Manufacturing method of 2.5D asynchronous, reverse and irregular three-dimensional fabric

A technology of three-dimensional fabrics and manufacturing methods, applied in fabrics, textiles and papermaking, textiles, etc., can solve the problems of unusable, poor fabric uniformity, and poor dimensional accuracy, and achieve high damage tolerance, structural integrity, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

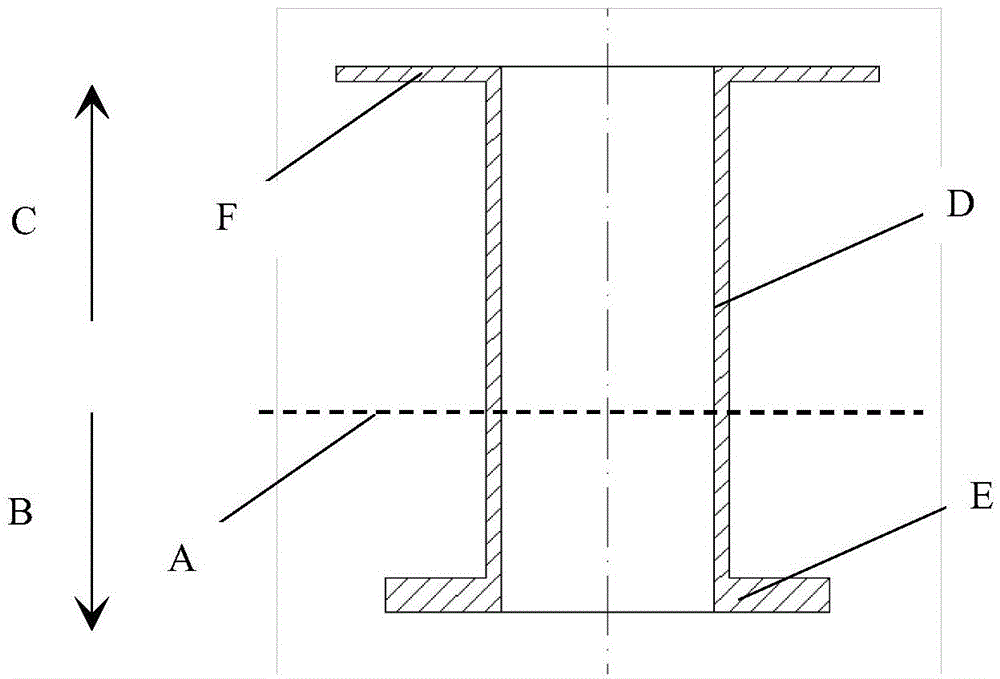

[0040] Embodiment 1: H-shaped band flanging tubular three-dimensional fabric (symmetric type)

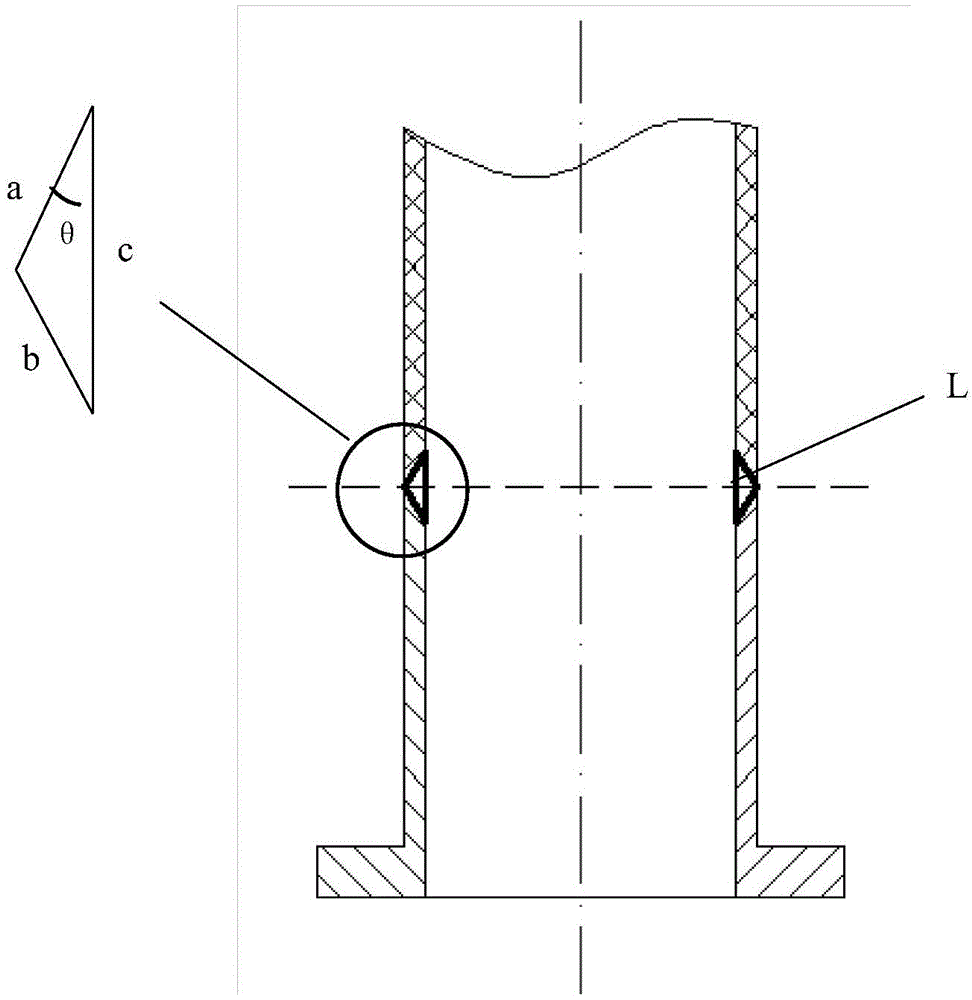

[0041] combine figure 1 , image 3 with Figure 4 The instructions are as follows: Set the thickness of the fabric cylinder and large flange to 1.8mm, the thickness of the small flange to 3.0mm, the number of warp layers for the cylinder and large flange to be 8 layers, add 5 layers of warp yarns to the small flange, and the warp density to 10.0 / cm, the weft density is 2.0 / cm.

[0042] Calculated according to formula 1 and formula 2: the side length of the triangle c=0.13mm, which is less than (1 / w=1 / 2), the triangle area can be ignored, that is, it does not need to be filled with a compensating weft inserting process.

[0043] Set the center line in the length direction of the three-dimensional fabric as the starting position, such as figure 1 As shown, the part below the starting position is the B segment fabric (along the B direction), and the part above the starting positio...

Embodiment 2

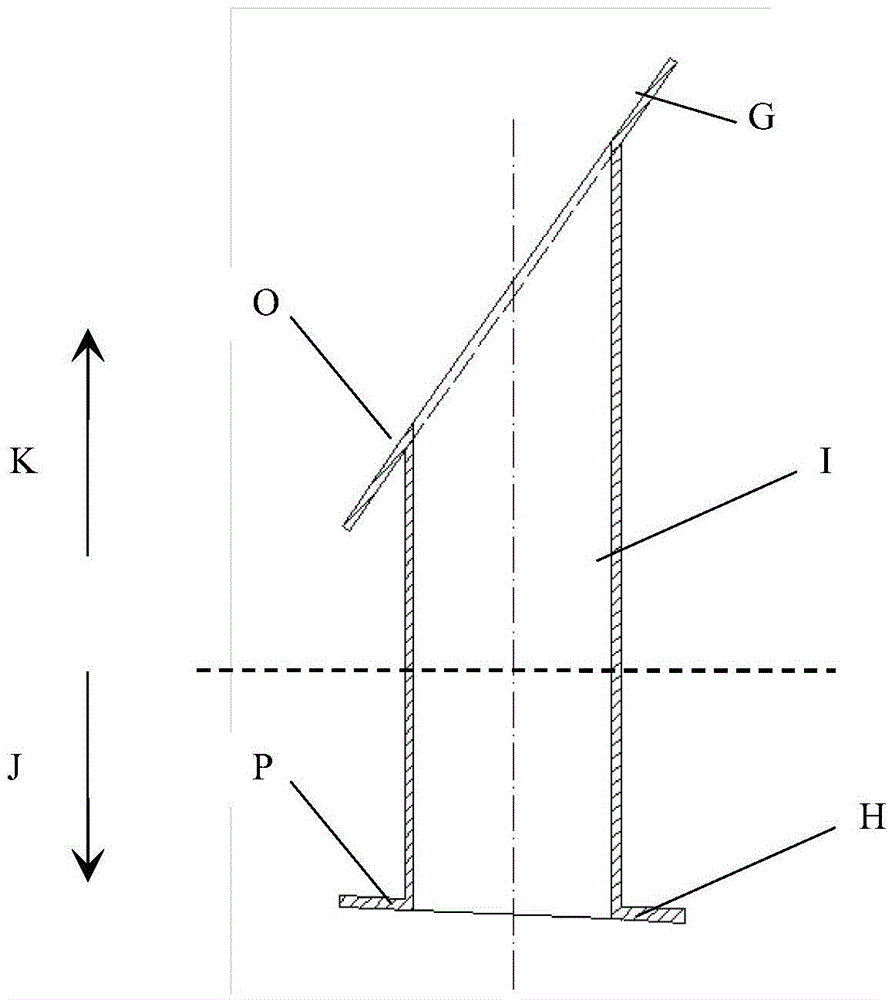

[0074] Embodiment 2: Schematic diagram of H-shaped tubular fabric with flanging (similar symmetrical type)

[0075] combine figure 2 , image 3 with Figure 4 The instructions are as follows: set the thickness of the fabric to be 12mm, the number of warp layers to be 20, the density in the warp direction to be 9.5 threads / cm, the density in the weft direction to be 3.0 threads / cm, and the angle between the beveled flanging and the cylinder to be 88 degrees.

[0076] Calculated according to Formula 1 and Formula 2: the side length of the triangle c = 0.86mm, greater than (1 / w = 1 / 3), the triangle area needs to be filled with a compensating weft insertion process; calculated according to Formula 3 to Formula 6 : M=2.57 is rounded to 3, N 1 =6.7 rounded to 7, N 2 =13.3 is rounded to 13. Therefore, the number of weft insertion layers in the triangular low-density area is 13 layers, and the weft number is 2 latitudes. Since the included angle between the descending flanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com