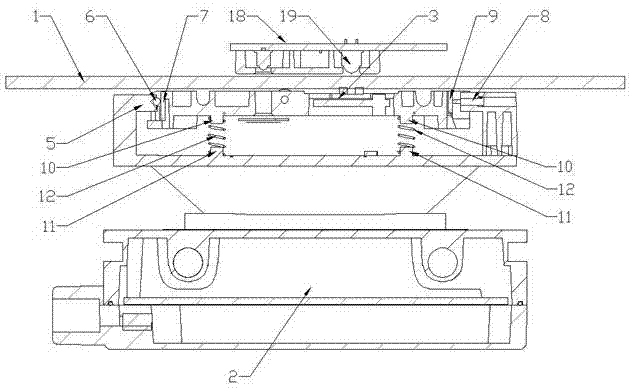

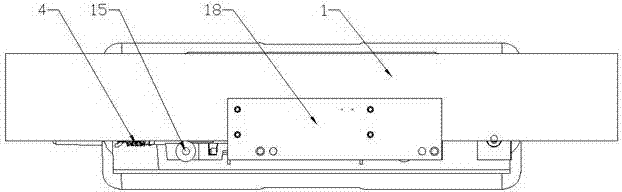

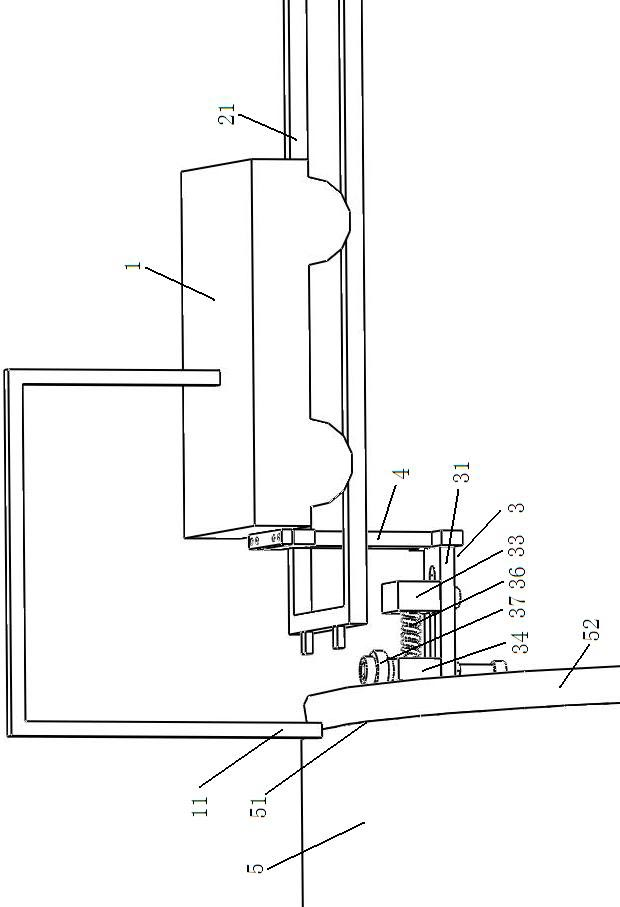

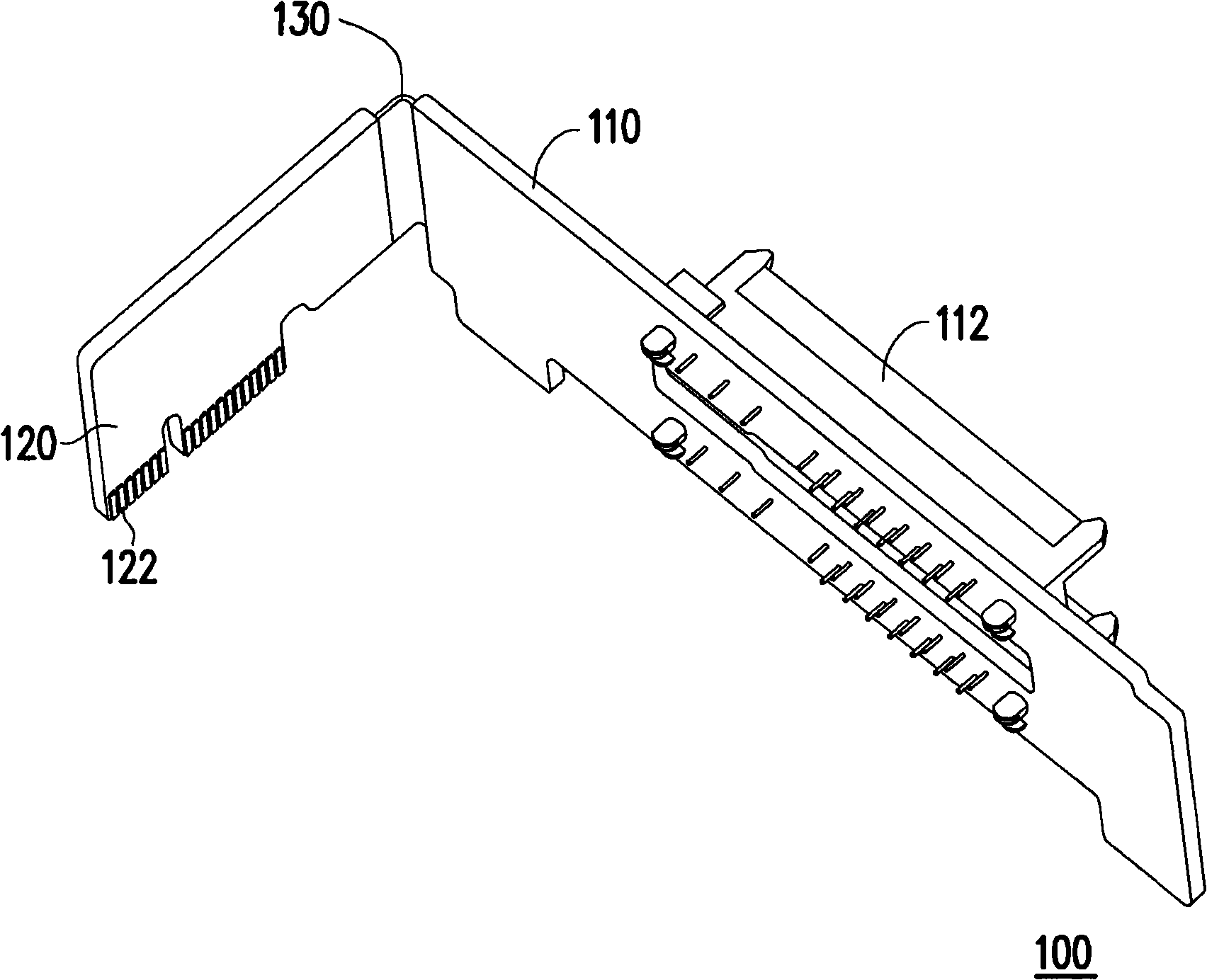

Grating ruler

ActiveCN104741973ANo relative displacementEliminate repeatability errorsMeasurement/indication equipmentsGratingMachine tool

The invention aims to provide a grating ruler which can eliminate measuring repeatability errors and can greatly improve measuring precision. The grating ruler comprises a reading head device and a ruler body device, a glass grating ruler engraved with grating line patterns are arranged in the ruler body device, the ruler body device is fixed onto a body of a machine tool, the reading head device comprises a reading head support and a trolley scanning device, the reading head support is connected onto a movable worktable of the machine tool and clamped on the trolley scanning device in a matched manner, a tension device is positioned at one end of the reading head support along the ruler body direction of the glass grating ruler, a thrust device is arranged at the other end of the reading head support, the tension device tensions one end of the trolley scanning device and contacts with the trolley scanning device, the thrust device contacts with the trolley scanning device and thrusts the trolley scanning device, the tension of the tension device and the thrust of the thrust device are consistent in direction and positioned on the same straight line, and the direction is consistent with the ruler body direction of the glass grating ruler. The grating ruler can be applied to the field of measuring equipment.

Owner:ZHUHAI EASSON MEASUREMENT TECH +1

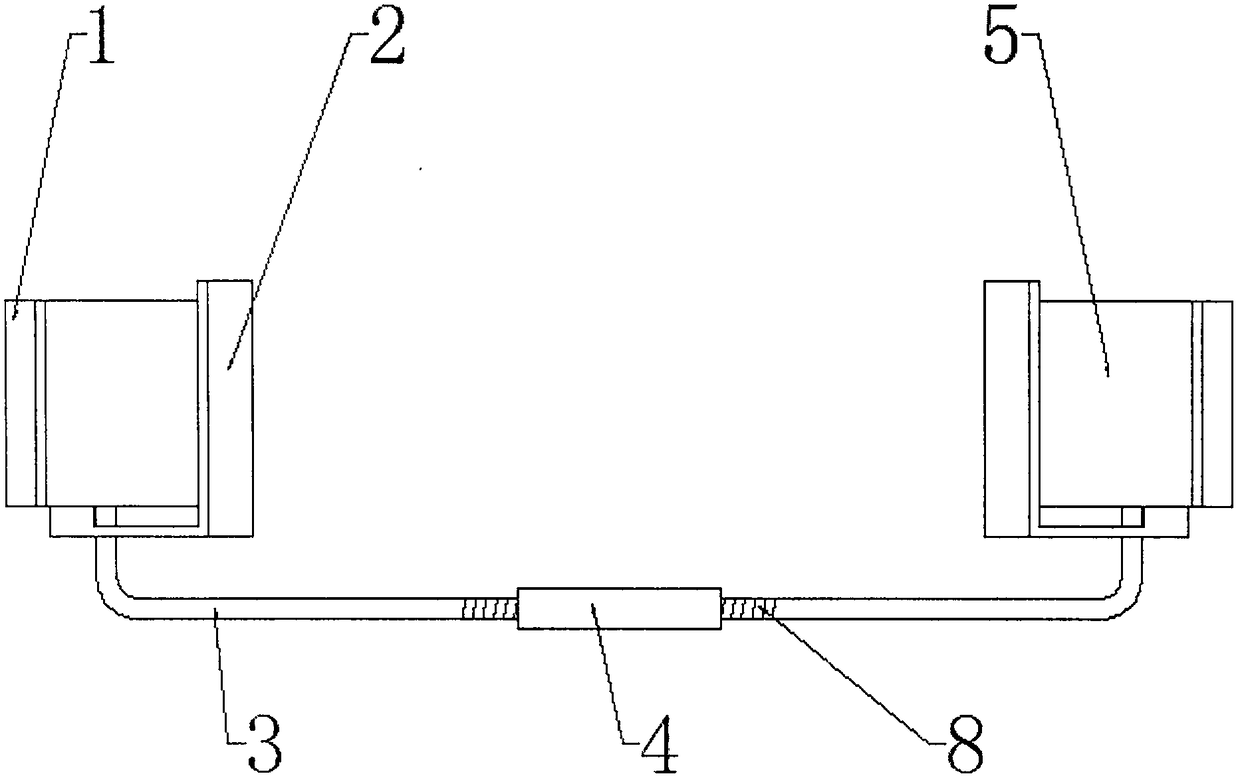

Submerged-arc welding synchronous follow-up device

ActiveCN102489850ASimple structureNo relative displacementWelding accessoriesAxial displacementRelative displacement

The invention discloses a submerged-arc welding synchronous follow-up device, which comprises a welding gun head extending out of a welding machine trolley, and is characterized in that: the welding machine trolley is connected with a clamping driving device, and the clamping driving device is clamped on an edge plate of a cylinder body by two bearings; and when the cylinder body rotates along a central shaft of the cylinder body to generate axial displacement, the welding machine trolley and the welding gun head on the welding machine trolley moves in the same displacement. The submerged-arc welding synchronous follow-up device has a simple structure; when the cylinder body rotates along the central shaft to form the deviation of axial motion, a submerged-arc welding machine and the cylinder body move axially by the clamping linkage device, so that relative displacement between the submerged-arc welding machine and the cylinder body in the axial direction is avoided; and the free rotation state of the cylinder body can be kept continuously by the clamped bearings, relative movement between the submerged-arc welding machine and a circular seam is avoided, the phenomenon of welding deviation is avoided, and the welding quality is improved.

Owner:苏州普洛代尔机电有限公司

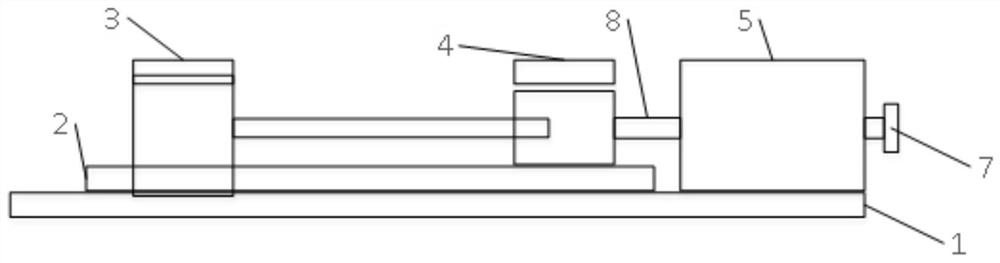

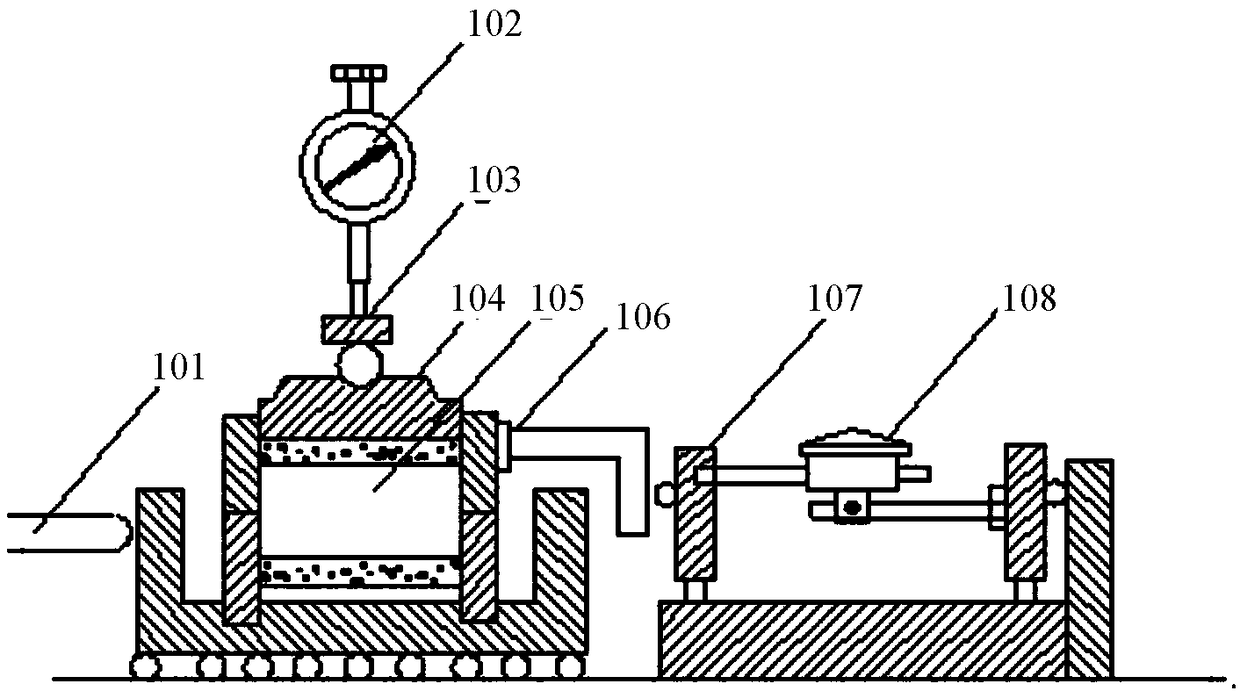

Strain calibration device and method for optical fiber sensor

InactiveCN112066903AEasy to implementMeet the needs of batch calibrationUsing optical meansPower apparatusStrain sensor

The invention provides a strain calibration device and method for an optical fiber sensor. The device comprises a base, a sliding rail, a fixed block, a sliding block, a transmission seat, a power device, a displacement transmission device and a measuring device. A to-be-measured optical fiber strain sensor is clamped between the fixed block and the sliding block; the scale distance of the to-be-measured optical fiber strain sensor is measured by using the measuring device; the power device is started, the sliding block moves; when the to-be-measured optical fiber strain sensor deforms, the measuring device is used for measuring and recording the deformation quantity of the to-be-measured optical fiber strain sensor; Calibration parameters are calculated, and calibration is completed. A method for stretching or compressing the to-be-measured optical fiber strain sensor is adopted; the strain value of the to-be-measured optical fiber strain sensor is obtained by dividing the variable quantity of the stretching or compressing by the scale distance. With the method adopted, the strain value can be obtained more visually and accurately.

Owner:CHINA ELECTRIC POWER RES INST

Expansion board and expansion board fixing structure thereof

InactiveCN101349935BNo relative displacementImprove reliabilityDigital processing power distributionSupport structure mountingElectrical and Electronics engineeringEngineering

Owner:INVENTEC CORP

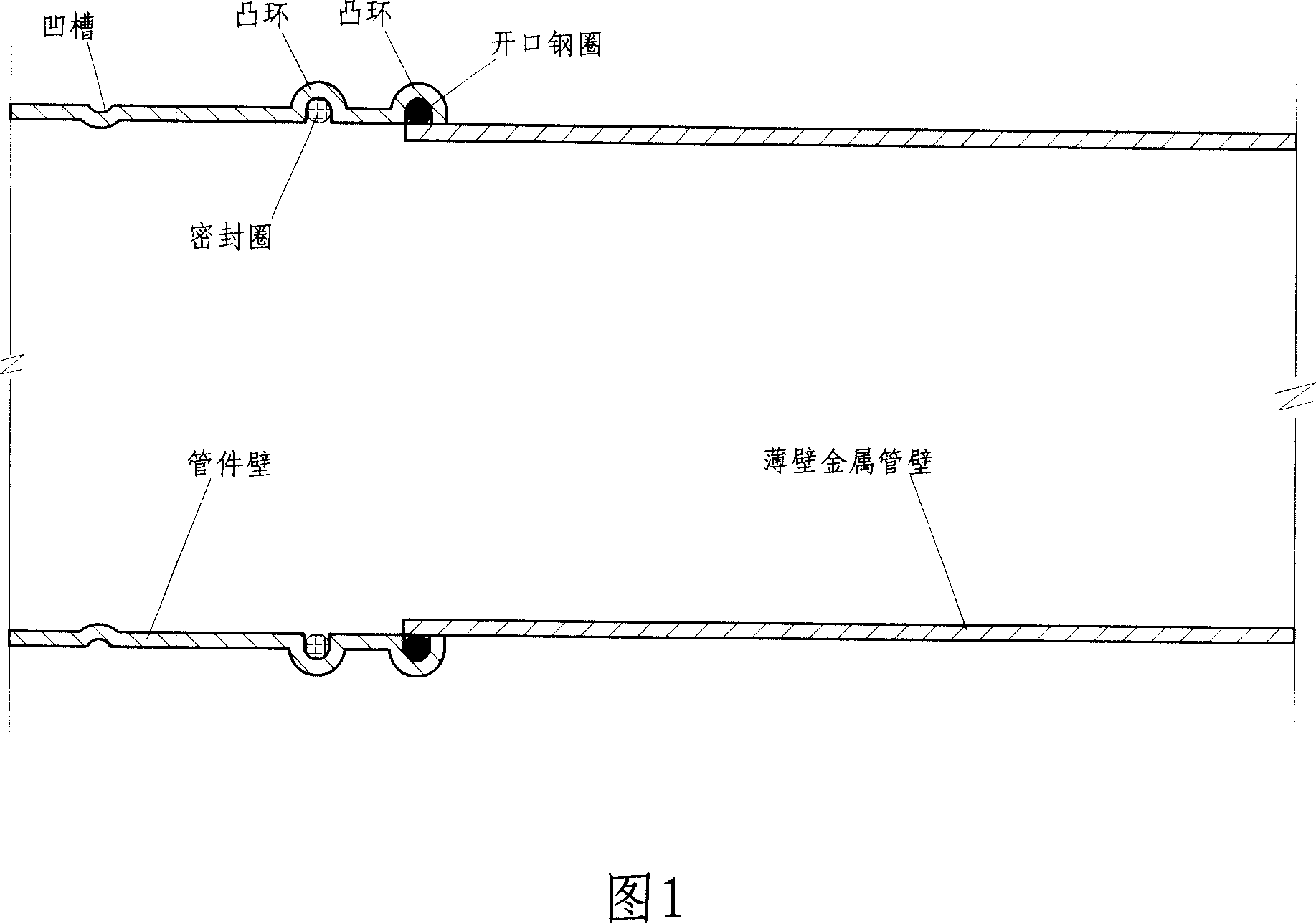

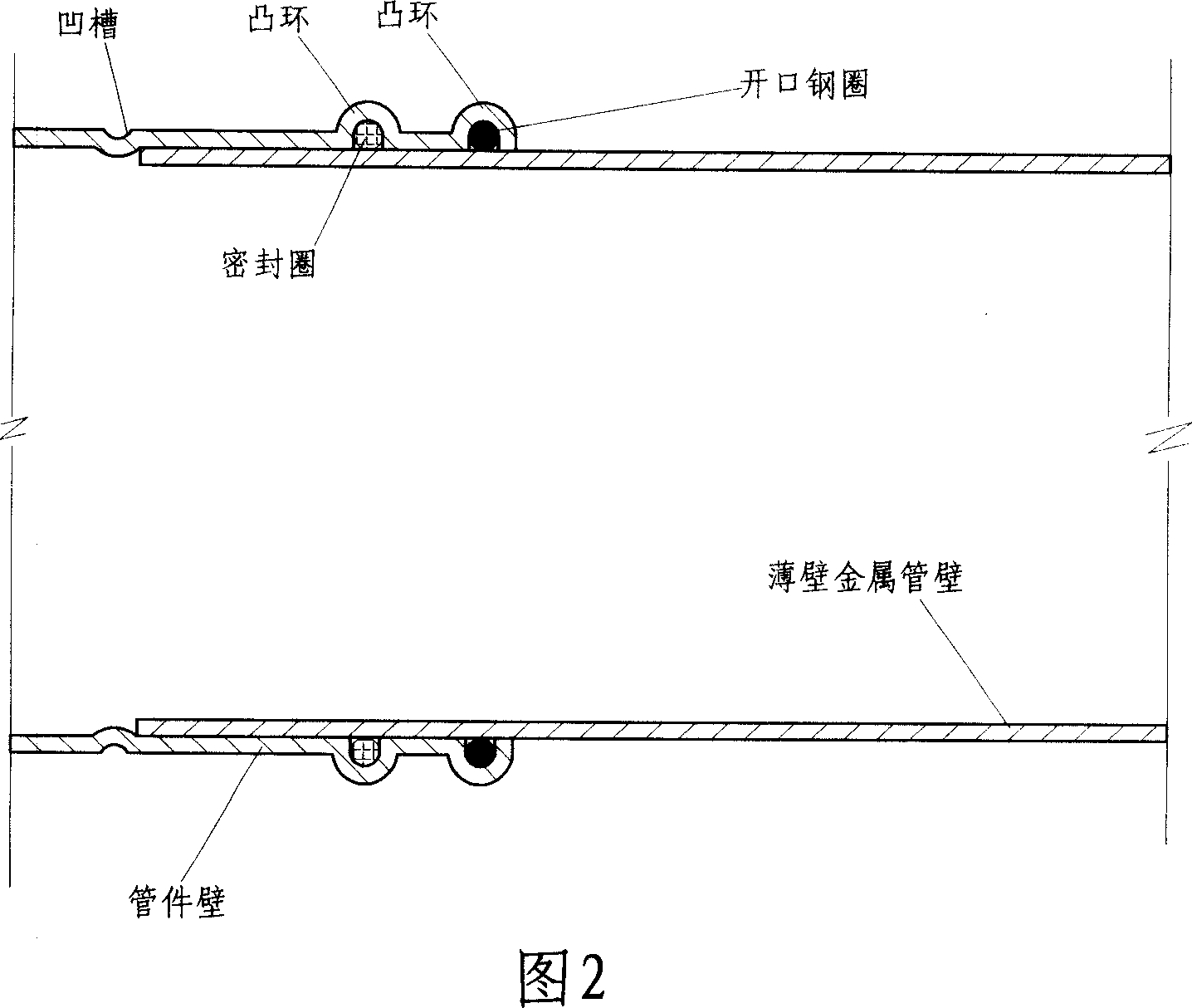

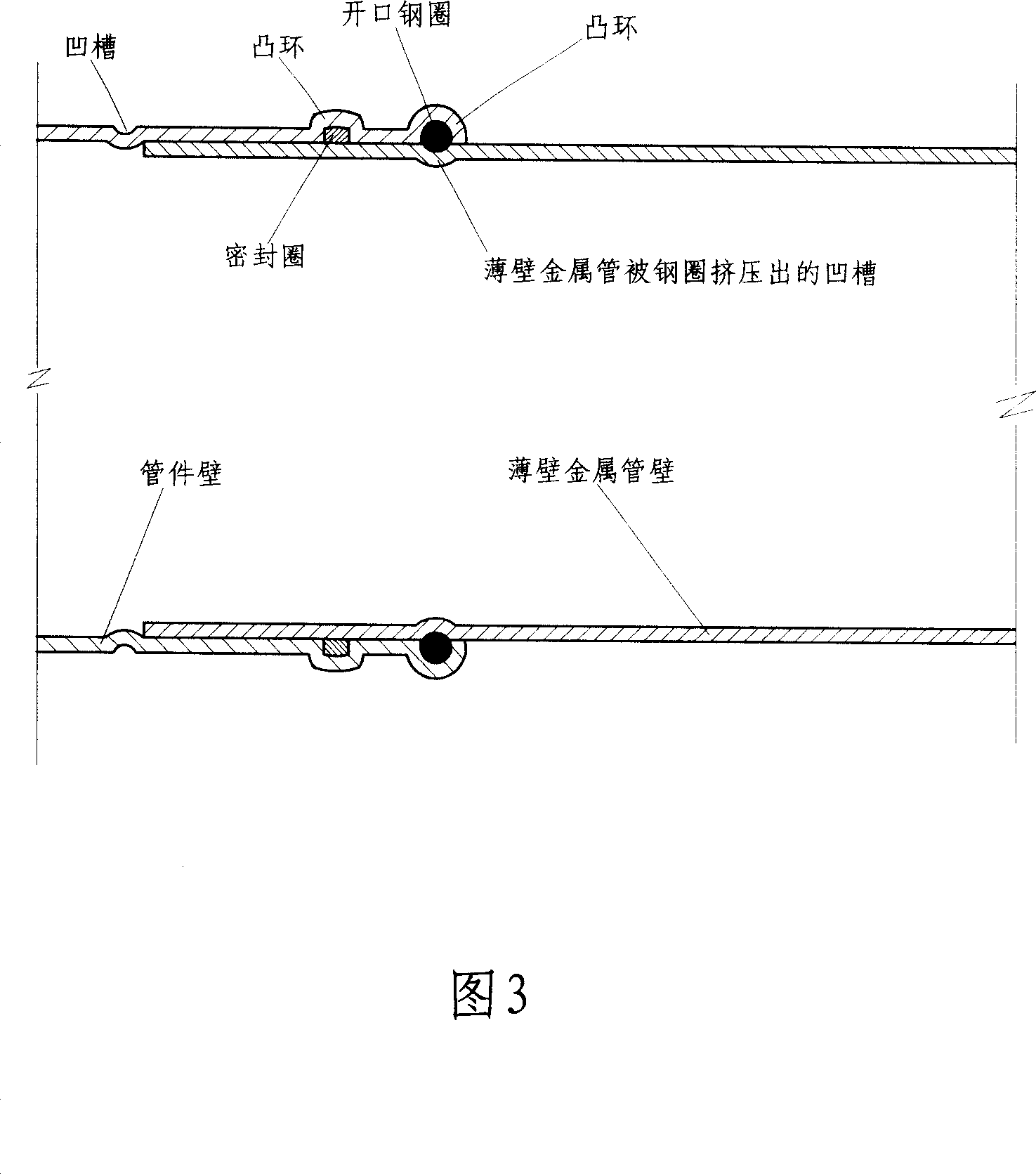

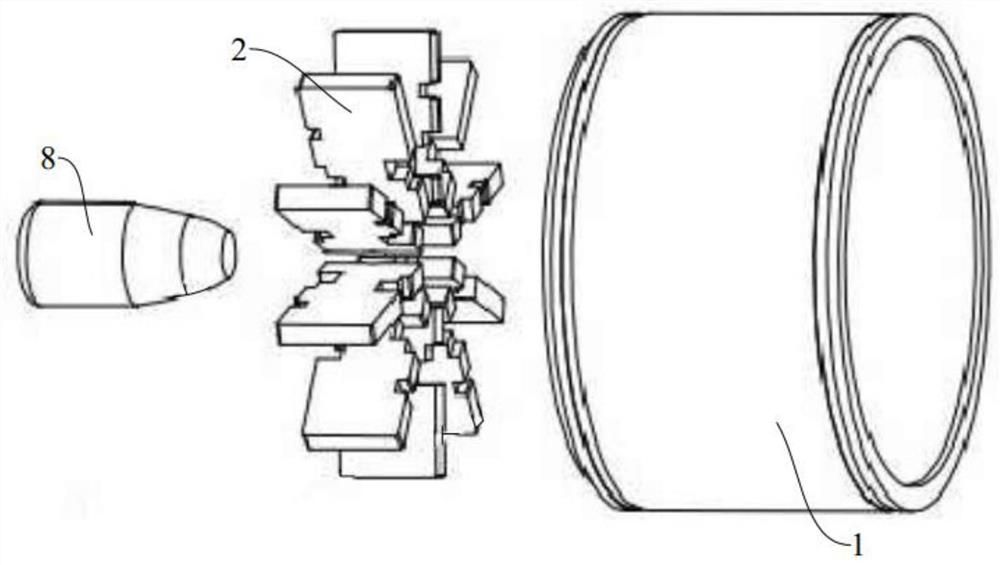

Clasp pipe fitting for connecting thin-wall metal pipe

InactiveCN101046266AReduce manufacturing costNo relative displacementNon-disconnectible pipe-jointsPipe fittingEngineering

The pipe fitting has such inner diameter as to fit the thin wall metal pipe to be connected, and possesses several raised rings with sealing ring or open-mouthed steel wire ring in the wall. After the pipe is inserted into the pipe fitting, the raised rings are compressed radially with special tool so as to reduce the interval between the raised ring and the thin wall pipe. Meanwhile, the open-mouthed steel wire ring is extruded to clamp the thin wall pipe, the sealing ring is extruded to fill the reduced interval to avoid leakage, and the thin wall pipe is connected to the pipe fitting. The pipe fitting has low manufacture cost, simple construction, reliable connection and good sealing effect.

Owner:杭州航宇管业有限公司 +2

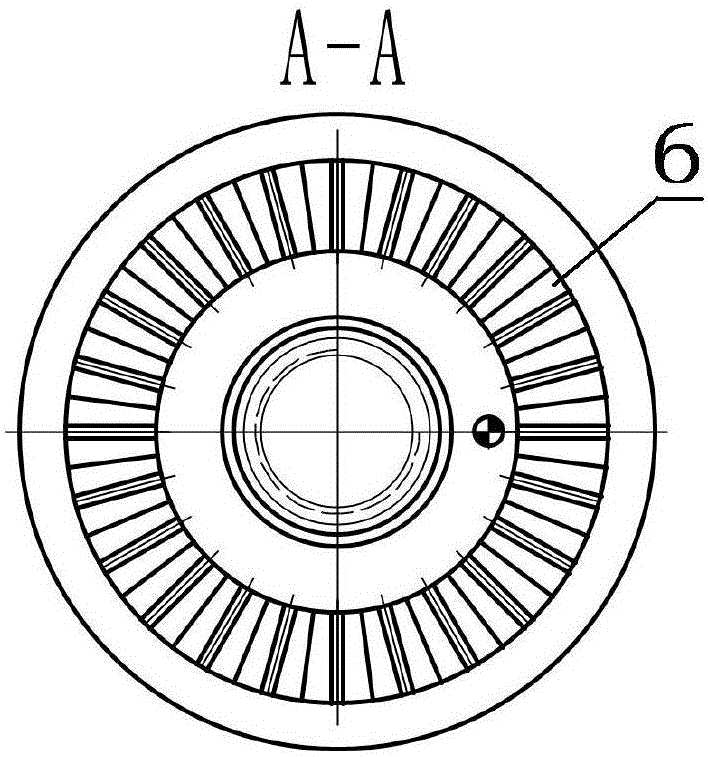

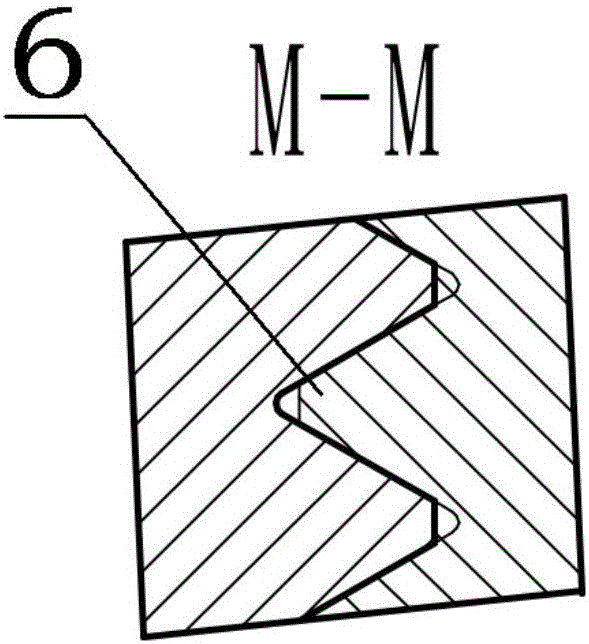

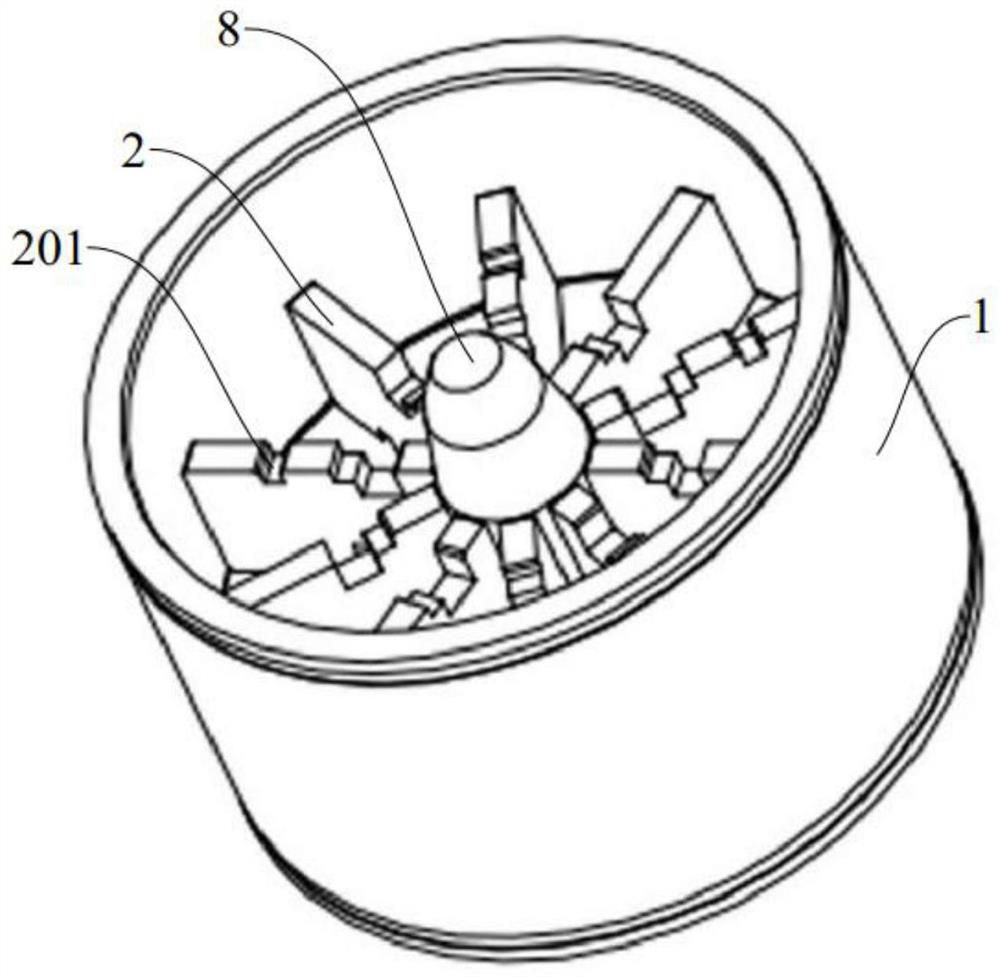

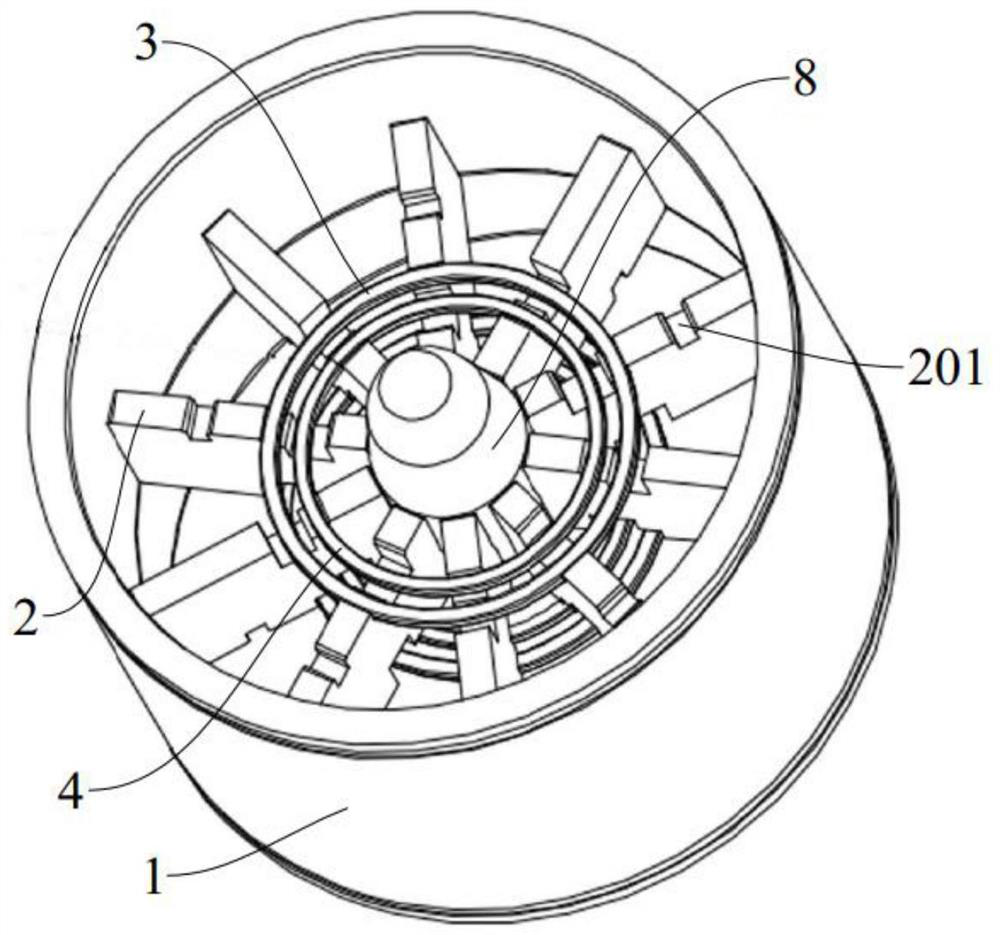

Assembly process of magnetron anode assembly

ActiveCN112242283AGuaranteed assembly accuracyMake sure to setElectrode assembly manufactureMagnetic polesEngineering

The invention provides an assembly process of a magnetron anode assembly. The process comprises the following steps of S1, loading an anode plate into an anode cylinder to form an anode cylinder assembly; S2, arranging a grading ring on the anode cylinder assembly; S3, assembling the A side of a magnetic pole by utilizing an A side die; S4, assembling an antenna by using a first positioning die and a second positioning die; S5, welding; S6, disassembling the die; S7, removing a central pin, and correcting the antenna; S8, adjusting the frequency, and installing the K side of the magnetic pole,wherein the anode cylinder assembly comprises an anode cylinder, an anode plate and the center pin. According to the present invention, the anode plate is tightly pressed on the inner circumferentialsurface of the anode cylinder by adopting the center pin, so that the anode plate and the anode cylinder are ensured not to generate relative displacement in the anode assembly assembling process, the assembling precision is ensured, and the antenna groove is ensured to be formed in the middle position of an antenna hole in the magnetic pole A side through the arrangement of a magnetic pole A side positioning die; by arranging the antenna positioning die, the position precision of the antenna is ensured; and by adopting the production process formed by the die, the assembly precision of the magnetron anode assembly is ensured, and the product percent of pass is improved.

Owner:GUANGDONG GALANZ MICROWAVE OVEN & ELECTRICAL APPLIANCES MFG +1

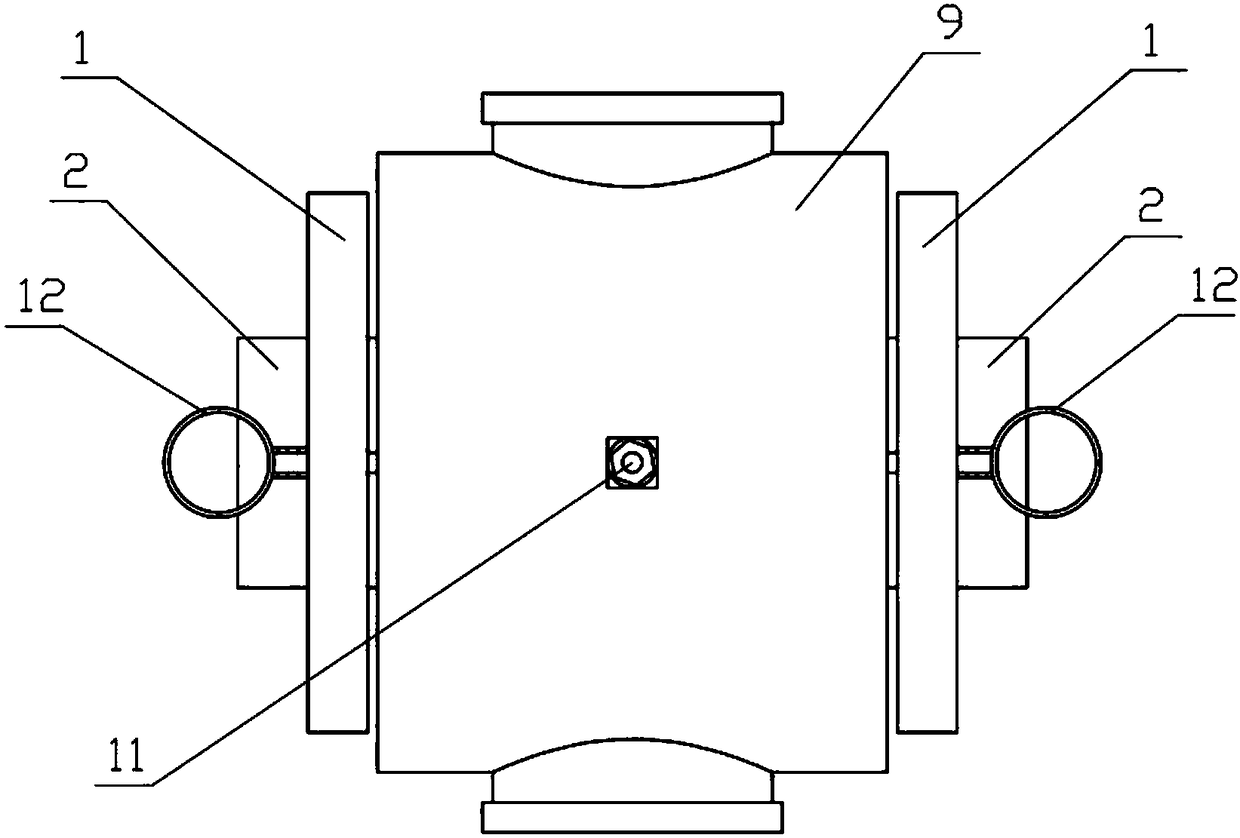

Soil sample eccentric compression prevention strain control type direct shearing tester

PendingCN108344646AAvoid eccentric compressionPrevent eccentric compressionMaterial strength using steady shearing forcesEngineeringForce direction

The invention discloses a soil sample eccentric compression prevention strain control type direct shearing tester which comprises a shearing box, a vertical pressure application device, a horizontal pressure application device, a gauge and an instrument pedestal. The shearing box is formed by an upper shearing box and a lower shearing box; the instruction pedestal is provided with a limiting structure for limiting the upper shearing box to move along a horizontal pushing force direction and a rail for defining the lower shearing box to move on the surface of the pedestal along the horizontal pushing force direction; the vertical pressure application part comprises a vertical pressurization lever, a weight, a vertical pressurization frame, a pressurization rod and a pressure transfer cover;the horizontal pressure application device comprises a pusher and a steel ring; when the pusher is pushed by an external force, the lower shearing box is pushed to slide along the rail; the pushing force direction is consistent with the rail direction. According to the tester, the defect of soil sample eccentric compression of a conventional strain control type direct shearing tester is overcome,and accuracy and reasonability of strain control type direct shearing testing are improved.

Owner:CCCC FOURTH HARBOR ENG INST +1

Valve protection device

InactiveCN108488461APlay a protective effectNo relative displacementValve housingsRelative displacementEngineering

The invention relates to a protection device, in particular to a valve protection device. The valve protection device comprises side plates, supporting barrels, supporting plates, installation nails,spiral thread plates, installation barrels, arc-shaped barrels, clamping sliding blocks, an overall connection barrel, a transmission mechanism, an installation mechanism, control mechanisms, bafflesand a buckle mechanism. The device can be installed along with a pipe valve when the pipe valve is installed to protect the pipe valve, and accidents caused by accident push of the valve are prevented; the eight clamping sliding blocks are made to slide in eight clamping sliding rails formed by the eight arc-shaped plates through rotation of the installation mechanism, the eight clamping sliding blocks clamp pipes on the two sides of the valve, it is guaranteed that relative displacement cannot occur, the eight clamping sliding blocks can clamp the pipes different in size, when the diameters of the pipes on the two sides of the pipe valve are different, the transmission manner in the transmission mechanism is changed by manually adjusting the control mechanisms, and rotation of the spiralthread plates on the two sides is controlled.

Owner:南京盈博医药生物技术创新研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com