Method and device for manufacturing barrier film layer

A barrier film and equipment technology, applied in the field of solar cells, can solve the problems of difficult uniform preparation of non-metallic films in a large area, slow deposition rate, difficult control of film uniformity, etc., to achieve adjustable film deposition rate, film The effect of large layer area and controllable uniformity of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

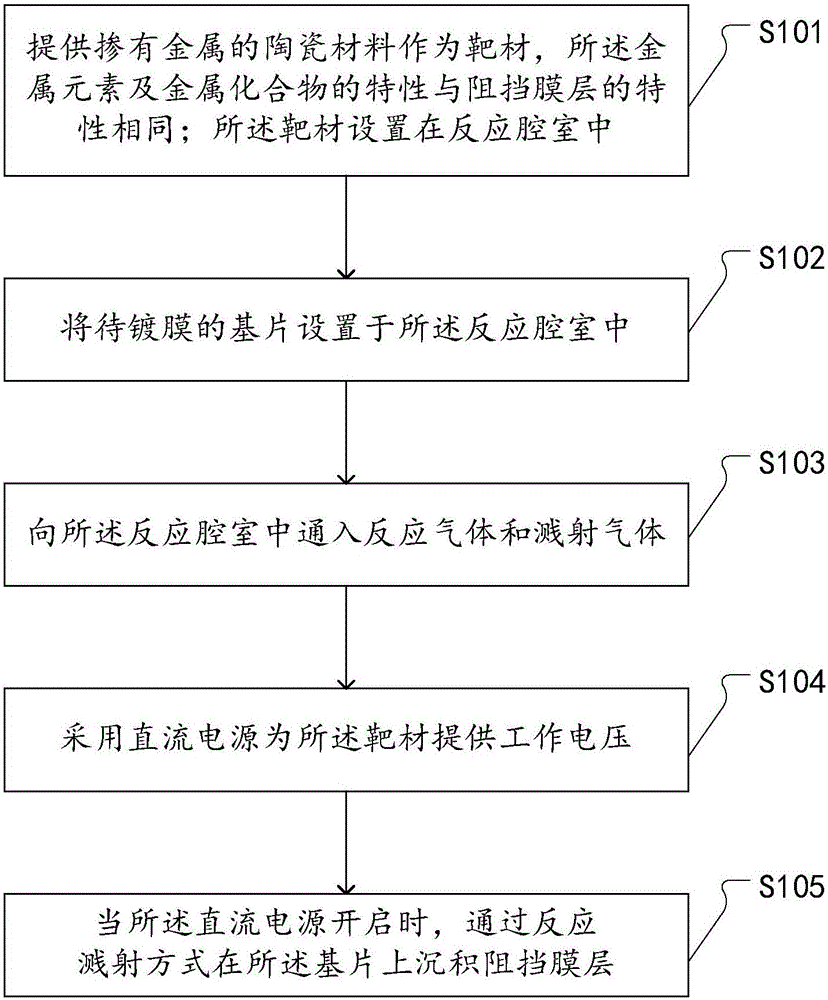

[0039] The invention provides a method for preparing a barrier film layer, which is mainly used in the preparation process of thin-film solar cells. Since thin film solar cells generally grow different thin film layers on the substrate, and the substrate may contain sodium, iron, oxygen plasma, these ions may diffuse into the film in the subsequent film preparation process, therefore, this method It can be applied in the process of preparing barrier film layer on the substrate.

[0040] In the preparation process of thin film solar cells, sputtering method or chemical vapor deposition method can be used to prepare thin film layers, for example, metal film layers can be prepared by DC sputtering method. However, the DC sputtering method requires the target to be able to transfer the positive charge obtained from the ion bombardment process to the cathode that is in close contact with it, so this method can only sputter conductive materials and is not suitable for insulating mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com