Method for preparing grapheme on basis of controlling ion implantation energy

A technology of ion implantation and energy injection, applied in the field of graphene, which can solve the problems of uneven thickness, uneven number of layers, and great influence of graphene, etc., and achieve the effect of easy transfer, controllable number of layers, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

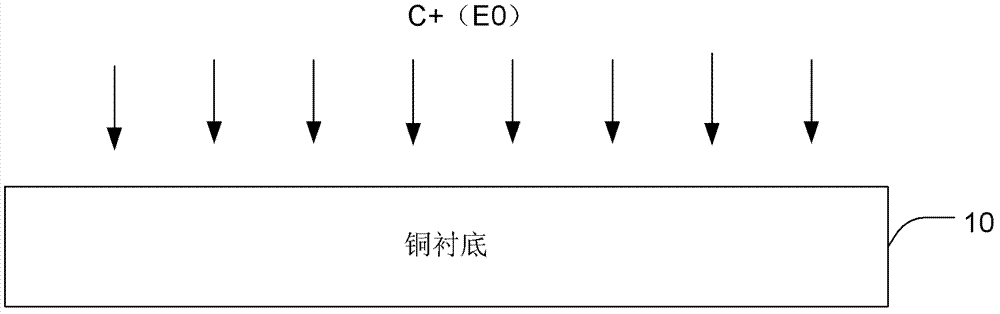

[0020] As shown in the figure, the method for preparing graphene based on controlling the energy of ion implantation in this embodiment includes the following steps:

[0021] The first step: implanting carbon ions into the catalytic substrate based on at least one implanting energy. Wherein, the catalytic substrate includes any material with low carbon solubility, preferably including but not limited to: copper, nickel and the like.

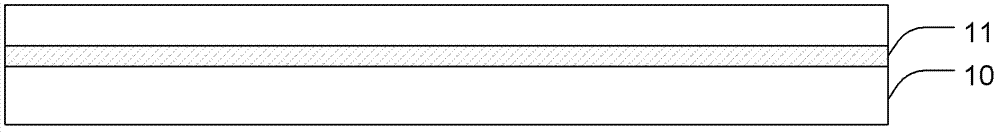

[0022] For example, if figure 1 As shown, carbon atoms are implanted into the copper substrate 10 based on the implantation energy E0, thus, the distribution of each carbon atom based on the implantation energy E0 forms a doped layer 11 in the copper substrate 10, as figure 2 shown.

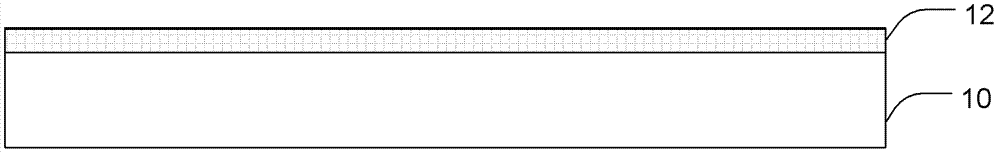

[0023] Step 2: annealing the catalytic substrate implanted with carbon ions to precipitate the implanted carbon atoms, so as to form at least one graphene film layer on the catalytic substrate surface.

[0024] For example, yes figure 2 The catalytic substrat...

Embodiment 2

[0028] As shown in the figure, the method for preparing graphene based on controlling the energy of ion implantation in this embodiment includes the following steps:

[0029] The first step: implanting carbon ions into the catalytic substrate based on at least one implanting energy. Wherein, the catalytic substrate includes any material with low carbon solubility, preferably including but not limited to: copper, nickel and the like.

[0030] For example, if Figure 5 As shown, carbon atoms are first implanted into the copper substrate 20 based on the implantation energy E1, and then carbon atoms are implanted into the copper substrate 20 based on the implantation energy E2. Preferably, the energy E1>energy E2, thus, each based on the implantation energy E1 Carbon atoms are distributed in the copper substrate 20 to form a doped layer 21, and each carbon atom based on the implantation energy E2 is distributed to form a doped layer 22 in the copper substrate 20, such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com