Gas sensor made of graphene-tungsten disulfide composite material and preparation method of gas sensor

A gas sensor, tungsten disulfide technology, applied in chemical instruments and methods, analytical materials, material resistance, etc., can solve problems such as unfavorable contact between nanosheets and gas molecules, and achieve a wide range of detection objects, good ohmic contact, and a variable number of layers. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content of the present invention, in conjunction with the appendix Figure 1-4 The present invention is described in detail with examples.

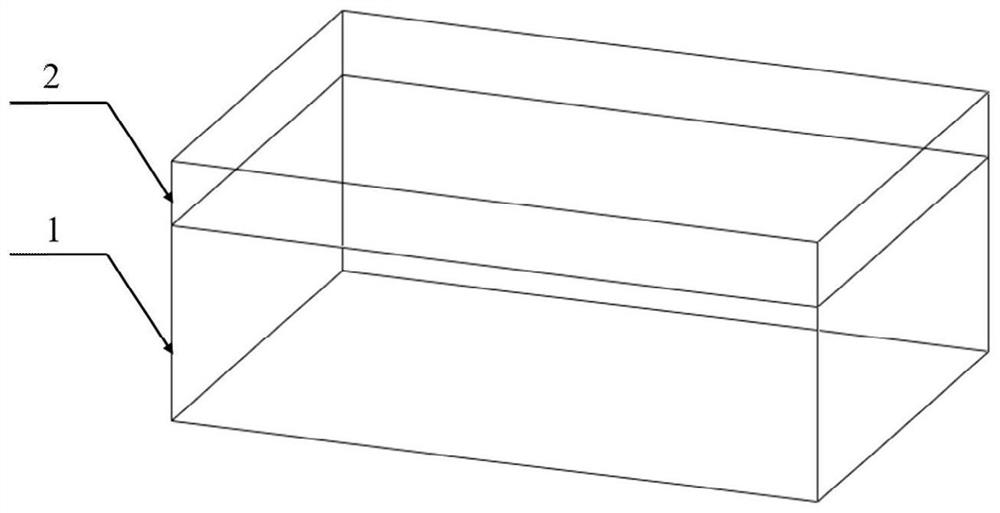

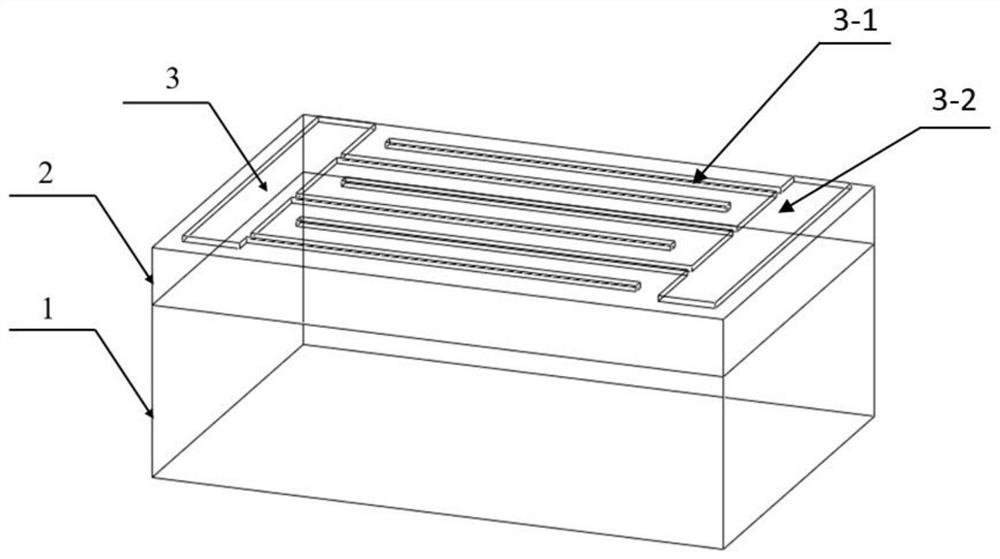

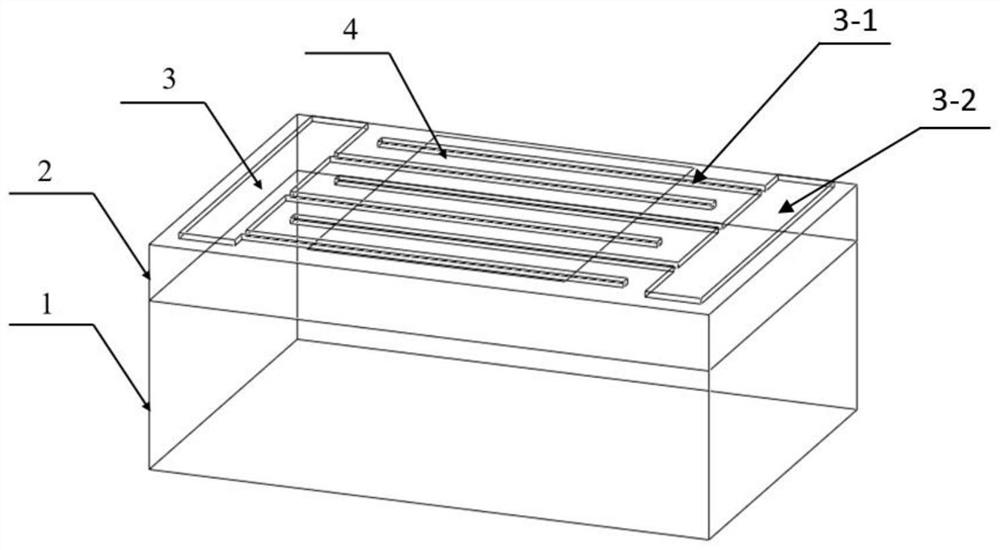

[0024] This implementation provides a graphene-tungsten disulfide composite gas sensor, such as Figure 1-4 As shown, from bottom to top, it includes a silicon base layer 1 , a silicon dioxide insulating layer 2 , an electrode layer 3 , a graphene layer 4 and a tungsten disulfide layer 5 . The size of the silicon base layer is 20mm in length and 10mm in width, the silicon dioxide insulating layer covers the upper surface of the silicon base layer, the electrode layer is arranged on the surface of the silicon dioxide insulating layer, and the electrode layer is a gold metal electrode, including inserts. The tooth electrode 31 and the large electrode 32, the large electrodes are located at both ends of the tooth-shaping electrode, the graphene layer is a single-layer graphene, covering the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com