Preparation method of independent titanium dioxide nanotube array film

A nanotube array and titanium dioxide technology, which is applied in the field of preparation of independent titanium dioxide nanotube array films, can solve the problems of difficulty in obtaining large-area titanium dioxide films, slow reaction speed, complex process, etc., and achieve wide application range, low cost, The effect of large film area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

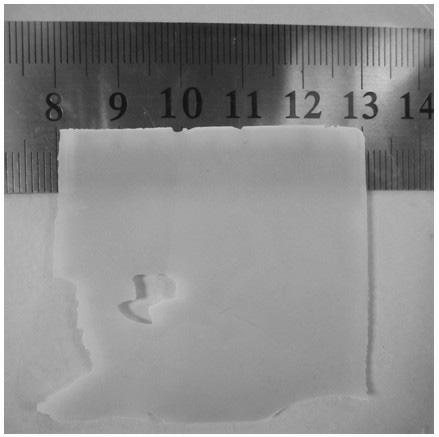

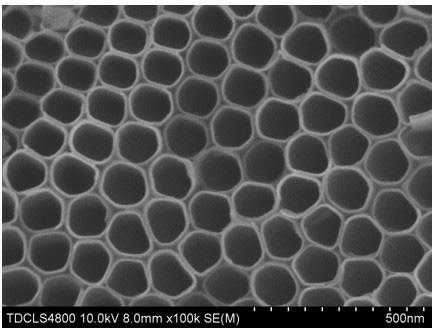

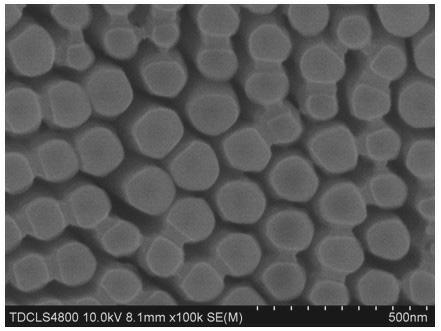

[0015] Make the area 60x55mm 2 , a polished pure titanium sheet with a thickness of 0.5mm was ultrasonically cleaned in acetone, ethanol and deionized water for 10min in sequence; As the anode, the platinum electrode is used as the cathode, the electrode distance is 3cm, the voltage is 60V, the electrolytic cell is kept at a constant temperature of 25°C, anodized for 10h, and the electrolyte is continuously stirred during the treatment process; the obtained sample is ultrasonically cleaned in ethanol, and then immersed in 100ml Mass fraction of 1% hydrofluoric acid solution, stand at 25°C for 2 minutes, the film is separated from the titanium sheet, the titanium dioxide film is taken out and rinsed with deionized water until it is neutral; finally, the dried film is heat-treated in an air atmosphere, and the heating rate is 10°C / min, hold at 450°C for 30 minutes, and cool to room temperature with the furnace. Finally, an independent anatase titanium dioxide nanotube array fil...

Embodiment 2

[0018] Make the area 60x55mm 2 , a polished pure titanium sheet with a thickness of 0.5mm was ultrasonically cleaned in acetone, ethanol and deionized water for 10min in sequence; As the anode, the platinum electrode is used as the cathode, the electrode distance is 3cm, the voltage is 60V, the electrolytic cell is kept at a constant temperature of 25°C, anodized for 24h, and the electrolyte is continuously stirred during the treatment process; the obtained sample is ultrasonically cleaned in ethanol, and then immersed in 100ml The mass fraction of 4% hydrofluoric acid solution, let stand at 25°C for 1min, the film is separated from the titanium sheet, and the titanium dioxide film is taken out and rinsed with deionized water until it is neutral; finally, the dried film is heat-treated in an air atmosphere, and the heating rate is 10°C / min, keep warm at 400°C for 30min, and cool to room temperature with the furnace. Finally, an independent anatase titanium dioxide nanotube ar...

Embodiment 3

[0021] Make the area 60x55mm 2 , a polished pure titanium sheet with a thickness of 0.5 mm was ultrasonically cleaned in acetone, ethanol and deionized water for 10 min in sequence; As the anode, the platinum electrode is used as the cathode, the electrode distance is 3cm, the voltage is 50V, the electrolytic cell is kept at a constant temperature of 25°C, anodized for 8h, and the electrolyte is continuously stirred during the treatment process; the obtained sample is ultrasonically cleaned in ethanol, and then immersed in 100ml Mass fraction of 1% hydrofluoric acid solution, let stand at 25°C for 1min, separate the film from the titanium sheet, take out the titanium dioxide film and wash it with deionized water until neutral; finally heat-treat the dried film in air atmosphere, the heating rate 10°C / min, keep warm at 400°C for 30min, and cool to room temperature with the furnace. Finally, an independent anatase titanium dioxide nanotube array film is obtained, the film thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com