High temperature-resistant ultrafine quartz glass fiber cotton and preparation method thereof

A technology of quartz glass fiber and quartz glass, which is applied in the field of high-temperature-resistant ultra-fine quartz glass fiber cotton and its preparation, and can solve the problem that ordinary glass fiber cotton cannot be used in high-temperature use environments, special use environments that cannot be applied to high temperatures, and the diameter of monofilaments. Uniformity is difficult to control and other problems, to achieve the effect of improving product use effect, good product quality, and easier control of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

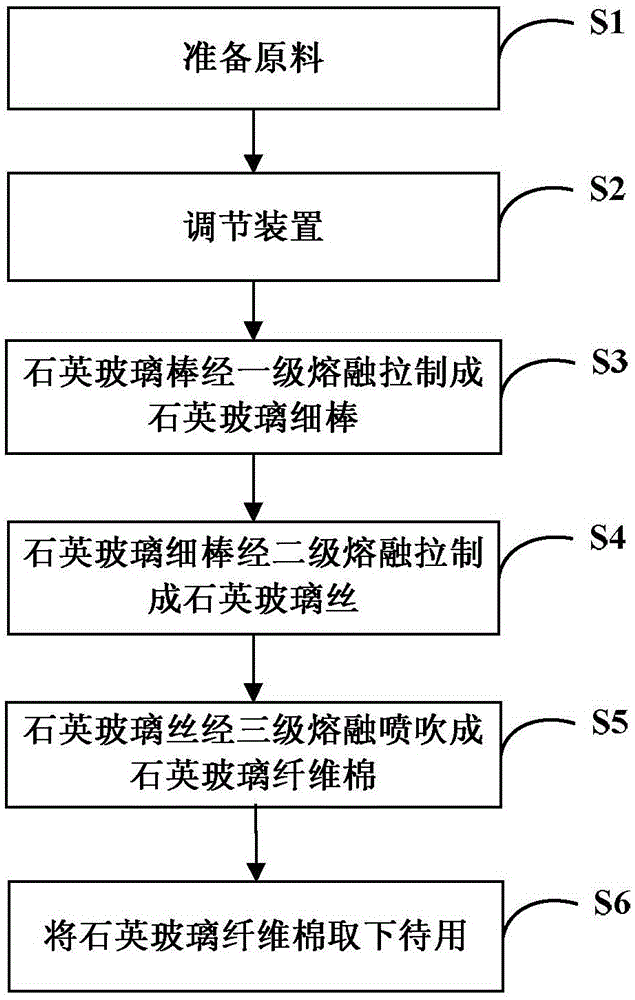

[0025] see figure 1 As shown, the present invention provides a method for preparing high-temperature-resistant ultrafine quartz glass fiber cotton. The preparation device required for the preparation method includes a moving clamping rod device, an electric heating device, a primary burner device, a secondary burner device, a primary drum, Secondary drum, quartz glass wire divider and special quartz glass rod tool, the preparation method comprises the following steps:

[0026] S1: Prepare raw materials: select 3 to 9 quartz glass rods with a diameter of 1.6-2.0mm and a silicon dioxide content ≥ 99.95%; put all the quartz glass rods into the mobile clamping rod device, and turn to S2.

[0027] During specific operation, the number of quartz glass rods is preferably 6; the diameter of the quartz glass rods is preferably 1.85mm.

[0028] S2: Debugging device: Turn on the electric heating device to raise the temperature to 1800-2000°C; turn on the primary burner device, and adjus...

Embodiment 1

[0038] Embodiment 1 provides a kind of preparation method of high temperature resistant ultra-fine quartz glass fiber wool, comprising the following steps:

[0039] S1: Select 3 quartz glass rods with a diameter of 1.6mm and a silica content ≥ 99.95%; put all the quartz glass rods together into the mobile clamping rod device, and turn to S2;

[0040]S2: Turn on the electric heating device to raise its temperature to 1800°C; turn on the primary burner device, adjust the flame temperature of the primary burner device to 1900°C by adjusting the natural gas valve and oxygen valve; turn on the secondary burner device, Gas valve, oxygen valve, adjust the flame temperature of the secondary burner device to 1900°C, adjust the jet flow speed to 200m / s, and turn to S3;

[0041] S3: Turn on the moving rod clamping device and adjust its linear speed to 7mm / min; the moving rod clamping device drives all the quartz glass rods to pass through the electric heating device at 1800°C at a consta...

Embodiment 2

[0046] Embodiment 2 provides a kind of preparation method of high temperature resistant ultrafine quartz glass fiber wool, and its basic steps are identical with embodiment 1, and difference is:

[0047] The number of quartz glass rods in S1 is 9, and the diameter is 2.0mm; the specific steps of S2 are: turn on the electric heating device, make the temperature rise to 2000°C, adjust the flame temperature of the primary burner device to 2300°C, and turn on the secondary The flame temperature of the burner device is adjusted to 2300°C, and the jet airflow speed is adjusted to 250m / s; the linear speed of the moving rod clamping device in S3 is 10mm / min, and the linear speed of the primary roller is 40mm / min, and the drawn quartz glass thin rod The diameter is 1.0mm; the linear speed of the secondary roller in S4 is 6200mm / min, and the diameter of the drawn quartz glass filament is 80μm; the diameter of the quartz glass fiber wool in S5 is 3μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com