Graphene test paper and preparation thereof and liquid analyzing method based on test paper

A liquid analysis, graphene technology, applied in the direction of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve the cost of a large number of instruments and reagents, personnel training costs, difficult to achieve flexibility, easy to carry, and impossible to carry. and other problems, to achieve the effects of low toxicity in the manufacturing process, good chemical sensing performance, and short detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can better understand.

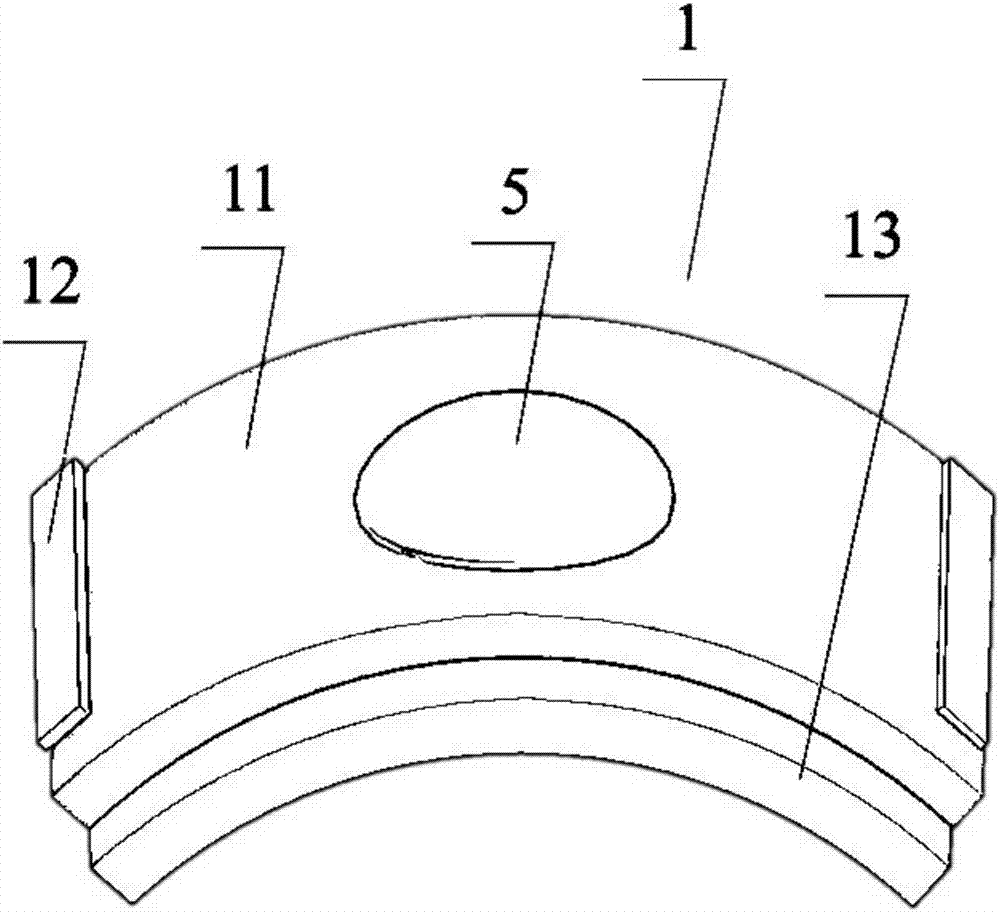

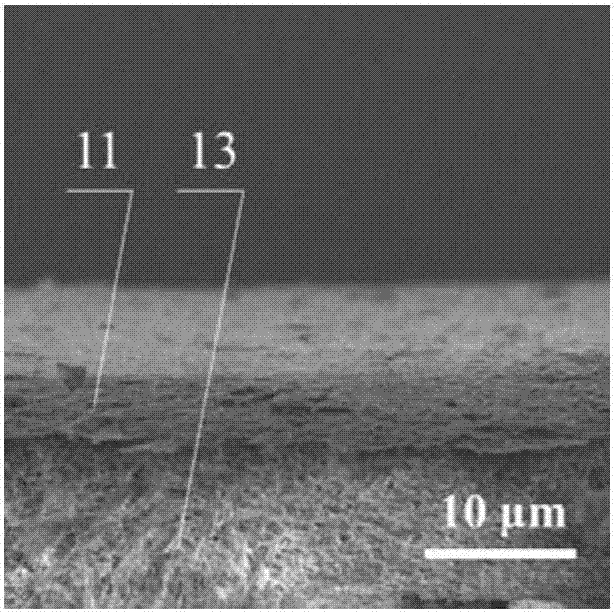

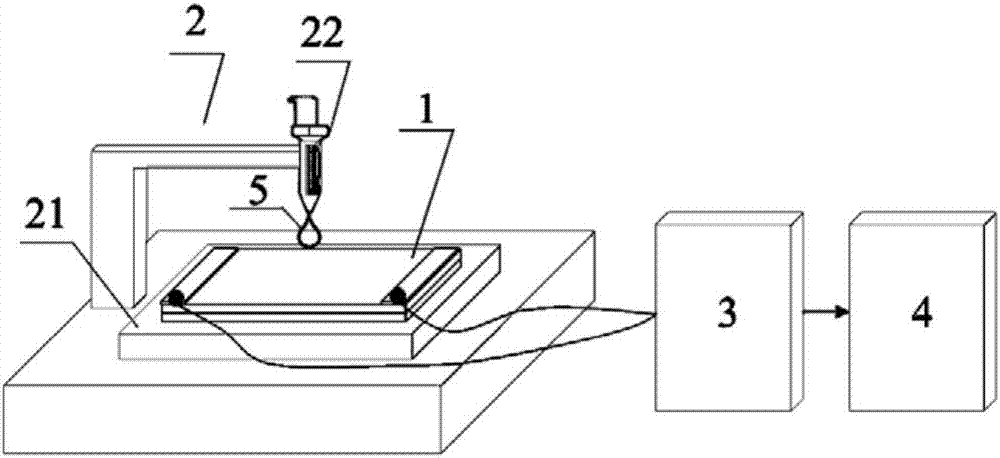

[0032] According to the first aspect of the present invention, a graphene test paper is provided, which is characterized in that the graphene test paper contains a film substrate 13 and a film structure 11 and a contact electrode 12 formed by stacking graphene sheets, the graphene The thin film structure 11 formed by lamination is closely combined with the film substrate 13; the contact electrode 12 is arranged on the thin film structure 11 of the graphene lamination; an auxiliary film forming agent and Chemical sniffing molecules. The auxiliary film-forming agent is sodium carboxymethylcellulose or ethylcellulose. The chemical sniffing molecules are sodium polystyrene sulfonate or manganese dioxide nanoparticles. The film structure formed by stacking graphene sheets has a thickness of 5-1000 mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com