Patents

Literature

103results about How to "The number of layers is controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

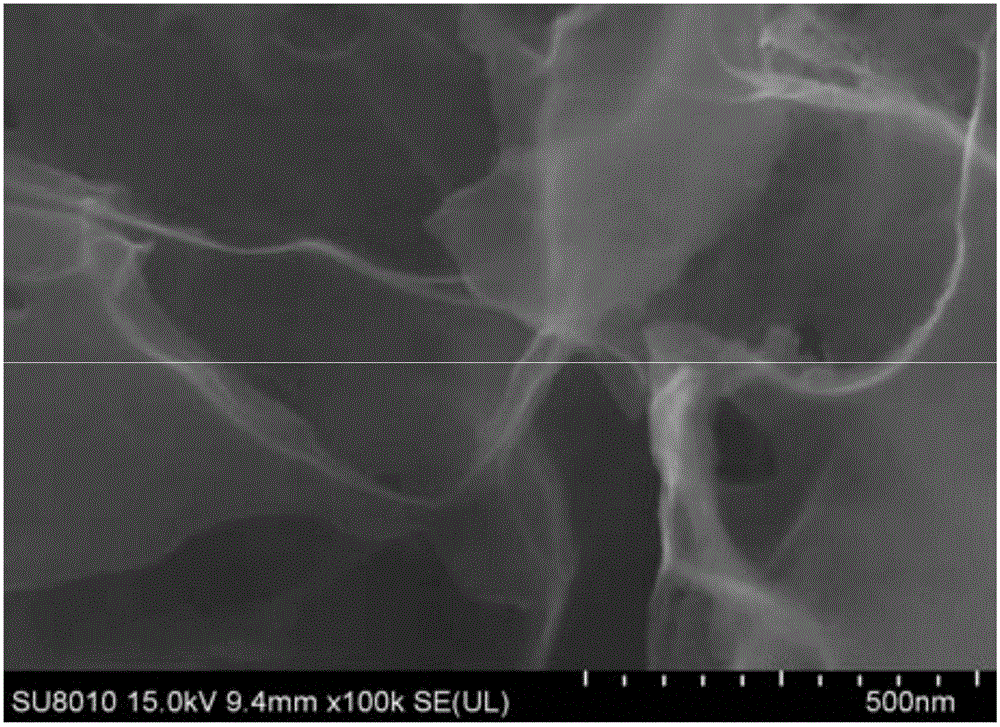

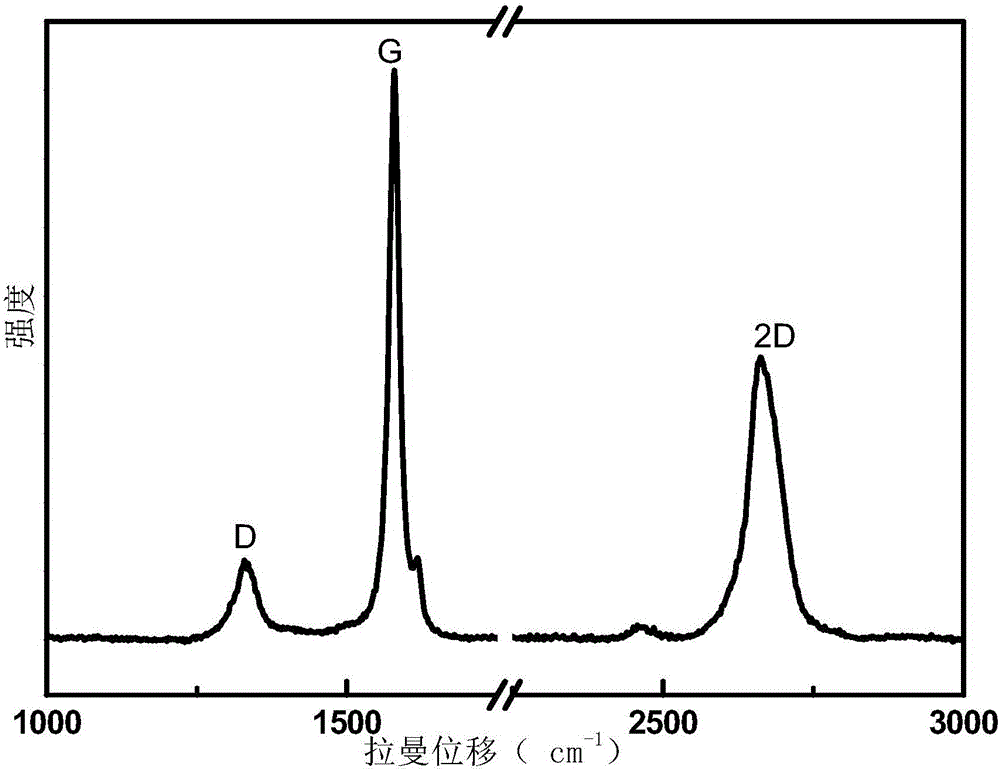

Three-dimensional continuous graphene network composite material and its preparation method

InactiveCN102786756ASimple preparation processEasy to controlNon-conductive material with dispersed conductive materialChemical vapor deposition coatingPtru catalystElectrical battery

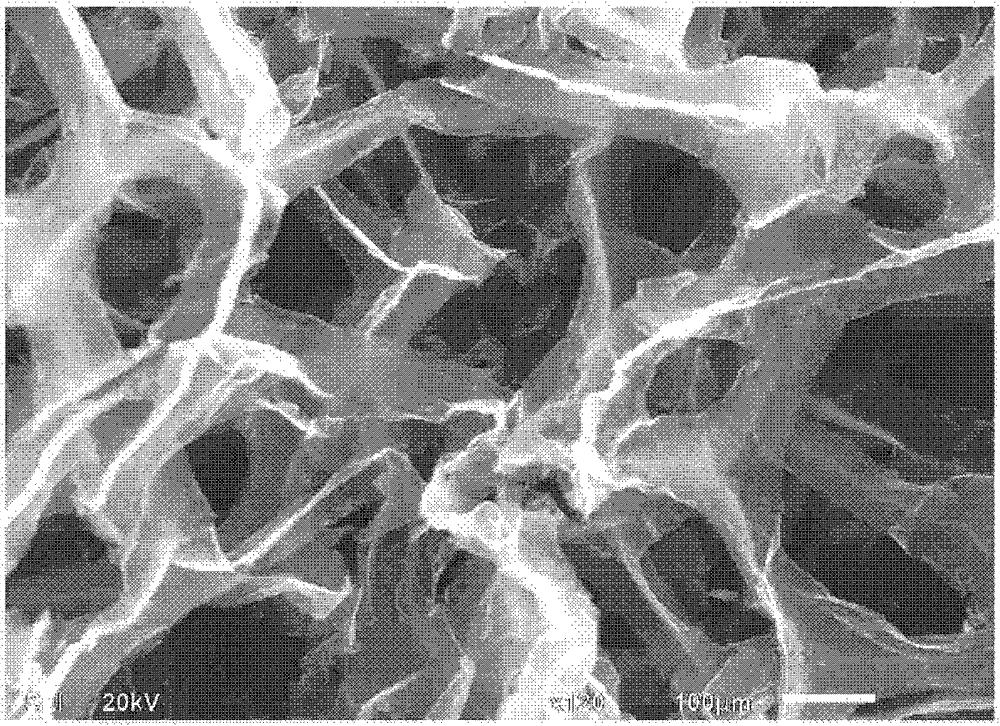

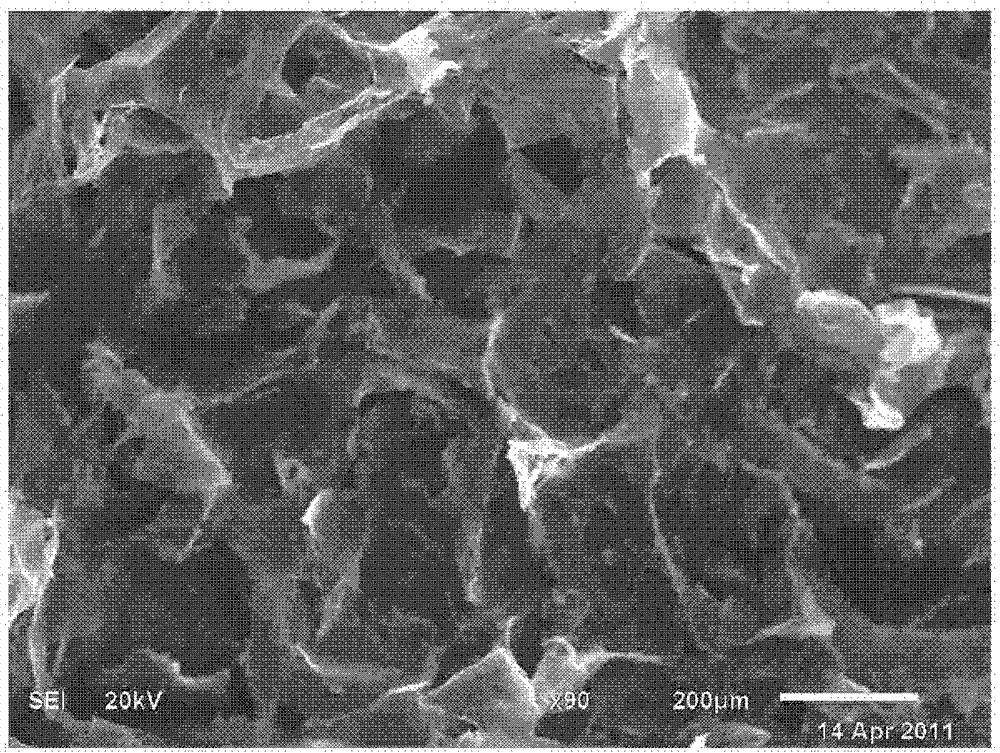

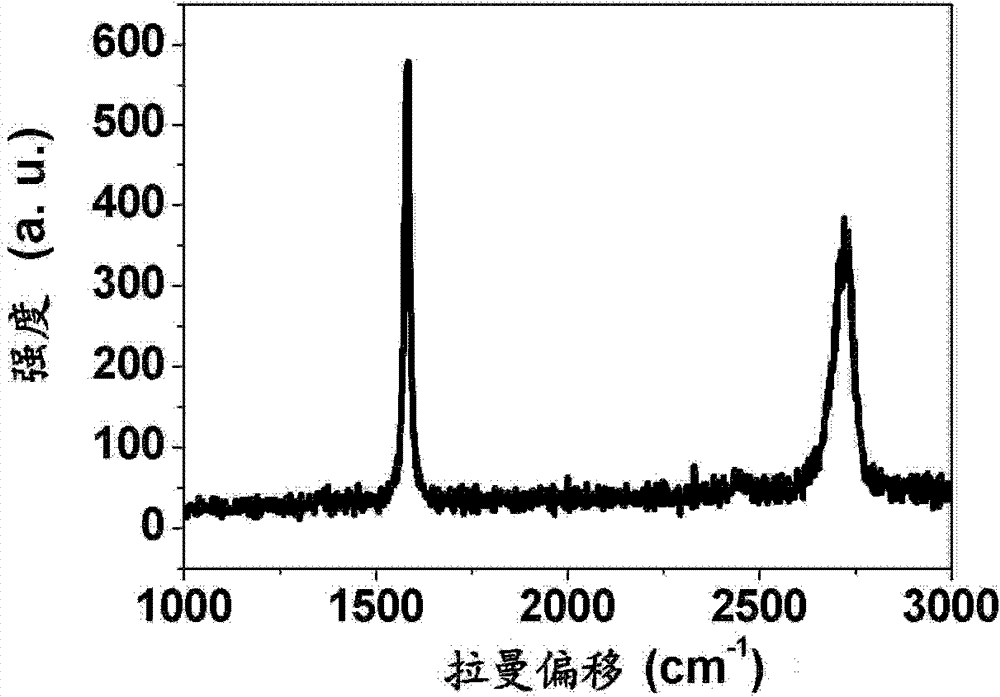

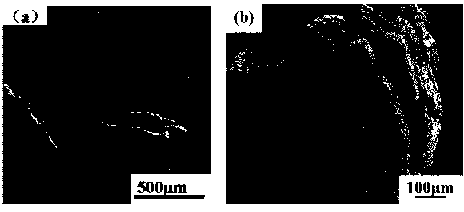

The invention belongs to the nanocomposite material field, and relates to a preparation method of a novel three-dimensional graphene network composite material. The method comprises the following steps: obtaining a three-dimensional continuous graphene skeleton composite structure by adopting a metal template having a three-dimensional continuous pore structure as a catalyst, by growing the graphene through utilizing a chemical vapor deposition method until the graphene sklayer number is 1-20, and by adopting an etching liquid to remove the metal template; and compositing the graphene composite structure with a high polymer material to obtain the three-dimensional graphene network composite material. The three-dimensional graphene network composite material has the advantages of simple technology, easily controlled processes, excellent conductivity, and low preparation cost, and is suitable for the fields of solar cells, energy storage cells and conductive composite materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

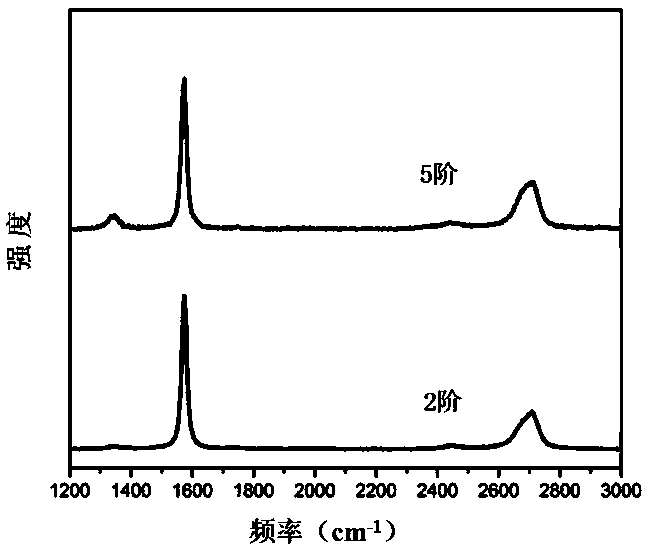

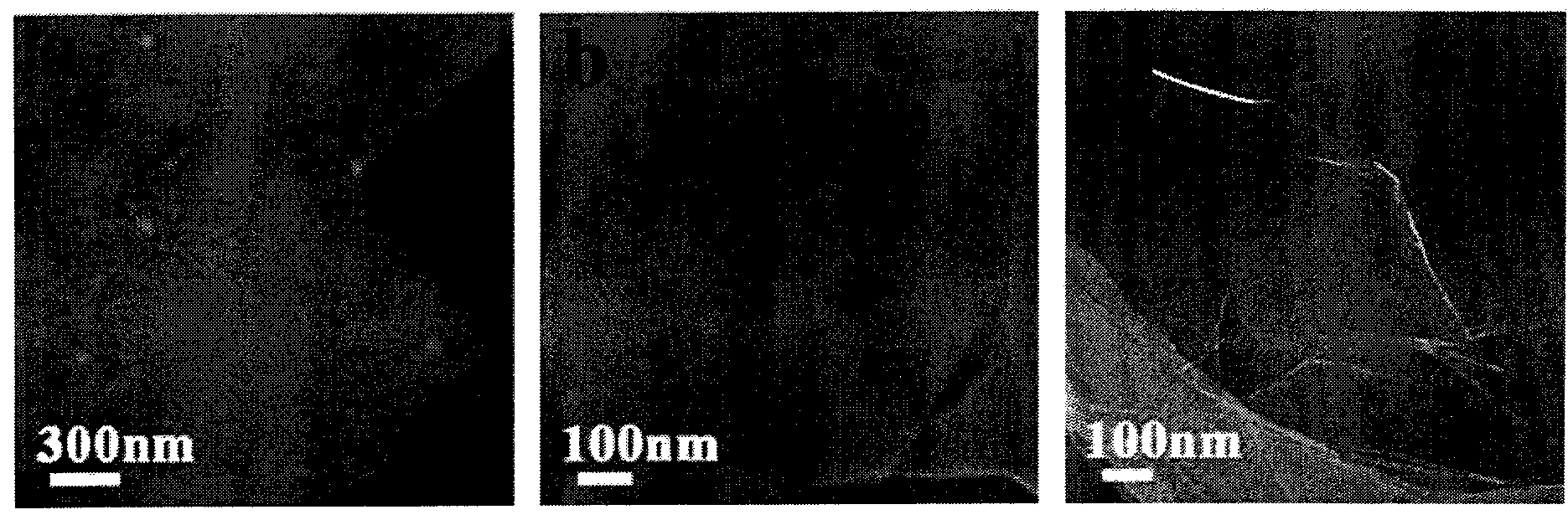

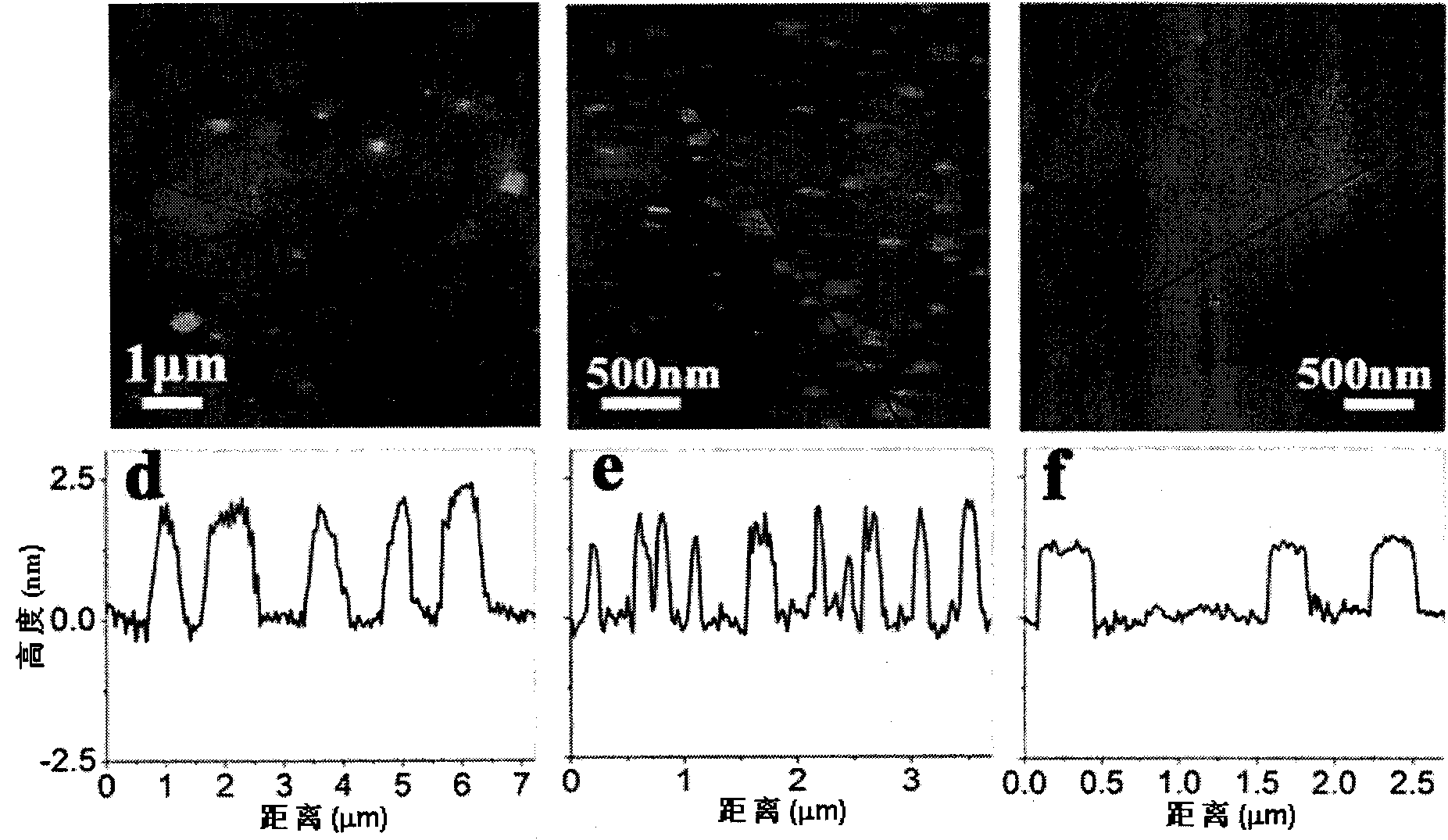

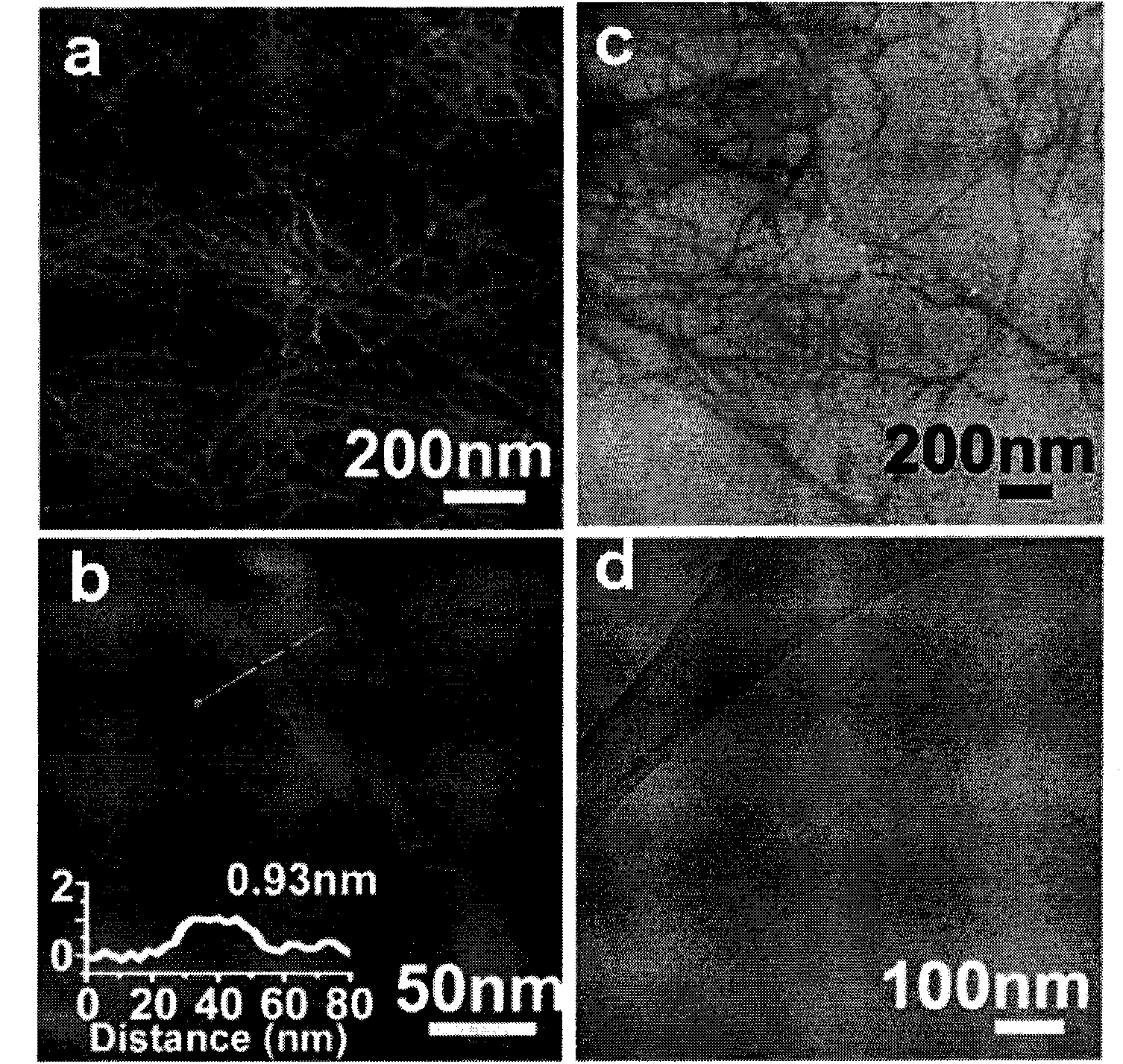

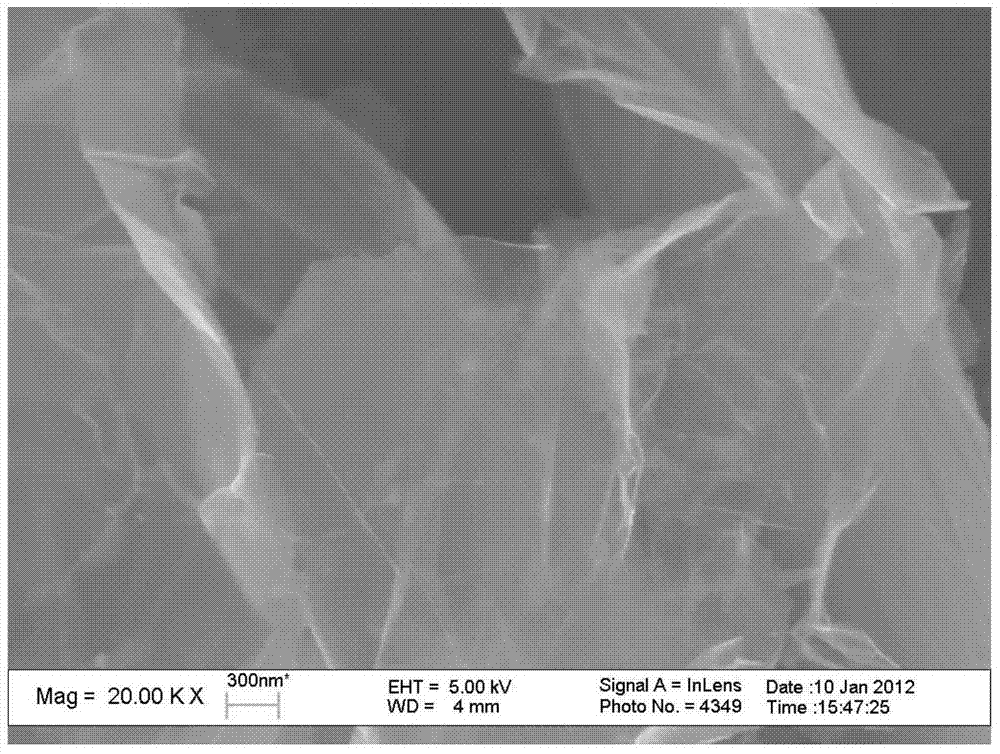

Method for preparing large-size high-quality graphene with controllable number of layers

The invention discloses a method for preparing large-size high-quality graphene with controllable number of layers, wherein graphite powder or flake graphite is mainly adopted as a raw material. The method specifically comprises the steps of intercalating the graphite raw material by virtue of an intercalating agent to initially weaken the intercalation interaction force and obtain different orders of graphite intercalation compounds (GICs); soaking the GICs in an appropriate expander, and then under the case that an auxiliary agent is added or not, enabling the intercalation materials to be quickly reacted with the expander to release a gases to obtain highly expanded wormlike graphene aggregate and further to cause the distances among graphene lamellar layers to be increased; and after certain processing, peeling, and then repeatedly centrifuging and dispersing to obtain a graphene dispersion with different numbers of layers. According to the method disclosed by the invention, the intercalation-expansion-peeling process is involved, raw materials are cheap, the reaction process is simple and easily controlled, and the number of layers of graphene is precisely controlled; the obtained graphene lamellar layers have the advantages of few defects, large size, high conductivity, high yield and the like, the large-scale industrial production is easily implemented, and the problems of high cost, low productivity, poor quality, small size, uncontrollable number of layers and the like in an existing graphene preparation technology are solved.

Owner:安徽百特新材料科技有限公司

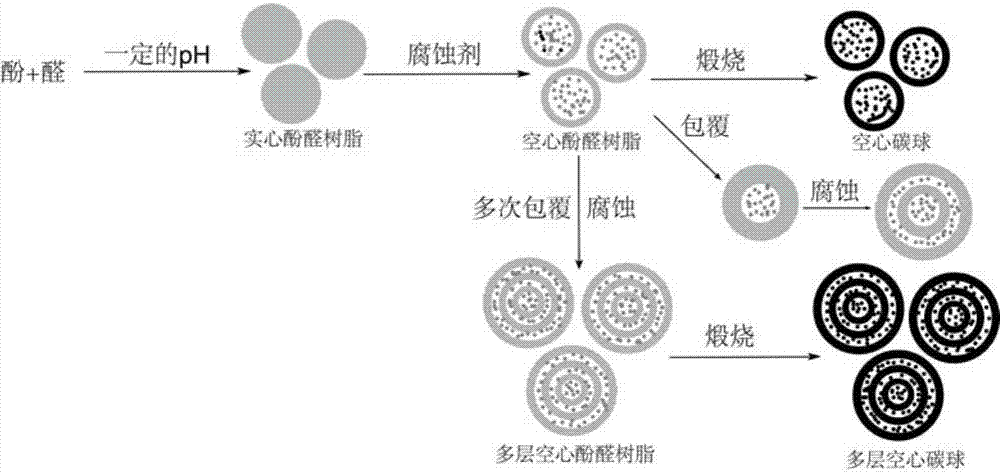

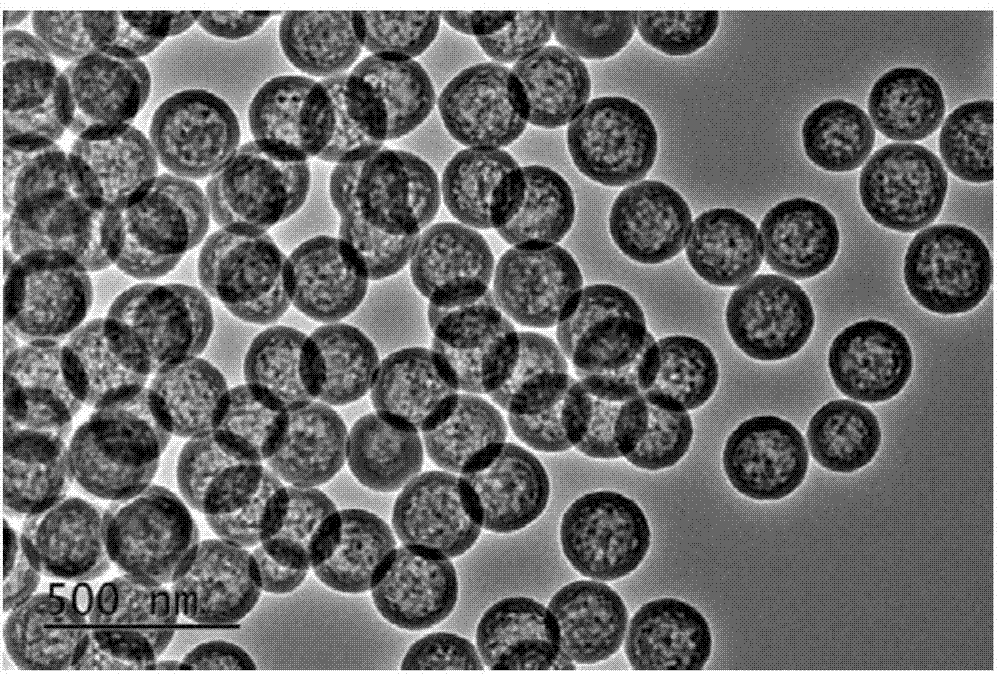

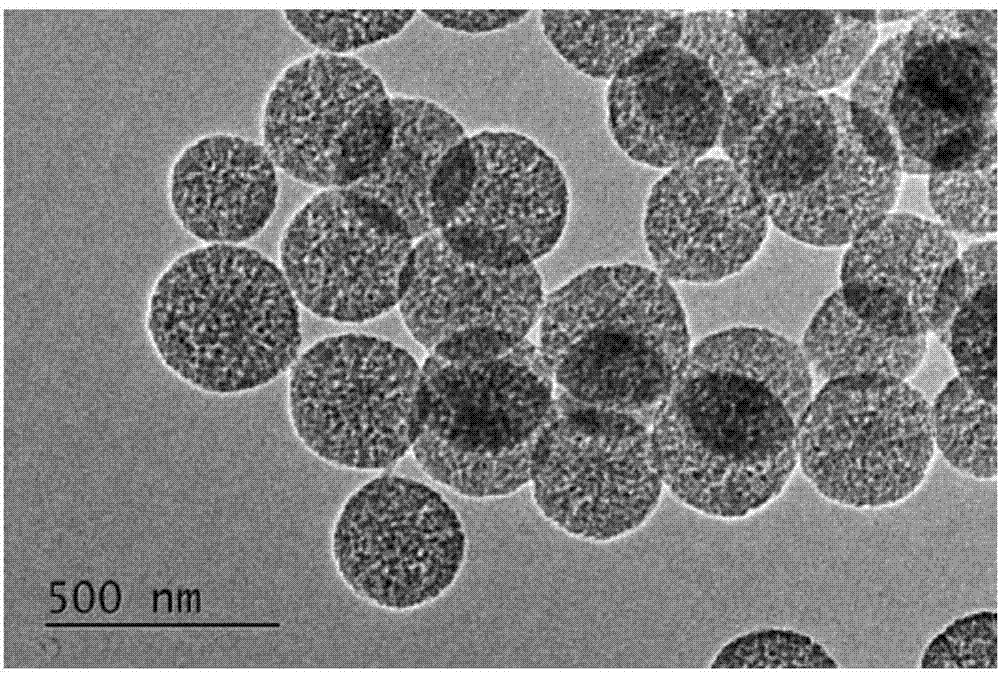

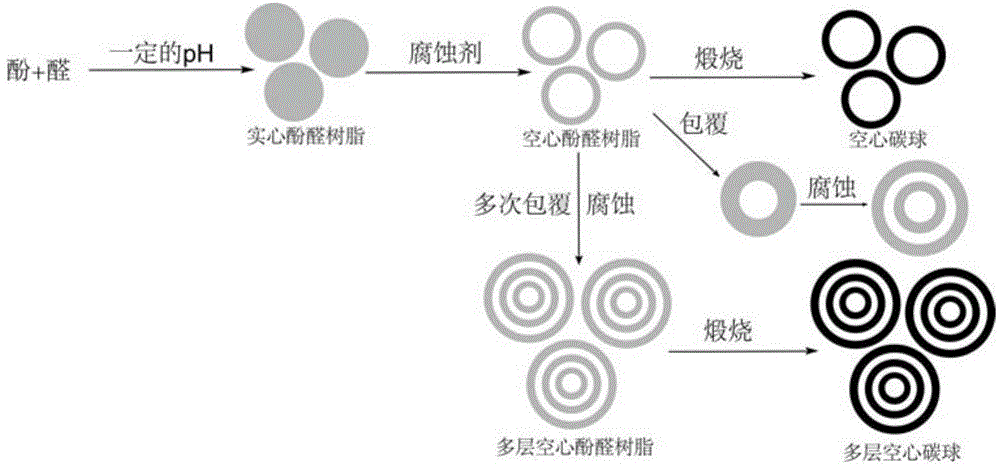

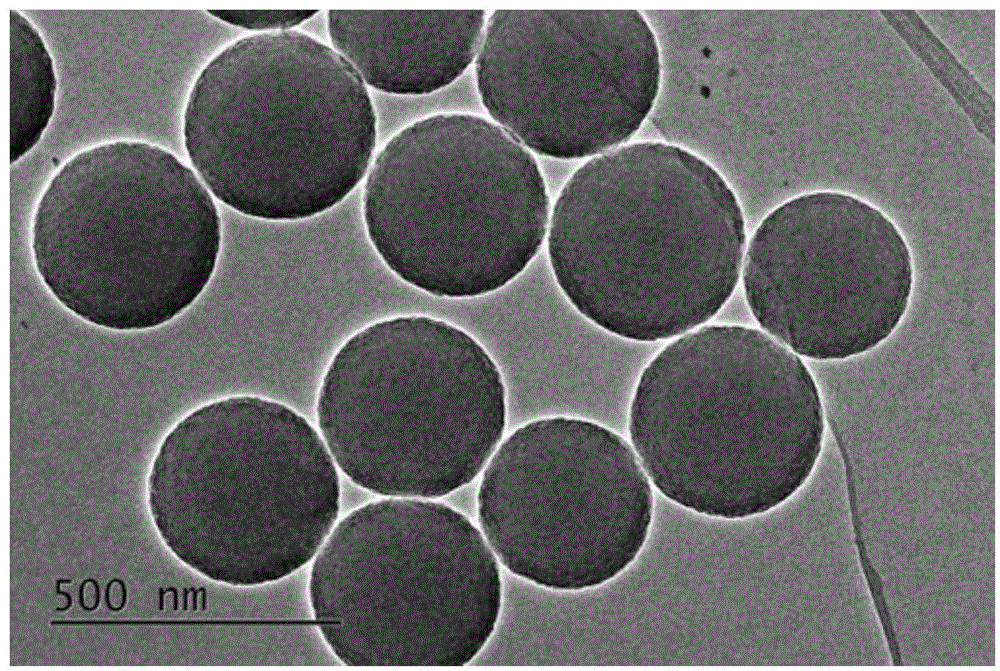

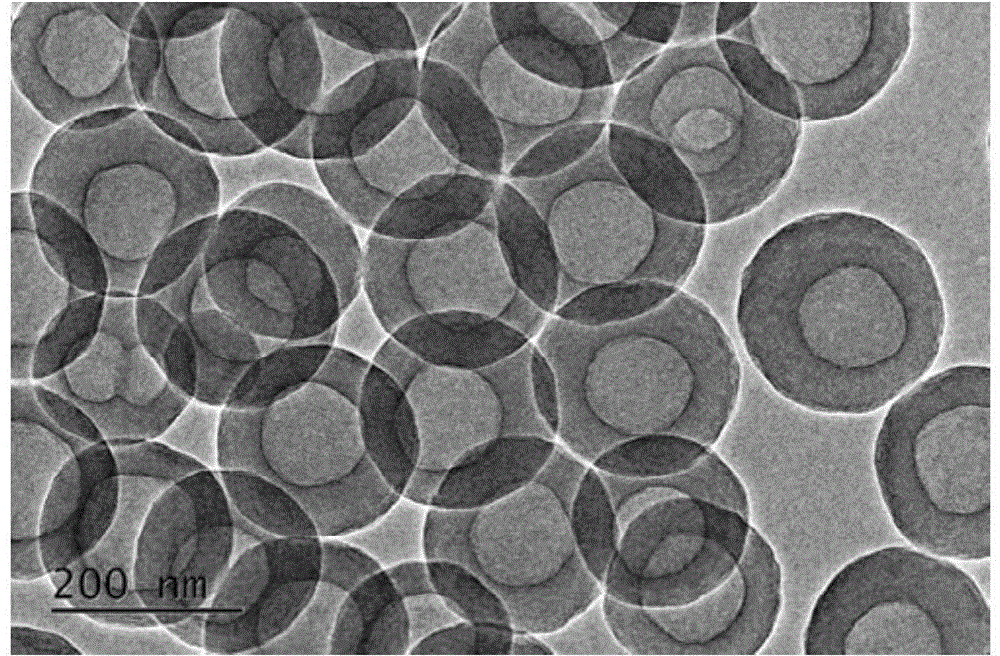

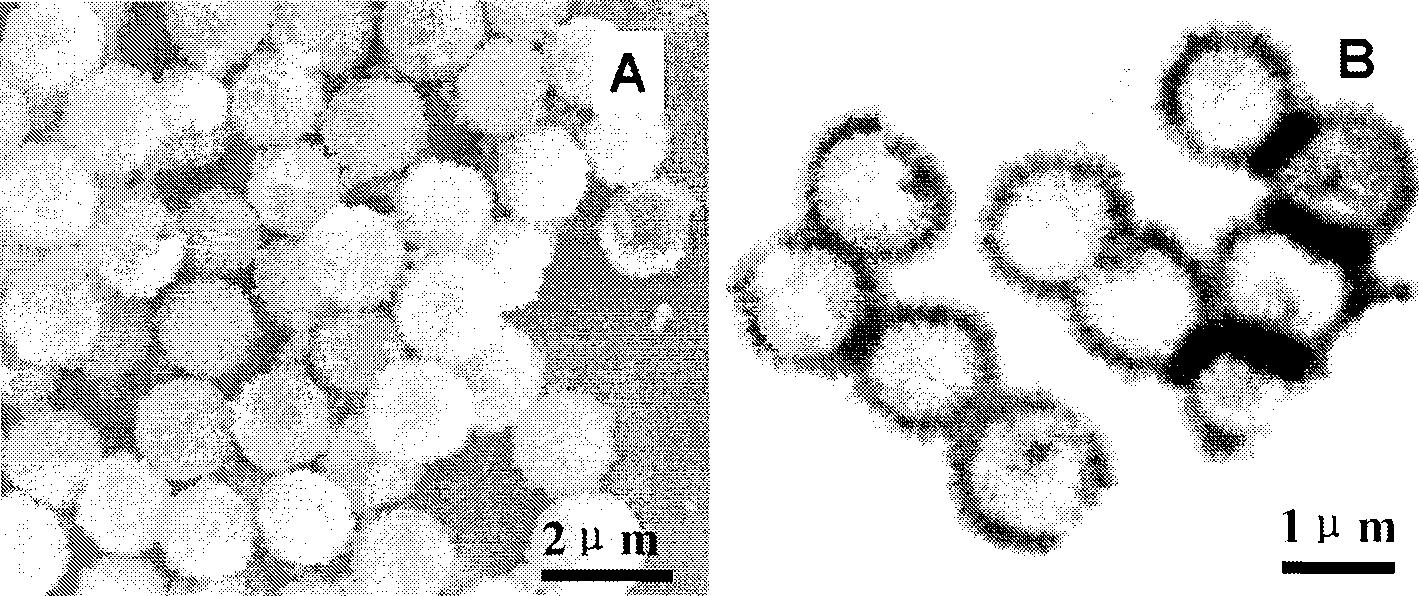

Single-layer and multi-layer hollow carbon nanosphere and preparation method and application thereof

ActiveCN104843665AEasy to operateMild reaction conditionsMaterial nanotechnologySolubilityIn situ polymerization

The invention discovers and proposes a characteristic that interior species of phenolic resin are nonuniform in distribution in a polymerization process, and discloses a method for preparing a hollow carbon sphere by utilizing the characteristic of phenolic resin. The method comprises: (1) putting phenol into water or a solvent, adjusting the pH, then adding aldehyde and stirring at a certain temperature for a period of time; (2) adding a corrosive agent in a reaction system, stirring at a certain temperature, and selectively removing a part with a relatively low polymerization degree inside a polymer by utilizing a solubility difference of interior species for different solvents, to obtain an intermediate product, that is, a hollow sphere of phenolic resin polymer; and (3) calcining the intermediate product that is obtained in step (2) in an inertia or reducing atmosphere, naturally cooling to room temperature, and thus completing preparation of the hollow carbon sphere. The method is simple and practicable, and the prepared hollow carbon sphere is uniform in shape and controllable in dimension. Moreover, by utilizing a characteristic that the phenolic resin can be in-situ polymerized on surfaces of different nanometer particles, on one hand, a multi-layer hollow structure can be prepared in a multi-cladding and layer-by-layer corrosion manner, and on the other hand, the different nanometer particles can also be packaged in a cavity in an in-situ mode, so as to prepare a nuclear shell or egg yolk-nuclear structure. The prepared hollow carbon sphere has a potential application value in aspects of silicon-carbon negative electrode material, Li-S battery, supercapacitor, heavy metal ion adsorption, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

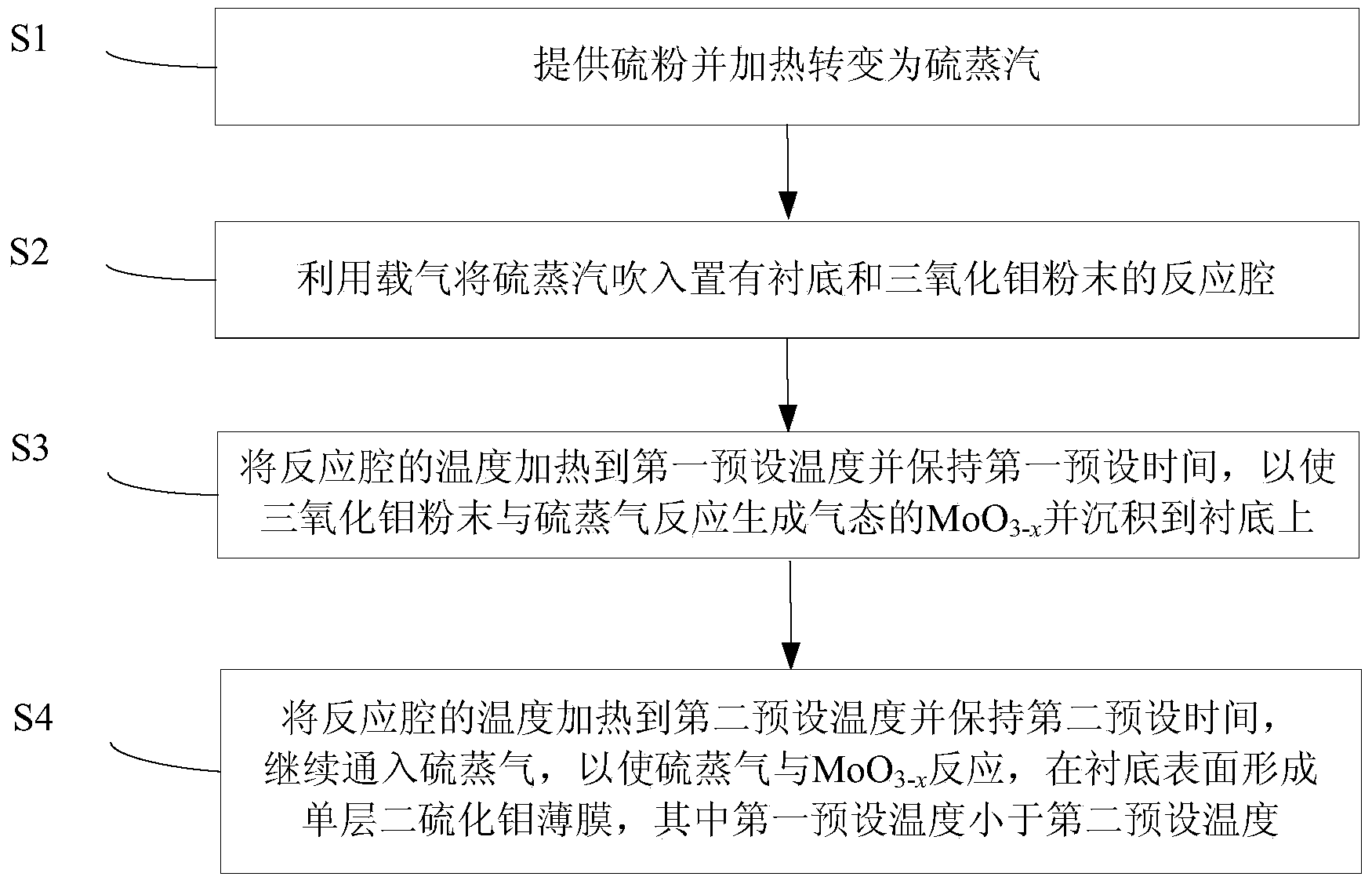

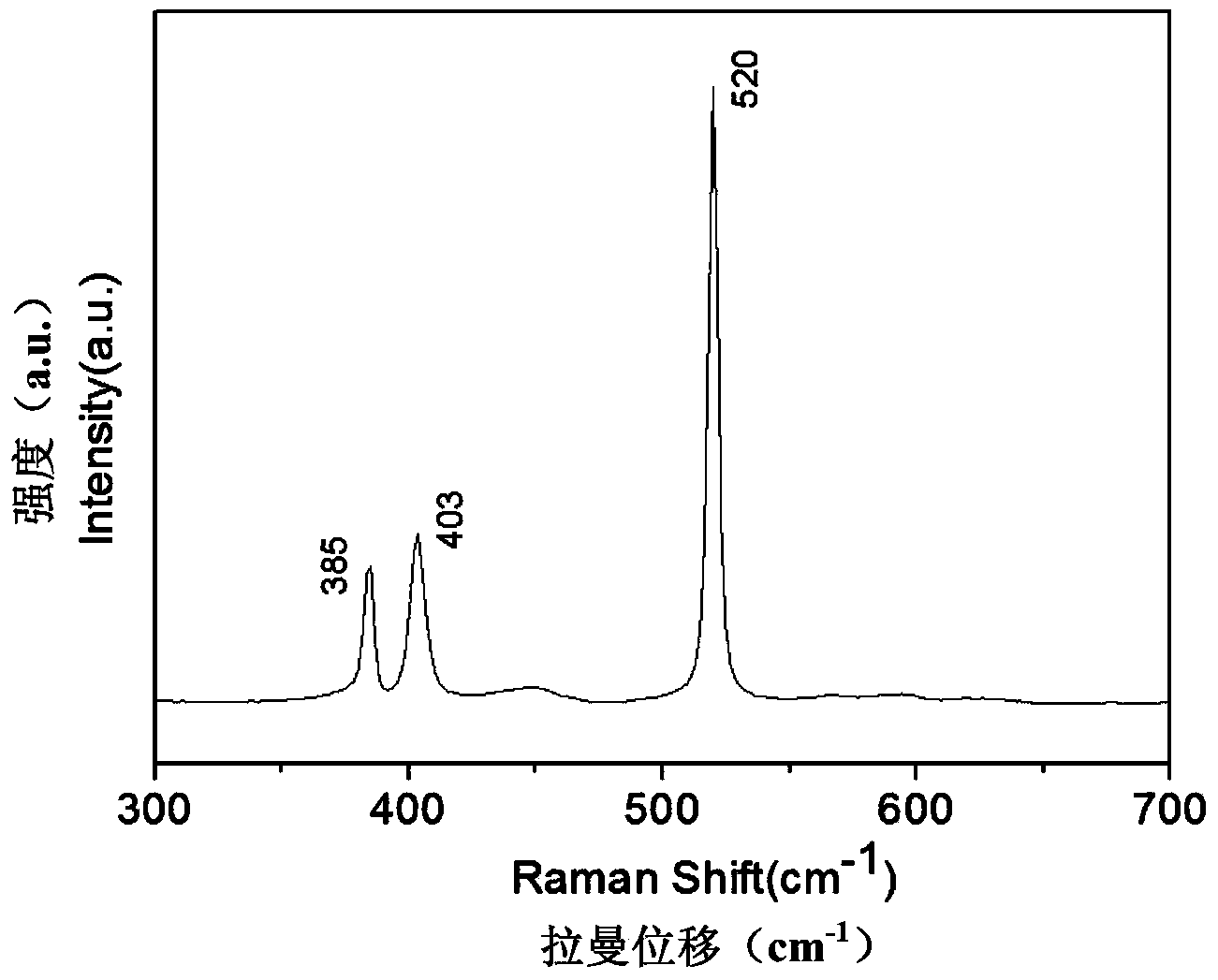

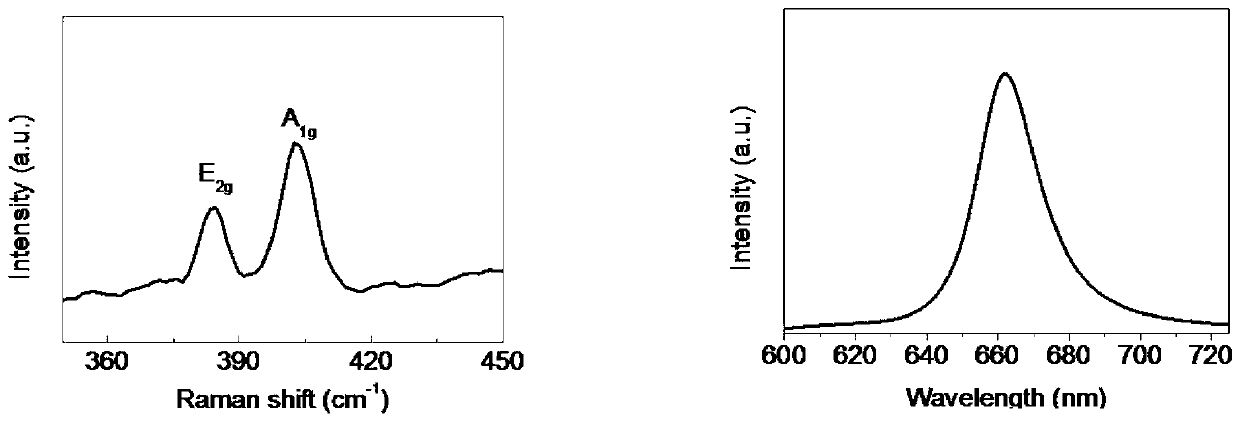

Method for preparing single-layer molybdenum disulfide film

ActiveCN103757602AThe number of layers is controllableChemical vapor deposition coatingSulfurMolybdenum trioxide

The invention discloses a method for preparing a single-layer molybdenum disulfide film. The method comprises the following steps: providing powdered sulfur and heating and transferring the powdered sulfur to sulfur vapor; blowing the sulfur vapor into a reaction cavity filled with a substrate and molybdenum trioxide powder by utilizing carrier gas; heating the temperature of the reaction cavity to a first preset temperature, and keeping the temperature for a first preset time, so that the molybdenum trioxide and the sulfur vapor are reacted to generate MoO3-x in a gas state to be deposited on the substrate, and x is more than 0 and less than or equal to 1; heating the temperature of the reaction cavity to a second preset temperature, keeping the temperature for a second preset time, continuously introducing the sulfur vapor, so that the sulfur vapor is reacted with the MoO3-x, and forming the single-layer molybdenum disulfide film on the surface of the substrate, wherein the first preset temperature is lower than the second preset temperature. According to the method, the large-area single-layer molybdenum disulfide film with controllable layers can be obtained through a two-step reaction method.

Owner:TSINGHUA UNIV

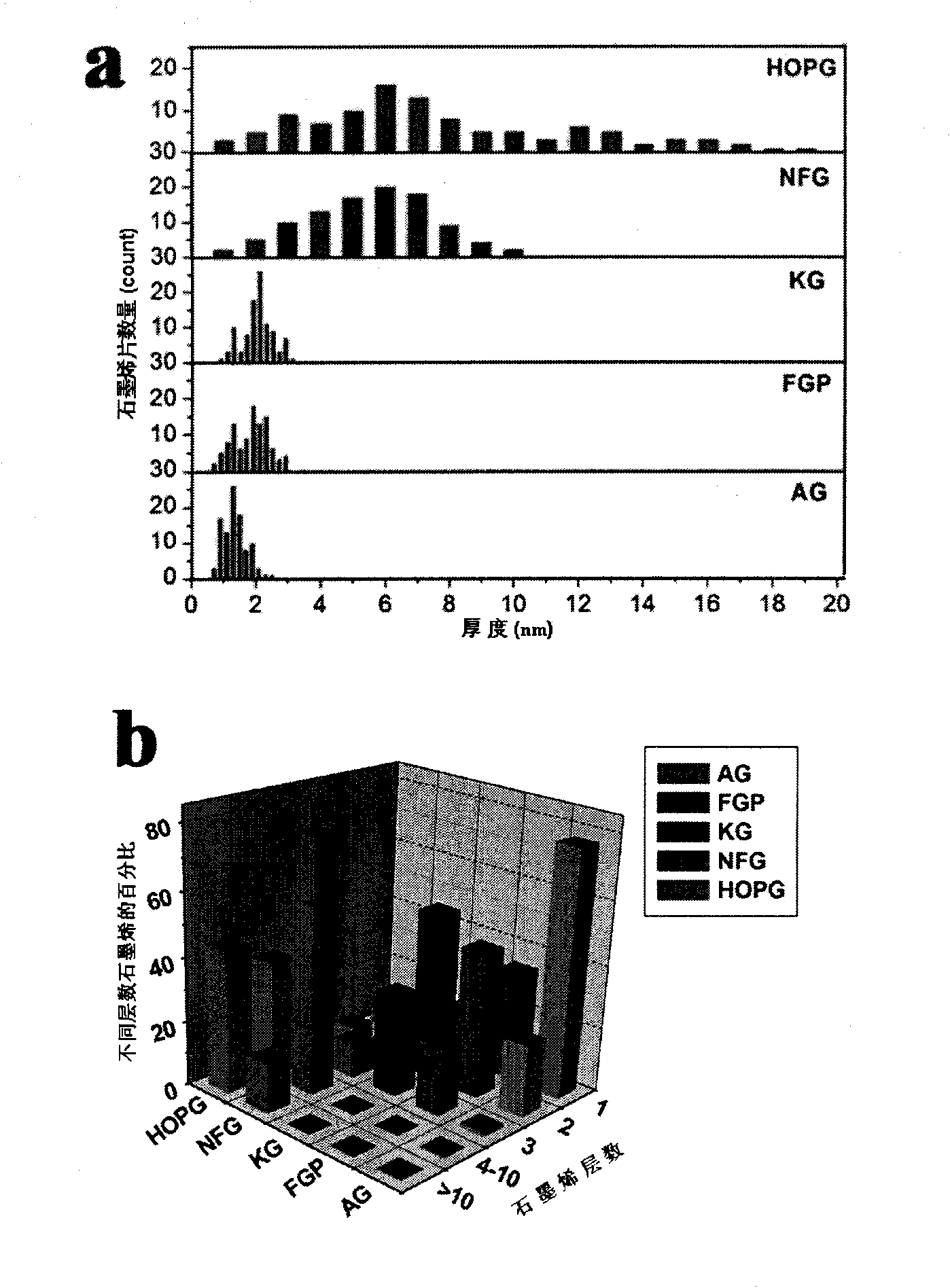

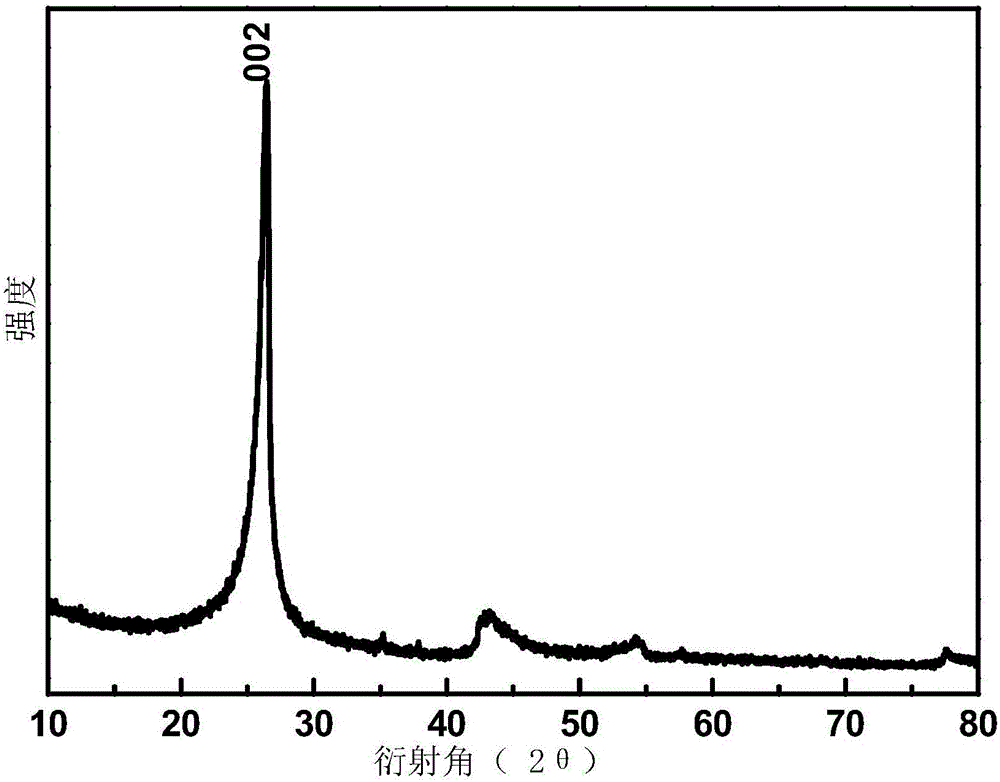

Method for preparing high-quality graphene with controllable layer number

The invention relates to technology for preparing graphene, in particular to a method for massively preparing high-quality graphene with a controllable layer number, which is suitable for massively preparing the high-quality graphene with the controllable layer number. In the method, graphite with different sizes and crystallinities is used as the raw material. The method comprises the following steps of: oxidizing the graphite by an Hummer method; swelling and splitting the oxidized graphite by a rapid heating method to obtain stripped graphite; reducing the stripped graphite at a high temperature; uniformly dispersing the reduced graphite in solution of a surfactant by an ultrasonic method; and removing the graphite which is not totally stripped and thick graphite sheets with large sizes by a high-speed centrifugation method so as to obtain the high-quality graphene with the controllable layer number. In the method, the layer number of the graphene is controlled according to different oxidization and splitting degrees of the graphite with different sizes and crystallinities, mixed gas of hydrogen and argon is used for reducing and stripping the graphite to further remove oxygenic functional groups in the graphene and improve the electrical conductivity of the graphene so as to prepare the high-quality graphene with the controllable layer number.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Single-layer and multi-layer hollow carbon nanospheres, and preparation and application thereof

ActiveCN104891468AEasy to operateMild reaction conditionsMaterial nanotechnologyHybrid/EDL manufactureYolkSolubility

The invention discloses a preparation method for hollow carbon nanospheres, comprising: 1) placing a phenol in water, adjusting the pH value, adding an aldehyde, and stirring the solution at a certain temperature for a period of time; 2) adding an etchant to the reaction system and performing stirring at a certain temperature to obtain an intermediate product through selective removal of parts with low polymeric properties in the polymer by using the solubility difference between internal substances for different solvents; 3) calcining, in an inert or a reducing atmosphere, the intermediate product obtained in Step 2), and cooling the substance, thereby completing preparation of the hollow carbon nanospheres. In addition, by using the property that the phenolic resin is capable of in-situ polymerization on different nanoparticle surface, on one hand, a multi-layer hollow structure can be made through multiple times of coating and layer-by-layer corrosion; and on the other hand, different nanoparticles can be in-situ packaged in a cavity, thereby making a core-shell or yolk-core structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme

The invention relates to a technology for producing graphene belts, in particular to a method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme. The method comprises the following steps of: firstly obtaining oxidized graphite in a Hummers method, selectively finishing line defects on the surface of the oxidized graphite by utilizing the oxygen-containing functional group in the process of oxidizing the graphite, and producing grapheme with surface line defects by combining high-temperature rapid expansion and peeling, thermal reduction, solvent dispersion and centrifugal separation; then cutting the graphene and recovering the structure of the graphene by utilizing ultrasonic shearing and chemical reduction; and finally removing large pieces of incompletely cut grapheme in a high-speed centrifuging method to further produce the graphene belt with controllable layer number and width. The method can be used for producing the graphene belt with controllable layer number, width and boundary by controlling the key cutting process parameters, such as graphite raw material variety, oxidization process, peeling process, reduction process, dispersion process and centrifugal treatment process, and the method is easy to operate and has low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

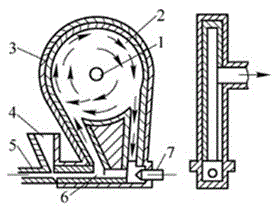

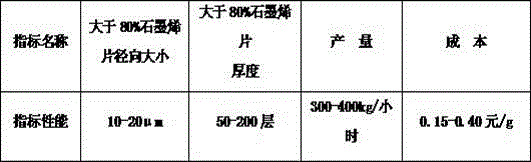

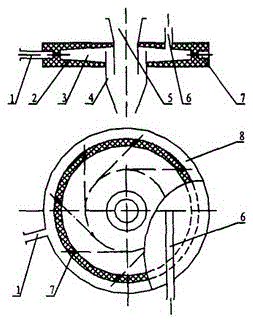

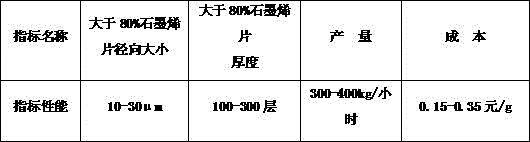

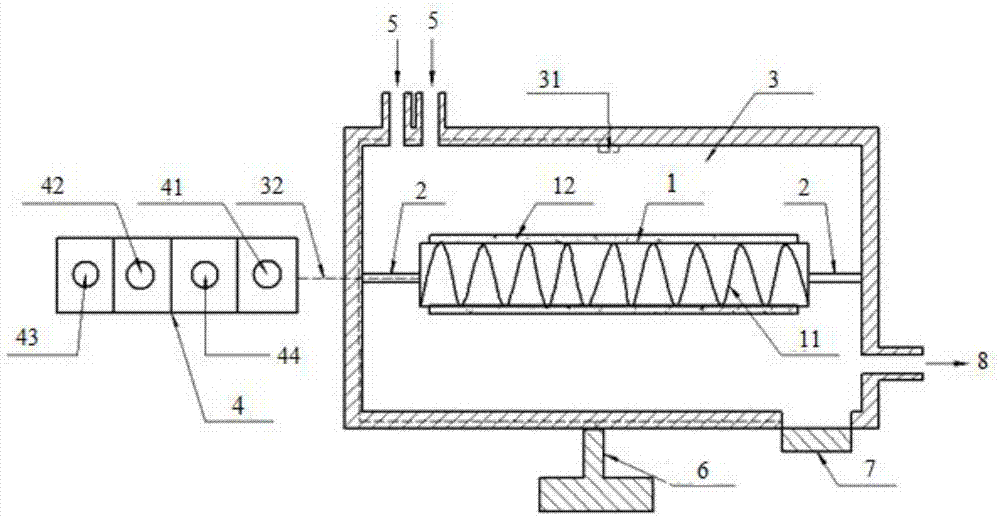

Method for preparing graphene micro-sheets by using counter-jet jet mill

The invention relates to the field of graphene materials, particularly relates to preparation methods for graphene micro-sheets and particularly relates to a method for preparing the graphene micro-sheets by using a counter-jet jet mill. According to the method, the graphene sheets are obtained through enabling melted ferric chloride and potassium chloride to enter an interlayer of graphite, enabling the powder materials to be in collision through high-speed airflow in the counter-jet jet mill by using the characteristic of brittleness of ferric chloride and potassium chloride crystal grains and the characteristics of good fluidity and difficulty in agglomeration of talcum powder, delaminating the graphite and the talcum powder by generated impact force, shearing force and frictional force, carrying out further separation by a grading room, refluxing unqualified powder material to a crushing chamber, and yielding delaminated graphite and talcum powder as well as gas together. The continuous and large-scale production of the graphene micro-sheets, which are uniform in layer number dispersion and good in fluidity and are not prone to agglomeration, is achieved, the yield is high, the cost is low, no pollution is caused, and the layer thickness meets the requirements of use in the fields of rubber reinforcing, plastic reinforcing, coating material anticorrosion, lubrication and sewage treatment, so that the promotion of the large-scale application of graphene is facilitated.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

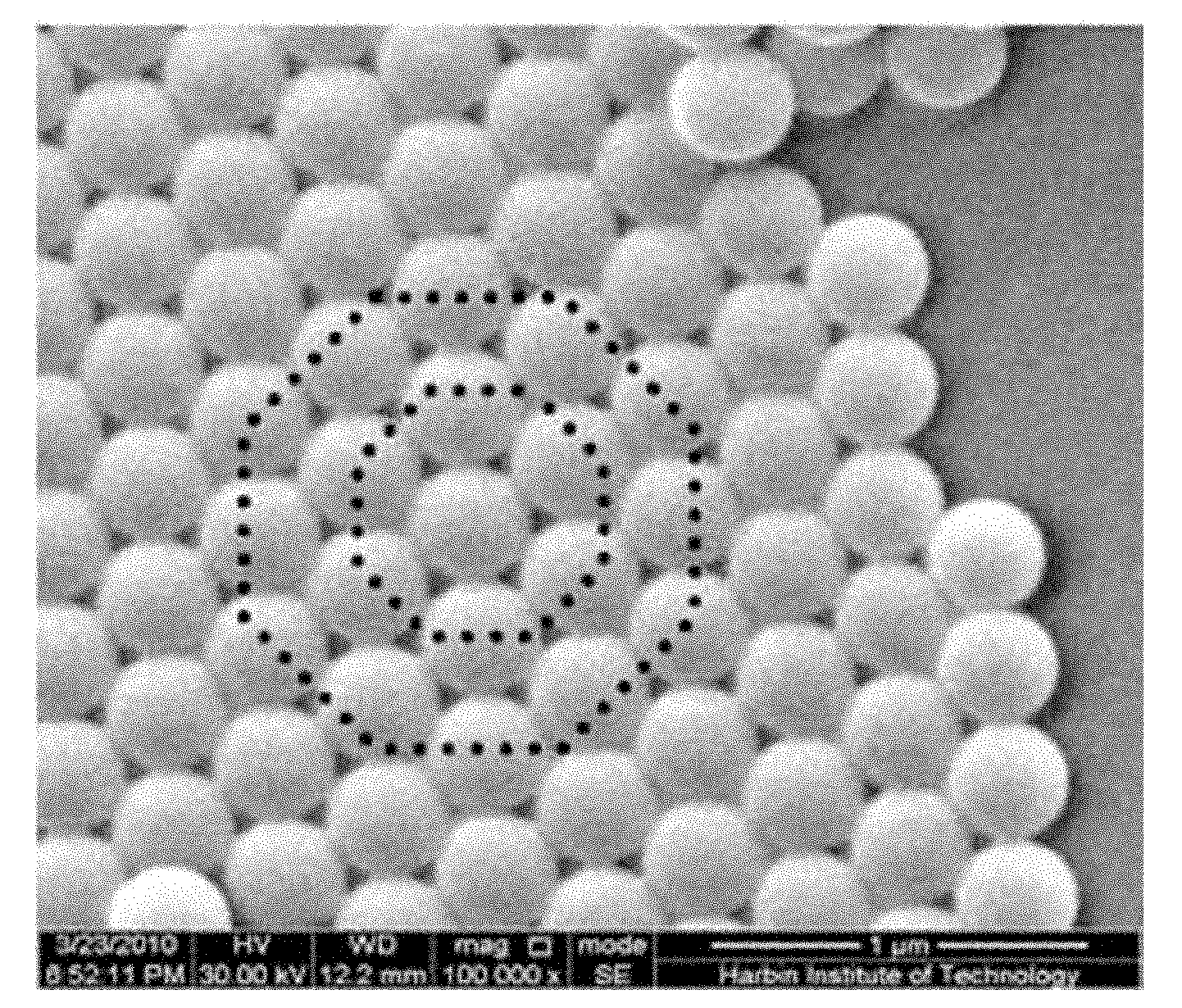

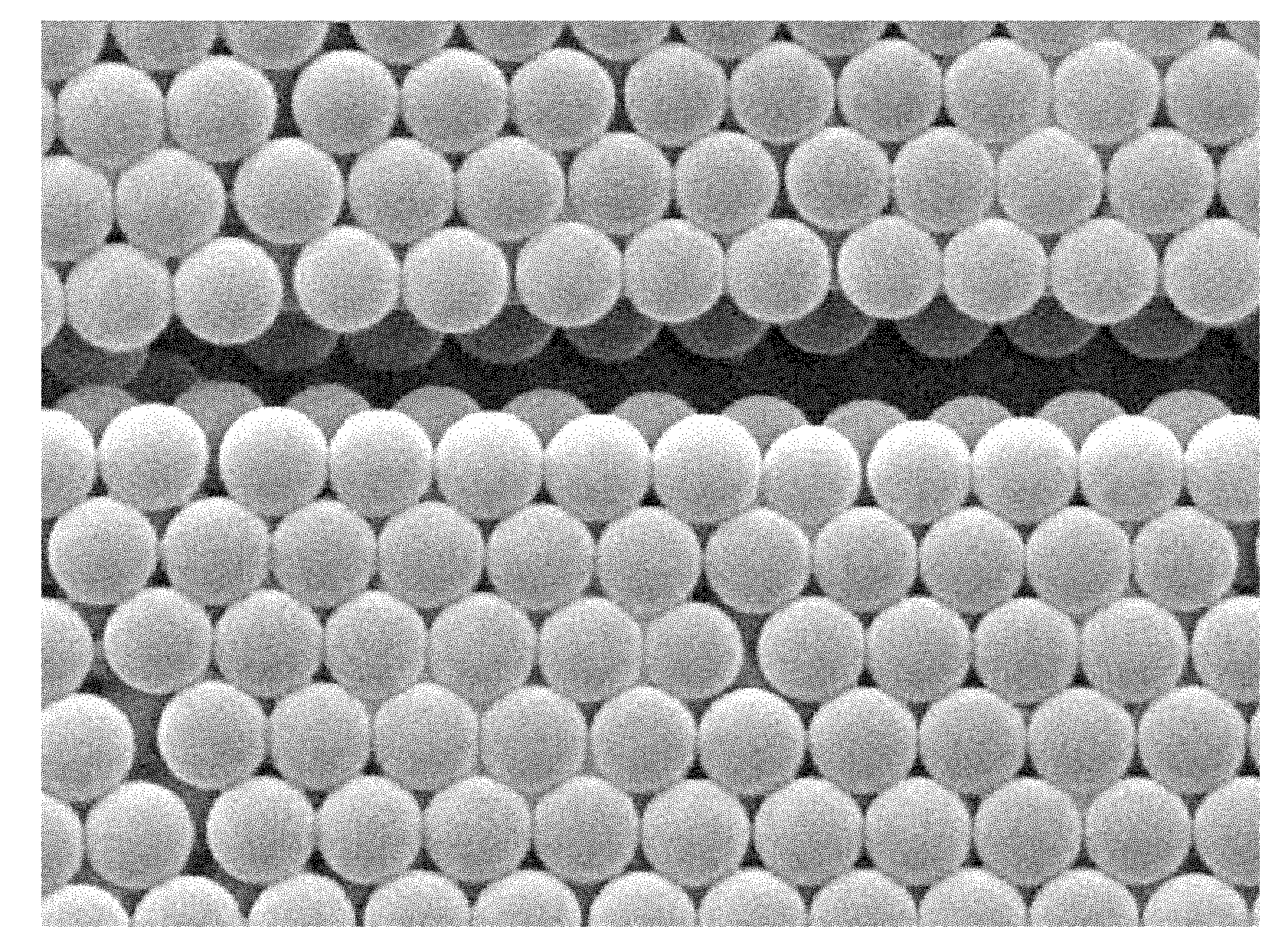

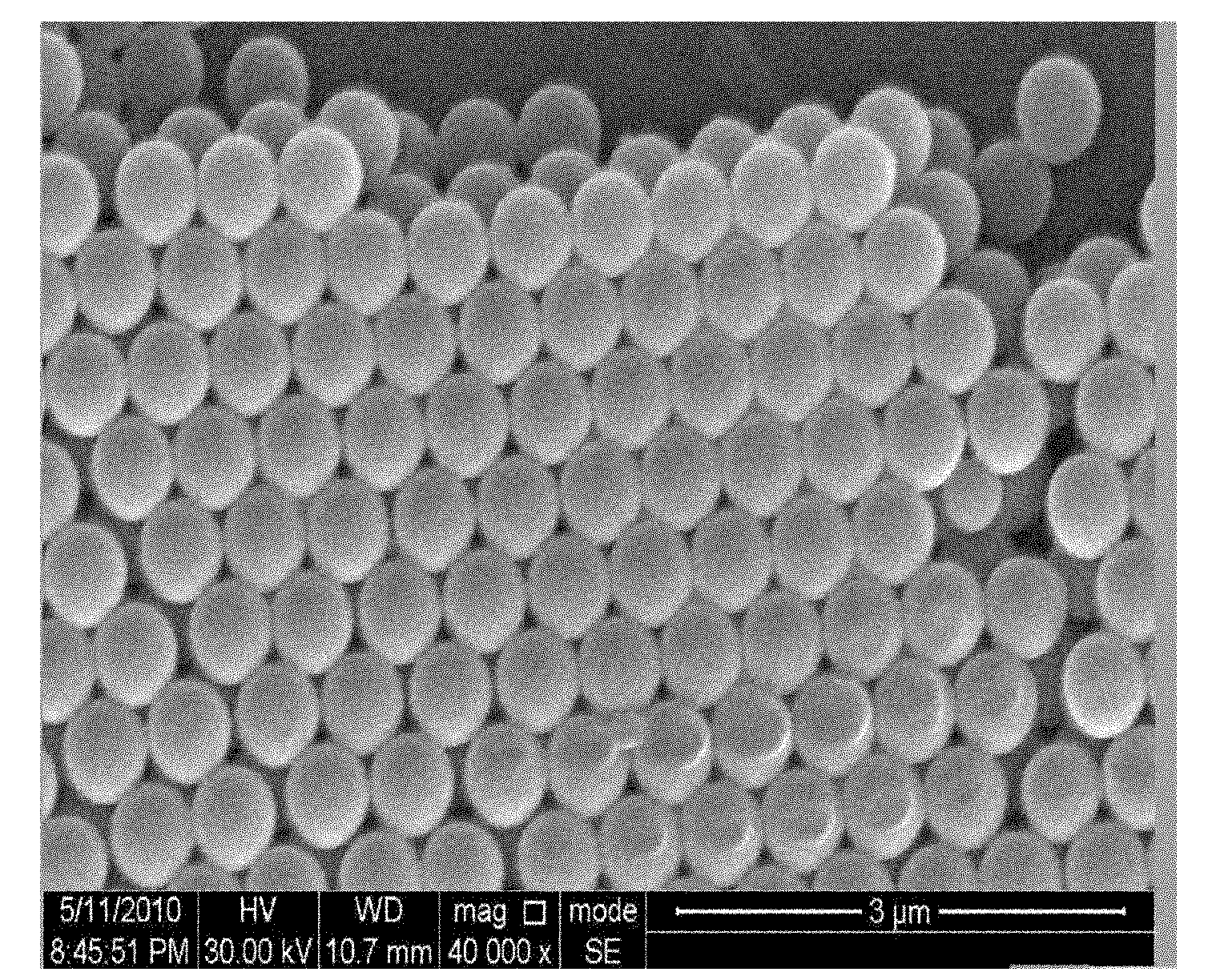

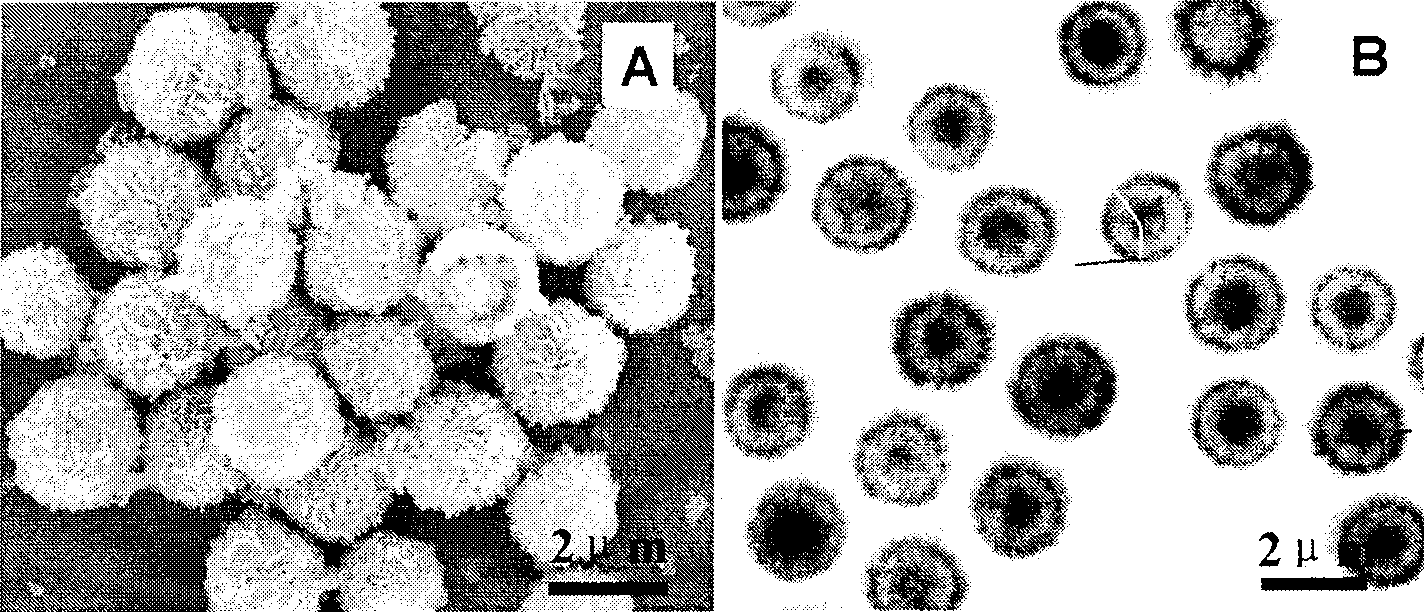

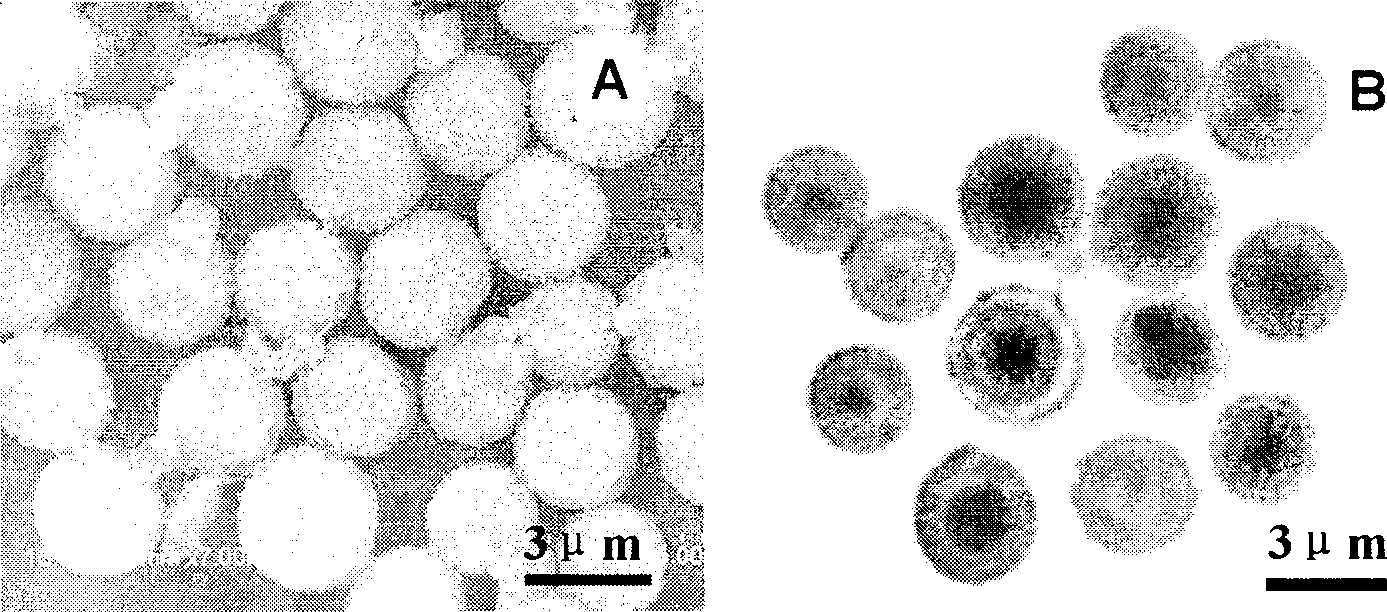

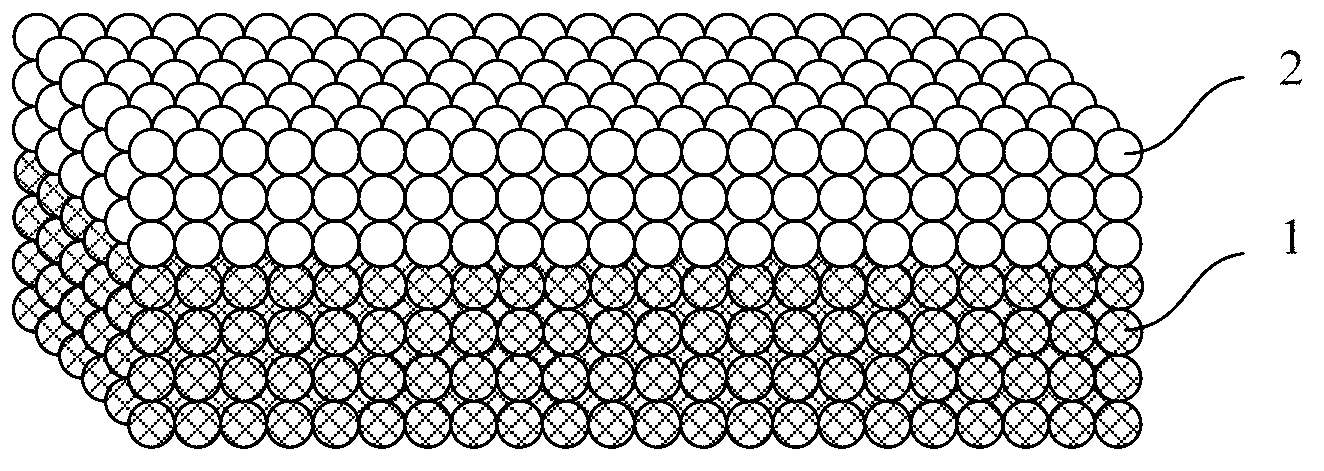

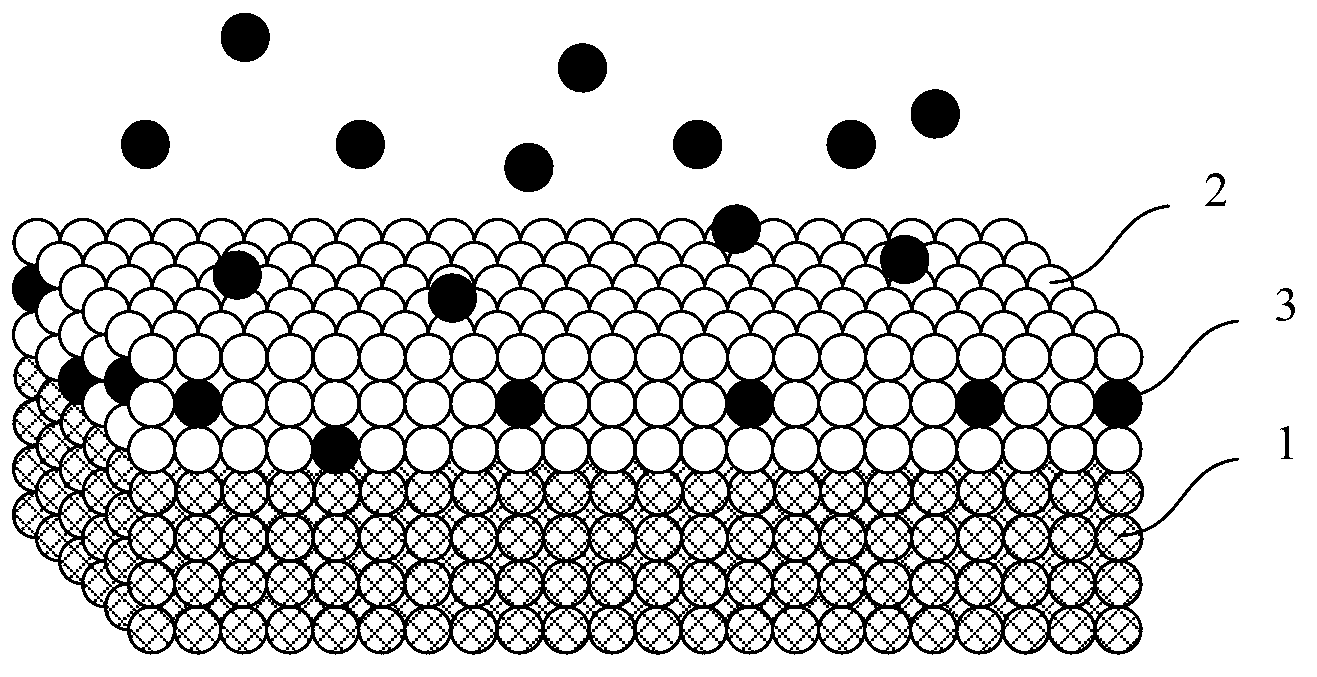

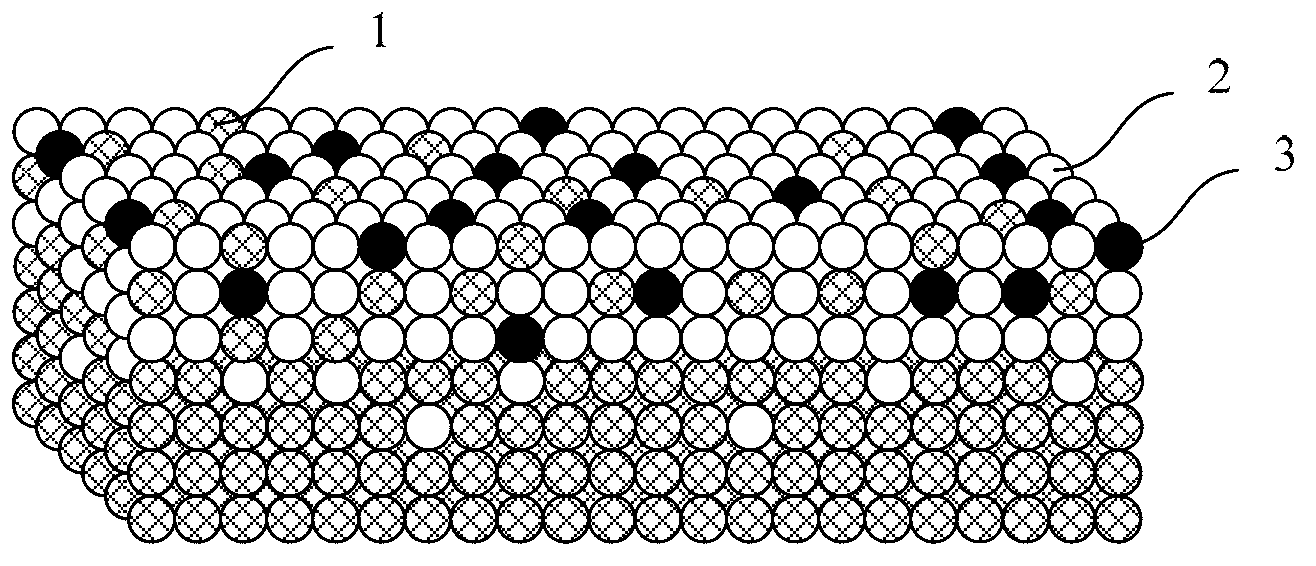

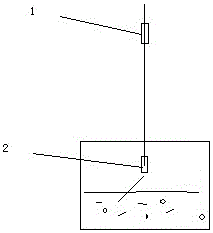

Self-assembling growth method of layer-controllable colloidal crystal

ActiveCN101934211AThe number of layers is controllableOvercoming the problem of poor orderPolycrystalline material growthColloidal chemistry detailsOptical propertyPhotonic crystal

The invention provides a self-assembling growth method of a layer-controllable colloidal crystal, which relates to a self-assembling growth method of a colloidal crystal and solves the problems that the traditional preparation method of colloidal crystal is more complicated, not easy to control and difficult to obtain the layer-controllable colloidal crystal. The method comprises the following steps of: 1. carrying out cleaning processing on a substrate, 2. preparing a colloidal particle suspension; and 3. inserting the substrate processed in the step 1 into the colloidal particle suspension prepared in the step 2, and placing into a constant-temperature incubator for 2-3 days. The method has the advantages of simple process, high efficiency, easy control and good repeatability and solvesthe problems of difficult layer number control of the self-assembling growing colloidal crystal and lower order degree of the obtained colloidal crystal of a traditional method and can be used for growing the colloidal crystals with large areas, ordered height and controllable layer number. The layer-controllable colloidal crystal obtained through self-assembly supplies a material for intensivelystudying the structure and the optical property of photonic crystals and simultaneously supplies a more rational and accurate template for three-dimensional ordered macroporous materials.

Owner:HARBIN INST OF TECH

Method for preparing graphene by using lignin

The invention belongs to the technical field of carbon material manufacturing technology, and in particular relates to a method for preparing graphene by using lignin as a raw material. The method is as follows: a layered or powdered material is used as a substrate, the lignin and a catalyst precursor are alternately assembled on the surface of the substrate by a layer-by-layer electrostatic self-assembly method, then a lignin / catalyst precursor / substrate composite is put into a double-temperature-zone tubular furnace, a H2 / Ar mixed gas is introduced into the double-temperature-zone tubular furnace at a certain speed, at the same time the double-temperature-zone tubular furnace is heated by a certain procedure, after the double-temperature-zone tubular furnace is heated to target temperature, the temperature of the double-temperature-zone tubular furnace is held for a certain time, when the double-temperature-zone tubular furnace is cooled to room temperature, the sample is taken out, and is soaked in an acid for catalyst removal, and after a plurality of times of washing and vacuum drying, the graphene is obtained. The method has the advantages of simple process and convenient operation, and the prepared graphene is good in growth, controllable in layer number and considerable in yield.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing graphene nanoplatelets with disk type jet mill

ActiveCN105523550AFacilitate the promotion of large-scale applicationEvenly dispersedGraphenePolymer scienceGraphite

The invention relates to the field of graphene materials, in particular to a method for preparing graphene nanoplatelets with a disk type jet mill. Graphite powder is subjected to heat treatment firstly, then graphene is pretreated with an intercalation agent, Van der Waals's force between graphite layers is decreased, graphite layers are easier to strip, the graphite powder is added to the disk type jet mill, graphite rubs and collides with one another in jet stream collisions to produce shear force serving as the main force, friction force and impact force, graphite layers are stripped, and the graphene nanoplatelets are obtained. Continuous and mass production of the graphene nanoplatelets with uniform layers is realized, the yield is high, the cost is low, pollution is avoided, the layer thickness meets the use requirement in fields of rubber reinforcement, plastic reinforcement, coating corrosion prevention, lubrication and sewage treatment, and large-scale application of graphene is promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

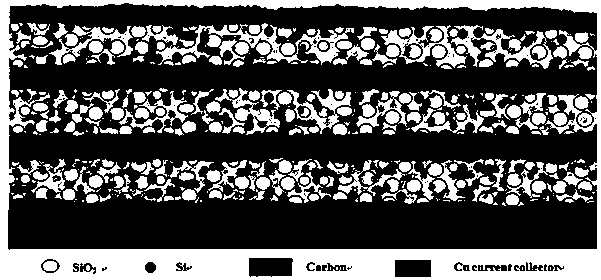

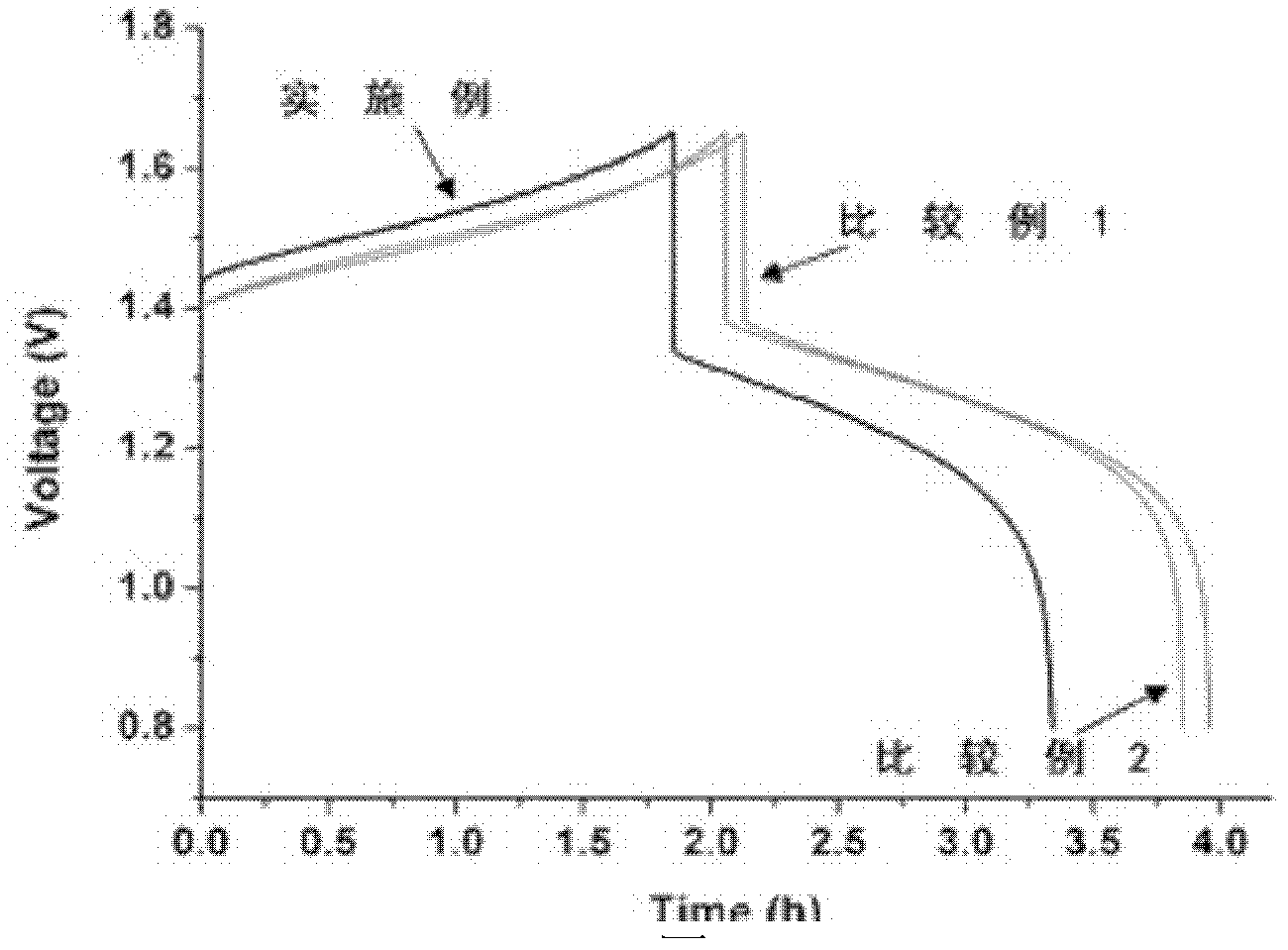

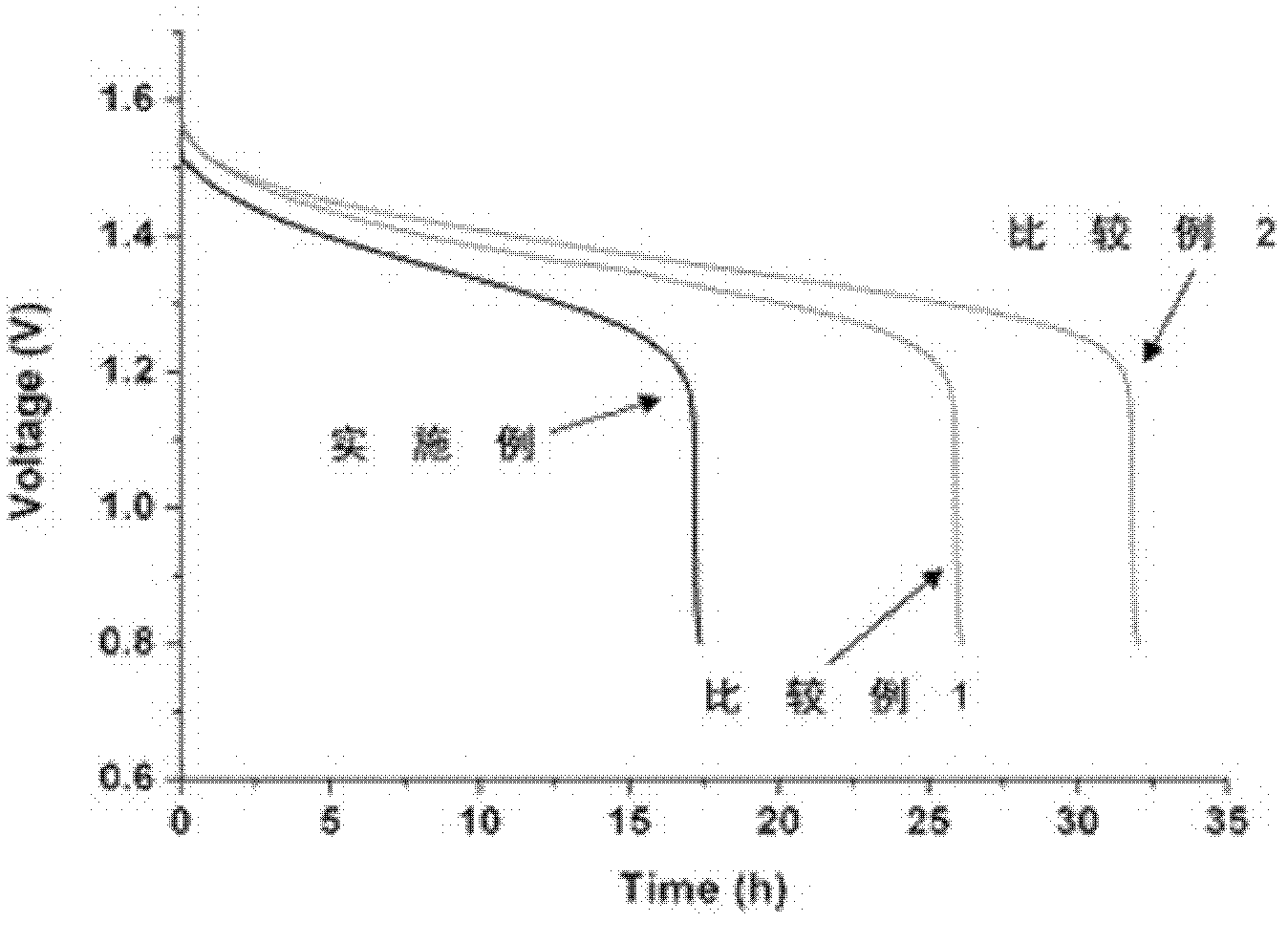

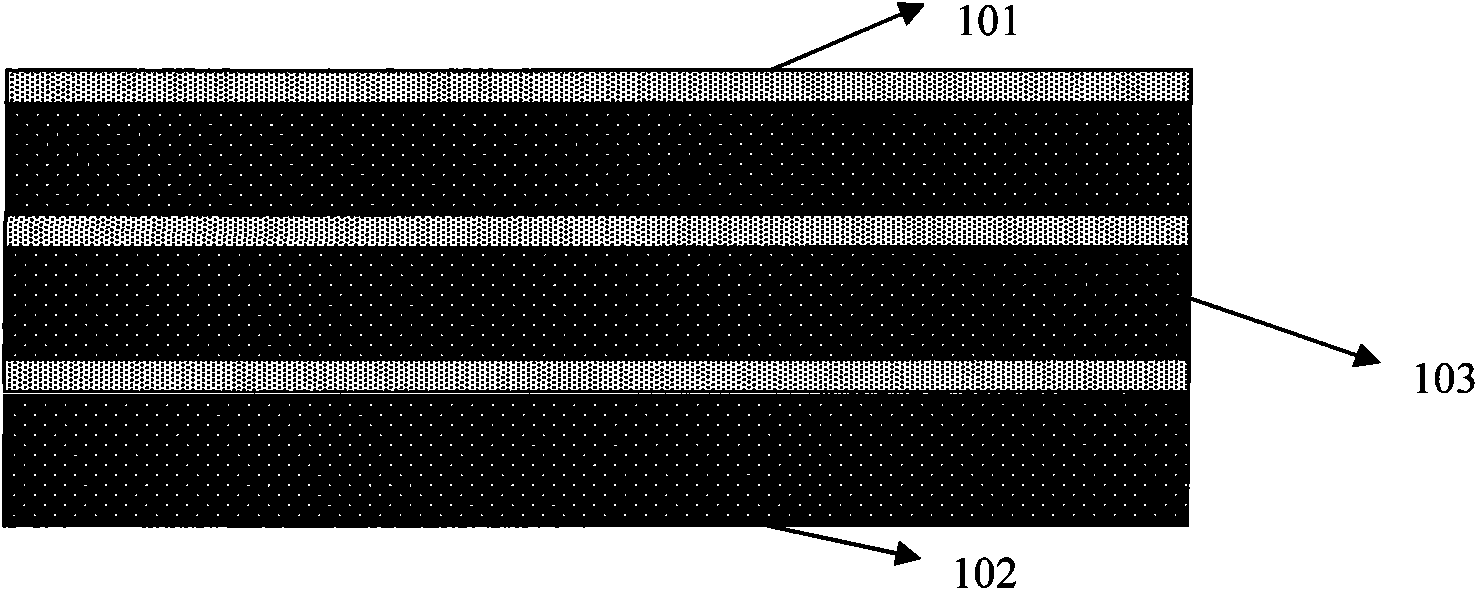

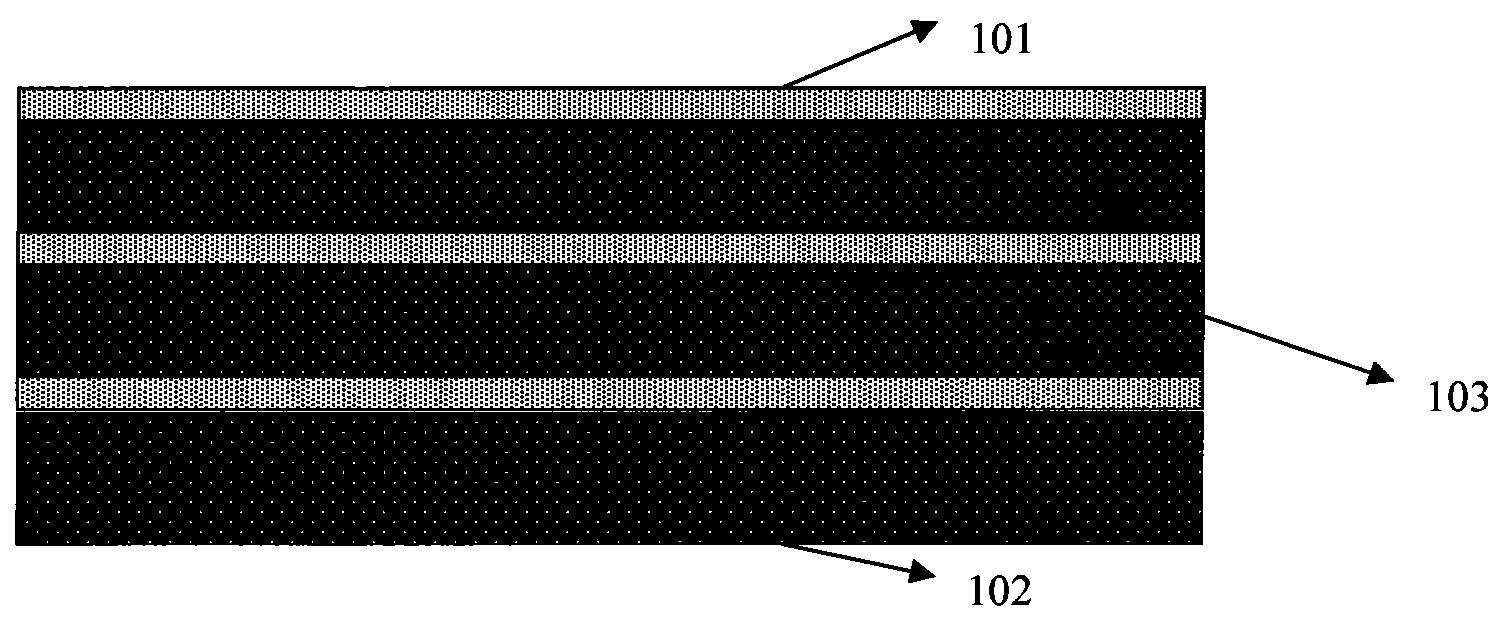

Multilayer membrane electrode and preparation method and application thereof

InactiveCN104218213AThe number of layers is controllableImprove conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon layerSilicon dioxide

The invention discloses a multilayer membrane lithium ion battery negative electrode comprising a substrate, a silicon base layer and a carbon layer, the silicon base layer and the carbon layer are laminated alternately, the silicon base layer comprises silicon, silicon dioxide and carbon filled between the silicon and the silicon dioxide. The invention also discloses a preparation method using the microwave plasma enhanced chemical vapor deposition (MPECVD) for preparing the multilayer membrane lithium ion battery negative electrode, the multilayer membrane lithium ion battery negative electrode is controllable in the number of electrode layer and thickness, due to the advantages of the structure, the electrode has good conductivity and mechanical adhesion strength, so that the loading capacity of active substances of the electrode is allowed to be improved by increasing of the number of layer, and the energy density of the electrode is improved. The SiO2&Si / C membrane electrode with a 12-layer sandwich structure can achieve good capacity holding rate, and under the current density of 1 / 8C, the reversible capacity reaches 0.46mAh / cm<2> specific capacity per unit area. The material structure strategy can also be applied to other materials, and excellent performances are also expected to be achieved.

Owner:SUN YAT SEN UNIV

Graphene material and preparation method of electrode material of graphene material

ActiveCN104876213ASolve difficult preparationFix stability issuesCell electrodesPorous grapheneHeat conducting

The invention relates to a halide intercalated porous graphene material. The halide intercalated porous graphene material contains porous graphene sheets and a halide; the halide is intercalated between the porous graphene sheets; the particles of the halide are evenly spread between the porous graphene sheets at one single layer. The preparation method of the halide intercalated porous graphene material comprises the steps of taking a halide intercalated graphite compound as the raw materials and performing ultrasonic stripping on the raw material in a solvent to prepare the halide intercalated porous graphene material. The method is simple; the raw material is cheap and the equipment is easy to obtain; the production cost of the graphene is greatly reduced; in short, the method can be widely applied to the field of preparation of lithium-ion reversible battery electrode materials, energy source materials, conductive materials, heat-conducting materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

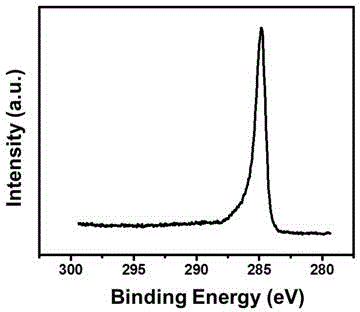

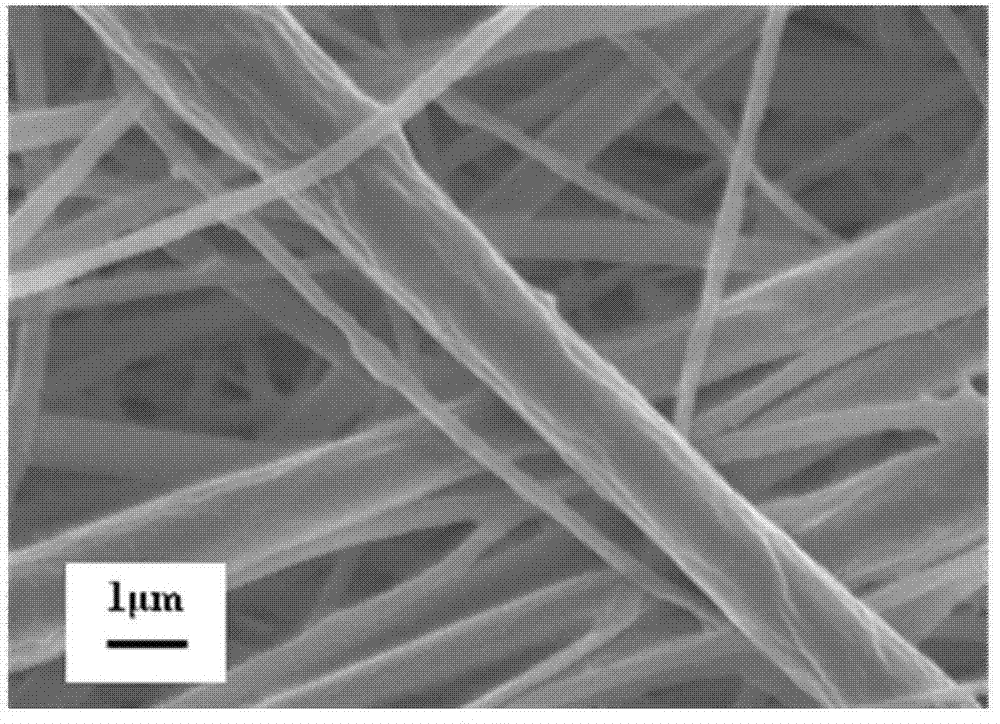

Modified cellulose nanofiber membrane based on layer-by-layer self-assembly of lysozyme and silk protein based as well as preparation and application thereof

ActiveCN103536958AExcellent adhesionAvoid infectionAbsorbent padsBandagesCell adhesionCellulose acetate

The invention discloses a modified cellulose nanofiber membrane based on layer-by-layer self-assembly of lysozyme and silk protein as well as preparation and application thereof and belongs to the technical fields of high polymer materials and biomedical materials. According to the invention, a cellulose acetate nanofiber membrane is prepared by utilizing an electrospinning technique and lysozyme and silk protein which are opposite in charges are alternately assembled on the surface of the cellulose nanofiber membrane by adopting a layer-by-layer assembly technique so as to obtain the modified cellulose nanofiber membrane disclosed by the invention. The membrane disclosed by the invention has the advantages that the preparation equipment is simple, raw materials are low in cost, non-toxic and biodegradable, the whole process is simple to operate and the number of lysozyme / silk protein layers is controllable. Proved by antibacterial tests, cell survival tests, cell fluorescence staining tests, cell adhesion tests and in vitro wound healing tests, the modified cellulose nanofiber membrane disclosed by the invention has good antibacterial performance and cell adhesiveness and is capable of increasing the wound healing efficiency and preventing the wound infection, so that the membrane is a very good wound repairing material and can be used in the wound repairing field.

Owner:HUBEI SAILUO BIOLOGICAL MATERIAL CO LTD

Lithium cell negative pole material and preparation thereof

InactiveCN101453017AThe number of layers is controllableElectrode manufacturing processesNickel oxidesZinc

The invention relates to a lithium cell cathode material and a method for preparing the same, which belong to the technical field of micron and nanometer material. The prior transition metal oxide lithium cell cathode material is a monolayer and has low space utilization rate. The provided cathode material is a multilayer spherical metal oxide; the layer number of the sphere is between 1 and 4; the particle diameter of the outermost layer is between 1.5 and 5 mu m; the metal oxide is cobaltosic oxide, ferroferric oxide, ferric oxide, nickel oxide or zinc oxide. PVP and soluble salt of cobalt, iron or nickel are dissolved in organic alcohol according to mass ratio of between 0.02-0.5:1 and react in a hydrothermal kettle for 12 to 24 hours at a temperature of between 180 and 200 DEG C to obtain a precursor; and the precursor is calcined for 0.5 to 3 hours at a temperature of between 350 and 450 DEG C to obtain the lithium cell cathode material. The layer number and the particle diameter of the cathode material are controllable; and the lithium cell has high performance and simple preparation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Growing method of grapheme with controllable number of layers

The invention provides a growing method of grapheme with a controllable number of layers. The method at least comprises the following steps of: (1) providing a Cu substrate, and forming a Ni layer on the Cu substrate; (2) injecting C in the Ni layer by utilizing an ion injection method; and (3) carrying out annealing treatment on a structure formed in the step (2) so that partial Cu in the Cu substrate enters the Ni layer to form a Ni-Cu alloy; and squeezing C injected in the Ni layer out of the Ni layer by the Cu entering the Ni layer, and carrying out reconstruction on the surface of the Ni-Cu alloy to form grapheme. A grapheme membrane prepared by utilizing the growing method has the advantages of good quality, large size and controllability in the number of layers and is easy to transfer. Besides, an ion implantation technique and an annealing technique are very mature techniques in the conventional semiconductor industries, and the wide application of grapheme to the semiconductor industry can be promoted by the growing method of the grapheme with the controllable number of layers.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

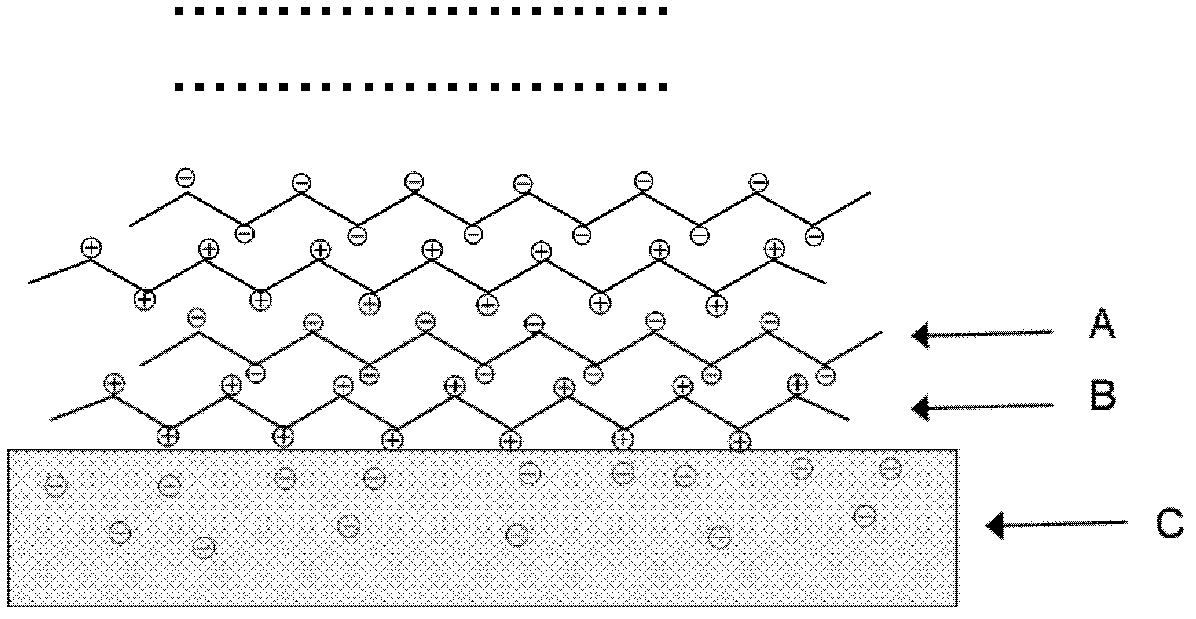

Composite film for flow energy storage battery and application thereof

InactiveCN102867928AHigh ion selectivityImprove hydrophilicitySynthetic resin layered productsCell component detailsComposite filmOrganic polymer

The invention discloses a composite film for a flow energy storage battery and an application of the composite film in the flow energy storage battery. The composite film disclosed herein is characterized by using one or more than two of organic polymer resin or sulfonated polymer resin as raw material to prepare a porous film as a matrix, and successively alternately self-assembling cationic polymer resin and anion polymer resin layer by layer on the surface of the matrix by static electricity to form the composite film. The composite film disclosed herein has the advantages of simple preparation method, environmentally friendly process, controllable number of assembling layers, and adjustable ionic selectivity. Compared with original porous films, the composite film disclosed herein has good hydrophilicity and vanadium ion blocking ability, and an all vanadium flow energy storage battery assembled by using the composite film has higher efficiency and longer self-discharge time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic wafer material by tape casting

InactiveCN101844925AImprove fracture toughnessGive full play to antioxidantCeramic layered productsMultilayer membraneFlexural strength

The invention relates to ZrB2-SiC complex phase ultrahigh temperature ceramic, in particular to a process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material by tape casting. The process for preparing multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material by tape casting is realized by the following steps: preparation of SiC ceramic biological membrane, preparation of ZrB2-SiC complex phase ceramic biological membrane, multilayer membrane stacking and laminating, binder removing and sintering; fracture toughness of the acquired multilayer ZrB2-SiC complex phase ultrahigh temperature ceramic material reaches 7-12Mpa.m1 / 2, flexural strength is 600-800MPa. The two indexes are obviously higher than those of ZrB2-SiC complex phase ceramic prepared by conventional method.

Owner:南通市通州区益君劳务有限公司

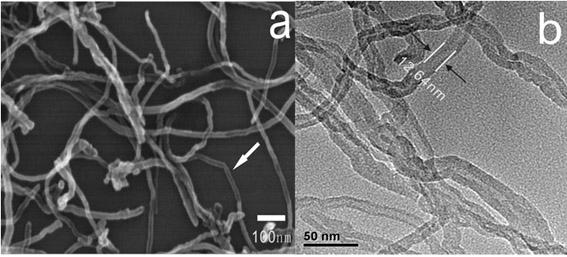

Method for preparing grapheme nano belts by etching carbon nano tubes through water vapor

InactiveCN102616770AQuality improvementHigh yieldGrapheneNanotechnologyWater vaporGraphene nanoribbons

The invention discloses a method for preparing grapheme nano belts by etching carbon nano tubes through water vapor. The method comprises the steps of putting multi-wall carbon nano tubes into a polyfluortetraethylene inner liner, adding a certain amount of distilled water into the inner liner, vibrating to ensure that the nano tubes are uniformly dispersed, then putting the polyfluortetraethylene inner liner into a reaction kettle, heating to 150 to 225 DEG C, keeping constant temperature for 5 to 20 h, so as to ensure that the multi-wall carbon nano tubes are longitudinally cracked to form high-quality grapheme nano belts. The grapheme nano belts prepared through the method have the advantages of less folds, uneasiness in aggregation, controllable number of layers, high yield and the like, at the same time, the preparation process is simple and easy to operate and can be accomplished at one step, a surface active agent is not required to be adopted for dispersing, and the process ispollution-free and environmental-friendly. The method overcomes the disadvantages of complex process, severe pollution, low yield and the like during the grapheme preparation through other methods.

Owner:FUZHOU UNIV

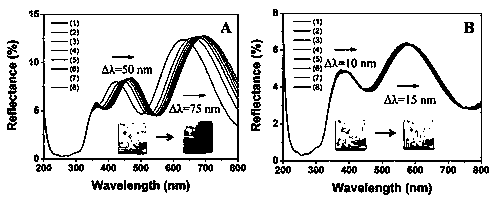

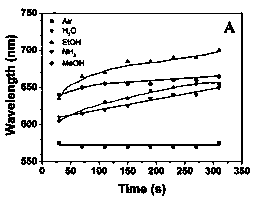

Preparation method and application of graphene oxide array color-changing film/composite film

ActiveCN107655856AAchieving controllable equipmentHigh sensitivityMaterial analysis by observing effect on chemical indicatorPhase-affecting property measurementsDispersityComposite film

The invention belongs to the technical field of chemical materials, and particularly relates to a preparation method of a graphene oxide film or composite film capable of presenting different colors in different gas environments. The graphene oxide film can be applied in preparing gas sensors for detecting humidity and harmful gas. The preparation method specifically includes: preparing a grapheneoxide solution and a macromolecular solution, sequentially spin-coating the solutions on a modified silicon wafer substrate through a spin coater, and drying to obtain a color-changing graphene oxide / macromolecular composite film. Dispersity and selectivity of a graphene gas-sensitive material are improved; functionalized macromolecules are introduced, so that graphene lamellar structure is stabilized while gas-sensitive selection is improved, and a graphene / macromolecular schemochrome thin film which is flat and controllable in number of layer is prepared; a characteristic that conventionalgraphene gas-sensitive materials depend on electrochemical detection is broken through, an organic small molecule visual detection assembly array based on interference light response is built, and real-time, quick, accurate and visual detection of humidity and harmful gas is realized.

Owner:QILU UNIV OF TECH

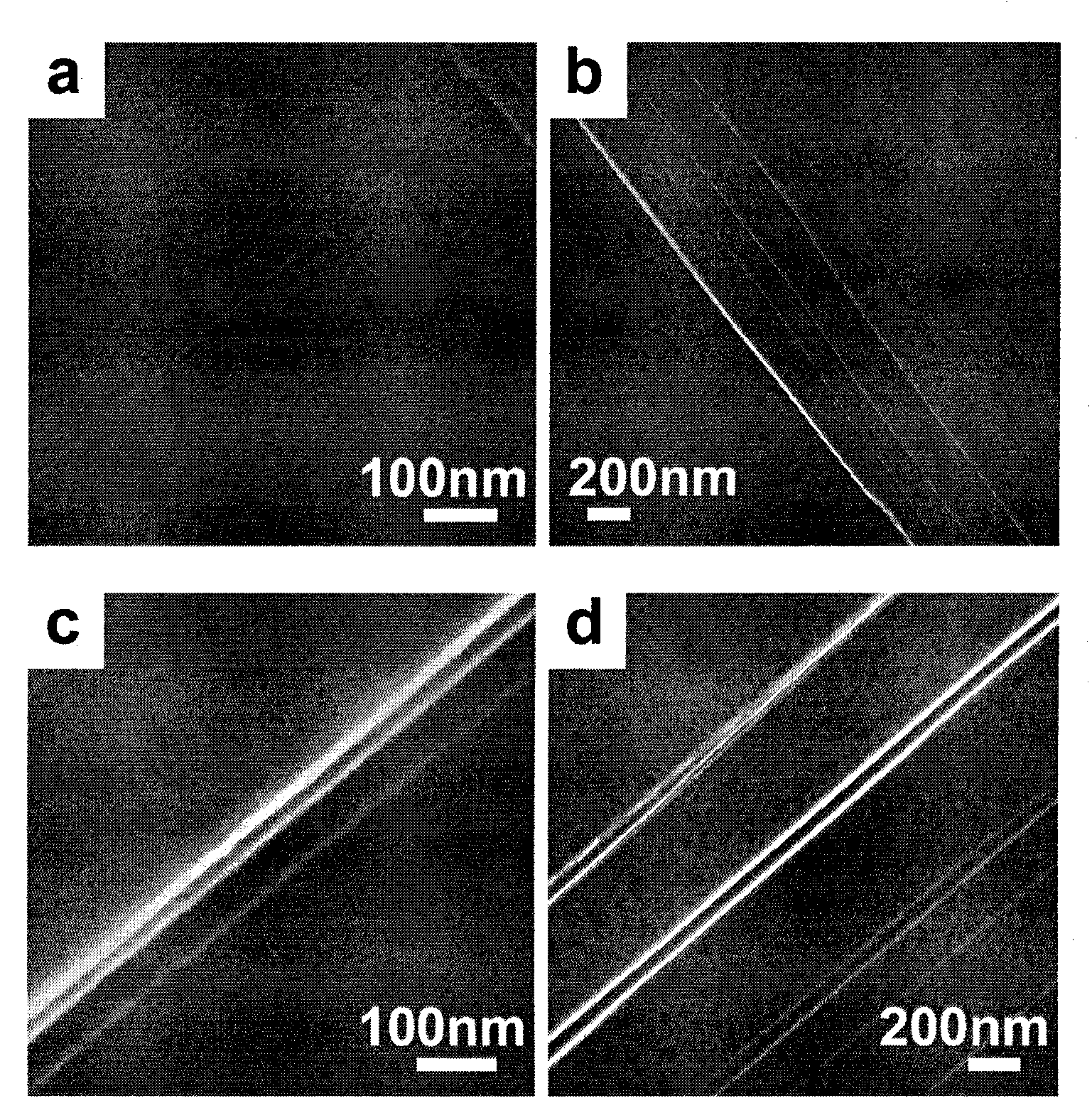

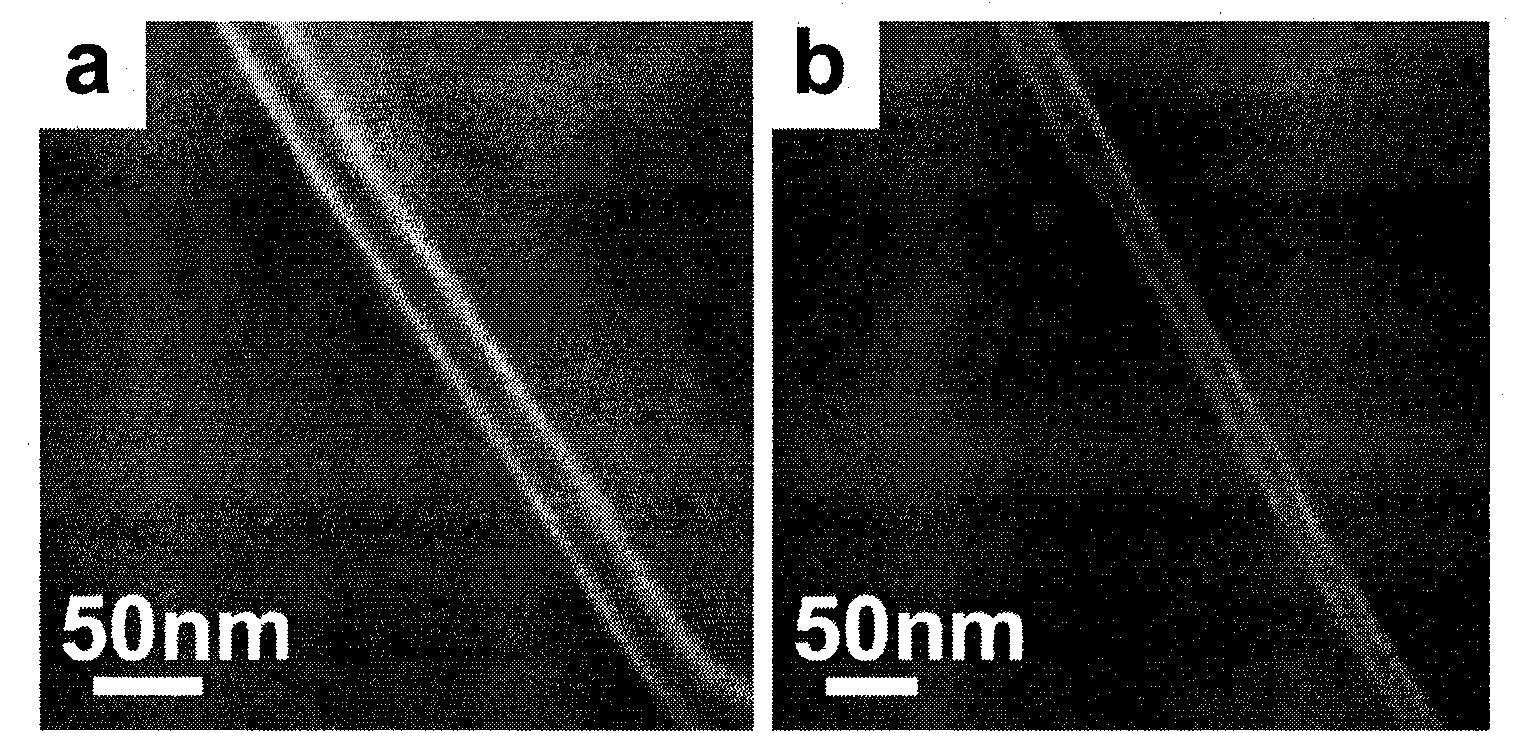

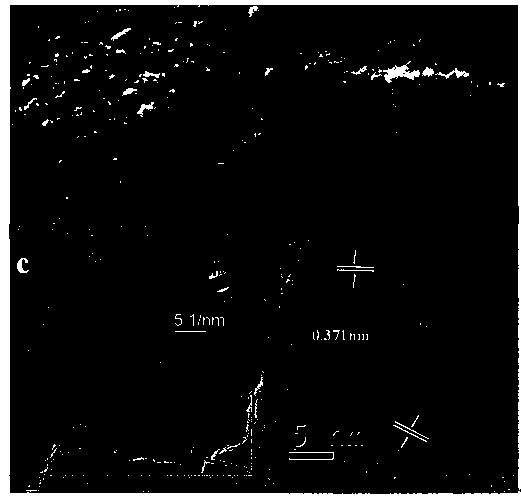

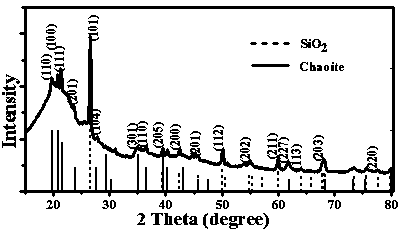

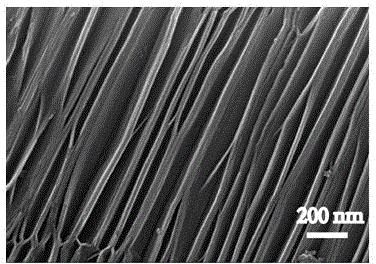

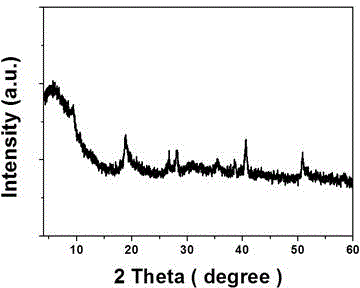

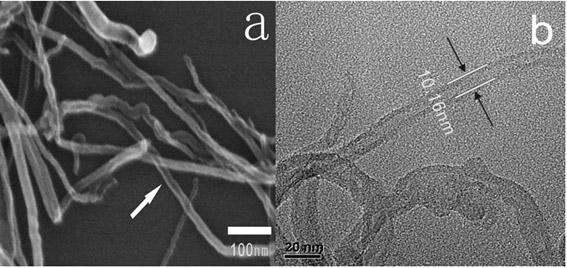

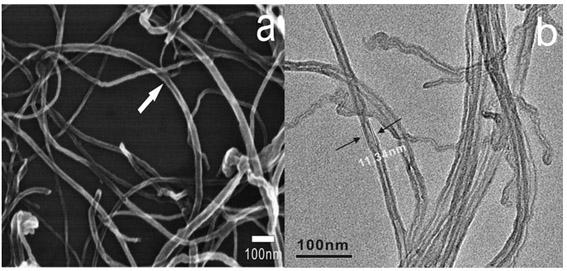

Controllable preparation method of high-oxidation-resistance high-purity single/double-wall carbon nanotube

ActiveCN102320593AOvercoming problems such as difficulty in large-scale productionImprove antioxidant capacityNanotechnologyDouble wallOxidation resistant

The invention relates to the field of the controllable preparation of high-oxidation-resistance single / double-wall carbon nanotubes, in particular to a controllable preparation method of high-oxidation-resistance high-purity single / double-wall carbon nanotubes. The controllable preparation method comprises the following steps of: introducing carbon-source gas by utilizing a floating-catalyst chemical vapor-deposition method and using ferrocene as a catalyst precursor and sulfur powder as a growth promoter at a higher temperature, growing the high-oxidation-resistance carbon nanotubes under a high hydrogen-gas carrier-gas flow quantity, and simultaneously realizing the controlled growth of the single-wall or double-wall carbon nanotubes by regulating and controlling the quantity of the added growth promoter for sulfur to obtain the high-purity high-oxidation-resistance single / double-wall carbon nanotubes, wherein the single-wall or double-wall carbon nanotubes account for more than 90 percent of the total content of carbon tubes, and the highest oxidation-resisting temperatures of the single-wall and double-wall carbon nanotubes are respectively 770 DEG C and 785 DEG C. The single / double-wall carbon nanotubes with high crystallization degrees, fewer structural defects and high purity are obtained by the method, have the characteristics of excellent electrical conductivity, highelasticity, high strength and the like and are expected to be applied to transparent conductive films and the related devices of the transparent conductive films.

Owner:唯碳纳米科技(沈阳)有限公司

Graphene and preparation method thereof

The invention provides a preparation method of graphene. According to the method, a nano-scale metal and / or metal oxide catalyst is attached on a rotatable reaction deposition part, a carbon source which can be decomposed into carbon and hydrogen is introduced, and the carbon source is cracked into the graphene under the action of the nano-scale catalyst; as the reaction deposition part is rotatable, the carbon source is in three-dimensional and dynamic contact with the catalyst, and more graphene can be deposited; in addition, the catalytic efficiency of the nano-scale catalyst to the carbon source is higher, and the preparation of the high-quality graphene even in thickness and controllable in number of layers can be effectively realized. The method is simple in process; the problems of less deposited graphene, large catalyst scale and low catalytic efficiency due to the static placement of the catalyst in the existing chemical vapor deposition technology are solved. The invention also provides a graphene; the layers of the graphene are bent to form a hollow cloth bag shape; the graphene of the structure has excellent hydrogen storage and lithium storage functions.

Owner:SHENZHEN DYNANONIC +1

Method for preparing graphene nanoplatelets with pulsed high pressure water jet mill

The invention relates to the field of graphene materials, in particular to a method for preparing graphene nanoplatelets with a pulsed high pressure water jet mill.According to the method, a plugging layer is pressurized, Van der Waals' force among graphite powder layers is reduced, so that the graphite layers are easy to strip, then graphite powder is crushed and stripped under the action of water jet and turbulent flow and cavitation through pulsed high pressure water jet of the pulsed high pressure water jet mill, the evenly-dispersed graphene nanoplatelets with the number of layers ranging from 100 to 200 are obtained.Continuous and large-scale production of the graphene nanoplatelets with the number of layers being even is achieved, the yield is high, the cost is low, no pollution is caused, the layer thickness meets the use requirements in the fields of rubber enhancement, plastic enhancement, coating corrosion prevention, lubrication and sewage treatment, and it is convenient to promote large-scale application of graphene.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

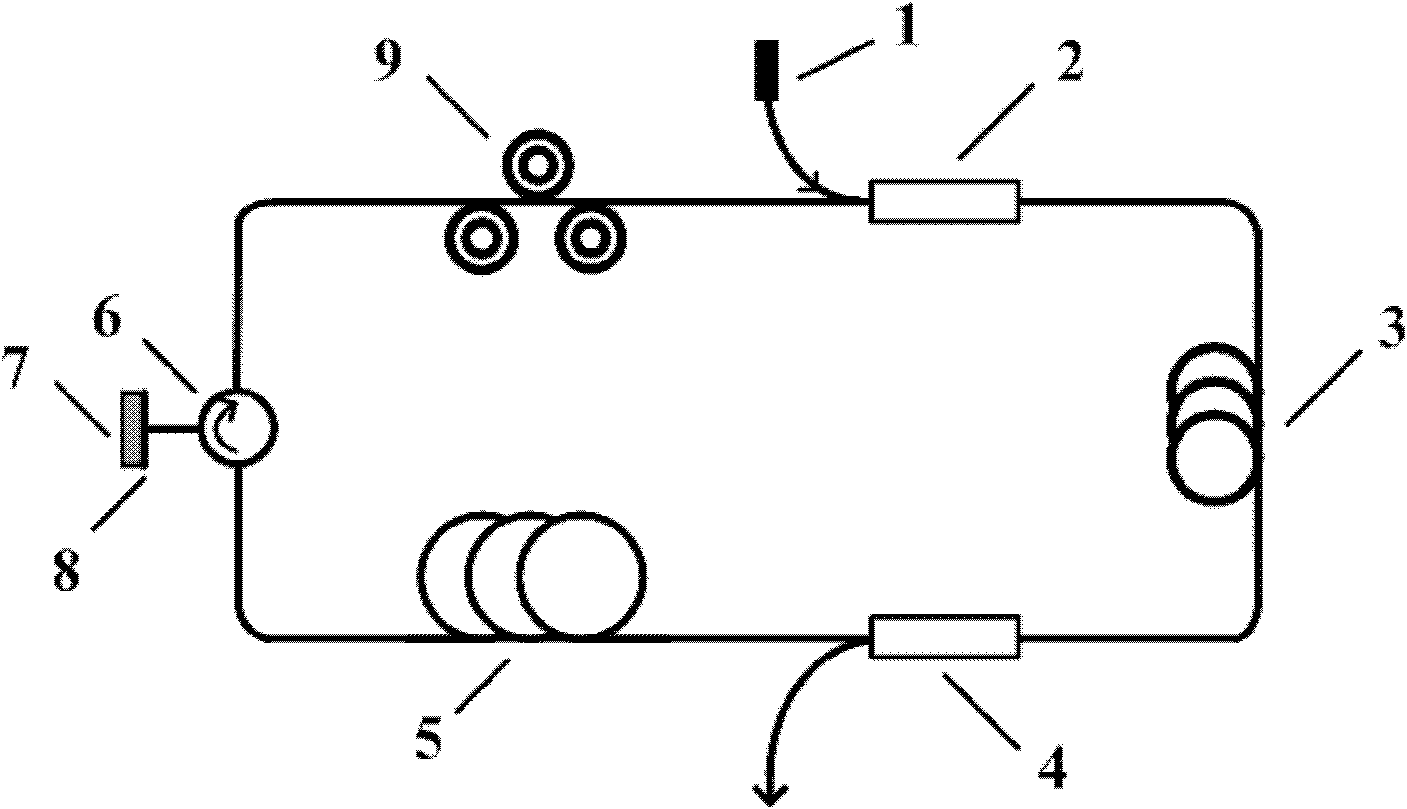

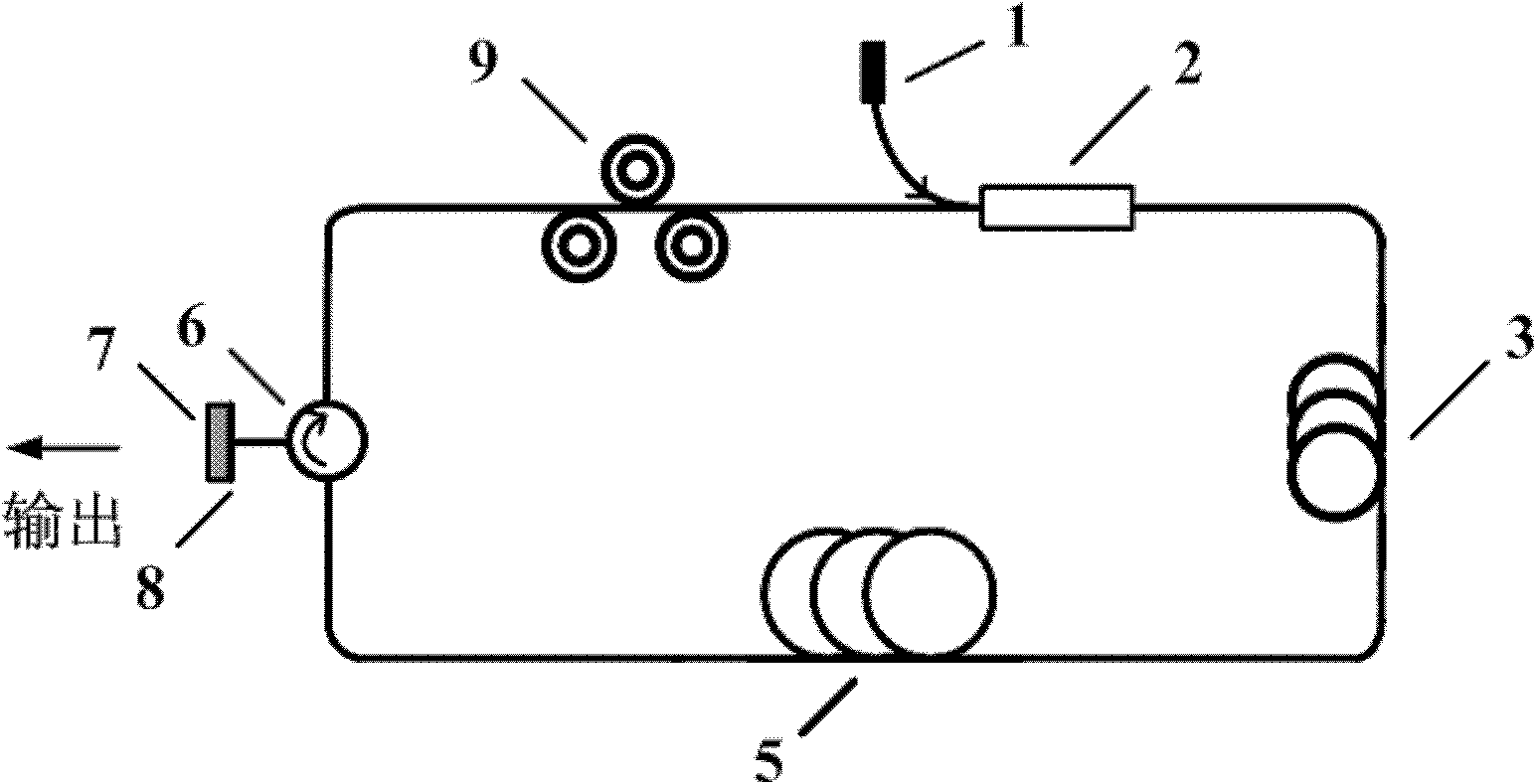

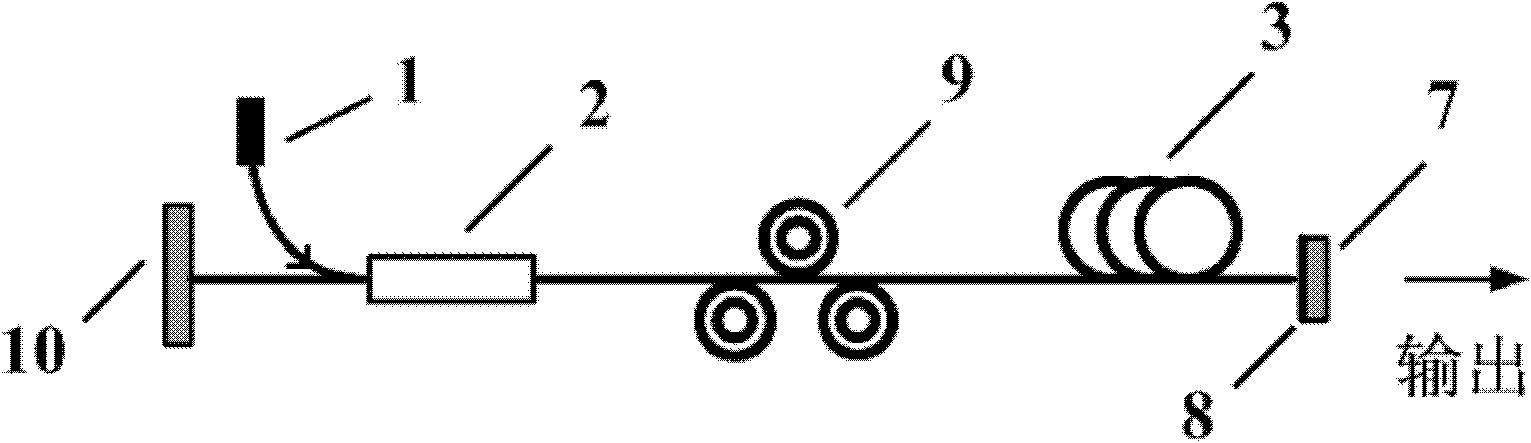

Passive mode-locking laser based on graphite alkene having epitaxial growth on SiC substrate

InactiveCN102208743ASimple structureLow priceOptical resonator shape and constructionActive medium materialNonlinear opticsMode-locking

The invention relates to a passive mode-locking laser based on graphite alkene having an epitaxial growth on a SiC substrate and is directed to the fields of laser technology and nonlinear optics. The passive mode-locking laser mainly comprises a SiC substrate, graphite alkene having an epitaxial growth on the SiC substrate, a doped fiber, a gain medium, a pumped source, a wavelength division multiplexing device, a laser beam splitter, a single-mode fiber, an annular device, a polarization controller and the like. A mode-locking laser output having high stability and high impulse energy is realized through utilizing the characteristic of saturable absorption of graphite alkene. Graphite alkene having an epitaxial growth on the SiC substrate is characterized by high repeatability, good thermal conductivity and strong operationality. Therefore, graphite alkene having an epitaxial growth on the SiC substrate is easier to be applied into the passive mode-locking laser at a low cost and a large scale.

Owner:ZHEJIANG IRIS LASER EQUIP CO LTD

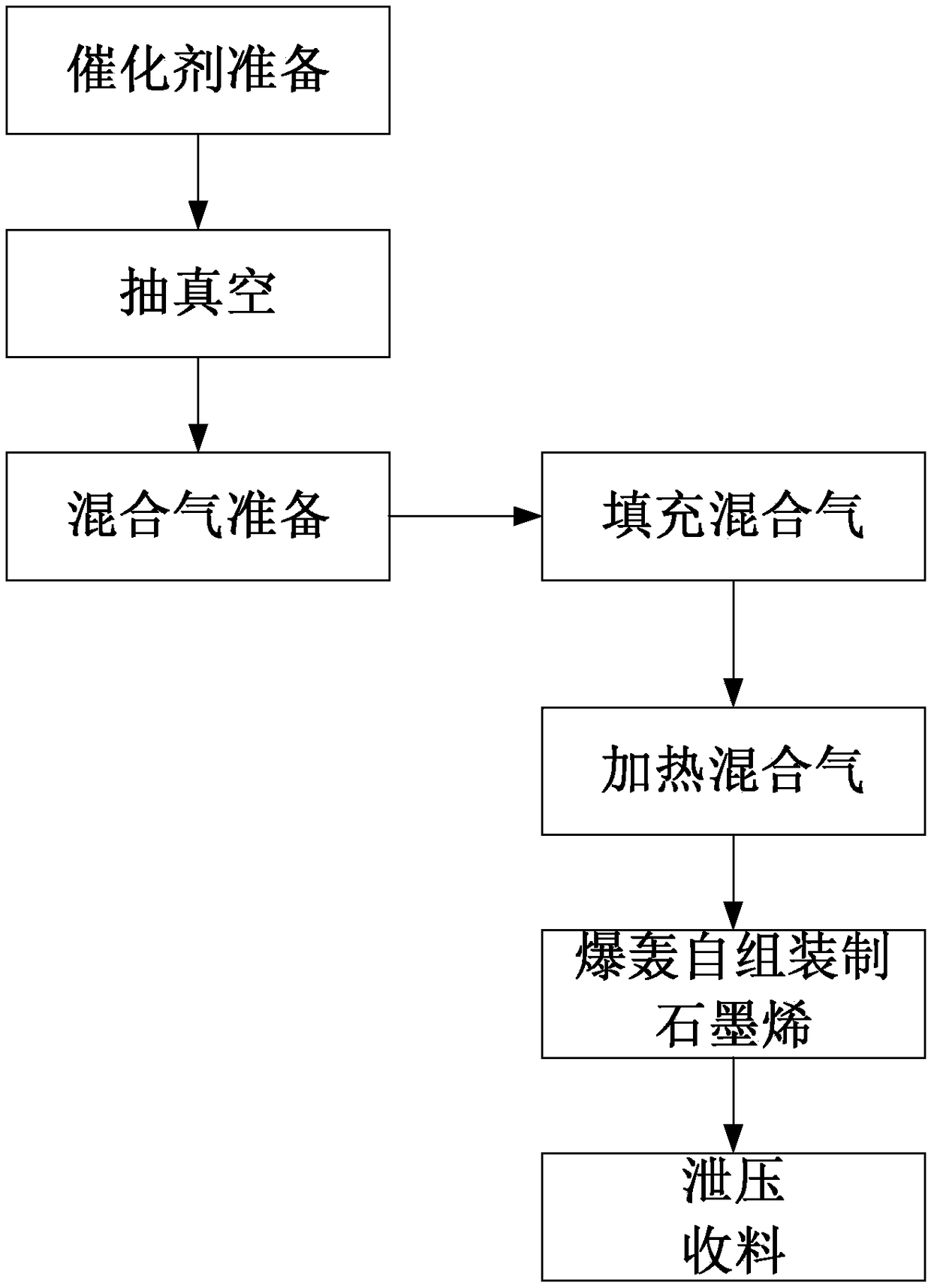

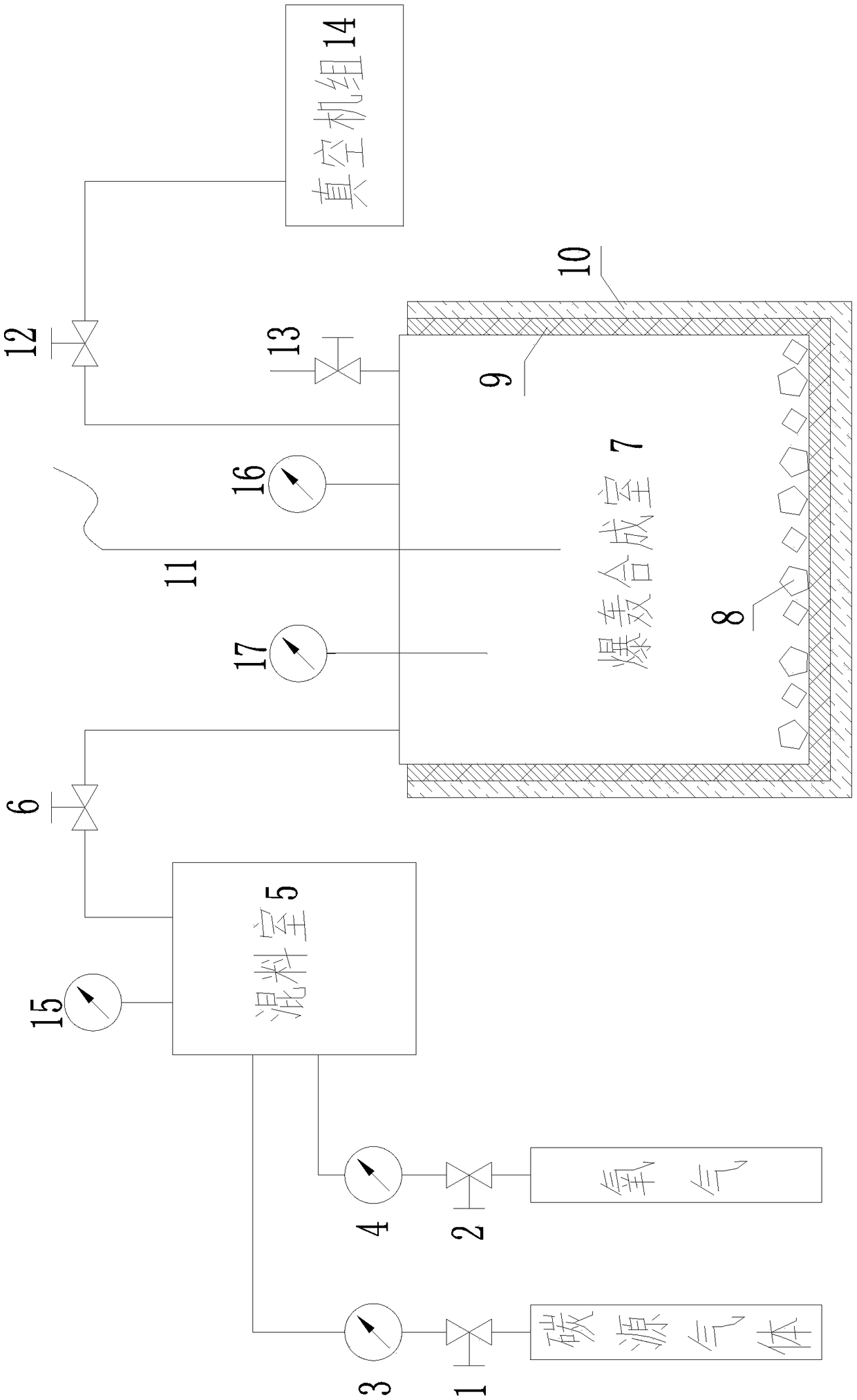

Method and device for preparing graphene based on detonation process

ActiveCN108946710ASimple structureRealize industrialized mass productionGrapheneDetonationWater vapor

The invention discloses a method for industrially producing graphene based on a detonation process and a device for preparing large-sized graphene. According to the method, a gaseous hydrocarbon is utilized as a carbon source and mixed with a certain proportion of oxygen, which are filled in a sealed detonation special device; an appropriate amount of solid metal or non-metal compounds are added as a catalyst; a mixed gas is preheated to a certain temperature and pressure, and is ignited by ignition of a high-energy ignition device; and condensed carbon and free carbon decomposed by hydrocarbons under high temperature and high pressure self-assemble into graphene, and oxygen components and hydrogen components are combined to form water vapor. Raw materials used by the method are low in cost; prepared graphene has no surface functional group, and is controllable in number of layers and in area, and the yield of the graphene yield is up to 30%-60%; and the method is extremely suitable for industrial scale production and application.

Owner:王联盟

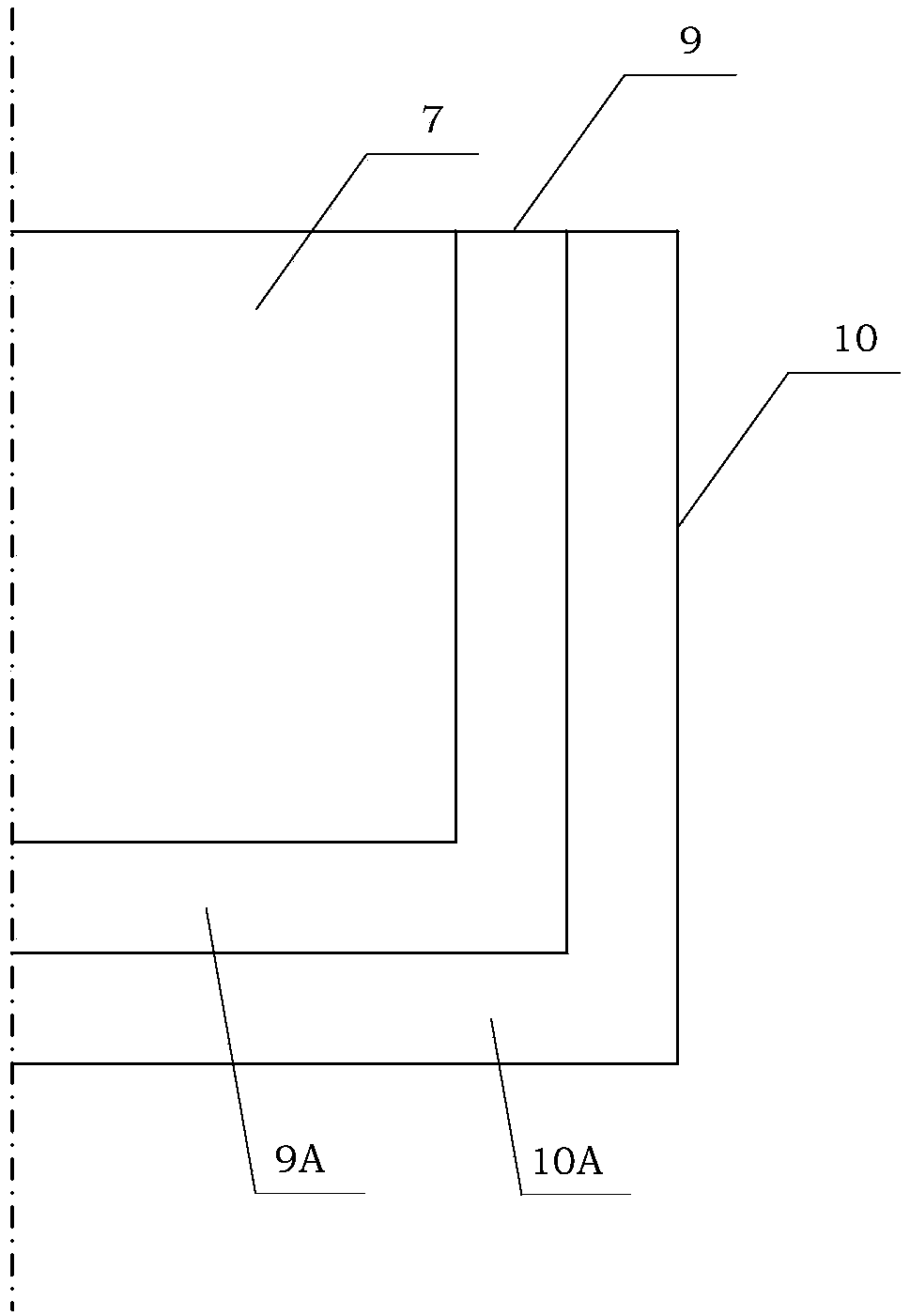

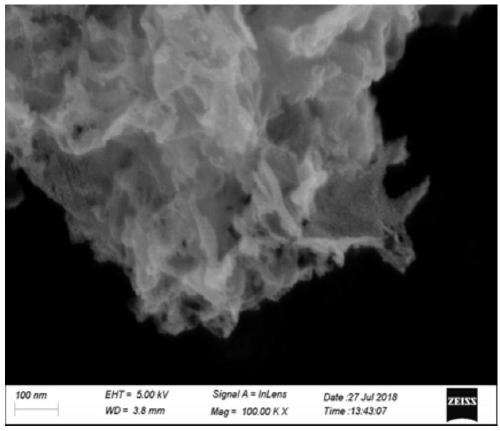

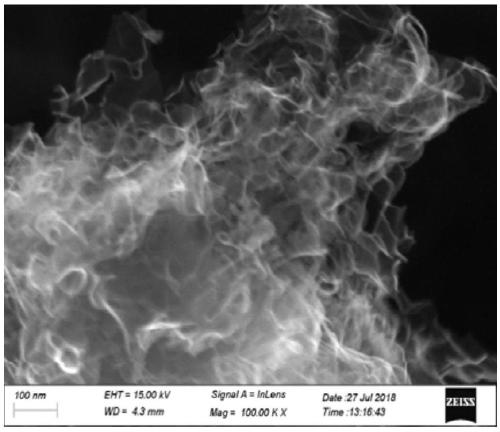

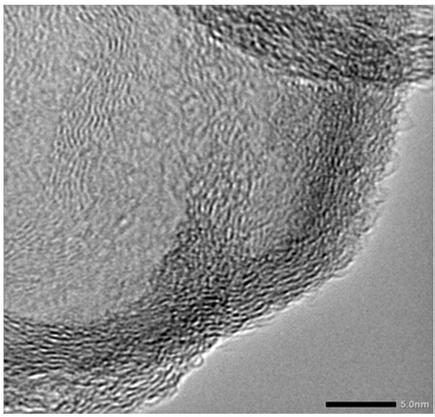

Method for controllably preparing three-dimensional nanometer porous graphene powder by chemical vapor deposition method

ActiveCN109264706AEliminate soft and hard agglomerationsImprove fluidization stateGraphenePorous grapheneGas phase

The invention discloses a method for controllably preparing a three-dimensional nanometer porous graphene powder by a chemical vapor deposition method. The method comprises the following steps of treating a solid catalyst by salt, and activating at high temperature; coating the surface of the solid powder, subjected to high-temperature activating, with a polymer, leading the solid powder, coated with the polymer, into a carbon source at high temperature, performing the chemical vapor deposition, and growing graphene; pickling, filtering, and drying, so as to obtain the three-dimensional nanometer porous graphene powder. The method has the advantages that the common core problem of particle agglomeration of a solid catalyst in a large-scale preparation process of graphene powder by the chemical vapor deposition method is solved by the surface coating of the catalyst; by adjusting the amount of the carbon source, the particle size of the solid catalyst and the amount of salt, the high-quality three-dimensional nanometer porous graphene powder can be controllably prepared; the technology process is simplified, the higher requirement preparation conditions on equipment is decreased, and the large-scale controllable preparation of the three-dimensional nanometer porous graphene powder is easy to implement.

Owner:陕西兴汉澜墨科技有限公司

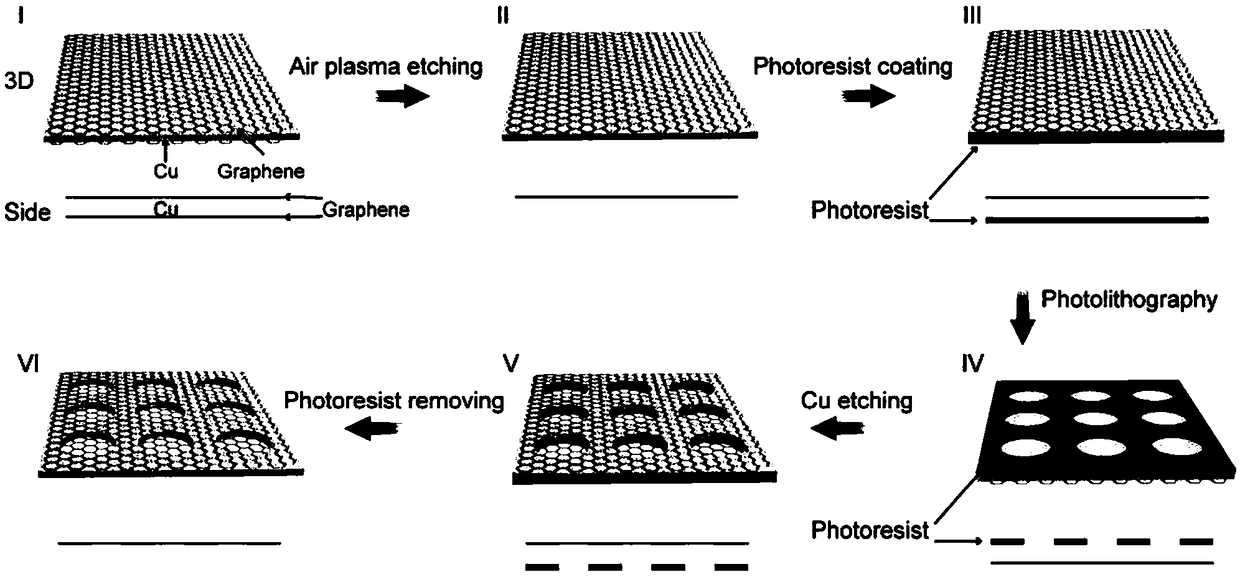

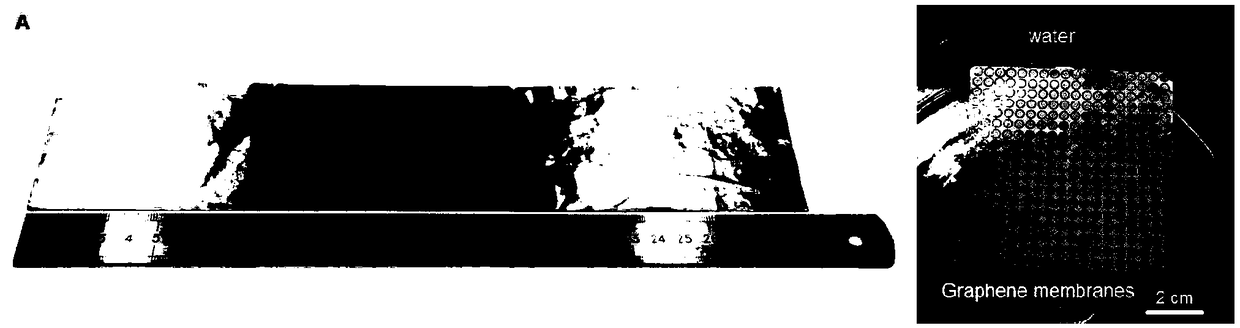

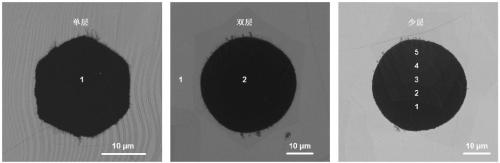

Method of preparing hanging graphene support film by selectively etching growth substrate

ActiveCN109437176AAvoid diversionSimple processMaterial nanotechnologyPolycrystalline material growthFiberHigh resolution imaging

The invention discloses a method of preparing a hanging graphene support film by selectively etching a growth substrate. The preparation method avoids a graphene transfer process, is high in efficiency and low in cost and can obtain the high-quality graphene support film by one-step etching. The prepared graphene support film does not require auxiliary support by any high polymer films and high polymer fibers; the number of layers of the graphene support film is controllable; the graphene support film is high in completeness (90-97%), large in hanging area (a diameter is 10-50 micrometers) andwide in clean area (greater than 100 nm); massive preparation can be achieved. In addition, the graphene support film can be directly used for a transmission electron microscope support film and achieve high resolution imaging of nano particles.

Owner:PEKING UNIV

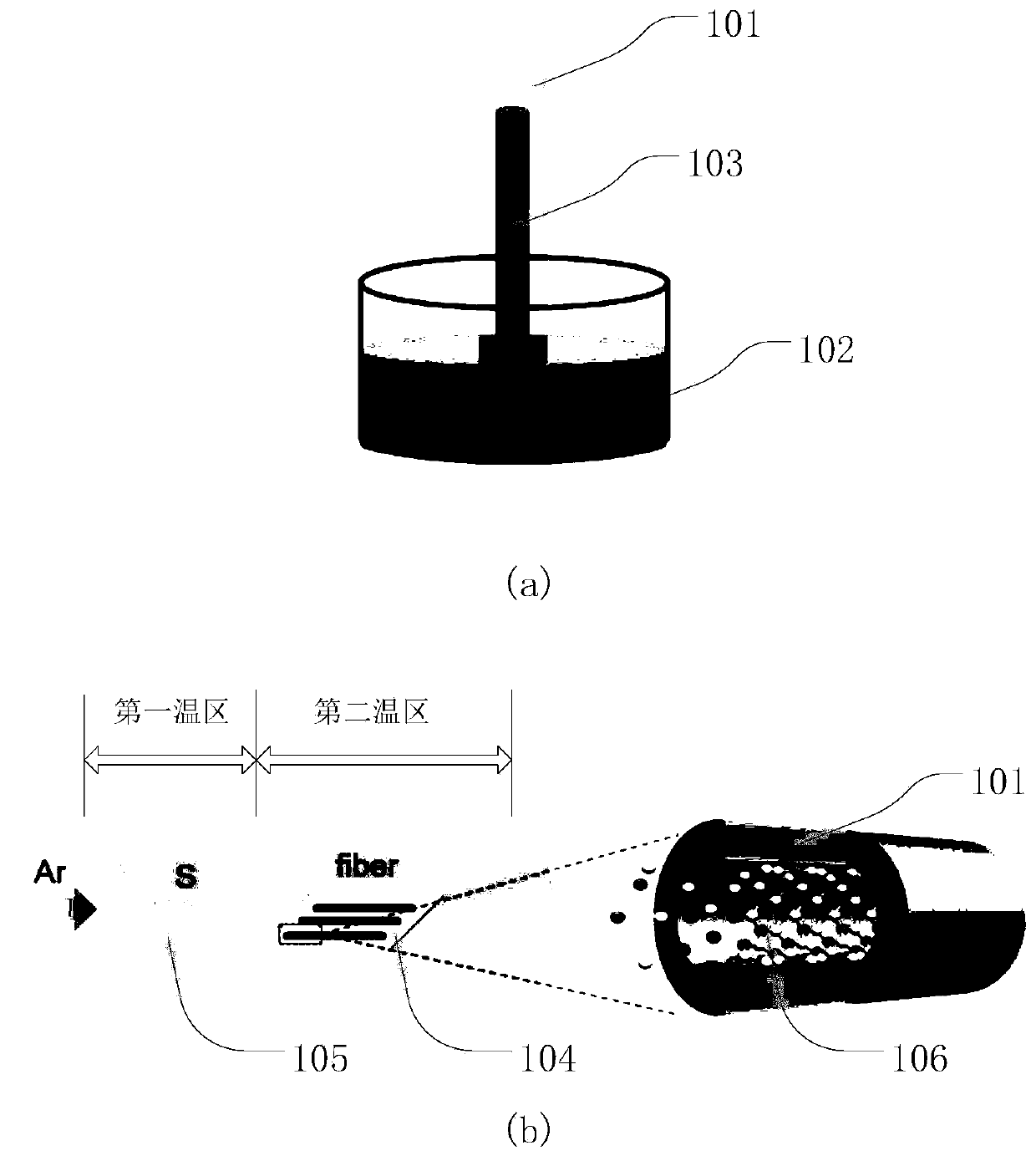

Method for rapidly preparing transition metal chalcogenide composite optical fiber material

ActiveCN110554455AThe number of layers is controllableQuality improvementOptical waveguide light guideNon-linear opticsPotassiumOptical communication

The invention relates to a method for rapidly preparing a transition metal chalcogenide composite optical fiber material. The preparation method comprises the following steps: infiltrating the opticalfiber by adopting molybdic acid or sodium tungstate / potassium salt solution, and then directly depositing high-quality single-layer or few-layer transition metal chalcogenide on the inner wall of anair duct in the center of the optical fiber or on the inner walls of a cladding air hole and a fiber core air duct of the photonic crystal fiber under the conditions of low pressure and high temperature. The optical fiber is made of quartz or quartz polymer. The excellent optical and electrical properties of the transition metal chalcogenide composite and the characteristics of the photonic structure of the optical fiber are combined to realize the multifunctional integration of the two-dimensional TMDC material and the optical fiber. The method has the characteristics of low cost, simple preparation method, short growth period and controllable layer number of the transition metal chalcogenide. The prepared transition metal chalcogenide composite optical fiber has potential application inthe fields of optical communication, sensing and novel optical devices.

Owner:PEKING UNIV

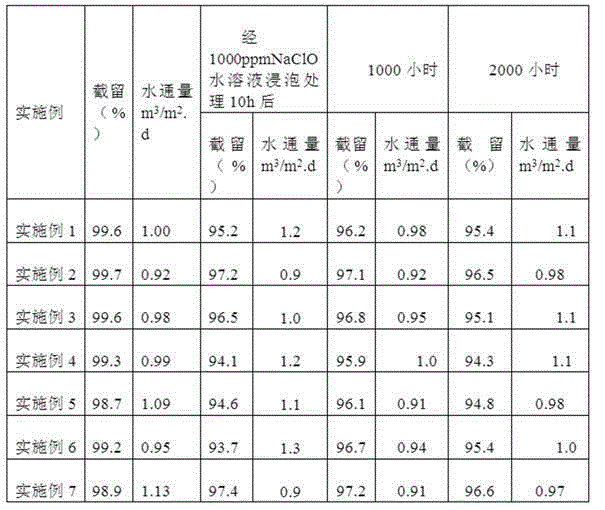

Method for preparing reverse osmosis composite membrane containing azobenzene polyamide

ActiveCN104607074AGood mechanical strengthHigh salt rejection and water fluxSemi-permeable membranesCross linked membraneSelf-assembly

The invention provides a method for preparing a reverse osmosis composite membrane containing azobenzene polyamide. The method comprises the following steps: through the instruction of series of azobenzene photoresponse groups and hydrophilic functional groups such as carboxyl and sulfonic acid groups, synthesizing azo-type anion / cation polyamide-function self-assembled molecules with ultraviolet photoresponse and a hydrophilic performance; then through the integration and coupling of electrostatic self-assembly and in situ photochemical reaction between layers, combining a layer-by-layer self-assembly technique with an ultraviolet curing technology science, and preparing the reverse osmosis composite membrane containing azobenzene polyamide, wherein the layer number is controllable, covalent bonds between the layers are firmly cross-linked, and the membrane body is charged, and high in mechanical strength, salt removing rate, water flux, and pollution resistance.

Owner:GUANGDONG UNIV OF TECH

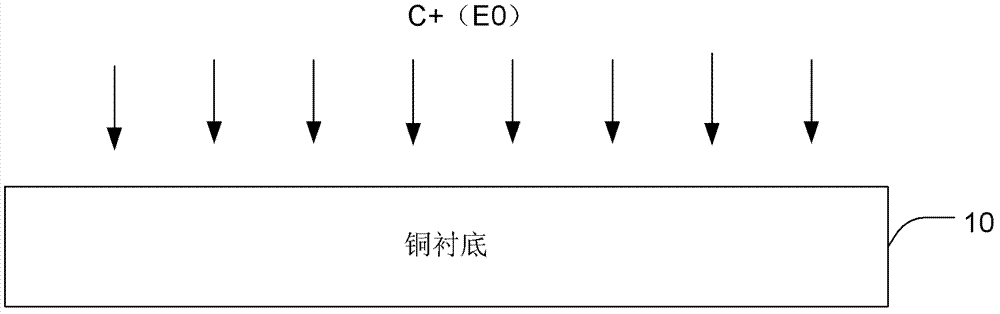

Method for preparing grapheme on basis of controlling ion implantation energy

InactiveCN103247520AThe number of layers is controllableEasy transferSemiconductor/solid-state device manufacturingChemical vapor depositionIon implantation

The invention provides a method for preparing grapheme on the basis of controlling ion implantation energy. As per the method provided by the invention, firstly, acrbonic ions are implanted into a catalytic substrate based on at least on implantation energy; then the catalytic substrate implanted with acrbonic ions is subjected from annealing so as to enable the acrbonic ions to be separated out, and at least one grapheme thin layer is formed on the surface of the catalytic substrate; and finally, the catalytic substrate with the grapheme thin layer on the surface is removed so as to obtain at least one grapheme thin layer. The grapheme prepared by the method has good quality, large size and controllable layer number, is easy to transfer compared with a SiC (suppressed ion chromatography) sublimed method, and has controllable layer number as compared with a chemical vaporous depositon method.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com