Lithium cell negative pole material and preparation thereof

A negative electrode material and lithium battery technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problem of low space utilization and achieve the effect of controllable layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Add 60 ml of ethylene glycol, 0.02 g of PVP (molecular weight: 30,000) and 1 g of cobalt acetate into 100 ml of polytetrafluoroethylene liner, stir and dissolve, put it in a hydrothermal kettle, and react at 180°C for 12 hours, the resulting solution was washed three times with deionized water and ethanol successively to obtain the precursor powder;

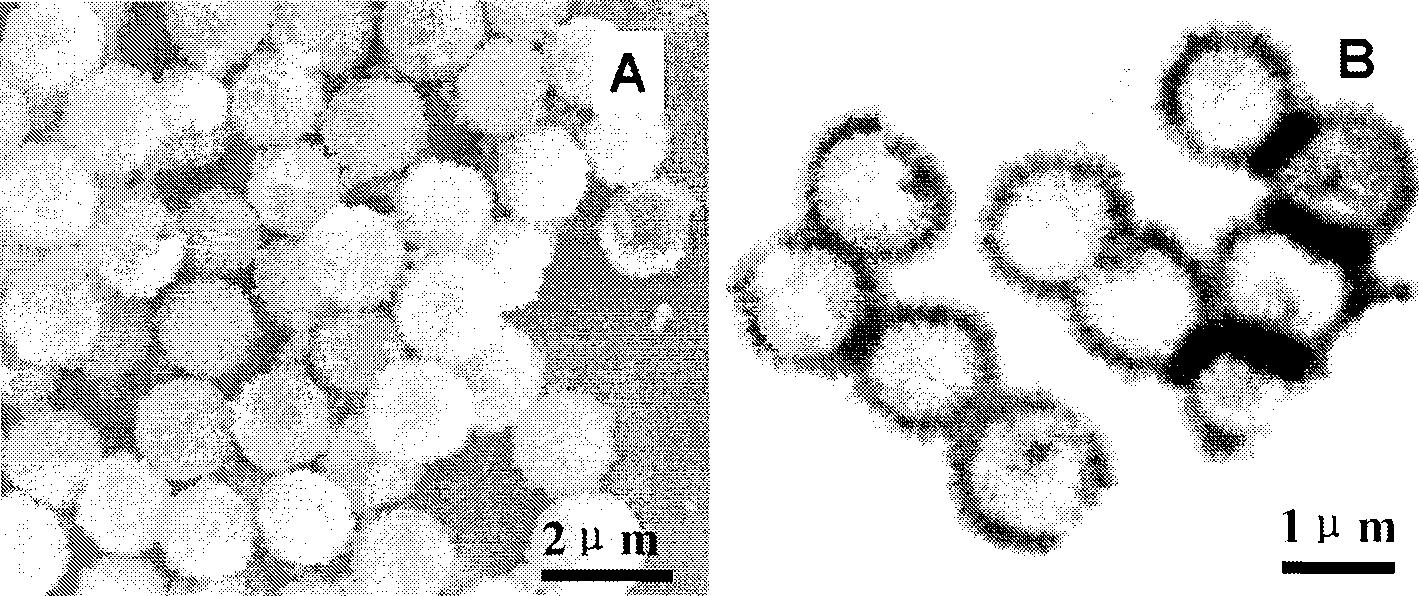

[0022] 2) Calcining the precursor powder at 350° C. for 0.5 hour to obtain single-layer cobalt tetraoxide hollow microspheres, the average particle diameter of the outermost layer is 1.5 μm.

Embodiment 2

[0024] 1) Add 80 ml of ethylene glycol, 0.15 g of PVP, and 1 g of cobalt oxalate to 100 ml of PTFE lining, stir and dissolve, put it in a hydrothermal kettle, and react at 200°C for 24 hours, and dissolve the resulting solution Wash with deionized water and ethanol three times respectively to obtain the precursor powder;

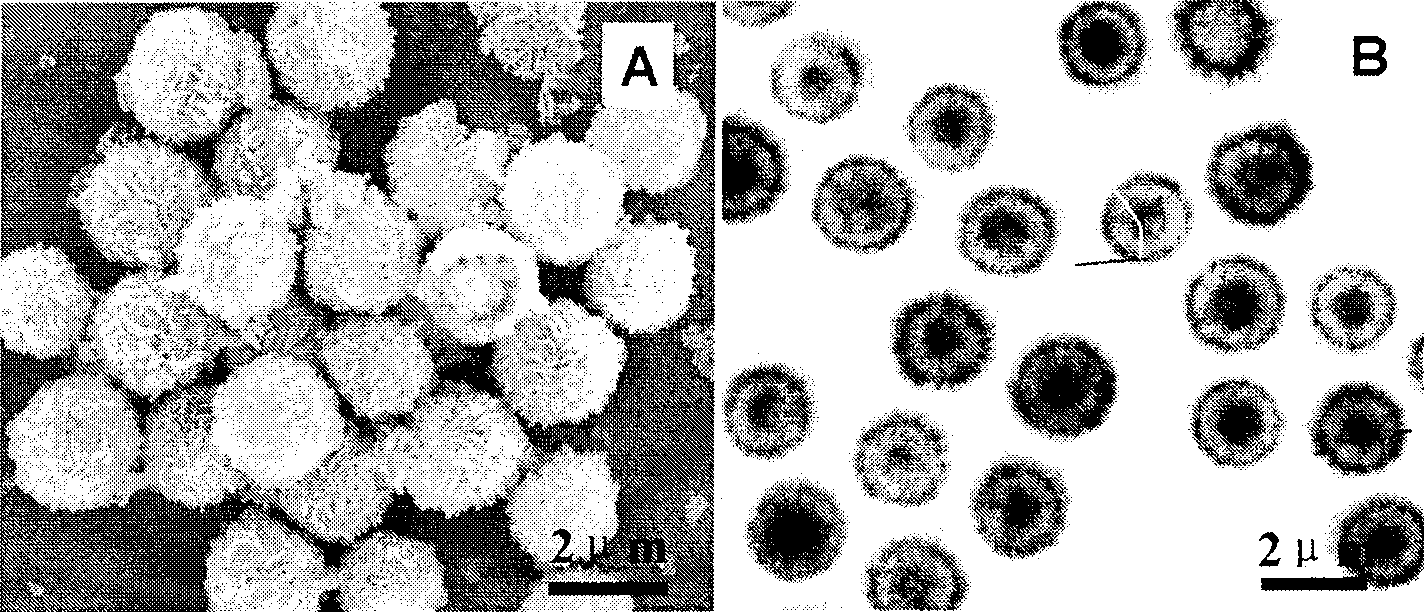

[0025] 2) Calcining the precursor powder at 450° C. for 3 hours to obtain two layers of cobalt tetraoxide hollow microspheres, the average particle diameter of the outermost layer is 2 μm.

Embodiment 3

[0027] 1) Add 70 ml of ethylene glycol, 0.30 g of PVP (molecular weight: 3000), and 1 g of cobalt chloride into 100 ml of polytetrafluoroethylene lining, stir and dissolve, put it in a hydrothermal kettle, and react at 190°C for 20 hours, the resulting solution was washed three times with deionized water and ethanol successively to obtain the precursor powder;

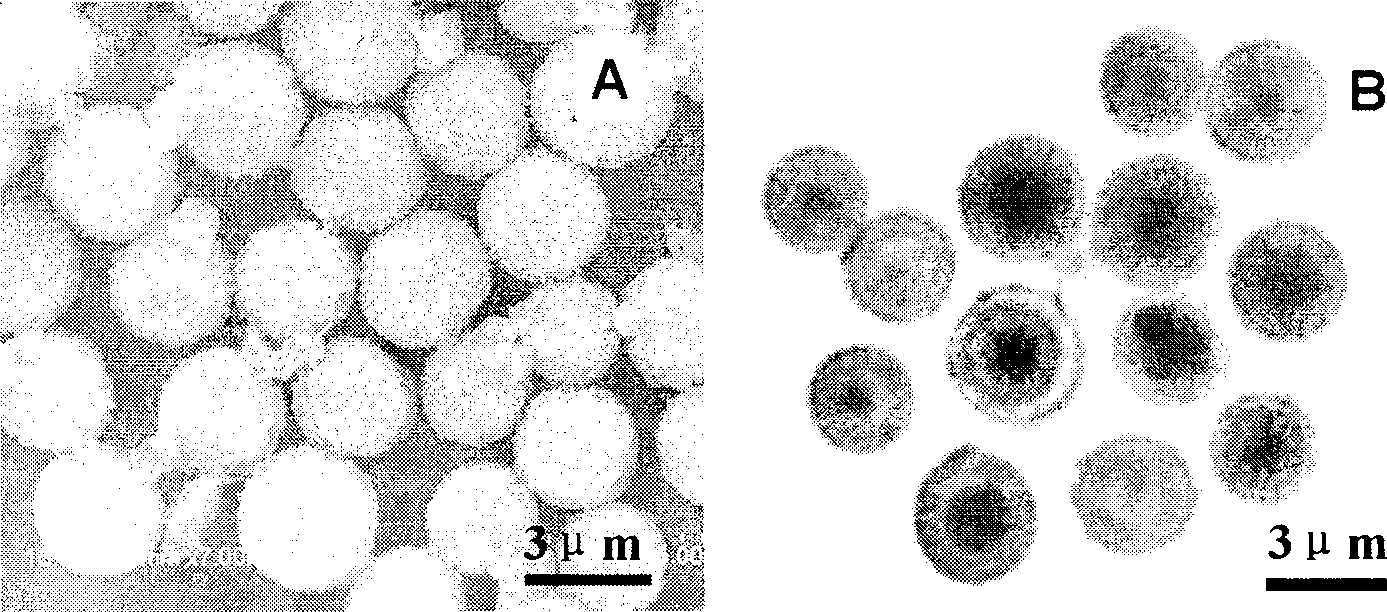

[0028] 2) Calcining the precursor powder at 400° C. for 2 hours to obtain three layers of cobalt tetraoxide hollow microspheres, the average particle diameter of the outermost layer is 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com