Patents

Literature

72results about How to "Uniformity controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

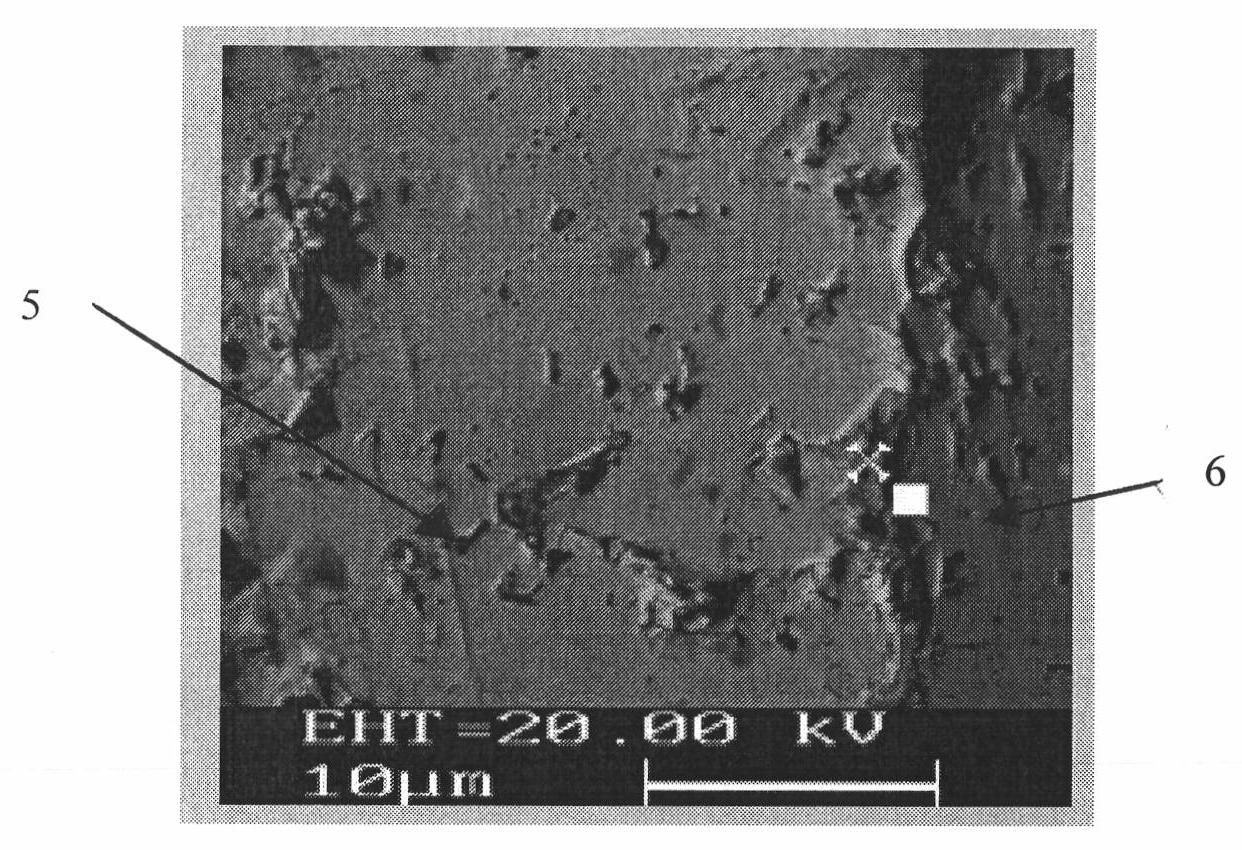

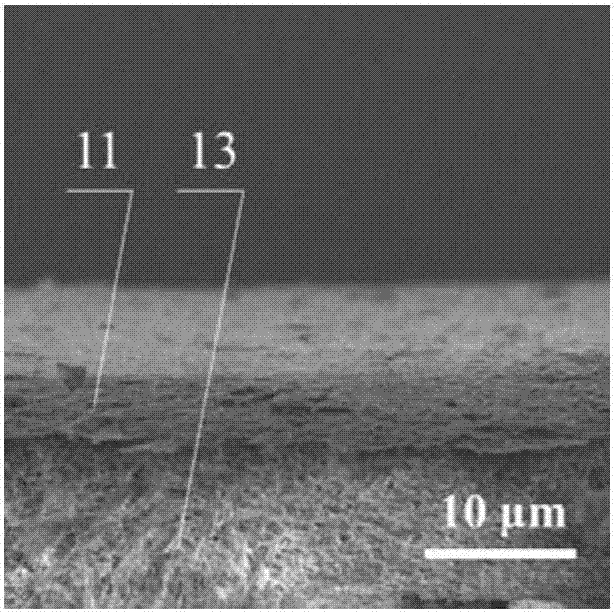

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

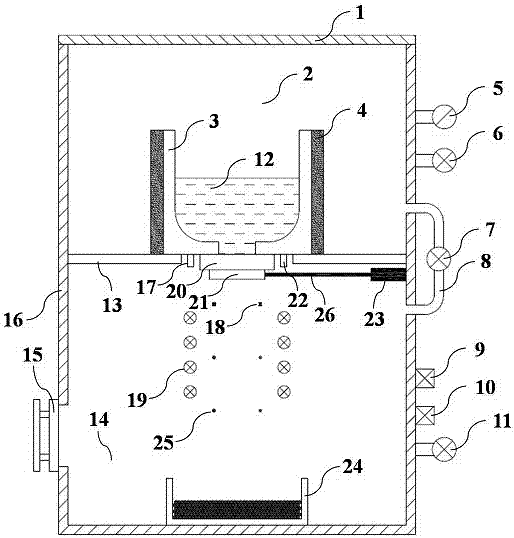

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

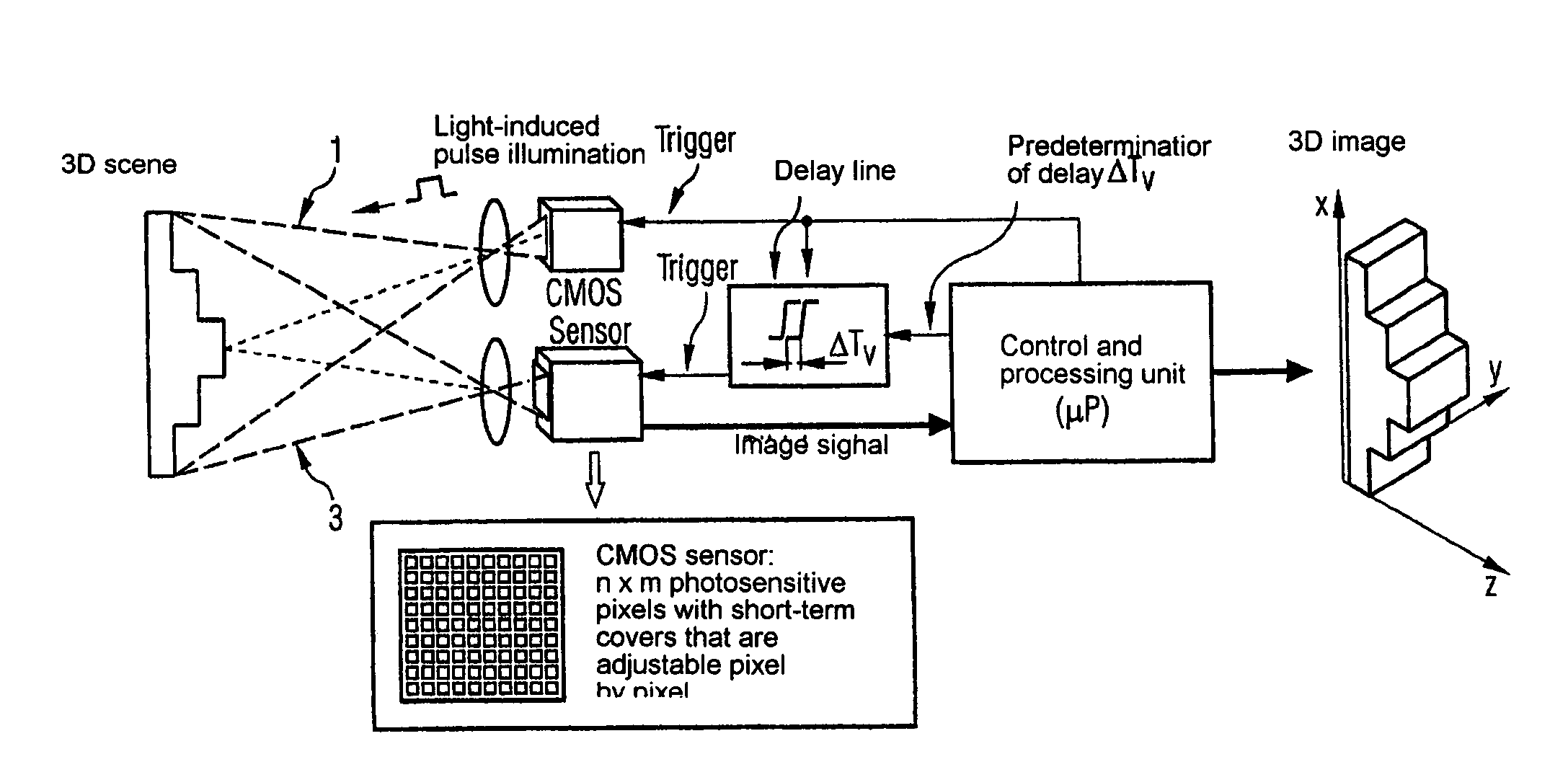

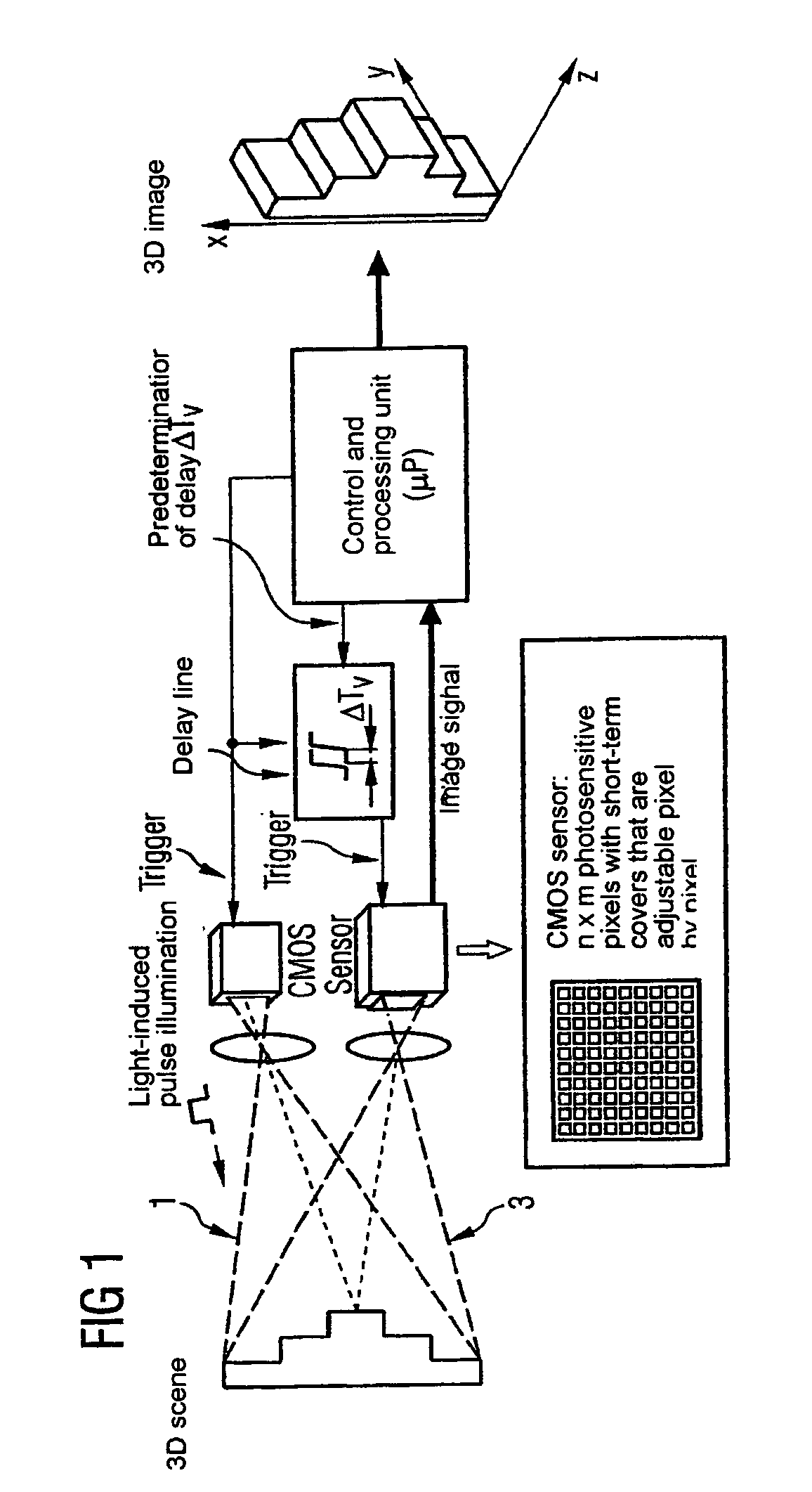

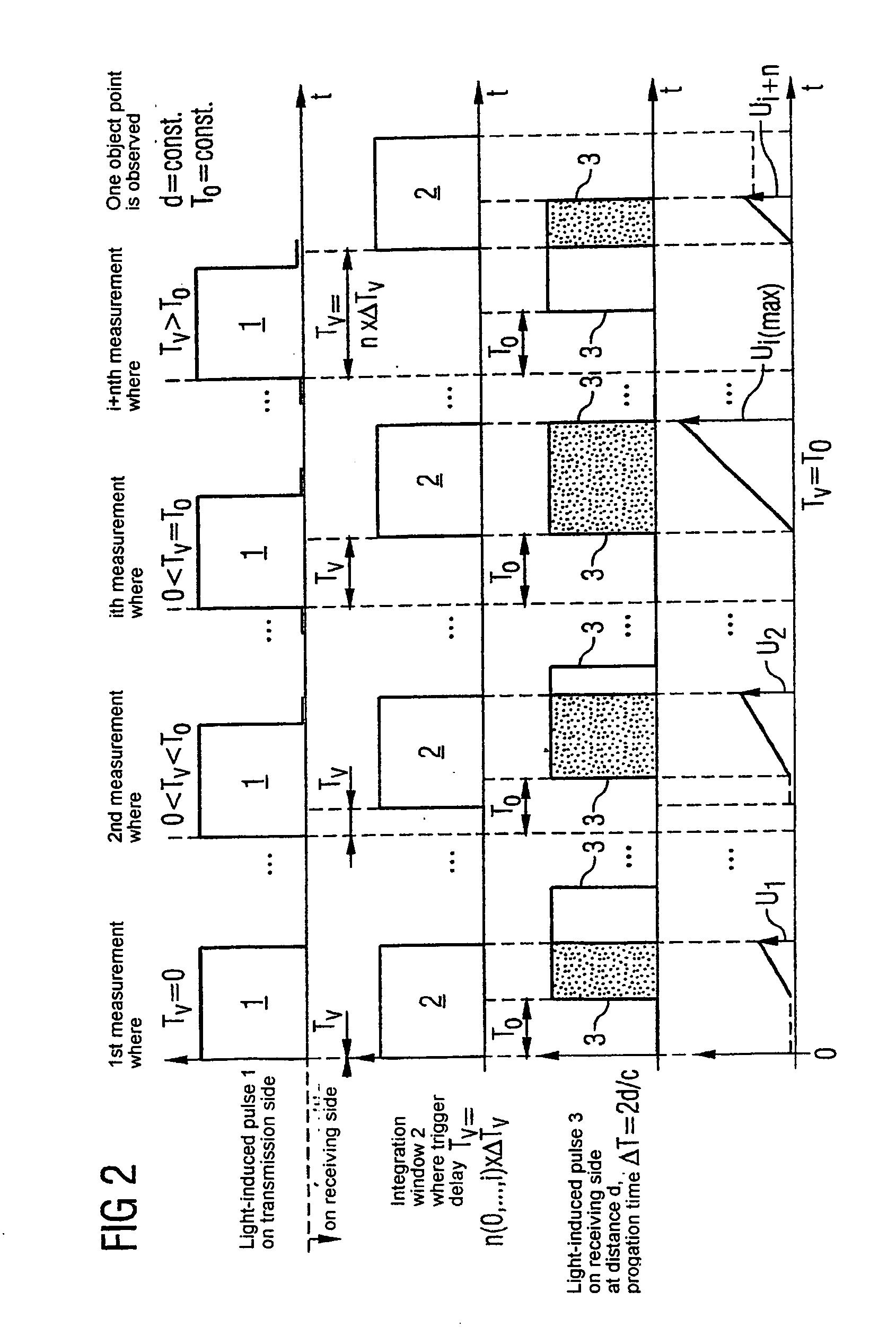

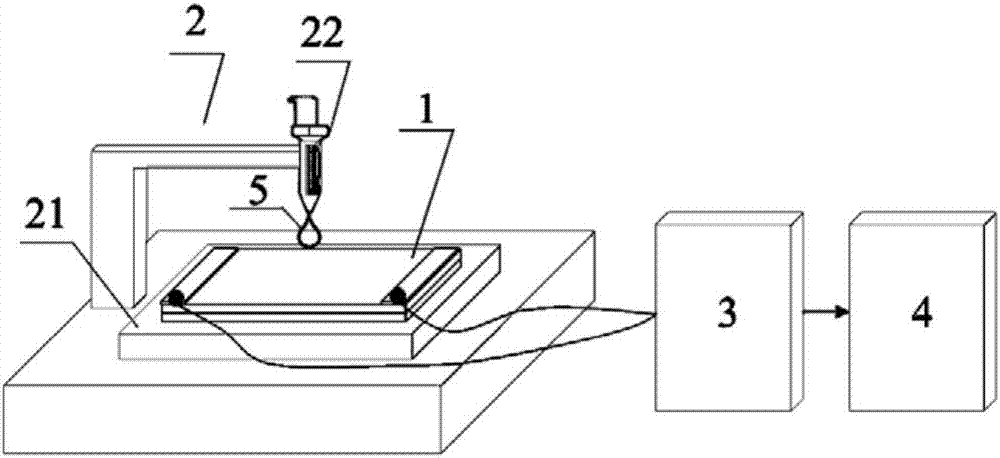

Method and device for recording a three-dimensional distance-measuring image

InactiveUS7212278B2Easy assessment processIncrease signal levelOptical rangefindersUsing optical meansPhotovoltaic detectorsTime delays

The invention relates to methods and devices for recording three-dimensional distance-measuring images of an object surface by measuring light propagation time using a short-term integrated photodetector. For starting a light-induced pulse on the transmission side, a trigger signal is produced that is at the same time used on the receiving side for opening at least one integration window for receiving back-scattered light-induced pulses with a predetermined time delay. A predetermined event such as a maximum or a zero crossing is detected which, by its interval relative to the integration windows, determines a trigger delay. The trigger delay is correlated with the light propagation time and allows calculation of the object point distance d.

Owner:ROCKWELL AUTOMATION

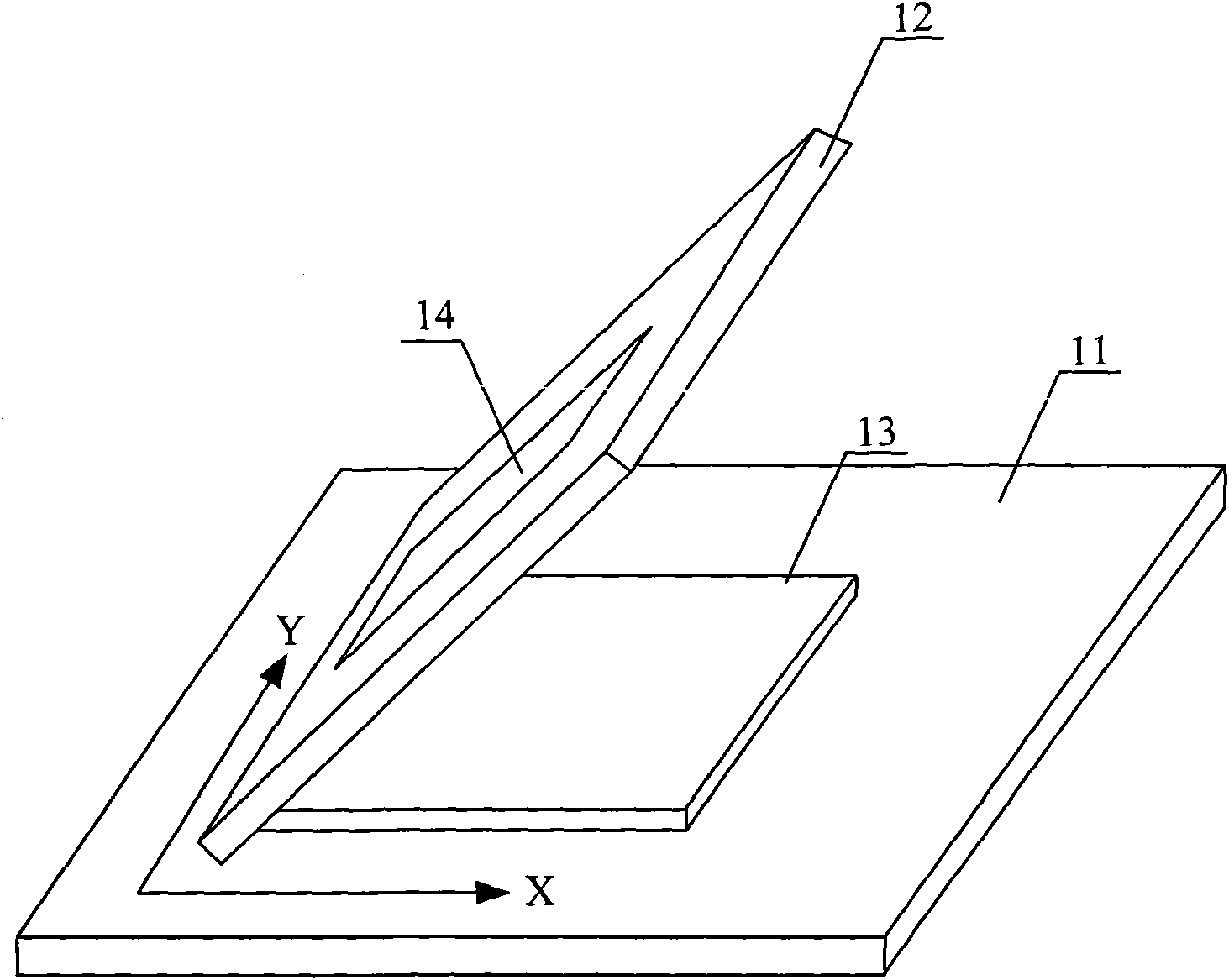

2.5-dimension (2.5d) multidirectional extensible weaving method

The invention relates to a 2.5-dimension (2.5D) multidirectional extensible weaving method, which is characterized in that (1) a fabric adopts a 2.5D structure; (2) weaving of the fabric adopts core die simulation weaving; (3) top pavement weaving on the top of the center is finished by the conventional yarn paving and weft lining technology; and (4) after the top pavement weaving on the top of the center is finished, expansion is executed by selecting an expansion shape consistent with the top shape of the fabric according to the top shape. The 2.5D multidirectional extensible weaving method has the advantages that (1) bidirectional or multidirectional expansion of the top of the fabric can be realized, and overall forming of the fabric with a relatively complicated top shape is facilitated; (2) the fibers on the top are high in continuity; and (3) the uniformity during fabric forming is easy to control. The fabric woven by the weaving method has comprehensive performances such as high strength, high modulus, high damage tolerance, impact resistance, layering resistance and fatigue resistance; and the method can be widely applied to weaving fabrics which have sealed tops and are in various shapes in the field of stereo fabrics.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

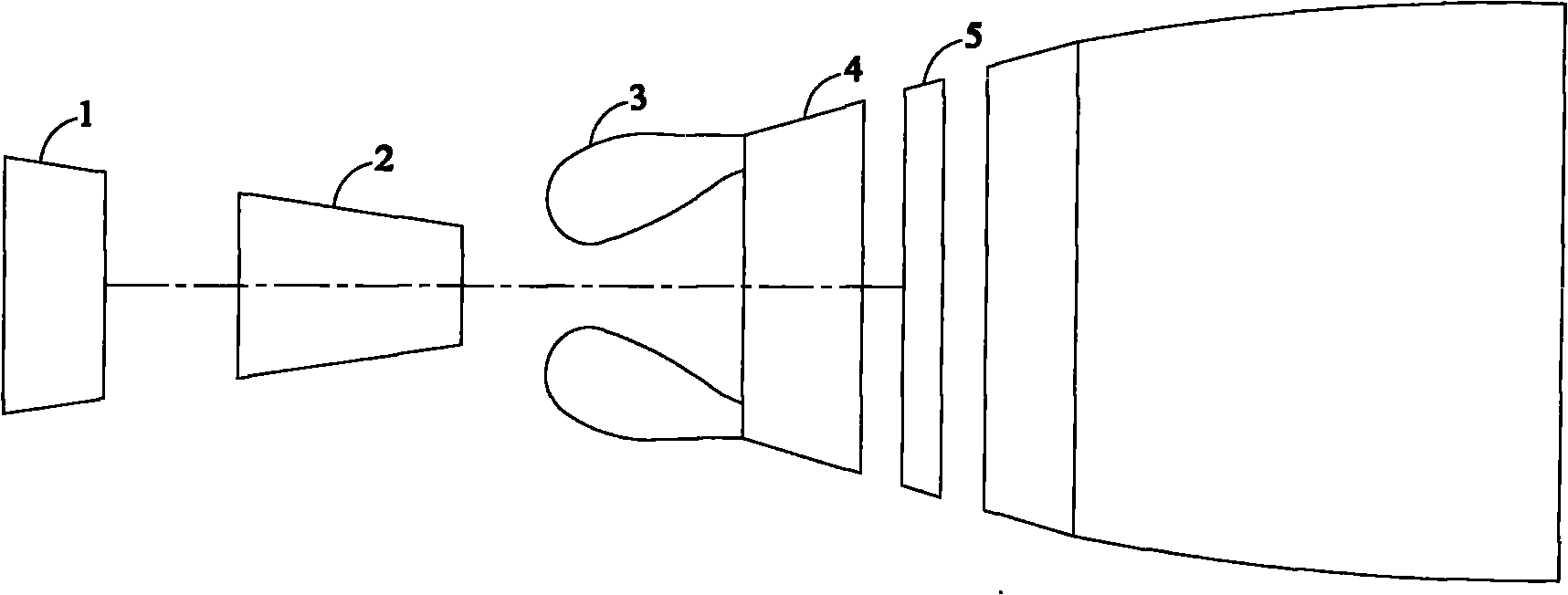

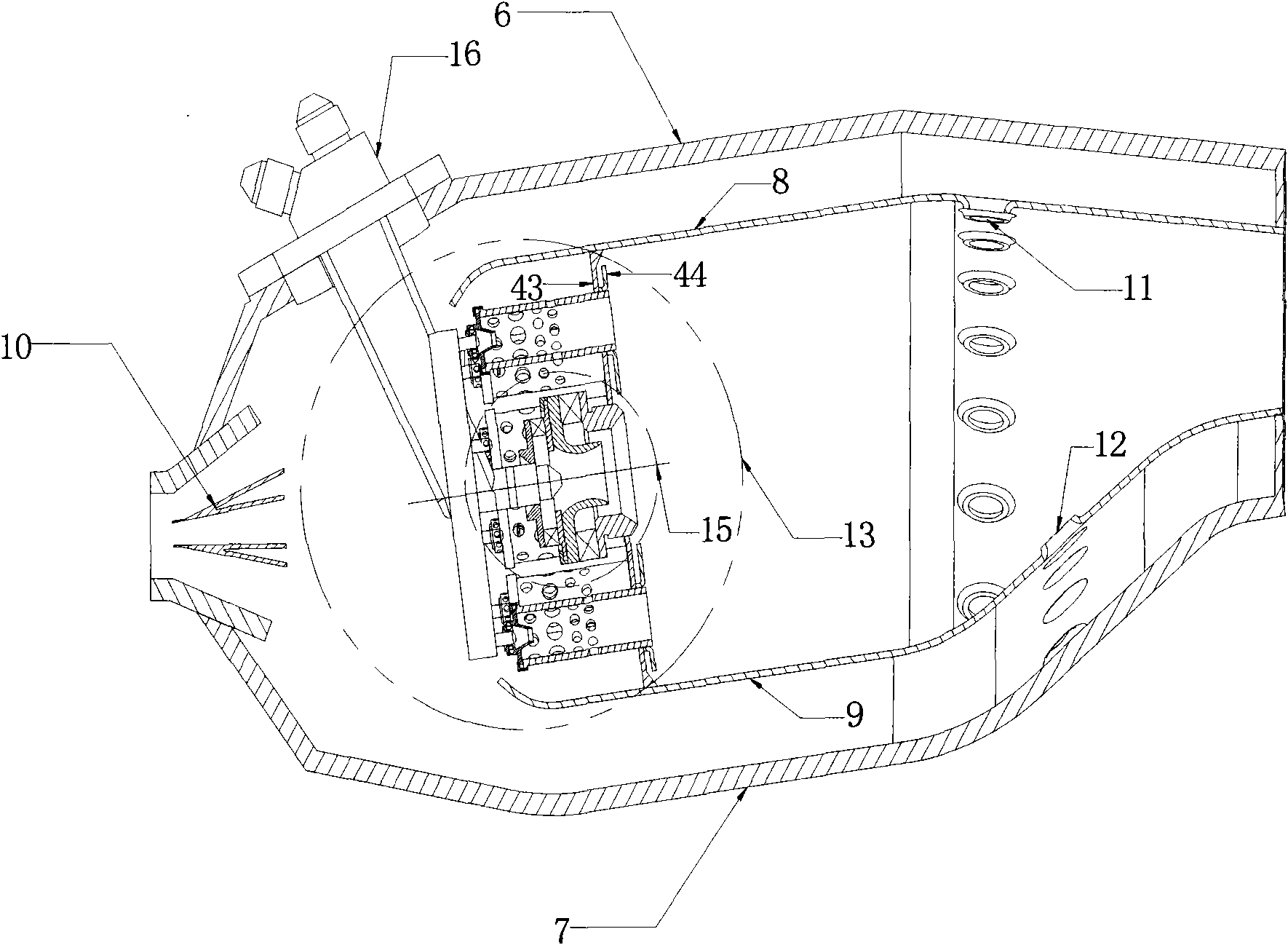

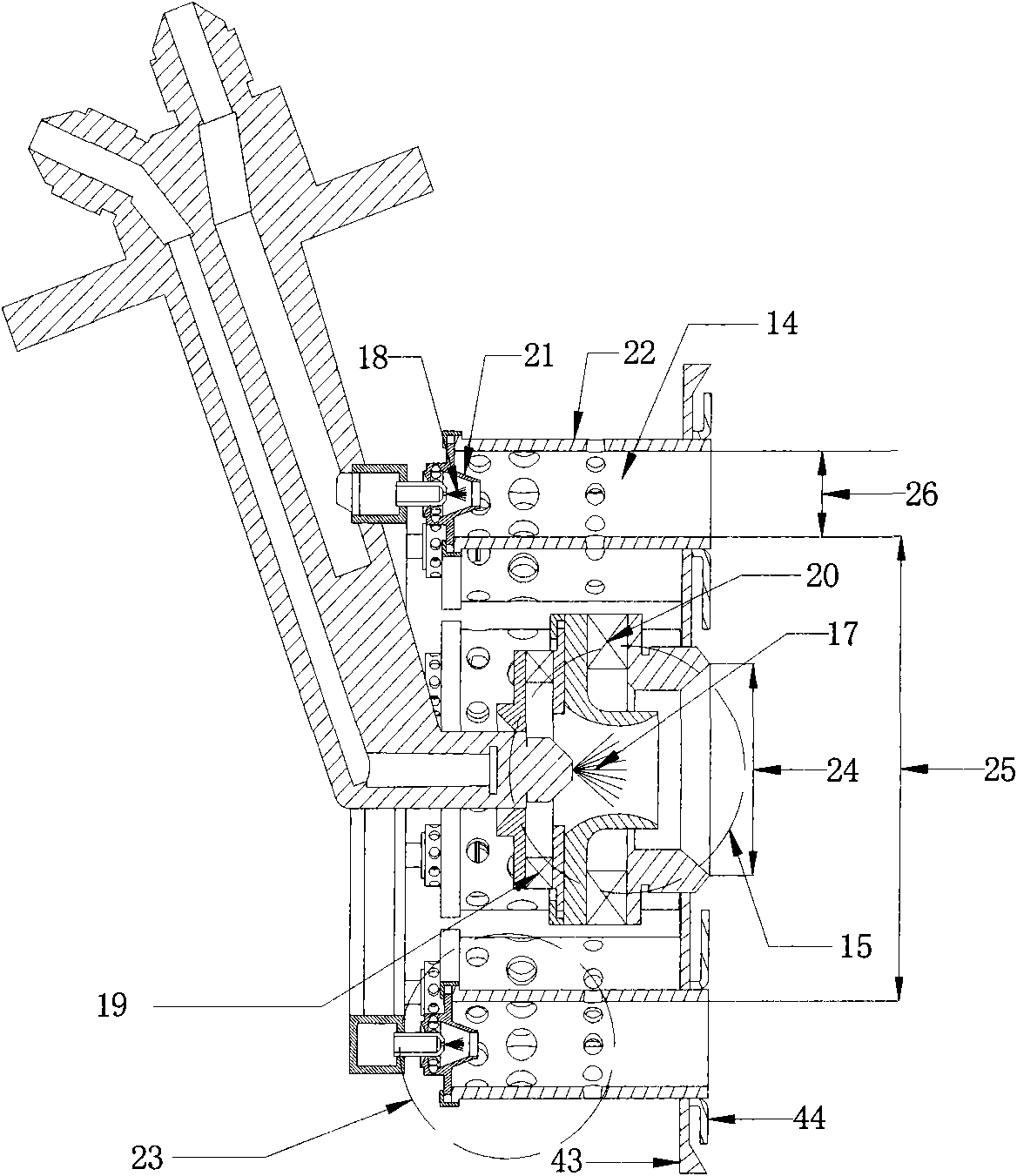

Premixing pre-vaporization combustion chamber for main combustible stage of discrete pipe

ActiveCN102032597AUniformity is easy to controlImprove combustion efficiencyContinuous combustion chamberAutomotive engineeringCombustion chamber

The invention provides a premixing pre-vaporization combustion chamber for a main combustible stage of a discrete pipe. The combustion chamber is in a single annulus structure, and consists of a combustion chamber outer case, a combustion chamber inner case, a flame tube outer wall, a flame tube inner wall and a combustion chamber head, wherein combusting air completely enters a flame tube from the combustion chamber head, a staged combustion scheme, namely a pre-combustible stage and the main combustible stage, is adopted; a swirl cup is adopted in the pre-combustible stage which is of a diffusion combustion organization mode; a premixing pre-vaporization device is adopted in the main combustible stage, a main combustible stage nozzle supplies fuel axially, the fuel is vaporized in the premixing pre-vaporization device and blended with air, the uniformly mixed combustible gas enters the combustion chamber to participate in combustion, namely a premixing combustion organization mode. The pre-combustible stage controls the range of stable work of the combustion chamber, and provides a stable ignition source for the main combustible stage; and the main combustible stage controls main pollution emission of the combustion chamber, and lower pollution emission of the combustion chamber is realized by controlling the equivalence ratio of premixed gas of the main combustible stage. The premixing pre-vaporization device has a simple structure, and can realize that the pollution emission of an aircraft engine combustion chamber can be reduced on the basis of not influencing the combustion stability.

Owner:BEIHANG UNIV

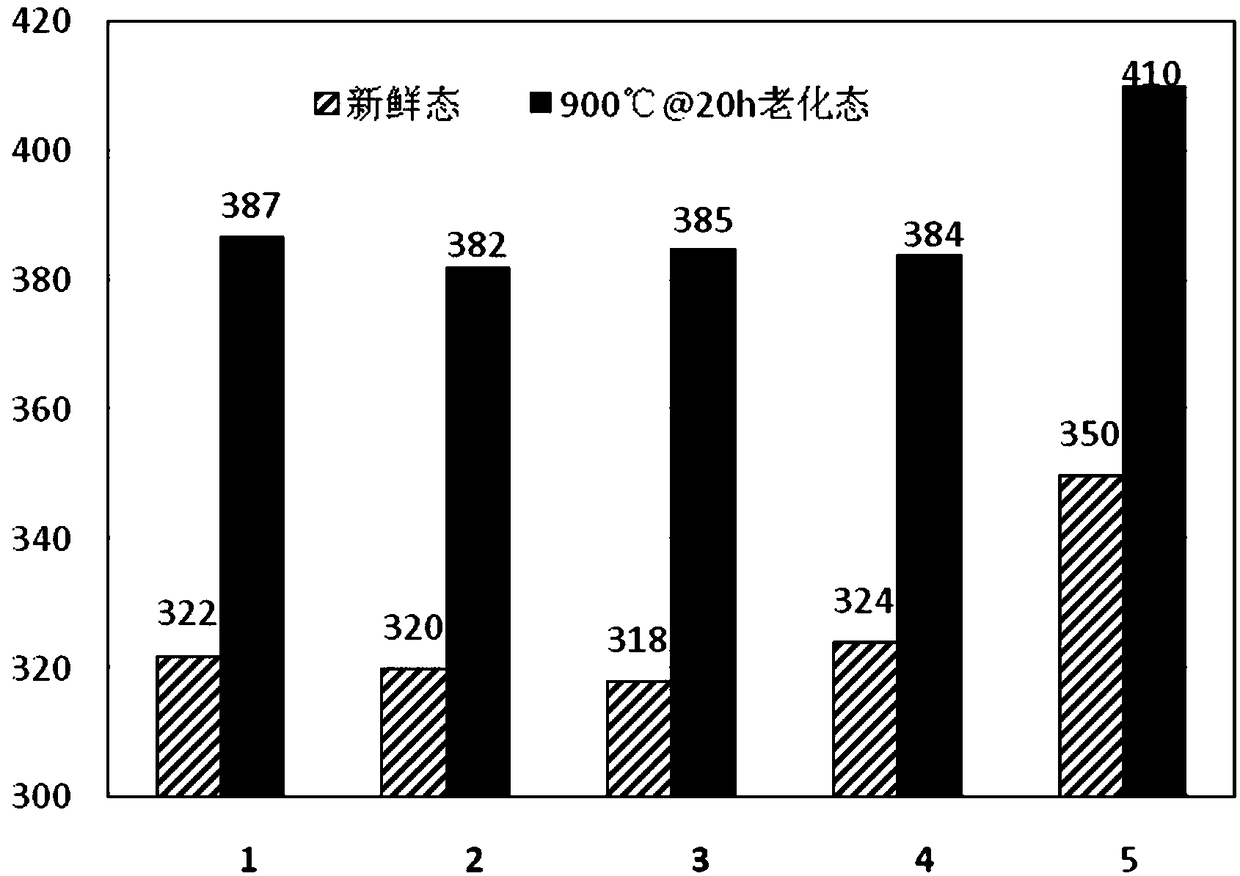

DPF with low-backpressure and low-initiation-temperature catalyst layer and preparation process of DPF

ActiveCN108561211ATake advantage ofAchieve light-offGas treatmentDispersed particle filtrationHigh energyCerium

The invention provides a DPF with a low-backpressure and low-initiation-temperature catalyst layer and a preparation process of the DPF. The invention discloses the DPF and the preparation process ofthe DPF, wherein the DPF is used for catching, purifying and conducting low-temperature catalytic oxidation on PM and PN particles in tail gas of diesel vehicles and has the low-backpressure catalystlayer. The preparation process includes the steps that soluble aluminum salt or aluminum oxide is added in a water-alcohol solvent system, and slurry A is obtained through high energy ball milling; soluble salt of cerium and zirconium is prepared into an ionic type mixed solution, the solution is added in the slurry A, slurry B is prepared through stirring, and high energy ultrasonic oscillation is conducted while the slurry B is aged, and a glue solution C with gel particles is formed; then, the glue solution C is dipped onto the wall face of a wall-flow type DPF gas inlet and holes in the wall through the dipping process, back flushing is conducted through gas flow finally so that the redundant glue solution C can be removed, a solution with active precious metal ions is dipped in the dried DPF with a coating layer in the form of gas mist spray, and a diesel particle catcher which can conduct low-temperature catalytic oxidation on PM and PN and has the low-backpressure characteristicis obtained through drying and roasting.

Owner:SINOCAT ENVIRONMENTAL TECH

Tin sulfide film solar battery

InactiveCN101378090AAbundant on EarthWide range of sourcesPhotovoltaic energy generationSemiconductor devicesHeterojunctionComposite film

A tin sulfide thin film solar cell comprises a conductive glass / metal gate electrode and a metal back electrode and is characterized in that uni-junction or multi-junction n-SnS2 or the composite thin film thereof and p-SnS or the composite thin film thereof are formed between the conductive glass / metal gate electrode and the metal back contact. The composite means the tin sulfide obtained by doping tin bromide (n-SnS2) and stannous sulfide (p-SnS). The solar cell is rich in material sources, safe and environment-friendly, convenient in processing and effectively solves the collection problem of current carriers with the aid of such electrodes as metallic tin by using SnS2 and SnS, which have the same components and different conduction types and liable to realize energy gap match, heterojunction transition and good transport property of the current carriers.

Owner:HEFEI UNIV OF TECH

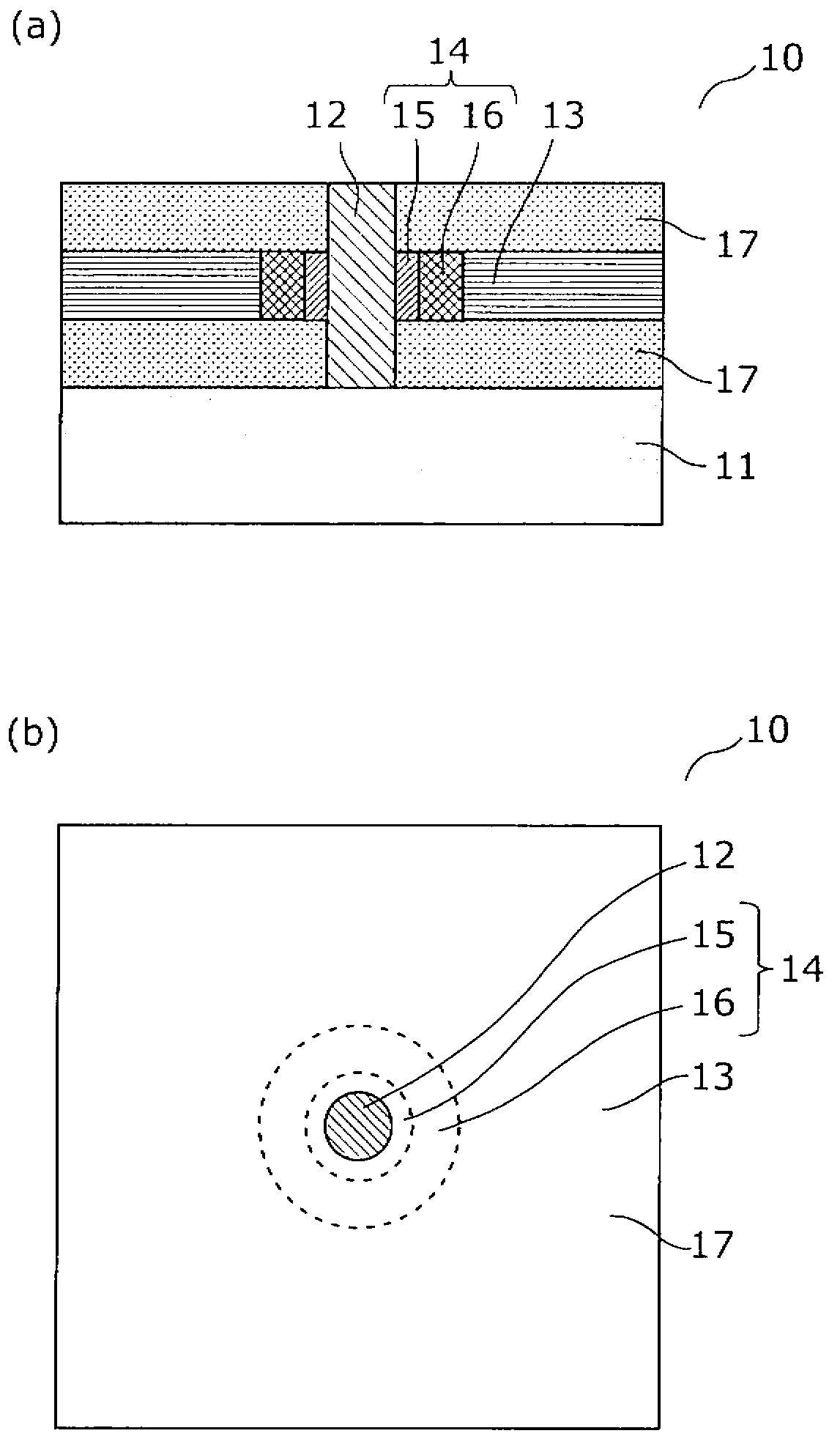

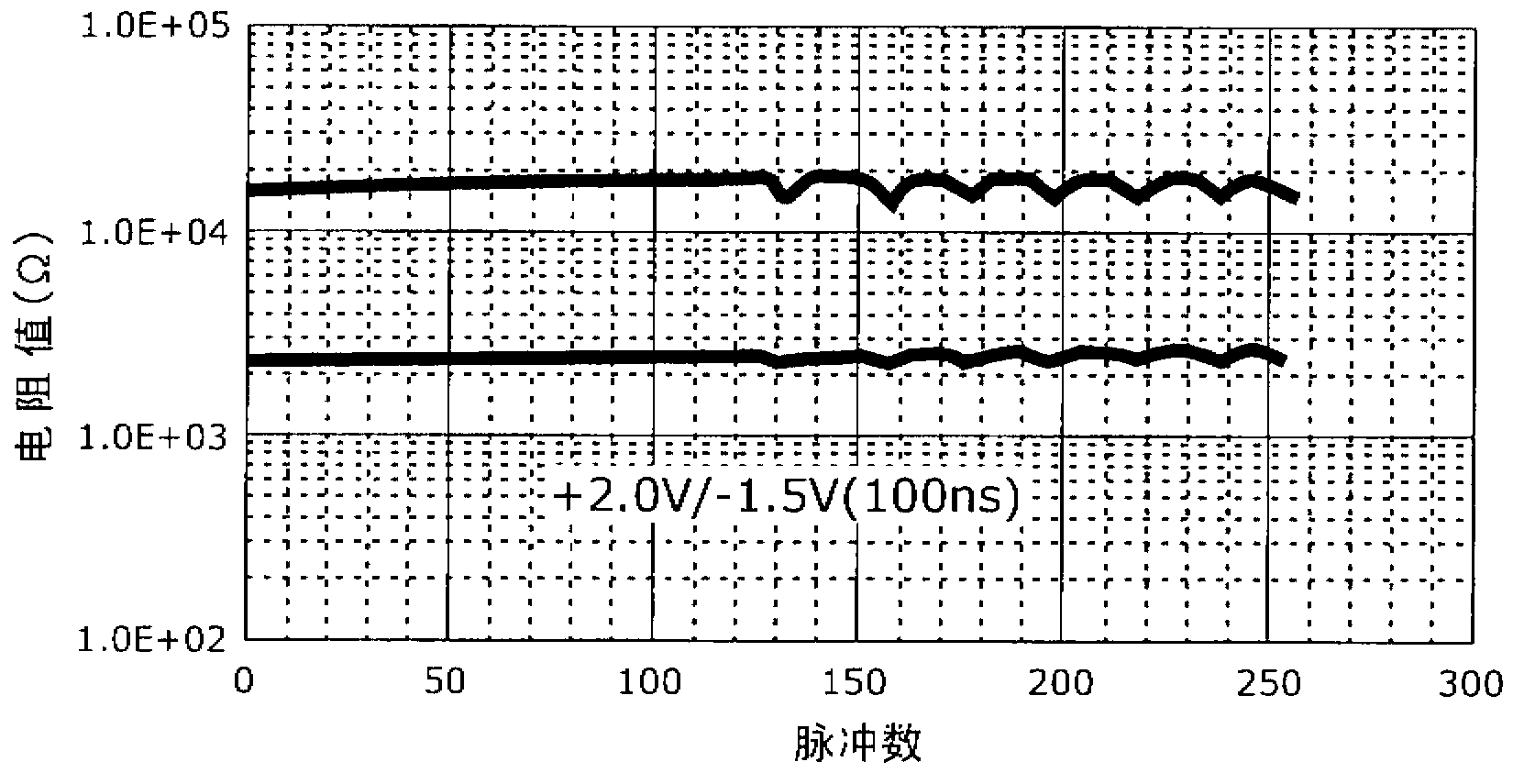

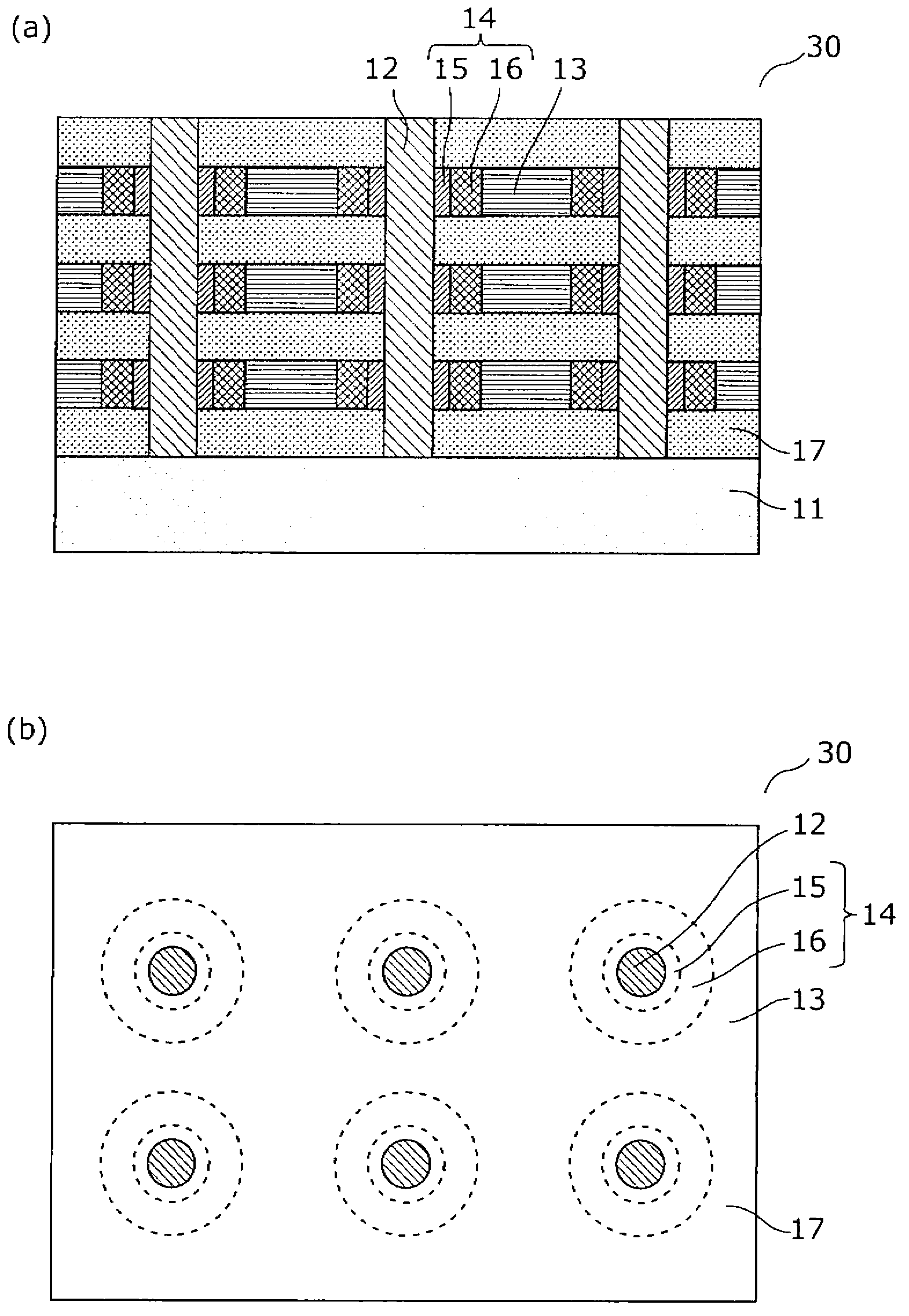

Method for manufacturing nonvolatile memory device, nonvolatile memory element, and nonvolatile memory device

ActiveCN102859690ASimplify the manufacturing processEasy to controlSolid-state devicesDigital storageGround layerMemory performance

Disclosed is a manufacturing method, whereby a nonvolatile memory device having a stable memory performance can be manufactured with a simple process. The method includes: a step wherein a laminated structure is formed by alternately laminating, on a substrate (11), a plurality of conductive layers (13) containing a transition metal, and a plurality of interlayer insulating films (17) composed of an insulating material; a step wherein a contact hole, which penetrates the laminated structure and exposes parts of the respective conductive layers (13) is formed; a step wherein the conductive layer (13) parts exposed in the contact hole are oxidized, and variable-resistance layers (14) wherein resistance values reversibly change on the basis of electrical signals transmitted thereto are formed; and a step wherein a conductive material is embedded in the contact hole, and a columnar electrode (12) connected to the variable-resistance layers (14) is formed in the contact hole.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

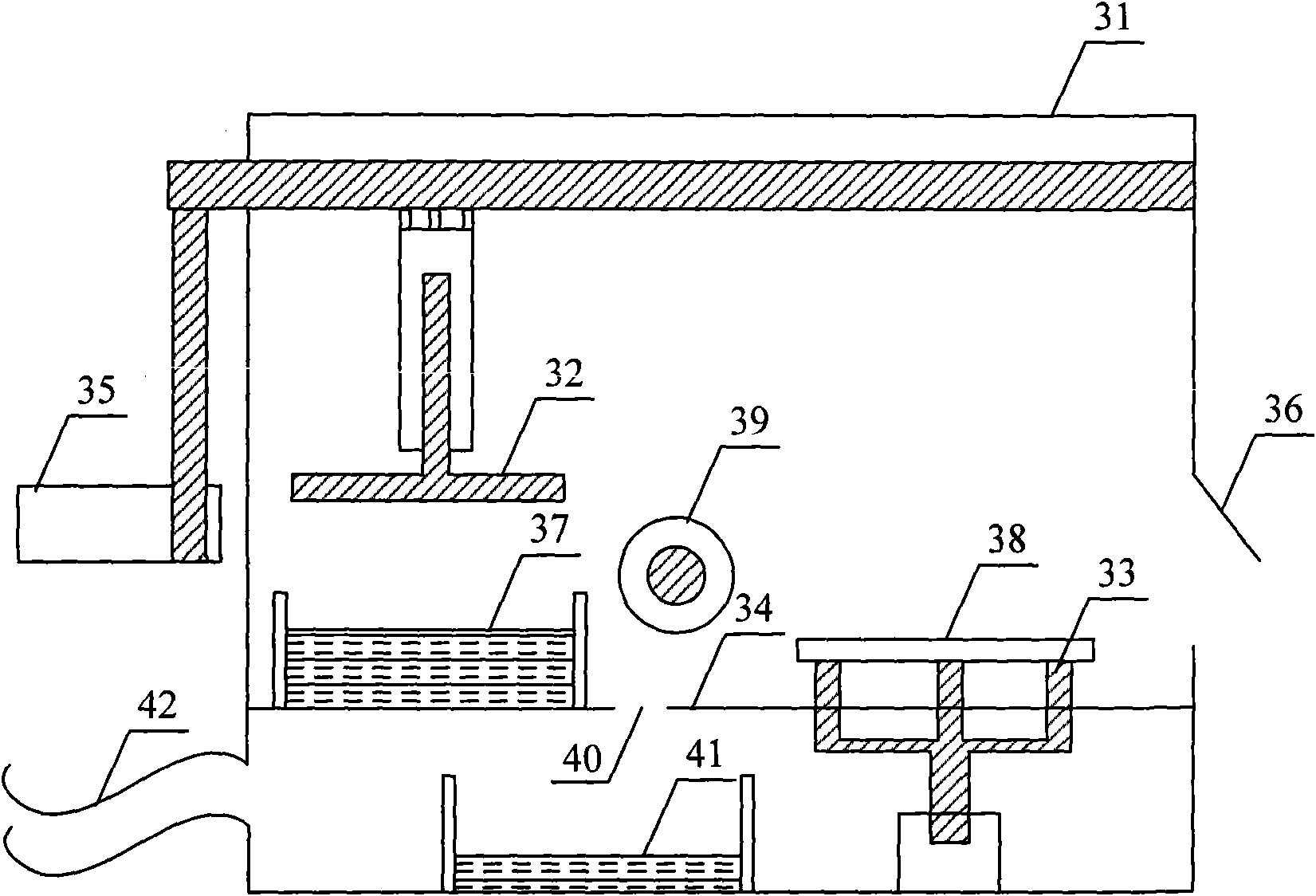

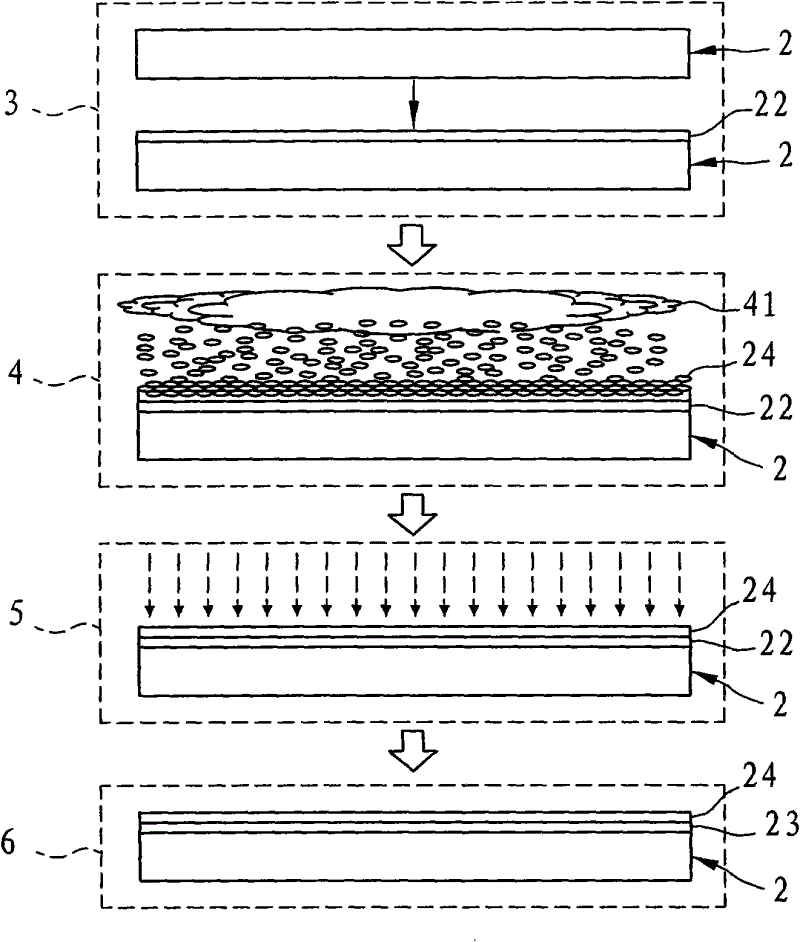

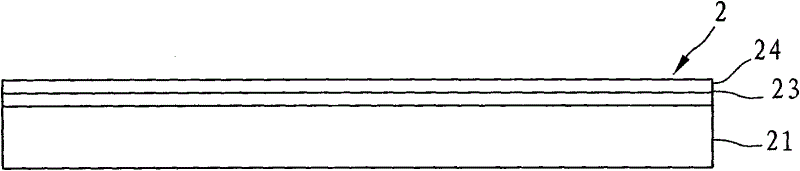

Composite plating manufacturing method of high-precision irregular grinding wheel

ActiveCN106584299AImprove wear resistanceHigh hardnessLiquid/solution decomposition chemical coatingGrinding devicesChemical platingGrinding wheel

The invention discloses a composite plating manufacturing method of a high-precision irregular grinding wheel. The manufacturing method comprises the following steps of preparing of a substrate and abrasives, treating before plating of the abrasives, preparing of a plating solution, treating before plating and preplating of the substrate, mould cavity abrasive grain dispensing, chemical plating thickening, passivating treatment after plating, testing and packing. The manufacturing method has the advantages that the compositely-plated grinding wheel has the characteristic of high profiling, and the consistency of abrasive molding surfaces reaches up to 95% or above; the height uniformity of the abrasives subjected to plating solidification is high, the abrasives can be used for grinding simultaneously to the largest extent, and machining efficiency is improved; and the shape preserving property is good, and the shape of the grinding wheel curve surface almost does not change under the continuous grinding condition, so that the grinding efficiency and the machining precision of the grinding wheel are guaranteed, and the service life of the grinding wheel is prolonged greatly.

Owner:郑州众邦超硬工具有限公司

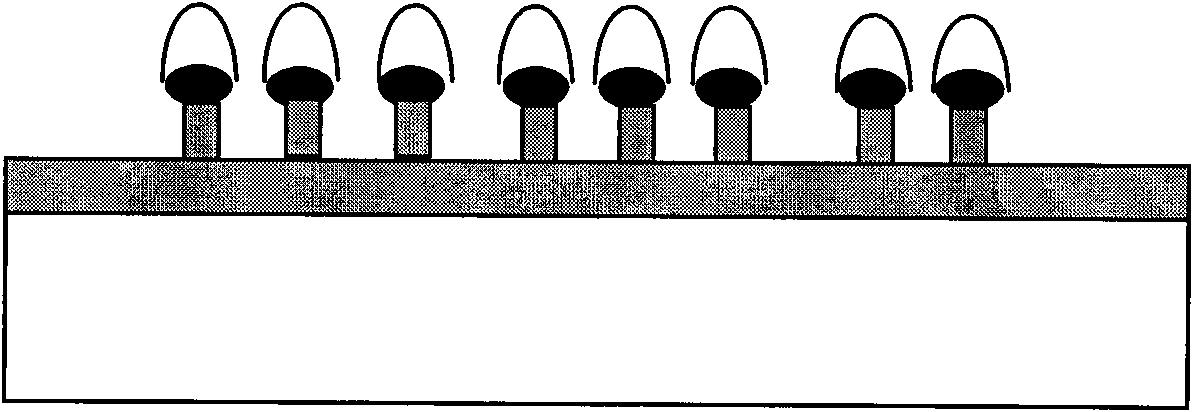

Flexible area light source, manufacturing method therefor, and electronic equipment

ActiveCN107093659AQuality improvementUniformity controllableStatic indicating devicesElectric circuit arrangementsEngineeringFluorescent light

The invention provides a flexible area light source, and the area light source comprises a flexible substrate, a plurality of LED chips, and a fluorescent layer. The plurality of LED chips are arranged on the surface of the flexible substrate in an ordered manner. The fluorescent layer is a prefabricated fluorescent film which covers the surface, equipped with the LED chips, of the flexible substrate. The LED chips are packaged in the fluorescent layer. The invention also provides a method for manufacturing the area light source, and electronic equipment employing the area light source. According to the invention, the area light source provided by the invention, the area light source manufactured through the method and the electronic equipment employing the area light source are good in bending performances, and are good in light emitting effect.

Owner:SHENZHEN LT OPTOELECTRONICS CO LTD

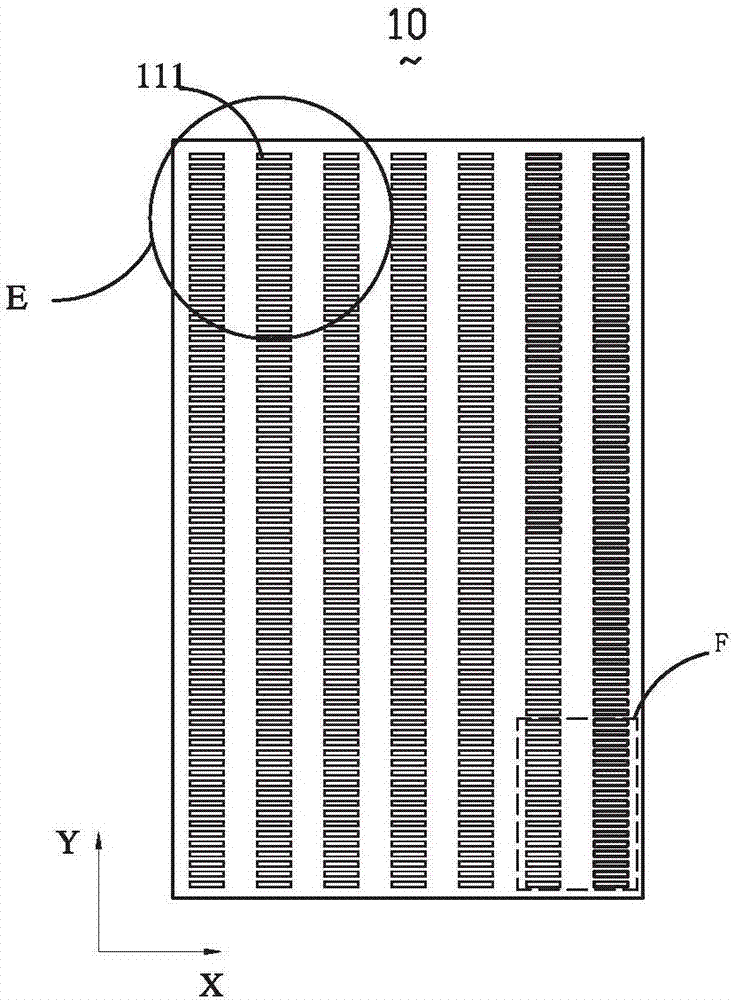

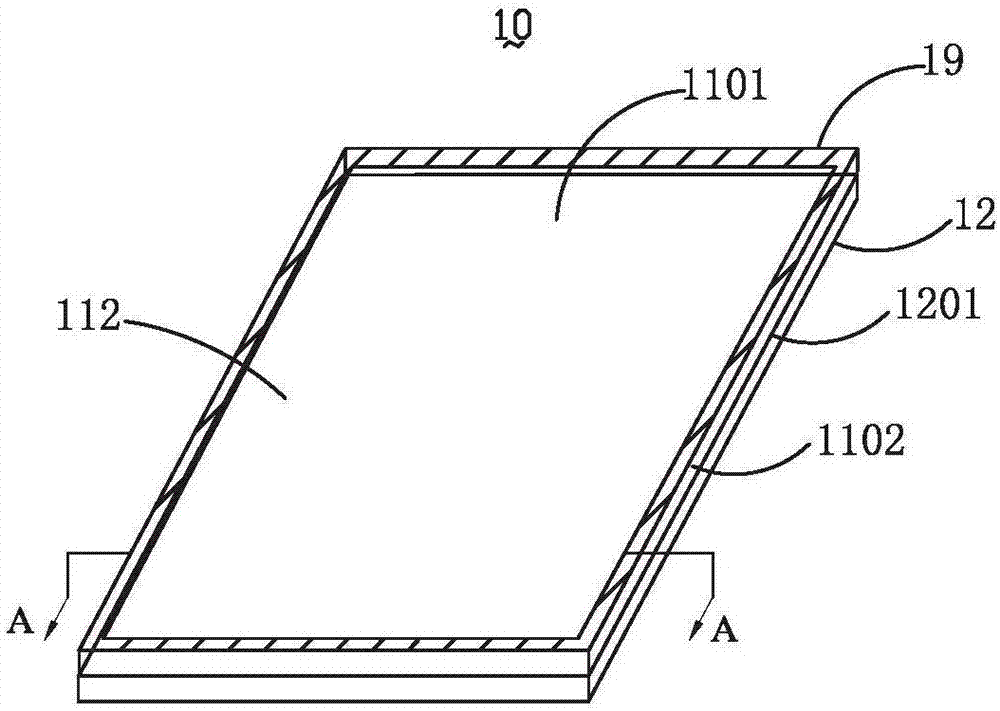

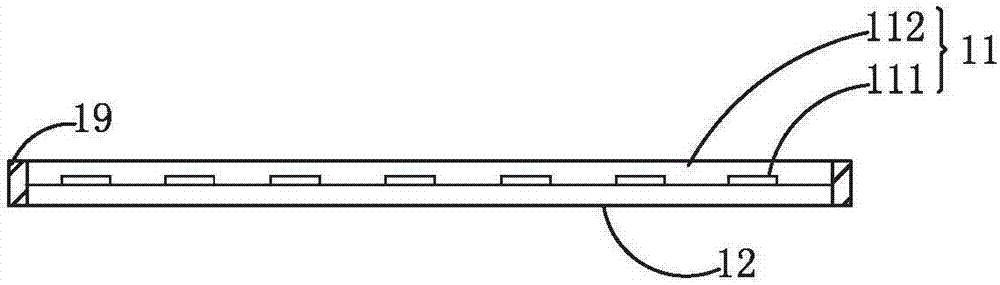

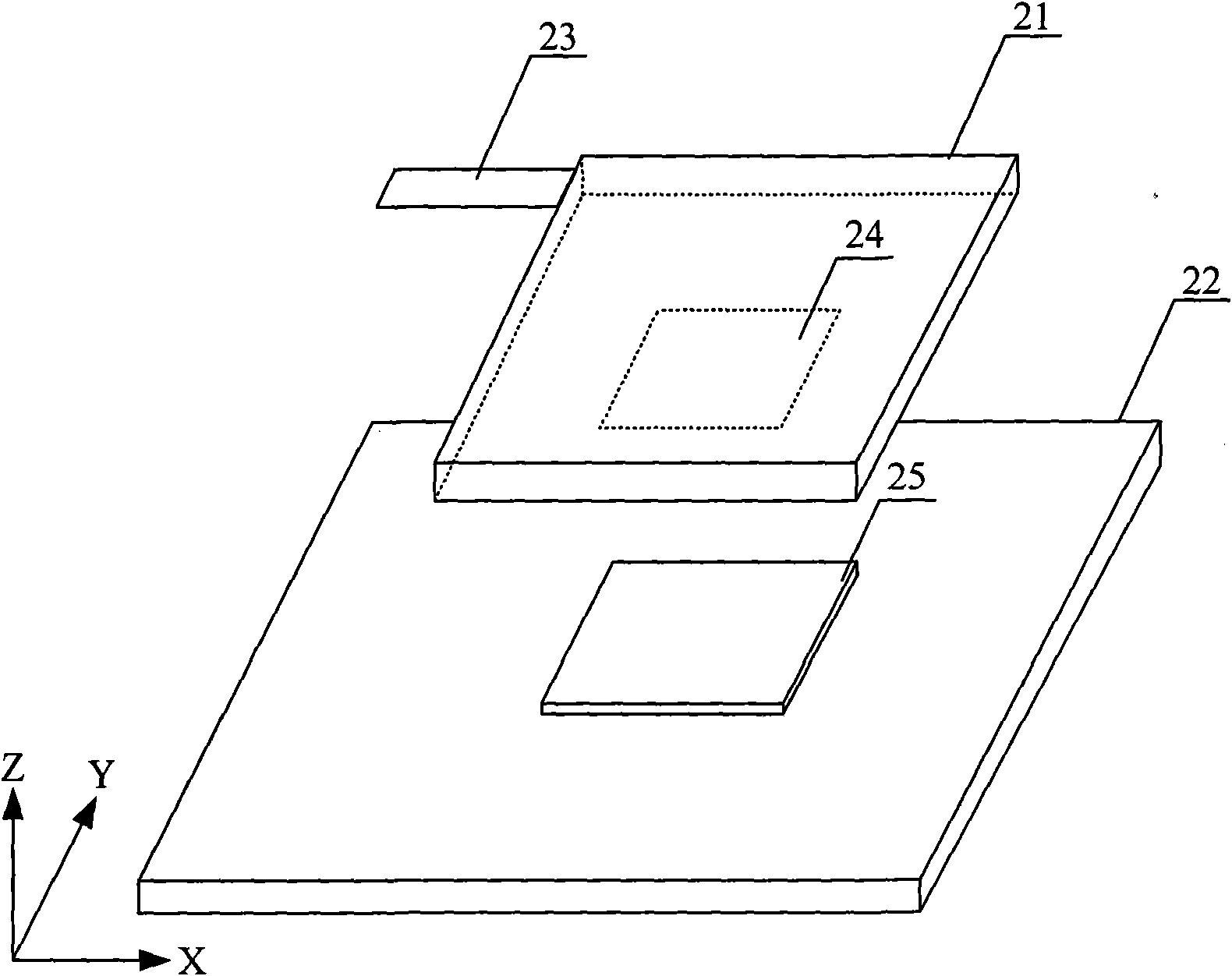

Method and device for attaching polarizer

InactiveCN101806971AEnsure consistencyUniformity controllableLamination ancillary operationsLaminationPolarizerLiquid-crystal display

The invention relates to a method and a device for attaching a polarizer. The device comprises absorption equipment, supporting equipment and power equipment, wherein the absorption equipment is used for absorbing first equipment; the supporting equipment is used for placing second equipment; an absorption plane of the absorption equipment is parallel to a supporting plane of the supporting equipment; the power equipment controls the absorption equipment and / or the supporting equipment to perform relative motion along the direction which is perpendicular to the absorption plane and the supporting plane, so the first equipment and the second equipment are attached; the first equipment is the polarizer and the second equipment is a liquid crystal display panel; and or the first equipment is the liquid crystal display panel and the second equipment is the polarizer. The method and the device for attaching the polarizer is characterized in that the uniformity of pressure applied to every area of the polarizer to be attached is easy to control, and the consistency of stress applied by the polarizer to be attached on the liquid crystal display panel in the X axis direction and the Y axis direction can be ensured.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

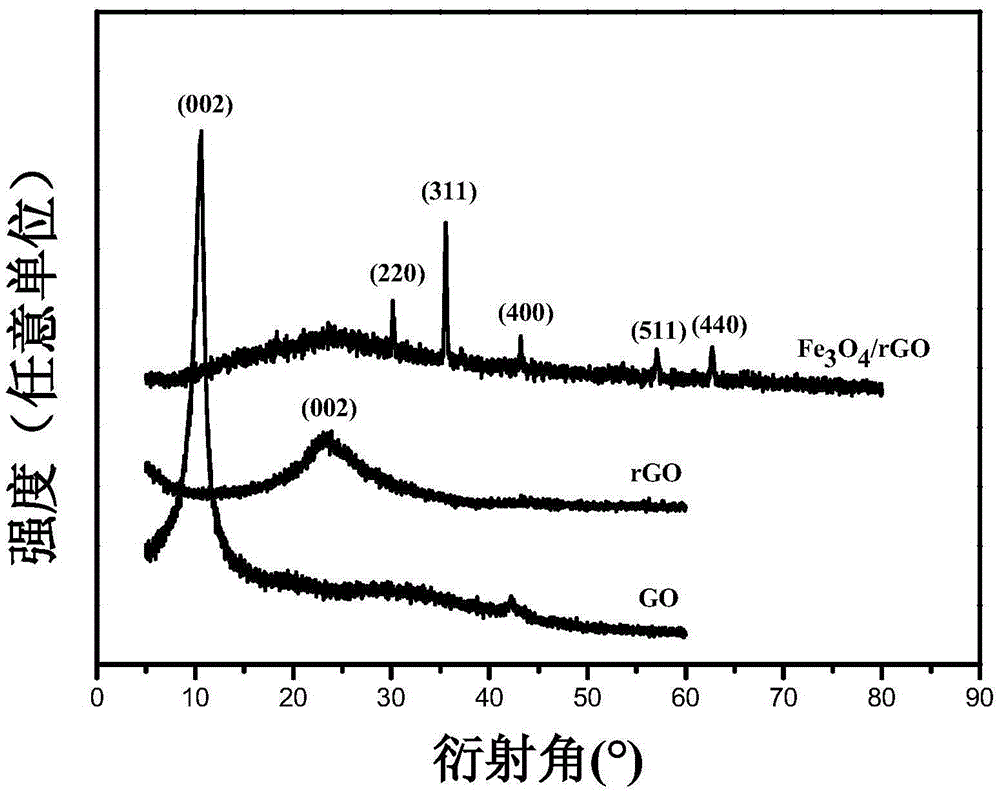

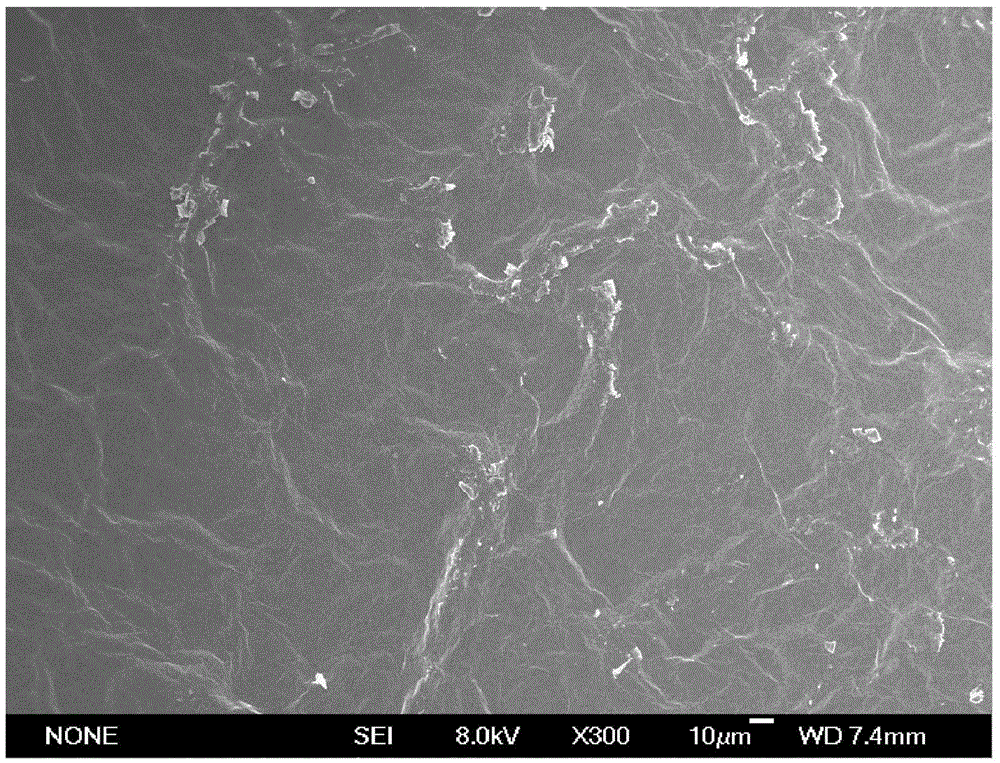

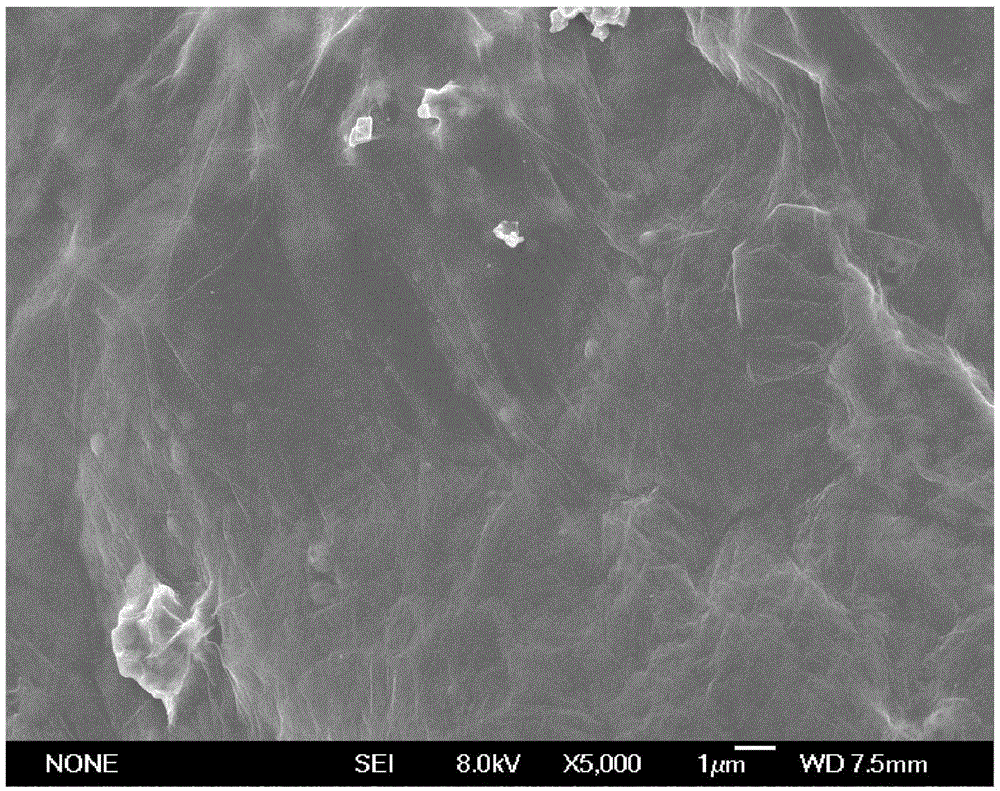

Preparation method of Fe<3>O<4>/graphene composite membrane

InactiveCN105609305ALow costUniformity controllableNanostructure applicationChemical vapor deposition applicationGrapheneElectron

The invention relates to a preparation method of an Fe<3>O<4> / graphene composite membrane. In summary, according to the method, by the process of mixing graphene oxide with Fe<3>O<4> nano-particles at a certain ratio to obtain a mixture solution, the Fe<3>O<4> / graphene composite membrane is prepared under drying and low-temperature stepped heating reduction conditions. The product prepared by the method is good in complex condition; the Fe<3>O<4> nano-particles are uniform to disperse; and the composite membrane has ferromagnetic property. The method disclosed by the invention is simple and easy to control; industrial production is facilitated; and the prepared self-supported composite membrane has a broad application prospect in the fields of information, electrons, energy, biology, military industry and the like.

Owner:JILIN UNIV

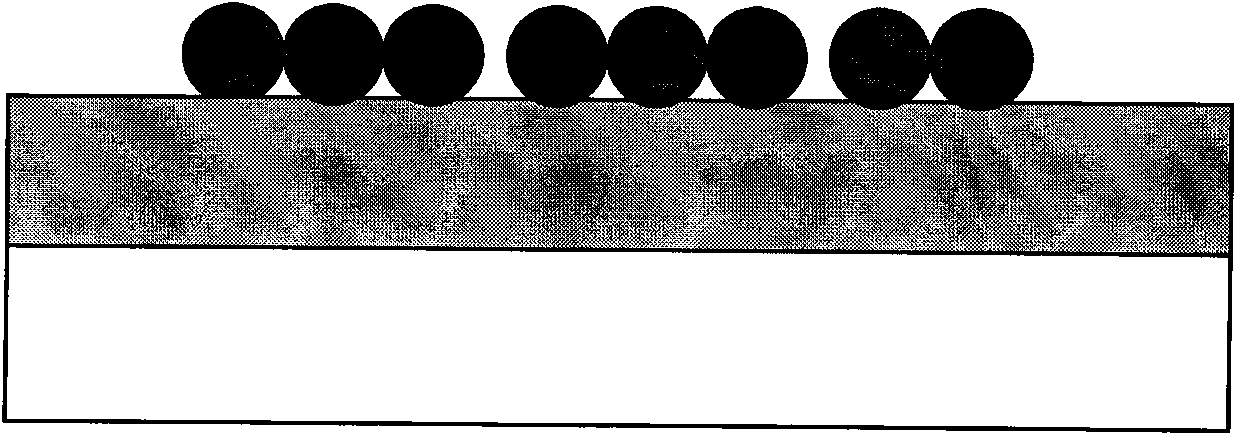

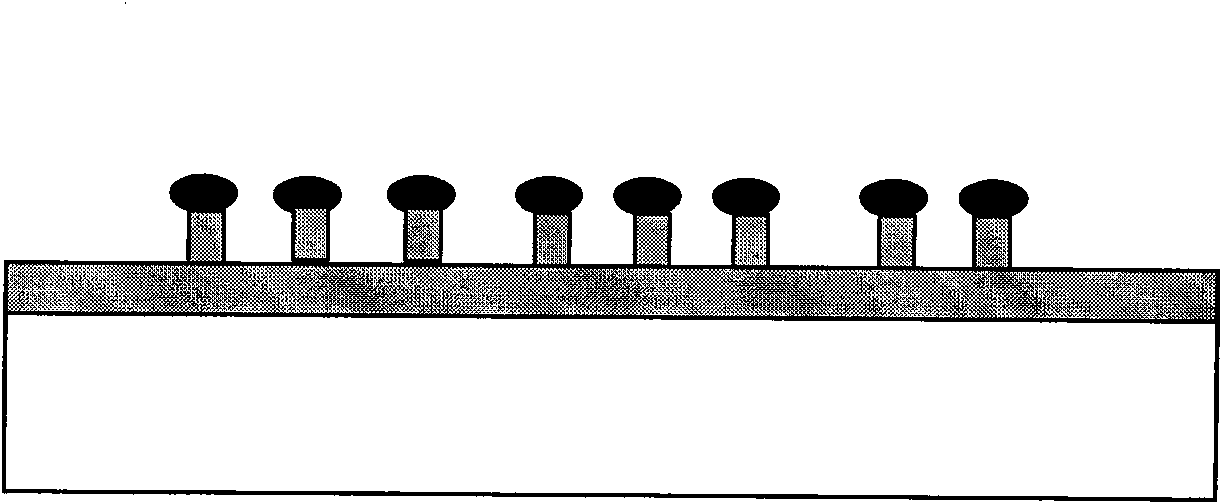

Method for preparing three-dimensional manometer load-type catalyst

InactiveCN101574670AEasy to makeSimple preparation processWater/sewage treatment by irradiationWater contaminantsNanometreDry etching

The invention relates to a method for preparing a three-dimensional manometer load-type catalyst, comprising the following steps of: (1) covering solution with nanosphere on a substrate evenly and drying; (2) using the nanosphere as a mask plate and adopting dry etching or wet corrosion based on different etching or corroding rate with the substrate; and (3) depositing a catalyst material. The method has simple process, low cost and is easy to be promoted and used. The scale of the catalyst carrier in the three-dimensional direction is within the nanometer magnitude and the body of the carrier has larger specific surface area so that the catalyst acts on large areas, and the catalyst materials are highly dispersed, easily recycled and can be reused.

Owner:DONGHUA UNIV

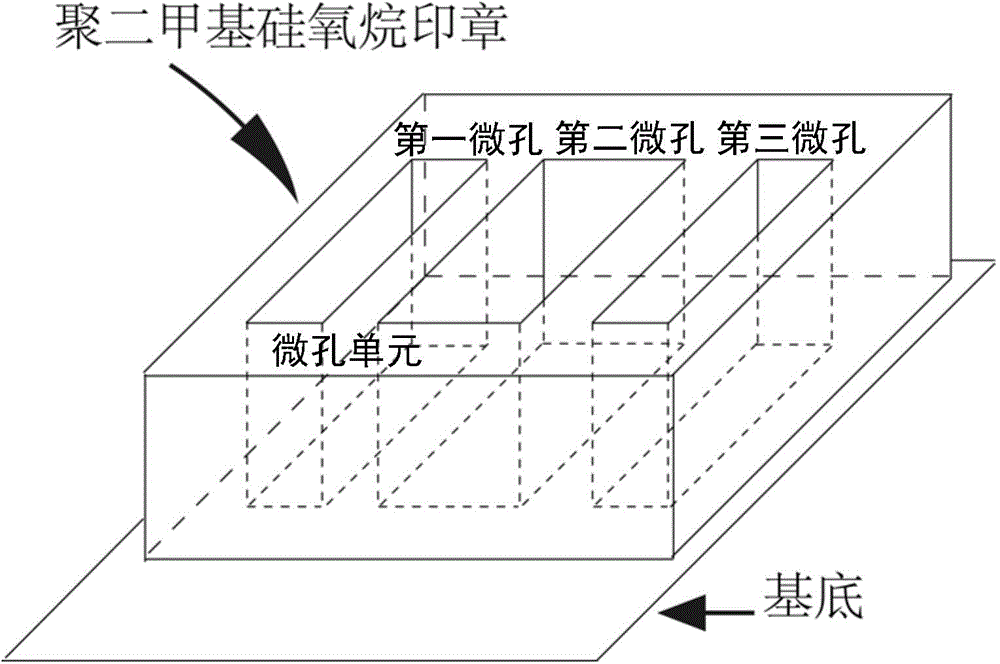

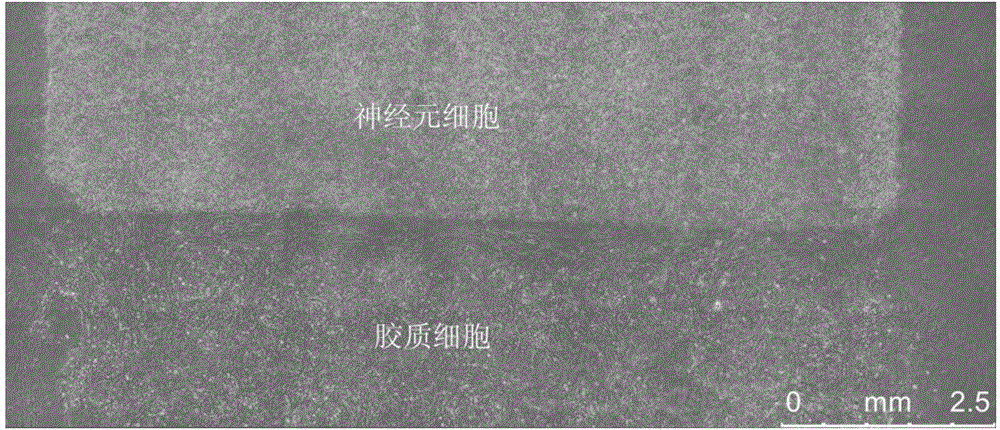

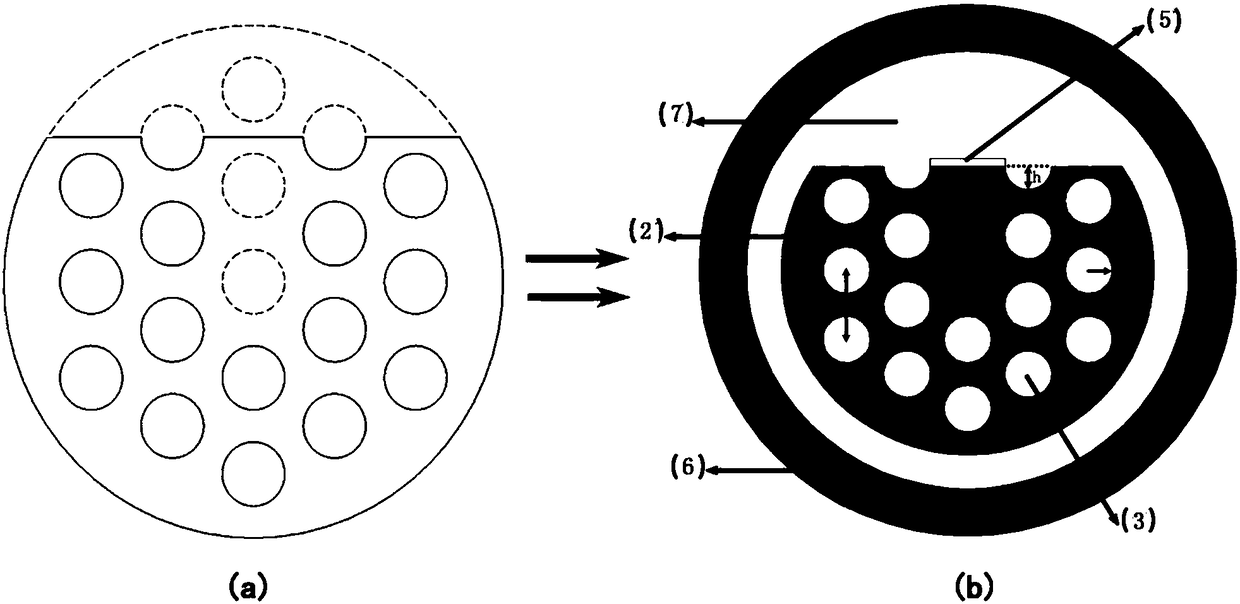

Neuronal and neuroglial cell ordered co-culture device and preparation method thereof, and neuronal and neuroglial cell ordered co-culture method

InactiveCN104130943AExtended interval between vaccinationsUniformity controllableNervous system cellsCell culture supports/coatingNeuronPolydimethylsiloxane

The invention relates to the cytobiology field, and discloses a neuronal cell and neuroglial cell ordered co-culture device and a preparation method and an application thereof. The device includes a substrate and a polydimethylsiloxane stamper, wherein the polydimethylsiloxane stamper can be removably compounded on the substrate; the polydimethylsiloxane stamper includes at least one micropore unit, the micropore unit includes at least one first through hole perpendicular to the substrate and at least one second through hole perpendicular to the substrate, the first through hole and the second through hole are arranged successively, and the first through hole and the second through hole respectively with the surface of the substrate form grooves having one end with an opening; the distance between the first through hole and the second through hole is 500 [mu]m-2000 [mu]m. Neuronal cells and neuroglial cells are inoculated through the first through hole and the second through hole which are perpendicular to the substrate, uniformity of the two kinds of cells is easy to control during inoculation in regions, cell quantity which can be used is increased, a population effect is obvious, and observation and study are facilitated.

Owner:民航总医院 +1

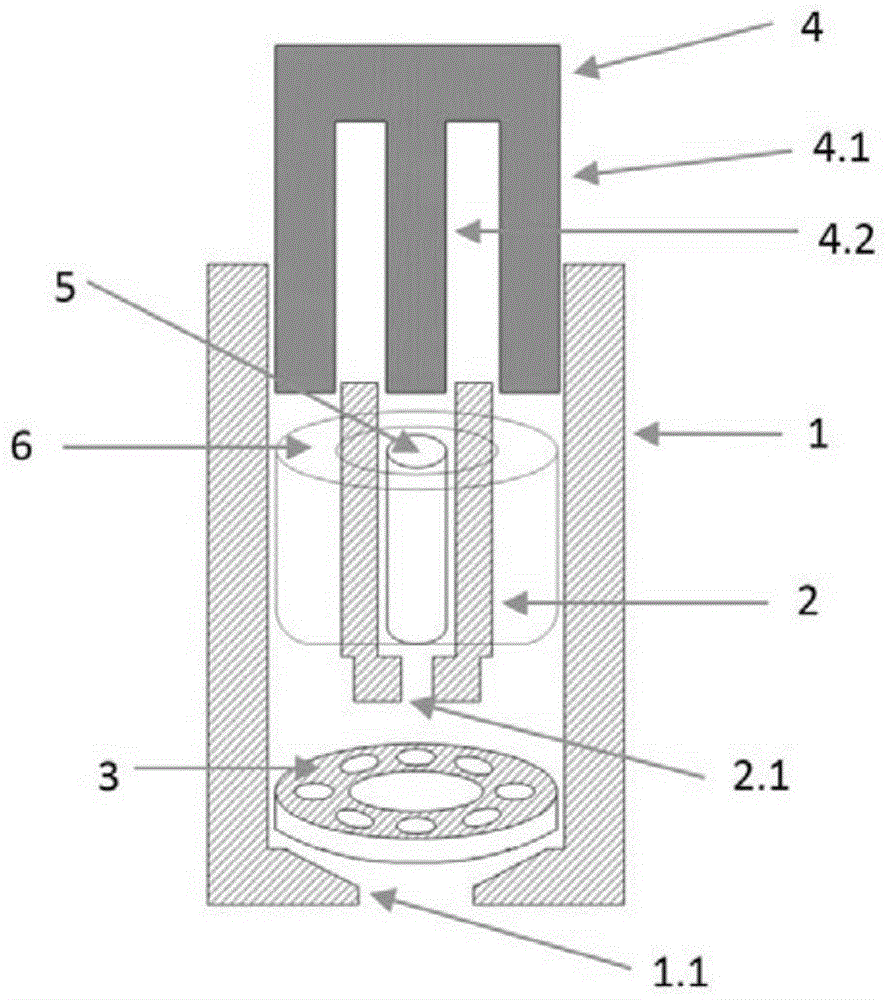

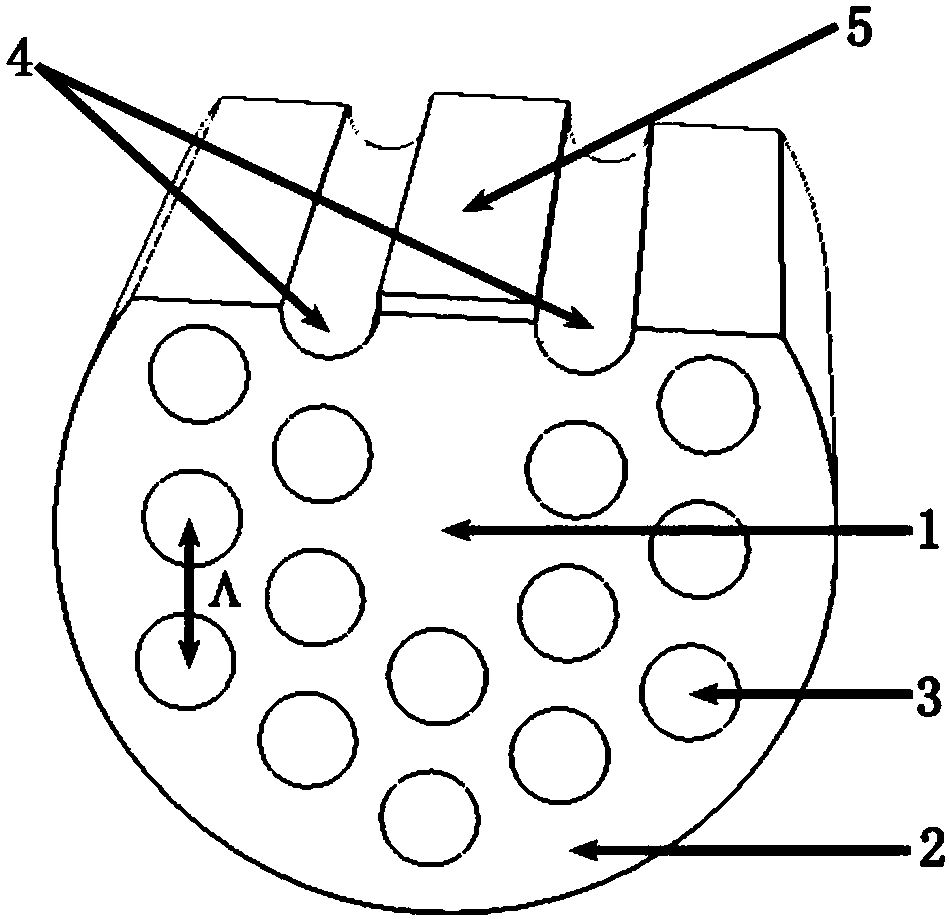

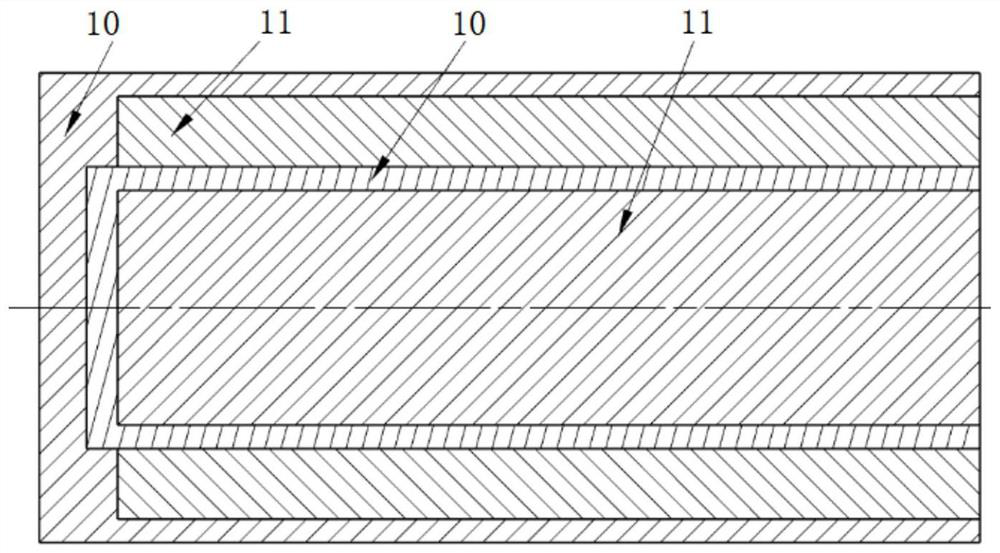

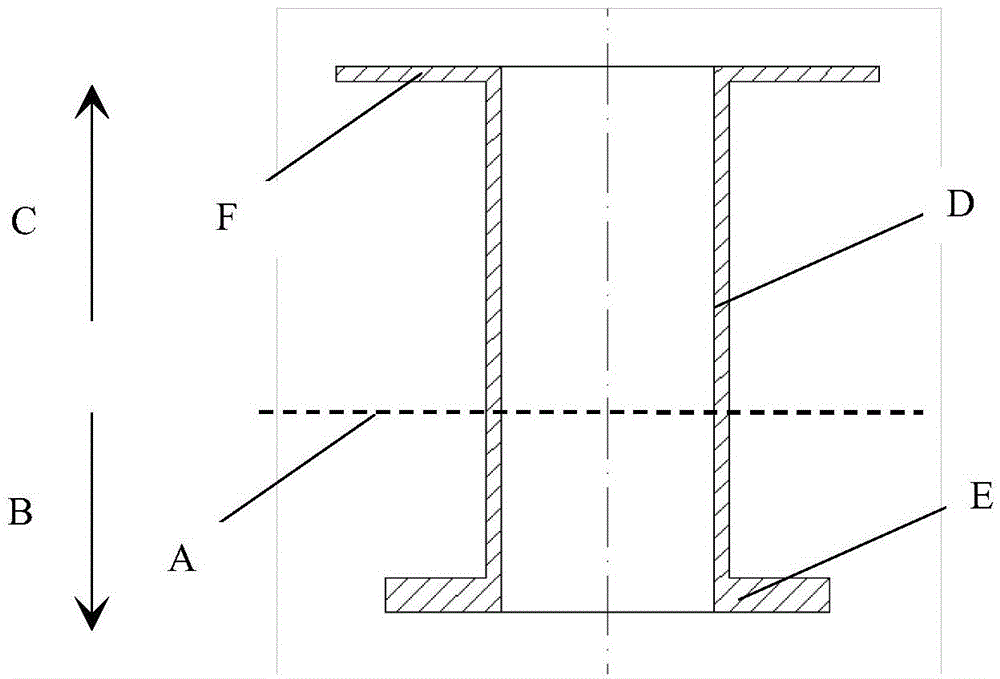

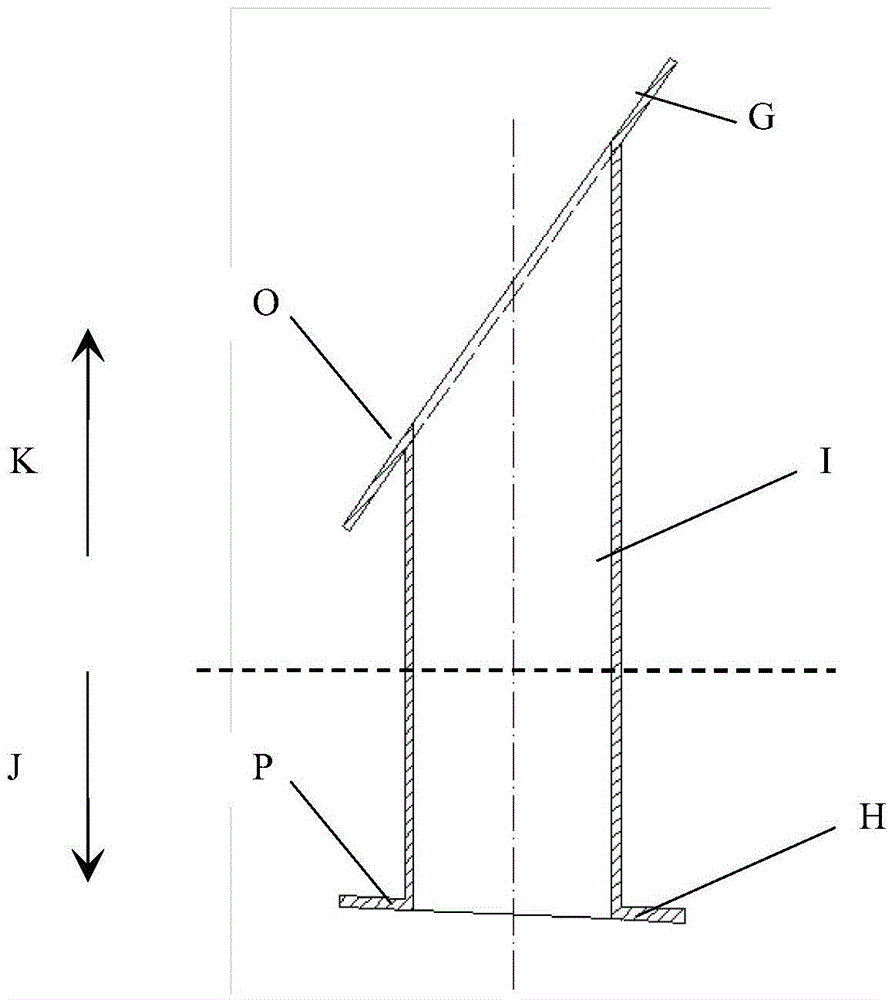

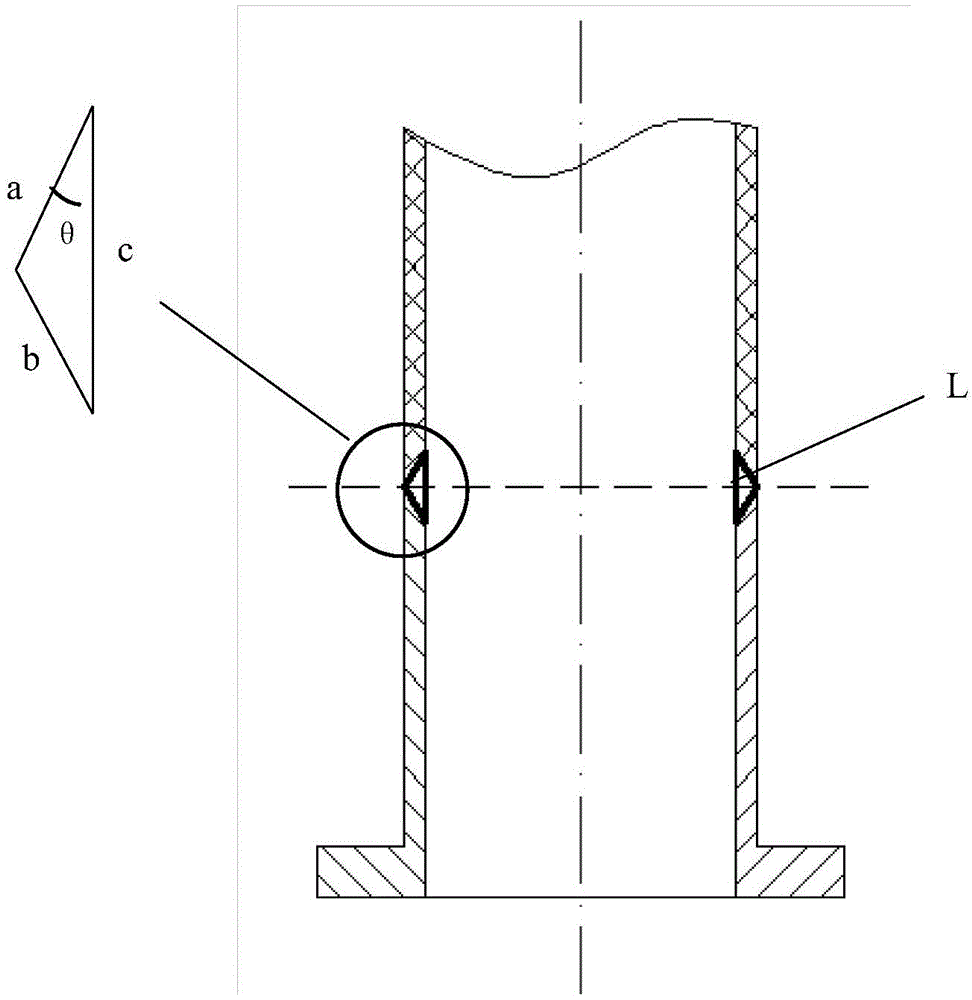

Double-sleeve extrusion die for extruding chalcogenide glass optical fiber preform rod and use method

ActiveCN104817263AUniformity controllablePrecise Control of UniformityGlass making apparatusChalcogenide glassEngineering

The invention discloses a double-sleeve extrusion die for extruding a chalcogenide glass optical fiber preform rod and a use method. The double-sleeve extrusion die comprises an outer sleeve, an inner sleeve, a splitter and a piston, wherein the inner sleeve is positioned in the outer sleeve, an outer sleeve nozzle and an inner sleeve nozzle are arranged at the bottoms of the outer sleeve and the inner sleeve respectively, the splitter is provided with a circular plate with a plurality of through holes, the through holes include a center hole and a plurality of peripheral holes formed in the periphery of the center hole, the splitter is arranged at the bottom of the outer sleeve, the inner sleeve nozzle is inserted into the center hole in the splitter, an annular groove matched with the inner sleeve is formed in the piston, so that the piston is right arranged in annular cavity between the outer sleeve and the inner sleeve and an inner cavity of the inner sleeve. The double-sleeve extrusion die can extrude chalcogenide glass optical fiber preform rods with the specific core package proportion and a shape of a specific core clad shape.

Owner:XUZHOU NORMAL UNIVERSITY

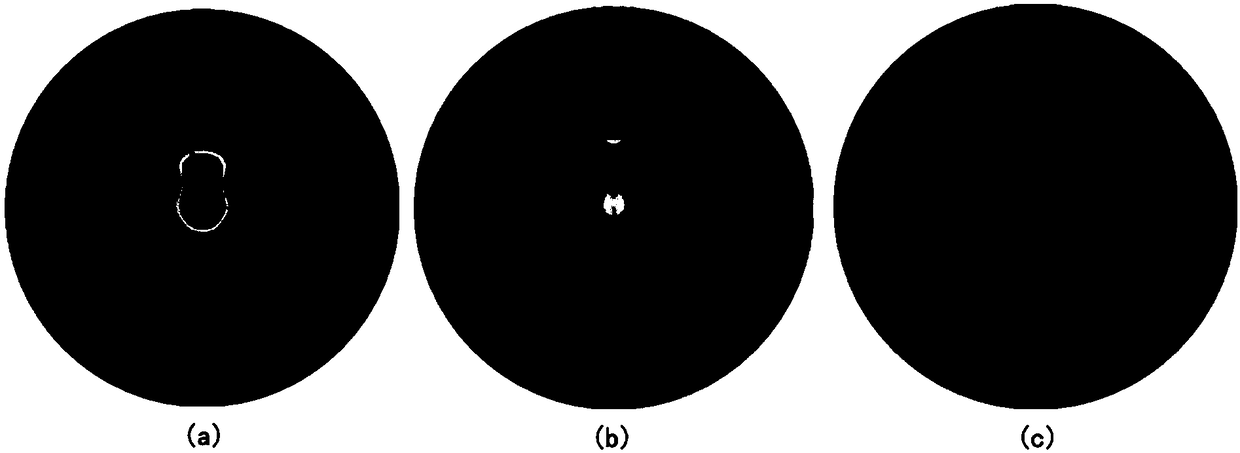

Microstructure optical fiber

PendingCN108088798AHigh Sensitivity Sensing CharacteristicsImprove sensing characteristicsPhase-affecting property measurementsFiberGold film

The invention discloses a microstructure optical fiber. The microstructure optical fiber is mainly prepared from a fiber core, a background material, a cladding layer air hole and a nano-gold film, wherein the background material is attached on the fiber core; the optical fiber is of a spherical crown shaped structure; the optical fiber with the spherical crown shaped structure is obtained by uniformly arraying inner and outer layers of air holes to form a cylindrical optical fiber with a regular hexagonal lattice structure and polishing a side face of the cylindrical optical fiber, wherein two holes in the air holes of the outer layer are located at a plane section of the spherical crown shaped optical fiber and form two semicircular groove body openings; a fluid channel is formed by thesemicircular groove body openings; the nano-gold film is deposited on the plane section of the spherical crown shaped optical fiber located between the two semicircular groove body openings; the two semicircular groove body opening, the air holes of the inner layer and the gold film are used for surrounding a fiber core region. The microstructure optical fiber disclosed by the invention has the advantages of simple structure, high sensing flexibility and the like.

Owner:YANSHAN UNIV

Graphene test paper and preparation thereof and liquid analyzing method based on test paper

ActiveCN107024510ALarge specific surface areaImprove conductivityMaterial resistanceEngineeringSolvent

The invention relates to graphene test paper and preparation thereof and a liquid analyzing method based on the test paper, and belongs to the technical fields of liquid sensing elements and liquid analyzing. The test paper comprises a film substrate, a thin film structure and a contact electrode, wherein the thin film structure is formed by stacking graphene layer sheets and is tightly bonded with the film substrate; an auxiliary film forming agent and chemical sniffing molecules are attached to each graphene layer sheet. The preparation method comprises the following steps of dispersing the graphene layer sheets, the auxiliary film forming agent and the chemical sniffing molecules into a solvent, so as to prepare graphene conductive ink; depositing the graphene layer sheets in the graphene conductive ink onto the film substrate, and then setting the contact electrode, so as to obtain the graphene test paper with good strength, flexibility and chemical sensitivity. The liquid analyzing method using the test paper is used for analyzing multiple types of liquids, such as organic solvent, salt solutions and beverages, and has the advantages that the demand amount of samples is small, the detection time is short, the manufacturing cost of instruments and reagents is low, and the like.

Owner:TSINGHUA UNIV

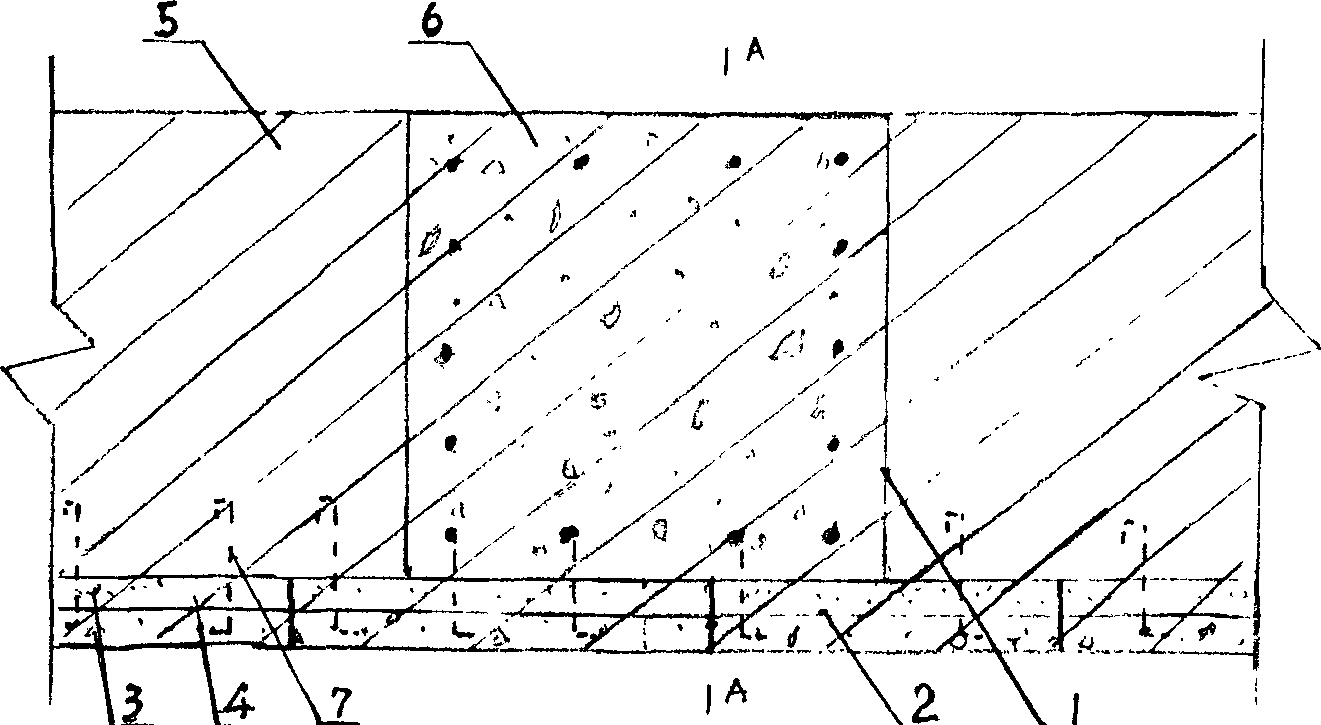

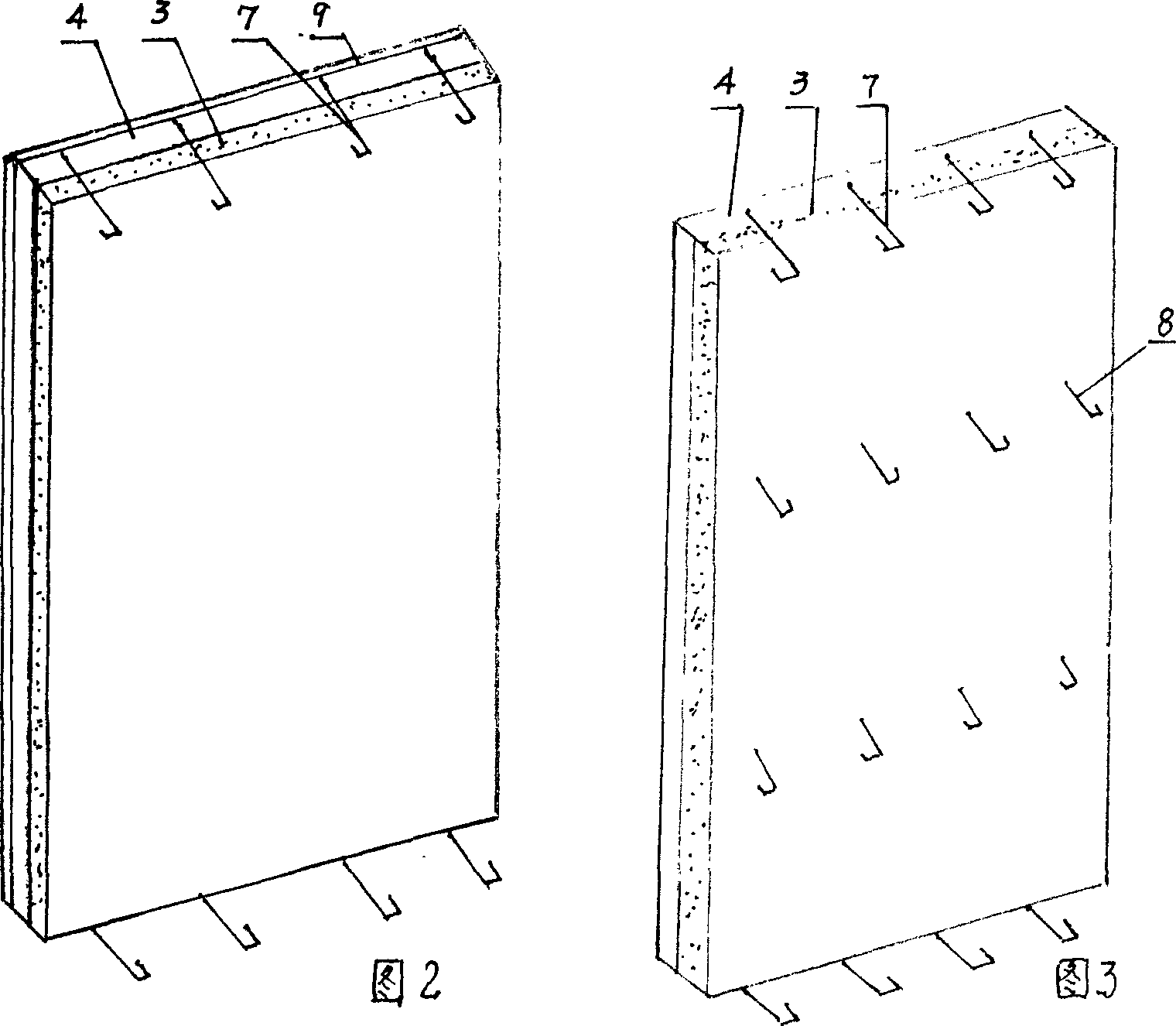

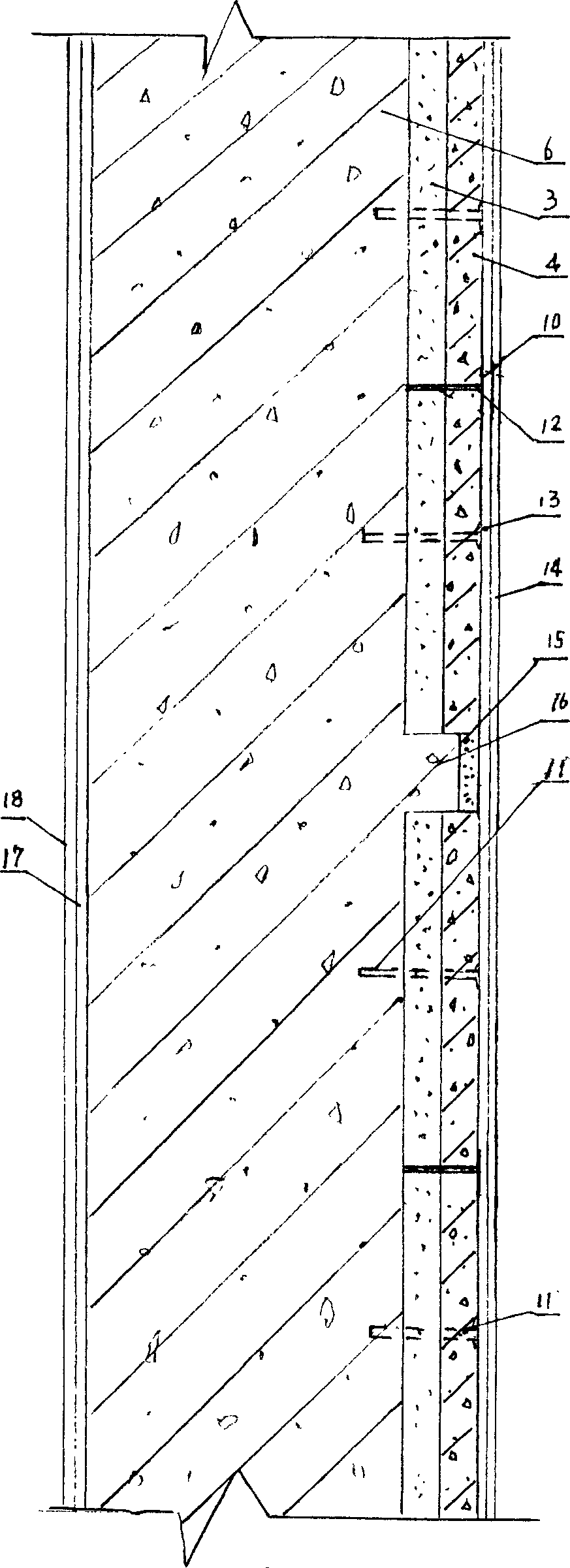

Energy saving composite self heat insulation wall for building

ActiveCN1858377AWon't breakThickness is easy to controlCovering/liningsWallsSurface layerElectrical and Electronics engineering

The energy saving building wall structure includes a base wall and a prefabricated composite heat insulating board layer fixed outside the base wall. The prefabricated composite heat insulating board layer is spliced with prefabricated composite heat insulating boards comprising concrete board and heat insulating board adhered together. The present invention has the advantages of low cost, low service life and less bubble, crack and peeling off in the surface layer, and is suitable for different areas.

Owner:单锦春

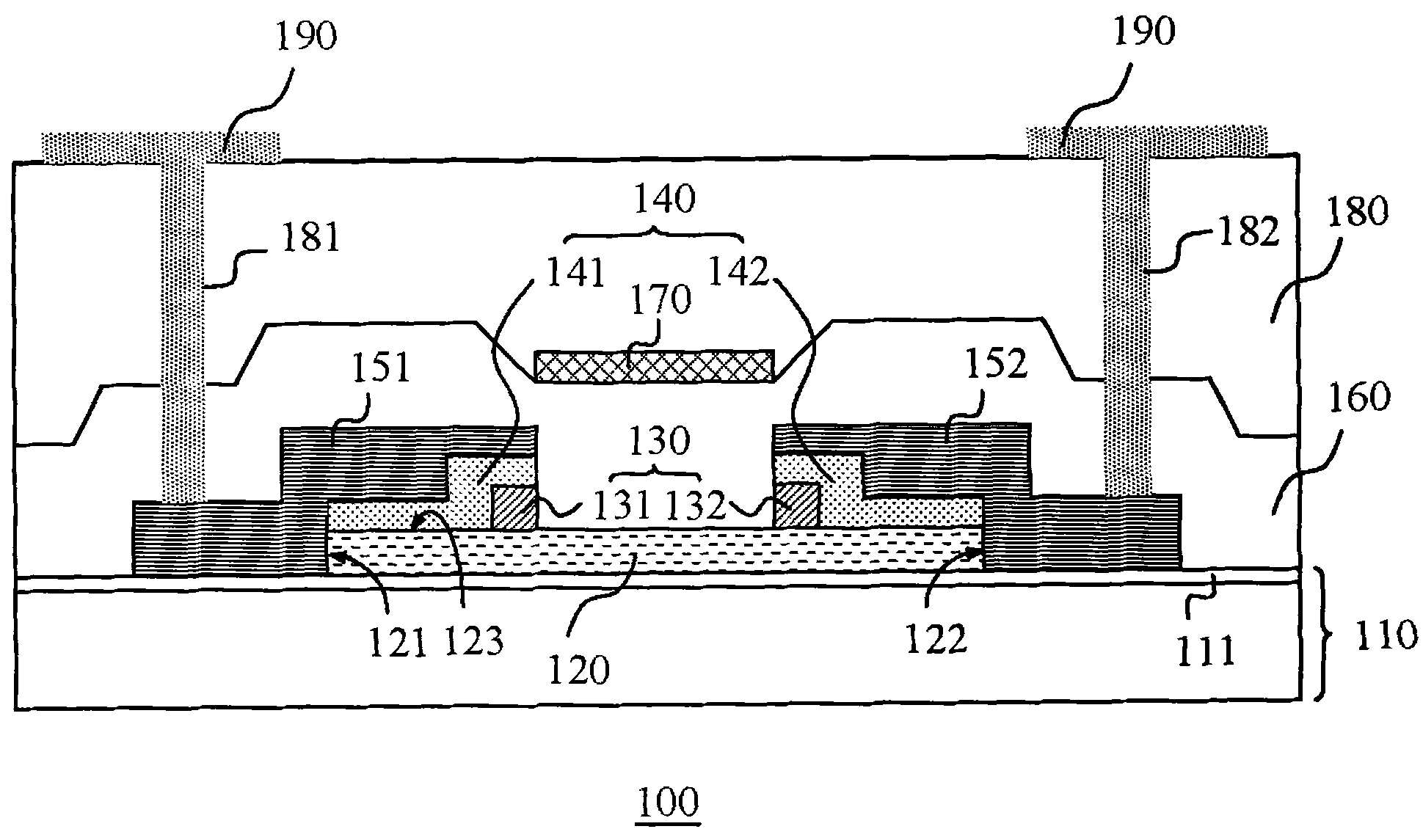

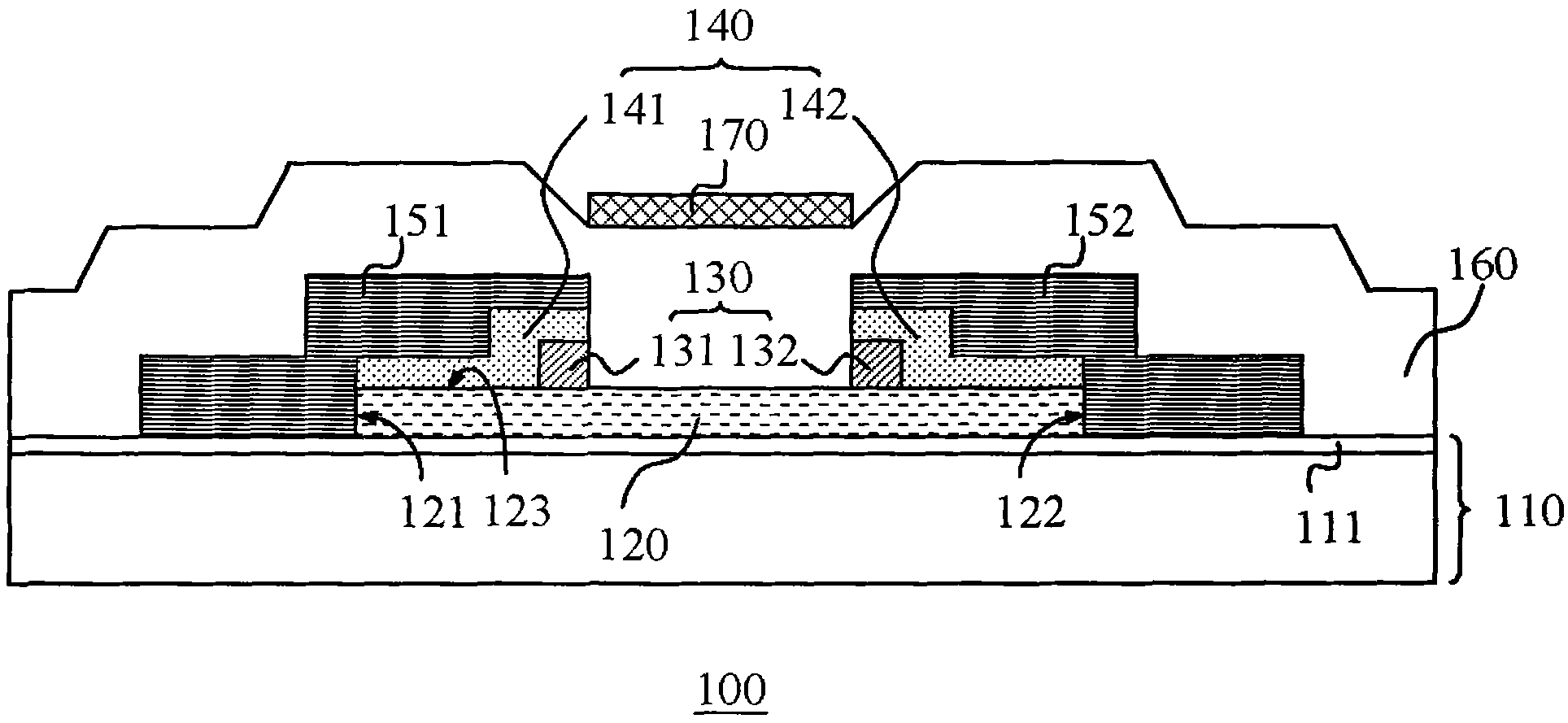

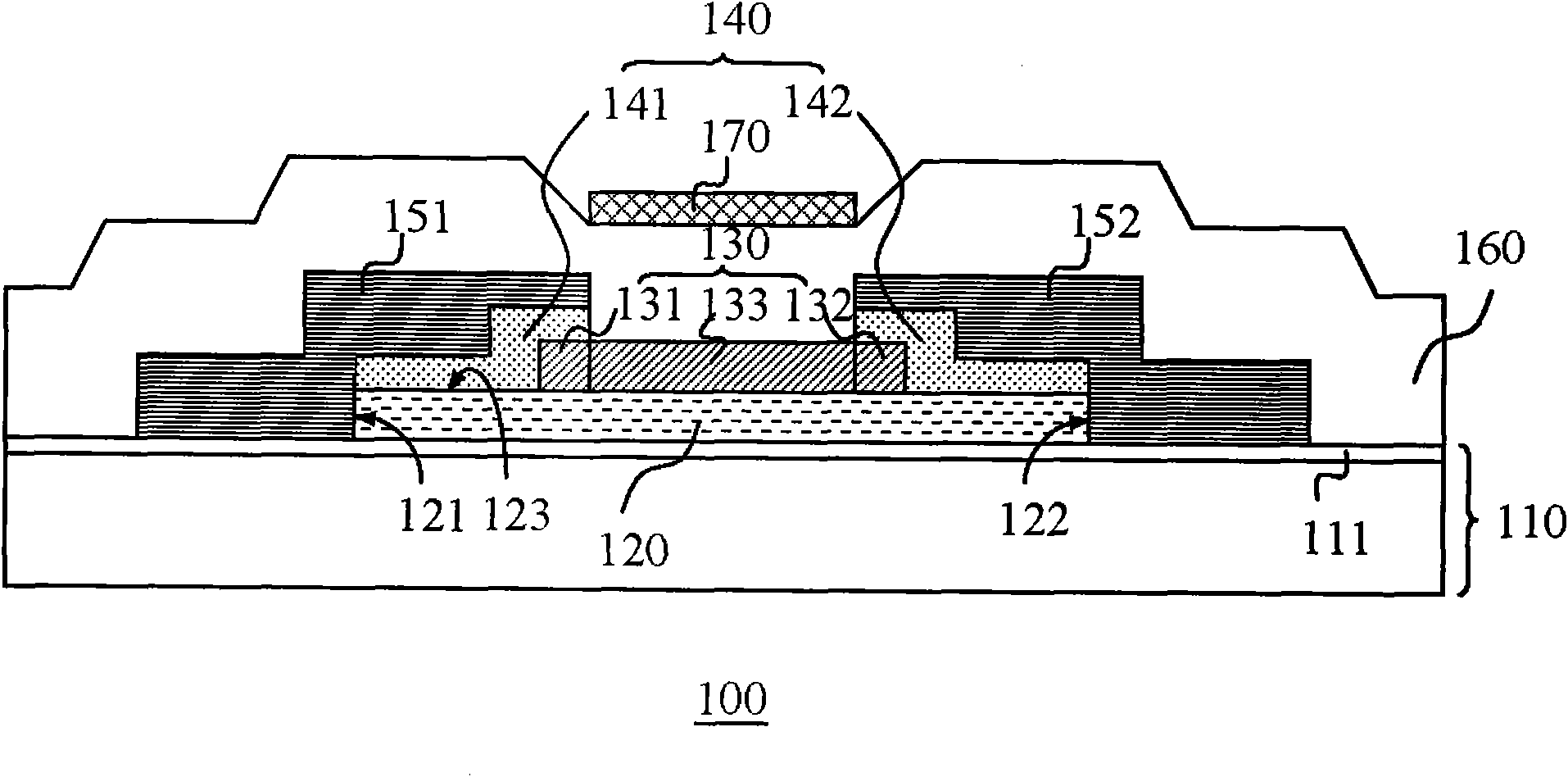

Transistor structure with etch stop layer and manufacturing method thereof

ActiveCN101976685AUniformity controllableImprove reliabilityTransistorSemiconductor/solid-state device manufacturingOhmic contactEngineering

The invention discloses a transistor structure with an etch stop layer and a manufacturing method thereof. The transistor structure of the invention is at least composed of a substrate, a crystallized semiconductor layer, an etch stop structure, an ohmic contact layer, a resource electrode, a drain electrode, a grid electrode insulating layer and a grid electrode. The manufacture method of the invention can simultaneously pattern the ohmic contact layer and the crystallized semiconductor layer by the same photomask or can simultaneously pattern the ohmic contact layer and an electrode layer by the other identical photomask.

Owner:AU OPTRONICS CORP

Film forming device and method

ActiveCN104711514AThe deposition rate is easy to controlFast depositionVacuum evaporation coatingSputtering coatingEngineeringDeposition process

The invention provides a film forming device and method. The device is used for forming an organic material film on a target position of a substrate and comprises a gas conveying mechanism and a gas injection mechanism, wherein the gas conveying mechanism is used for conveying a mixed gas of vapor of an organic material and an inert gas to the gas injection mechanism; the gas injection mechanism is used for injecting the mixed gas conveyed by the gas conveying mechanism to the target position on the substrate. The method comprises the following steps: conveying the mixed gas of vapor of the organic material and the inert gas to the target position on the substrate by using the film forming device provided by the invention, in order to deposit the organic material on the target position, wherein in the deposition process, the flow rate of the mixed gas at the early deposition stage of the organic material is smaller than the flow rate of the mixed gas at the middle deposition stage. Due to the film forming device and method provided by the invention, the film forming process of the organic material by deposition is easy to control, and target substrates with most sizes are applicable.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Semiconductor silicon wafer corrosive liquid and corrosion method thereof

InactiveCN106024675AReduce damageEasy to controlSemiconductor/solid-state device manufacturingMicroelectronicsCorrosion

The invention relates to the technical field of microelectronic processing and especially to a semiconductor silicon wafer corrosive liquid. The semiconductor silicon wafer corrosive liquid is formed by mixing nitric acid, hydrofluoric acid, and glacial acetic acid according to a volume ratio of 4-14: 4-14: 6-18. A semiconductor silicon wafer is placed in a closed container containing the semiconductor silicon wafer corrosive liquid in order to be corroded on a low-temperature condition. Different corrosion demands are satisfied by regulating the ratio of the nitric acid to the hydrofluoric acid. The corrosion rate and the corrosion depth of the semiconductor silicon wafer, and the surface cleanliness of the corroded semiconductor silicon wafer can be controlled on the low-temperature condition. The corrosion rate at a low-temperature environment is less than that at a normal-temperature environment, so the corrosive uniformity of the semiconductor silicon wafer is easier to control. The semiconductor silicon wafer corrosive liquid is easy to form, attainable in raw material, low in cost, and very suitable for industrial production of semiconductor microelectronics.

Owner:江苏佑风微电子有限公司

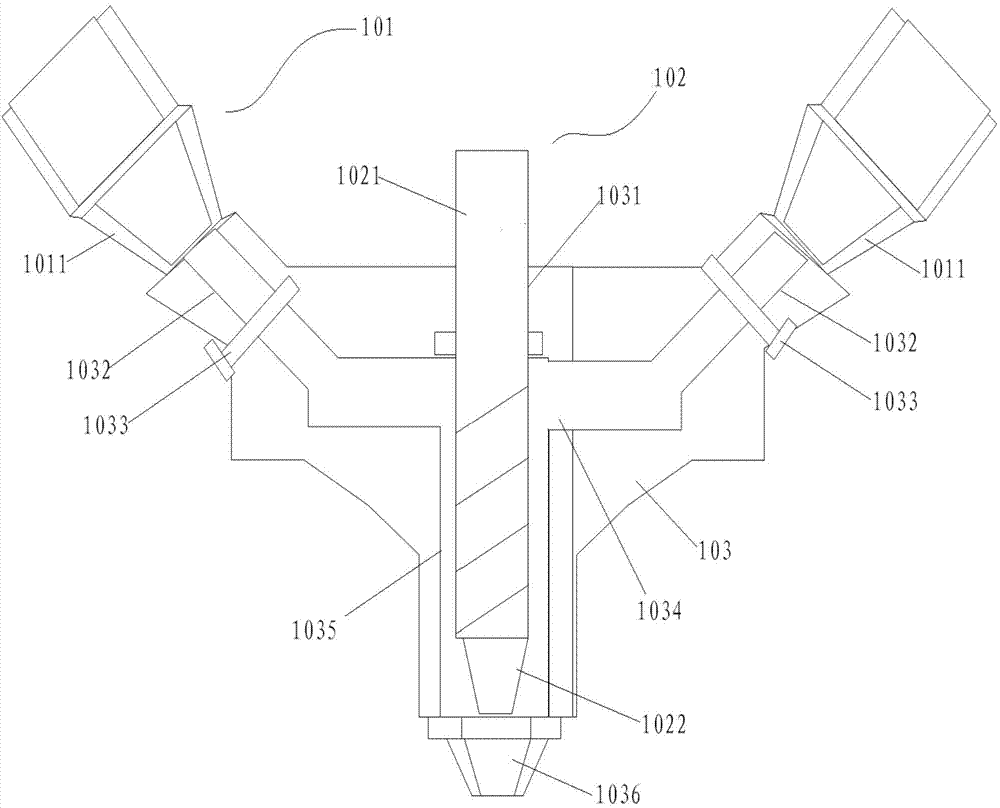

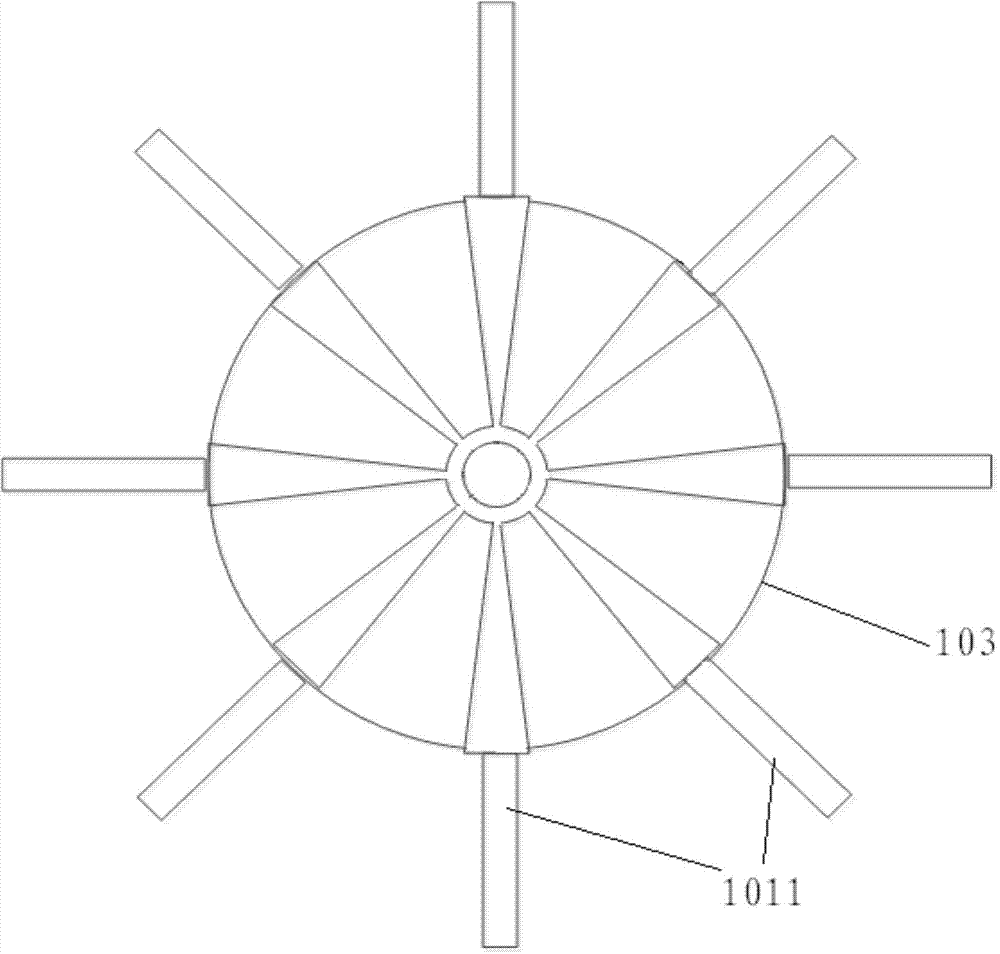

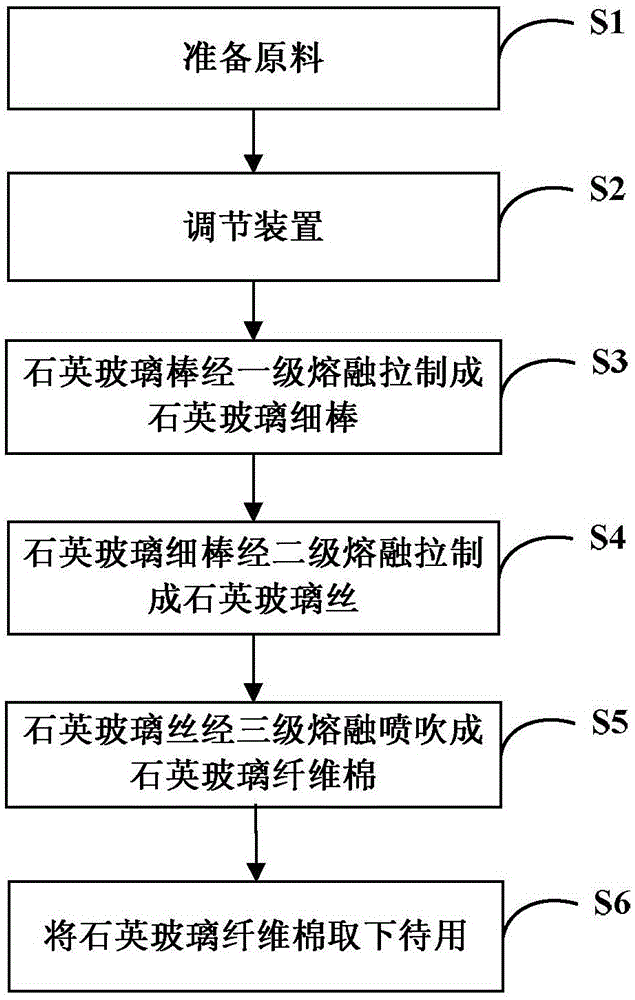

High temperature-resistant ultrafine quartz glass fiber cotton and preparation method thereof

ActiveCN105130183AImprove heat resistanceMeet the requirements for high-temperature service environmentsGlass making apparatusGlass fiberSilicon dioxide

The invention discloses a high temperature-resistant ultrafine quartz glass fiber cotton and a preparation method thereof, and belongs to the field of quartz glass fiber cotton preparation. The preparation method comprises following steps: three to nine quartz glass rods with a diameter ranging from 1.6 to 2.0mm and silicon dioxide content of 99.95% or higher are selected; the quartz glass rods are heated to be molten using an electric heating device, and are made into quartz glass thin rods with a diameter ranging from 0.8 to 1.0mm via drawing of a primary roller at a linear speed ranging from 25 to 40mm / min; the quartz glass thin rods are heated to be molten in a primary fire head device at 1900 to 2300 DEG C, and are made into quartz glass silk with a diameter ranging from 50 to 80<mu>m via drawing of a secondary roller at a linear speed ranging from 6000 to 16000mm / min; and the quartz glass silk is made into the quartz glass fiber cotton with a diameter ranging from 1 to 3<mu>m via blowing in a secondary fire head device at 1900 to 2300 DEG C at a jet stream speed ranging from 200 to 400m / s. The high temperature-resistant ultrafine quartz glass fiber cotton is capable of resisting super high temperature as high as 1100 DEG C; signal silk diameter is low; diameter uniformity is better; and product quality is high.

Owner:武汉鑫友泰光电科技有限公司

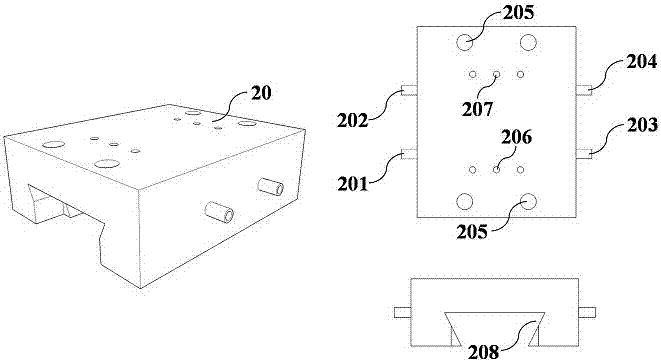

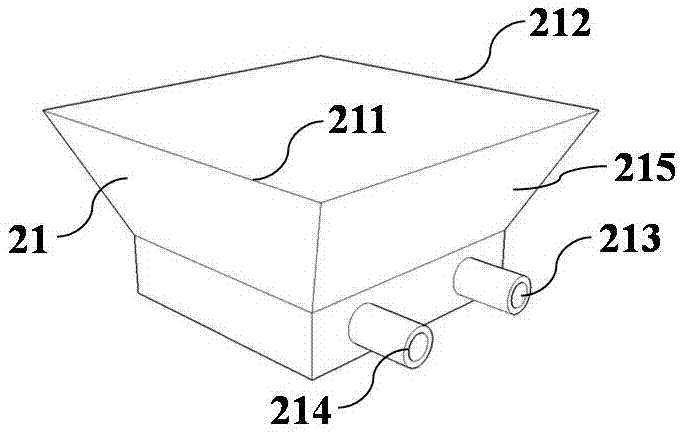

Method and device for preparing uniform spherical particles

The invention relates to a method and a device for preparing uniform spherical particles. According to the method, a water-cooling copper crucible is adopted for accommodating a raw material; througha heater, the raw material is heated to achieve the molten state; by utilization of a differential extrusion method, the molten-state raw material is extruded out of tiny holes in a flow guiding module at the bottom of the crucible; meanwhile, the extruded molten-state raw material is cut into tiny particles by adopting a high-frequency vibration cutting method; after the cutting process, the tinyparticles fall; when passing through heating zones of induction heaters, the falling tiny particles are molten-state; under the surface tension action, the molten-state tiny particles are shrunk to be spherical; and when continuing falling, the shrunk tiny particles are cooled so as to form solid-state tiny spheres. By adoption of the method, the hole diameter can be adjusted by replacing a cutting module at the bottom of the crucible; the tiny spherical particles of different particle diameters can be prepared; the method is simple and controllable; the sizes of the formed particles are controllable; and the efficiency is high.

Owner:张家港创博金属科技有限公司

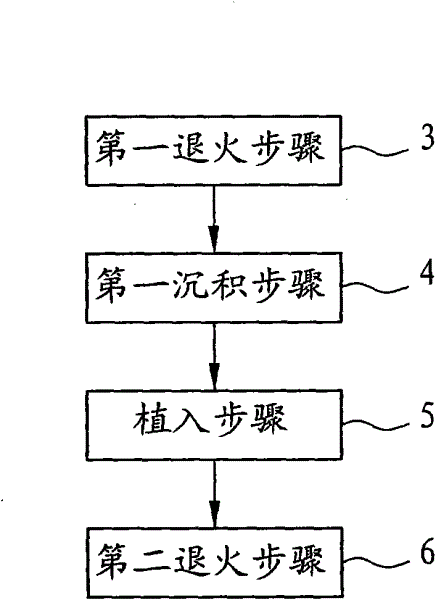

Wafer suitable for nanometer technology and method for manufacturing the same

InactiveCN102623304AReduce manufacturing costExcellent dielectric capacitySemiconductor/solid-state device manufacturingSemiconductor devicesOxygen ionsSilicon oxide

The invention relates to a wafer suitable for a nanometer technology and a method for manufacturing the same. The manufacturing method comprises the following steps: a first annealing step, a first deposition step, an implantation step and a second annealing step. According to the first annealing step, annealing processing is carried out on a wafer at the temperature of over 650 DEG C so as to form a high-quality silicon layer on the surface of the wafer. According to the first deposition step, a silicon-germanium gas source is utilized to deposit a silicon-germanium deposition layer on the high-quality silicon layer of the wafer after the annealing processing. According to the implantation step, oxygen ions are implanted into the wafer. And according to the second annealing step, annealing processing is carried out on the wafer with implantation of the oxygen ions at the temperature of over 650 DEG C so as to form a silicon oxide layer. Therefore, it is easy to control uniformity and surface flatness of all material layers of the manufactured wafer and thus a wafer with nonuniform mass and low price can be manufactured into a wafer with uniform mass, so that the nanometer technology can be utilized conveniently.

Owner:陈柏颖

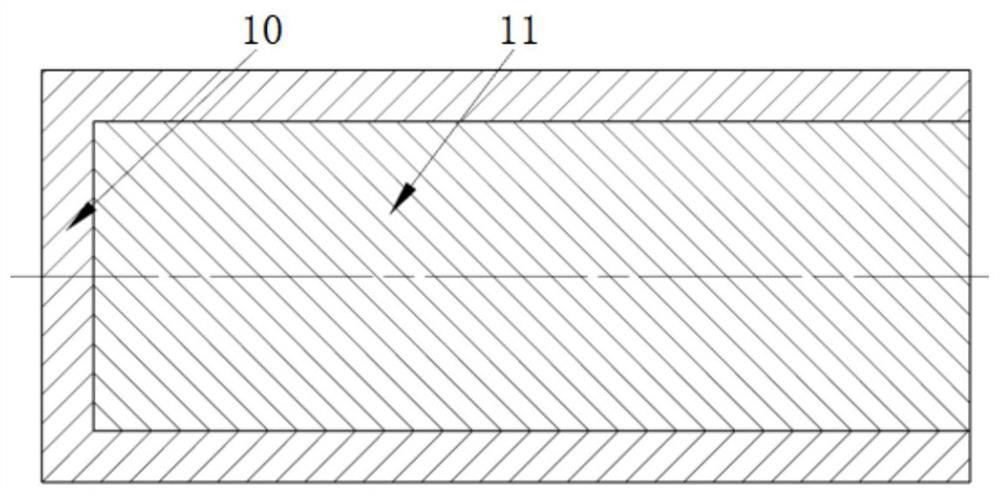

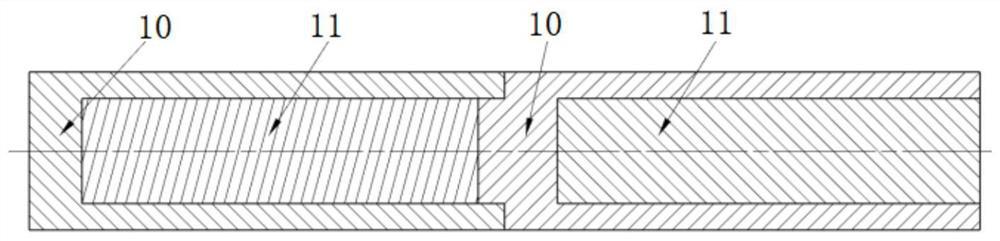

Composite penetrator with enhanced lateral efficiency and based on active material and inert material

ActiveCN113137897AStrong damageEfficient damageAmmunition projectilesProjectilesEngineeringUltimate tensile strength

The invention discloses a composite penetrator with enhanced lateral efficiency and based on active materials and inert materials, and relates to the technical field of penetrators with enhanced lateral efficiency. The penetrator with enhanced lateral efficiency comprises a front-section penetrator, a tail-section penetrator and one or more middle-section penetrators arranged between the front-section penetrator and the tail-section penetrator, wherein the front-section penetrator, the middle-section penetrators and the tail-section penetrator are in butt joint coaxially and sequentially, each of the front-section penetrator, the middle-section penetrators and the tail-section penetrator comprises a corresponding shell, a corresponding inner core and a corresponding sandwich part arranged between the corresponding shell and the corresponding inner core which are coaxially arranged in a sleeved mode, notch grooves are distributed in the outer walls of all the shells correspondingly, all the shells are made of the inert materials, and all the inner cores and all the sandwich parts are made of the active materials. The problems that an existing penetrator with enhanced lateral efficiency is single in damage mode, uncontrollable in fragment size and amount, low in penetrator body strength during high-speed penetration and the like are solved, kinetic energy and chemical energy combined damage and efficient damage to multi-layer target designated positions are achieved, and then the characteristics of impact energy release, fragment control, higher structural strength during high-speed impact and the like can be achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Manufacturing method of 2.5D asynchronous, reverse and irregular three-dimensional fabric

The invention discloses a manufacturing method of a 2.5D asynchronous, reverse and irregular three-dimensional fabric. The 2.5D asynchronous, reverse and irregular three-dimensional fabric is characterized in that the middle is tubular, and geometric shapes extend from two ends of the tubular middle, and a 2.5D structure is adopted. The method comprises the steps of setting a central line of the 2.5D asynchronous, reverse and irregular three-dimensional fabric in the length direction as a weaving starting position; setting one end of the 2.5D asynchronous, reverse and irregular three-dimensional fabric in the length direction as the end A and the other end as the end B; weaving from the weaving starting position to the end A, so as to finish the first molding; weaving from the starting position to the end B after the end A is worn so as to finish the second molding; when weaving from the end B of the 2.5D asynchronous, reverse and irregular three-dimensional fabric, a triangular low-density area caused by secondary molding at the starting position is filled by the compensating type weft insertion process. The 2.5D asynchronous, reverse and irregular three-dimensional fabric manufactured by the method is integrally molded and has the characteristics of being high in uniformity, and relatively high in dimension volume fractions.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

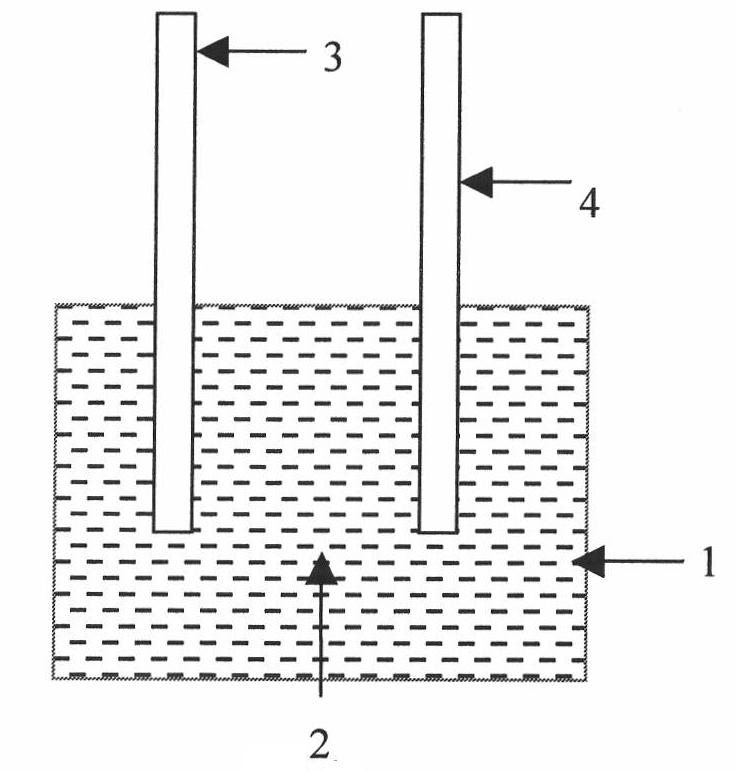

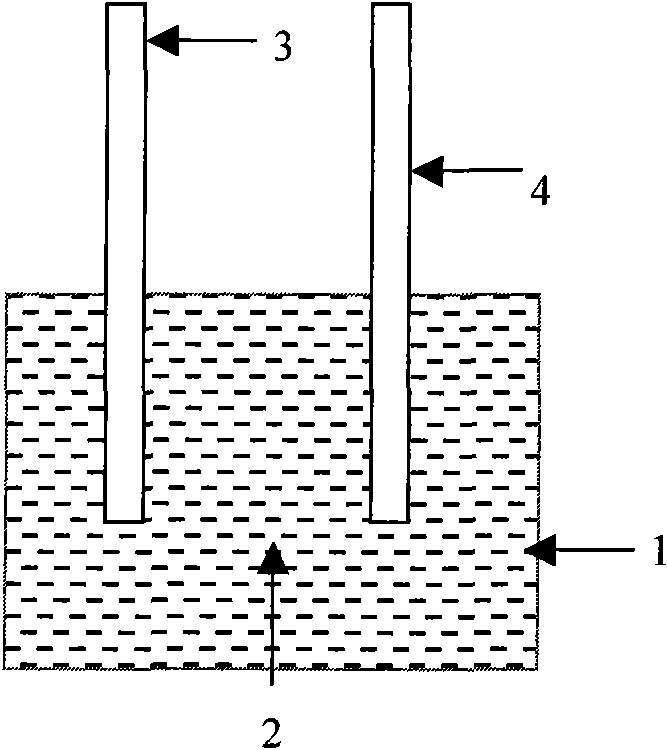

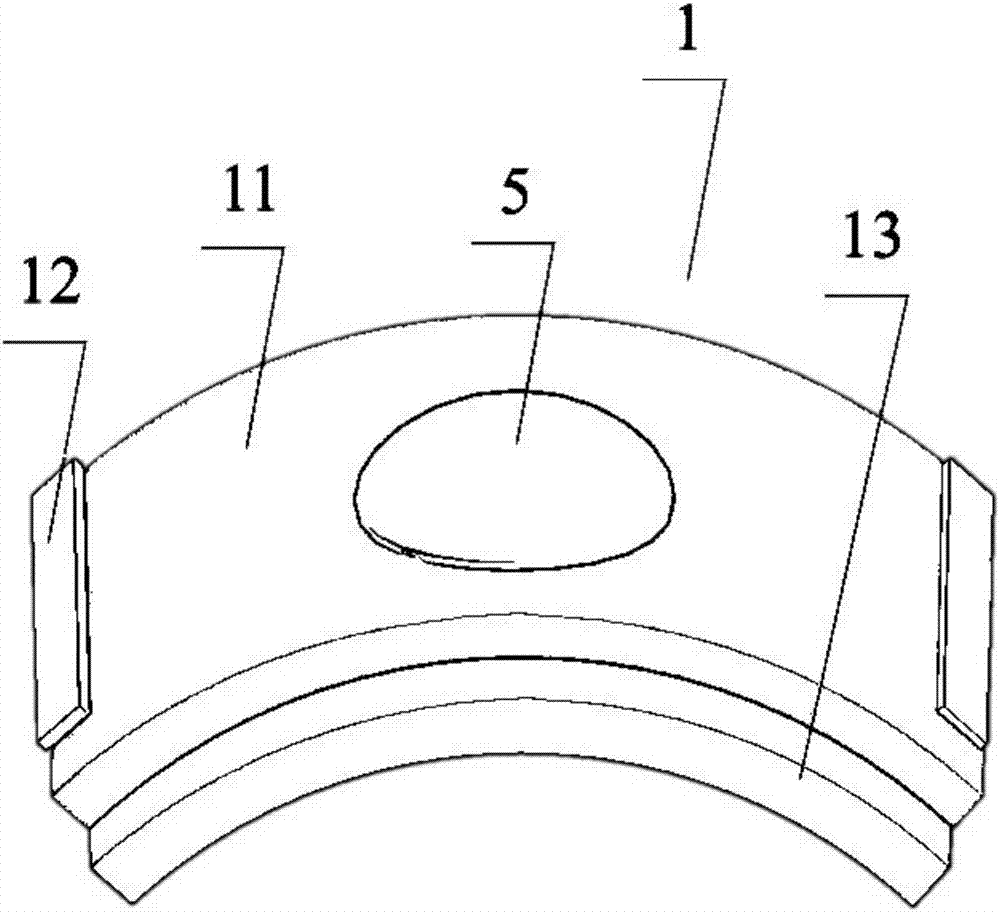

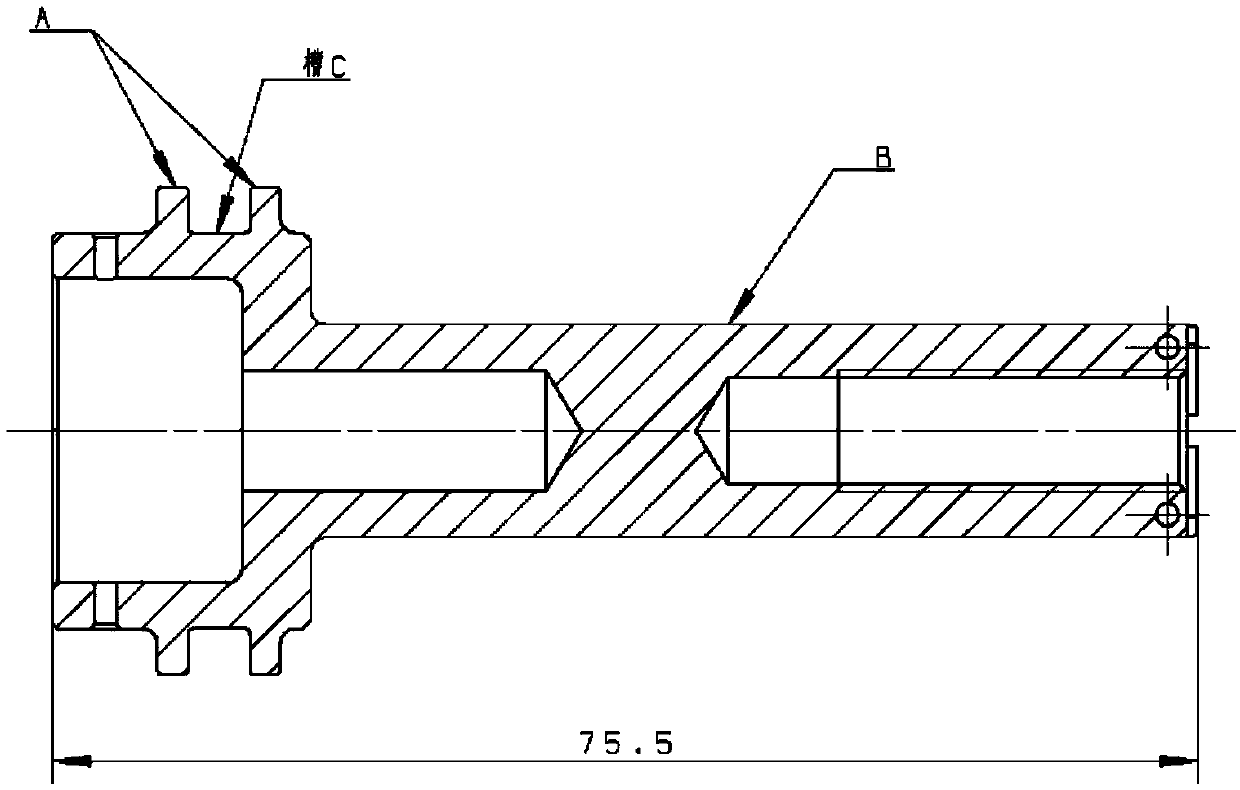

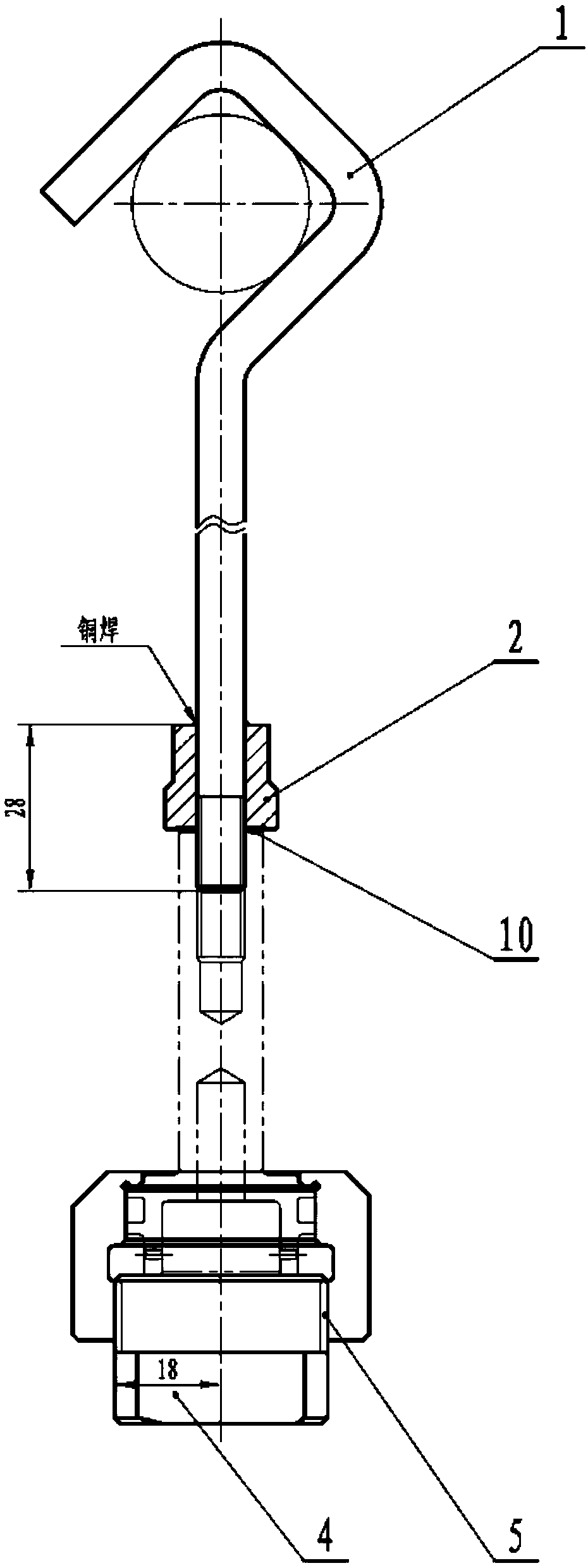

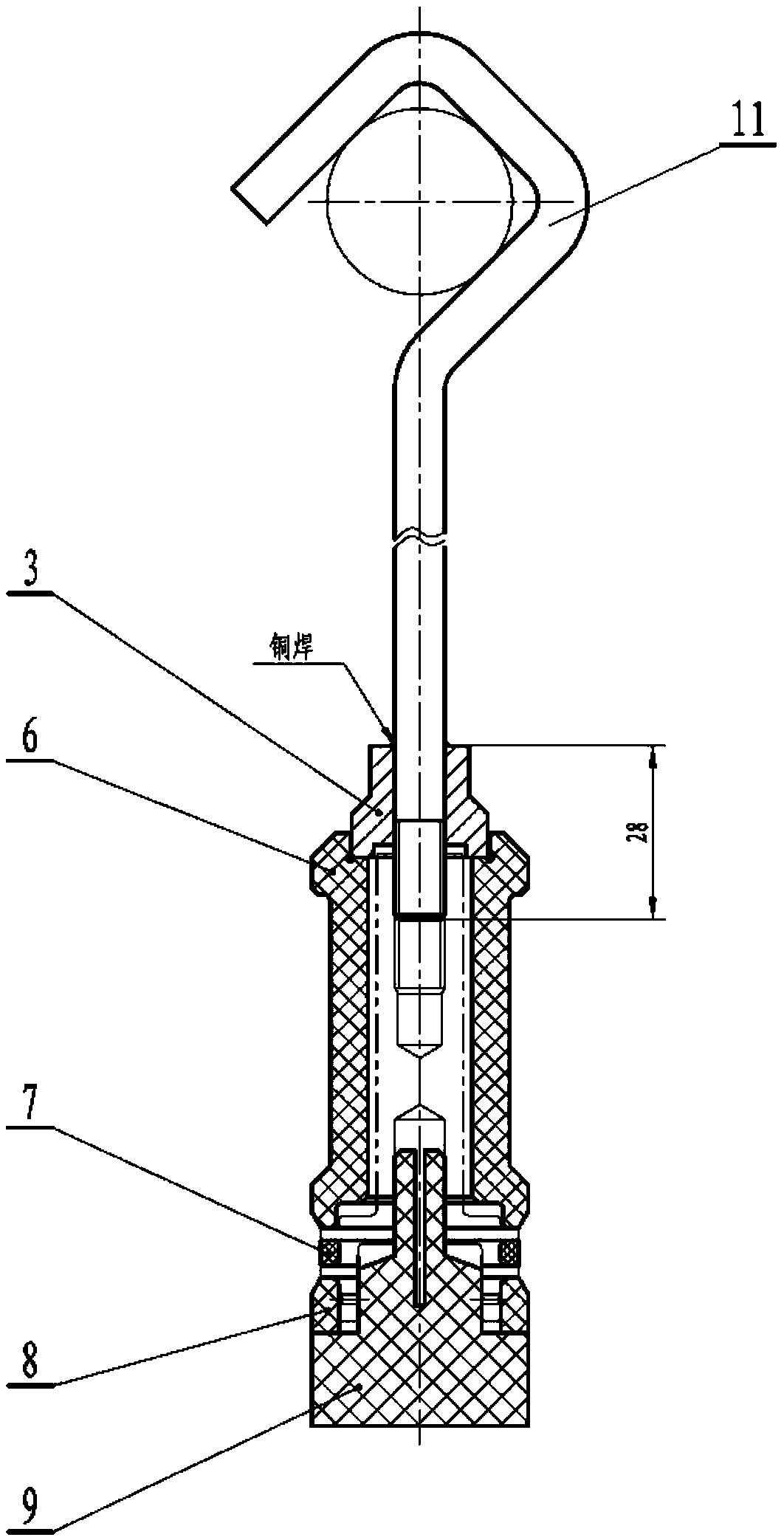

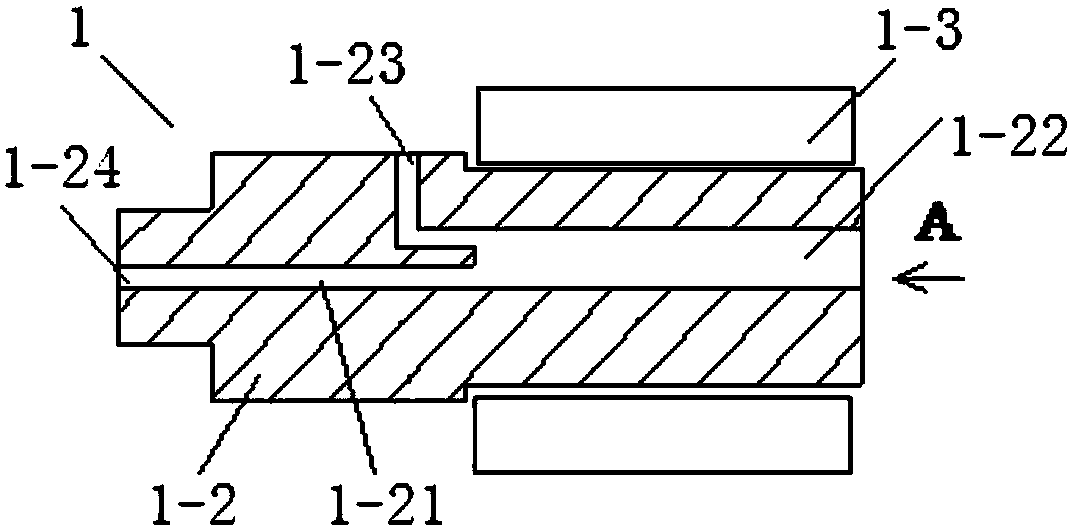

Piston rod partial chrome plating device

ActiveCN109628969AUniformity controllableSolve the problem of excessive thicknessElectrolysis componentsRubber ringEngineering

The invention discloses a piston rod partial chrome plating device. The piston rod partial chrome plating device comprises a piston rod rod-part chrome plating assembly and a big end chrome plating protection assembly, wherein the piston rod rod-part chrome plating assembly comprises a first hook (1), a first bushing (2), a gasket (10), a first plug (4) and a plug cover (5), and the big end chromeplating protection assembly comprises a second hook (11), a second bushing (3), a third bushing (6) , a rubber ring (7), a washer (8) and a second plug (9). According to the piston rod partial chromeplating device, a rod part and a big end of a piston rod are electroplated separately, the uniformity of chrome layers is easy to control, and the problems that the thickness of a chrome layer of therod part is thin and the thickness of a chrome layer of the big end is too thick are solved. When the big end is chrome plated, a groove is protected by the rubber ring, and the problem that a chromium layer remains in the groove caused by leakage of a solution is avoided. The piston rod partial chrome plating device is very easy to install and disassemble, and the production efficiency can be improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Method for manufacturing solid mandrel of insulator

The invention discloses a method for manufacturing a solid mandrel of an insulator. According to the method, a basic bar is manufactured by drawing an epoxy resin composite material by a pultrusion process; the basic bar is used as a base body, and one or more epoxy resin composite material pultrusion diameter-expansion processes are adopted. The diameter of the basic bar is between 70 and 90 millimeters; and in each epoxy resin composite material pultrusion, the diameter expansion amount of the basic bar is that: the cross section is expanded to be no more than 5,000 square millimeters. The epoxy resin composite material is a continuous glass fiber bundle dipped in epoxy resin glue solution. The method for manufacturing the solid mandrel of the insulator uses the basic bar as the base body and adopts one or more epoxy resin composite material pultrusion diameter-expansion process. The equipment and the process for manufacturing the basic bar can be adopted in the diameter expansion process, so the method has the advantages of simple process, easily controlled uniformity and equipment investment saving. The pultrusion diameter-expansion process also ensures that the mandrel has uniformly distributed glass fiber bundle and better mechanical performance.

Owner:浙江金凤凰电力科技有限公司

Short-flow efficient production process of double-metal composite belt material

ActiveCN108580849AShort processIncrease productivityMetal rolling arrangementsAcid washingComposite plate

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing yttrium barium copper oxide powder with uniform particle size

InactiveCN106145961ASimple preparation stepsImprove uniformityYttrium barium copper oxideChemical composition

The invention discloses a method for preparing yttrium barium copper oxide powder with uniform particle size, and belongs to the technical field of preparation of yttrium barium copper oxide powder. The present invention will Y 2 o 3 、BaCO 3 Mix ball milling with CuO, calcined and grind with nano-calcium carbonate to obtain precursor gel for later use, then mix kaolin powder with deionized water to obtain embryo body, after exposure to the sun and glazing, put the spare precursor gel into glazing The inside of the embryo body is frozen after firing, and then the internal yttrium barium copper oxide body is frozen and pressed, mixed with absolute ethanol for ball milling, ultrasonically dispersed and filtered to obtain a filter cake, and dried to obtain a uniform particle size yttrium barium copper oxide powder. The beneficial effects of the invention are: the preparation steps of the invention are simple, no repeated sintering is required, and the obtained product has good uniformity; the uniformity of the chemical composition is easy to control during the preparation process, and the particle size of the product is uniform.

Owner:仇颖莹

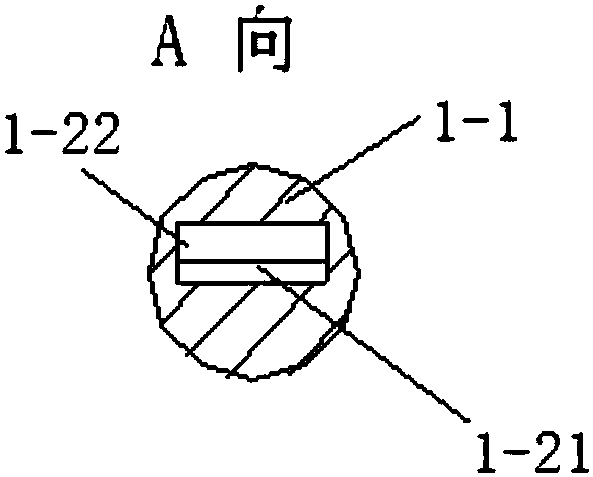

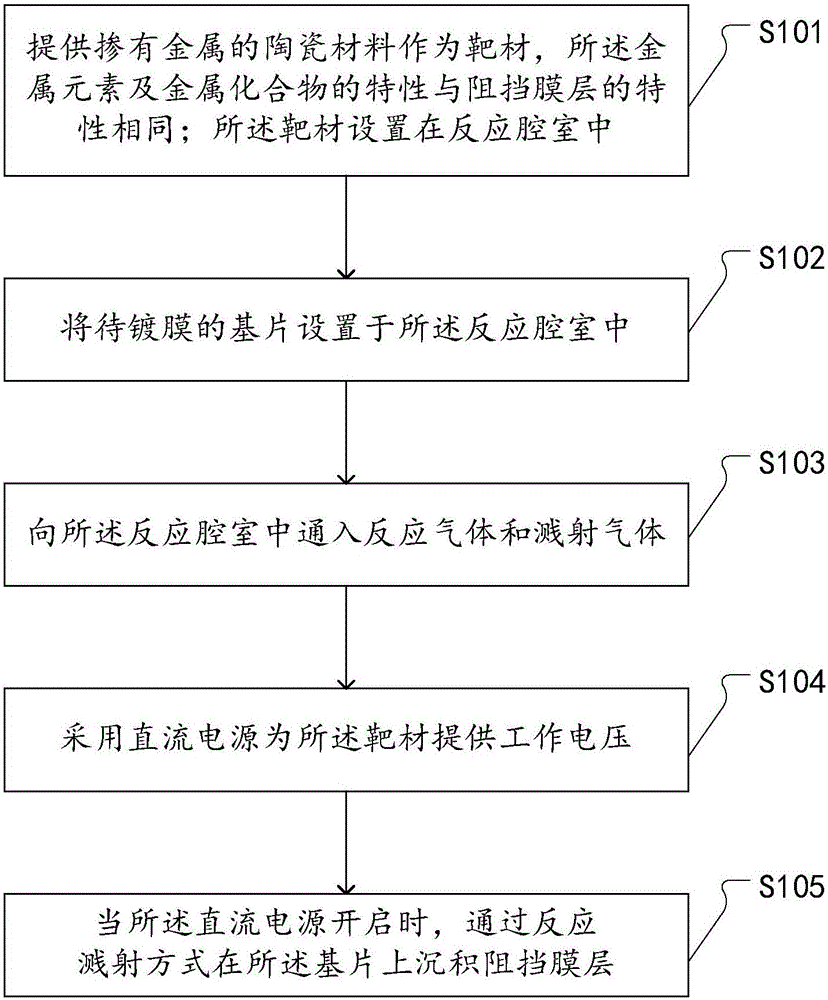

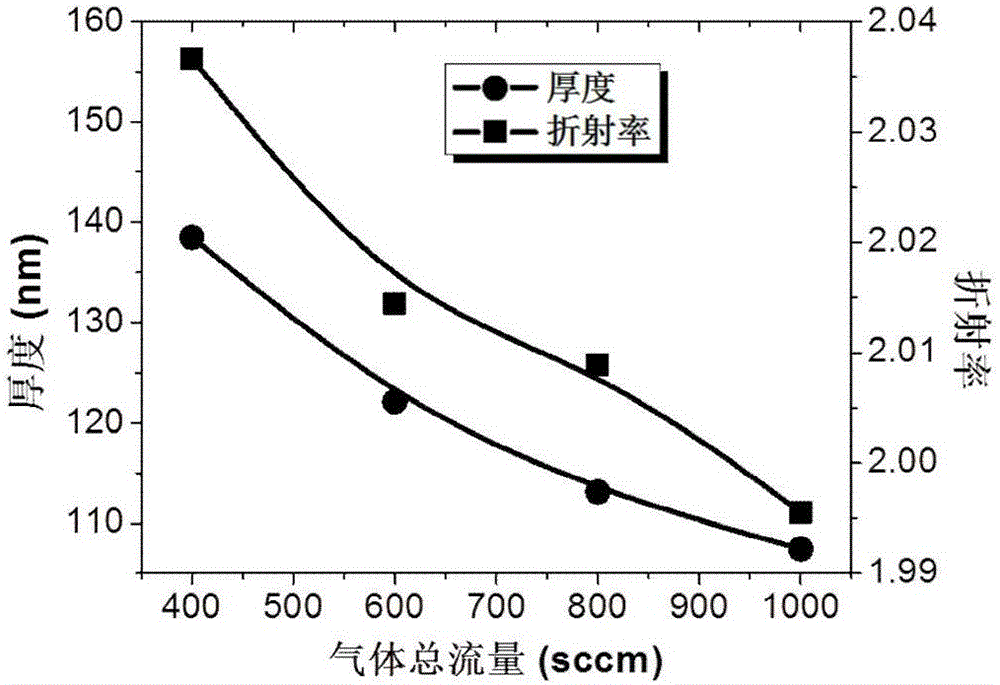

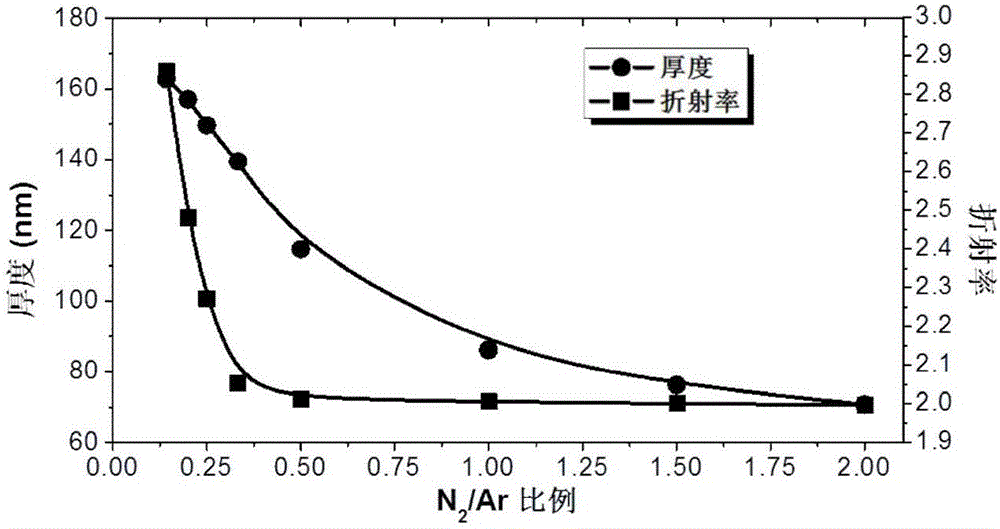

Method and device for manufacturing barrier film layer

InactiveCN105088152ALarge film areaReduce the temperatureVacuum evaporation coatingSputtering coatingMetalCoating

The invention discloses a method and device for manufacturing a barrier film layer. The method includes the steps that a ceramic material doped with metal is provided as a target, wherein the characteristics of metallic elements and metallic compounds are the same as those of the barrier film layer; the target is arranged in a reaction cavity; a substrate to be plated with a film is arranged in the reaction cavity; reactant gas and sputtering gas are introduced into the reaction cavity; a direct-current power source is adopted for providing the working voltage for the target; and when the direct-current power source is turned on, the barrier film layer is deposited on the substrate in a reaction sputtering manner. By the adoption of the method, the direct-current power source can be adopted for manufacturing the non-metallic ion barrier film layer, the method can be applied to actual production, the film layer manufactured through the method is large in area, the temperature is low, the deposition speed of the film layer is adjustable, and the evenness of the film layer is controllable.

Owner:APOLLO PRECISION (FUJIAN) LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com