Method for rapidly preparing transition metal chalcogenide composite optical fiber material

A technology of transition metal chalcogenide and composite optical fiber, which is applied in the direction of cladding optical fiber, microstructure optical fiber, optical fiber, etc. It can solve the problems of complex growth process, long growth cycle, and low quality, so as to simplify the preparation process, promote uniform growth, Favorable Diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

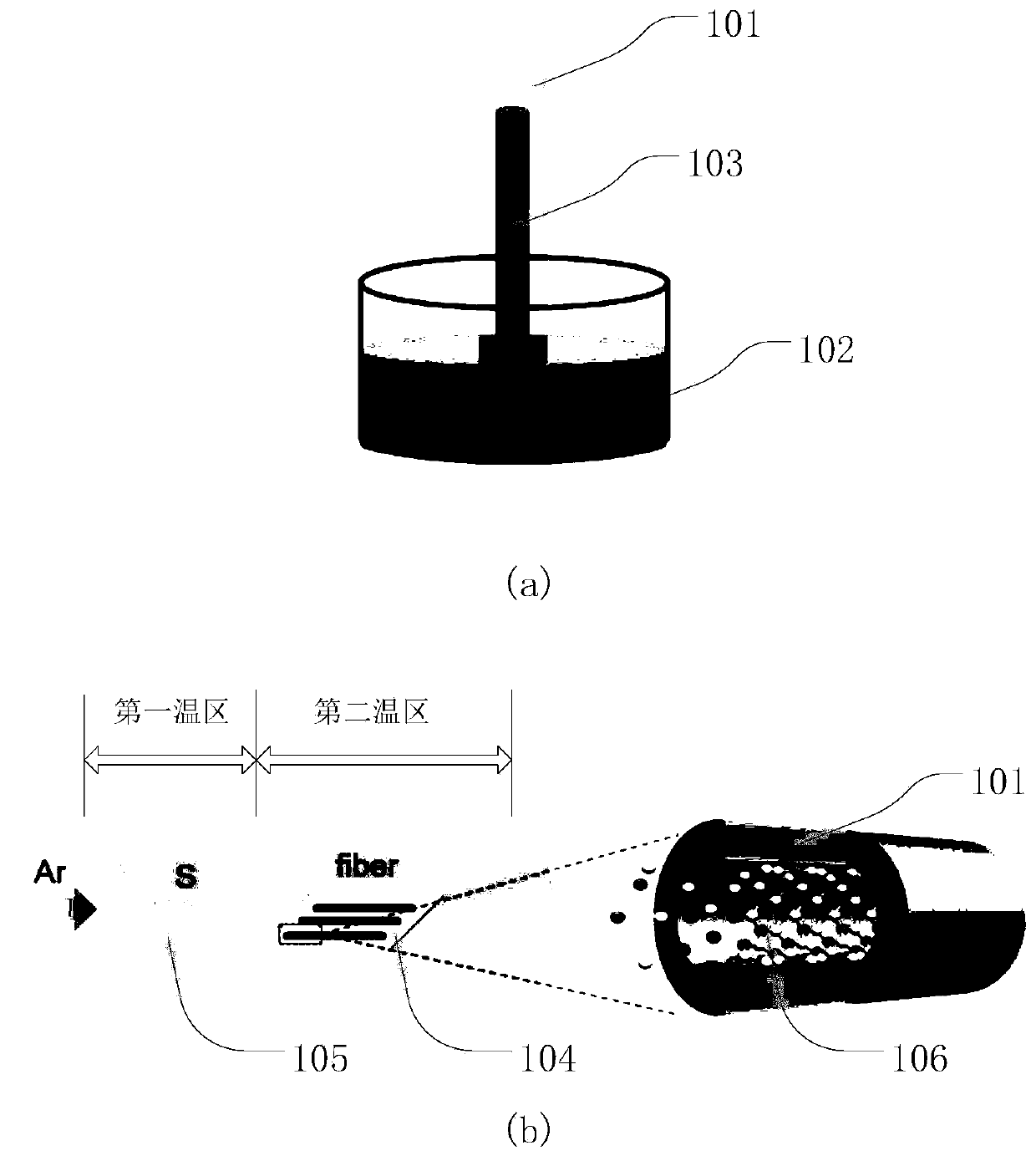

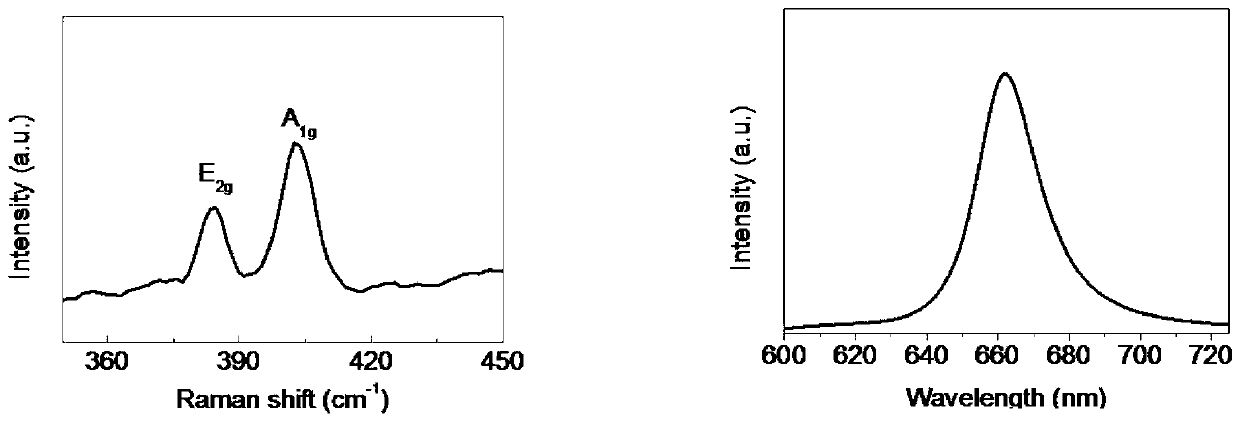

[0046] exist figure 1 In the shown schematic diagram of the device of the present invention, an ordinary total reflection optical fiber with an inner diameter of 50um is used as a substrate to prepare a molybdenum disulfide composite optical fiber material, and the specific steps are as follows:

[0047] (1) Put the sulfur powder in the first temperature zone of the high-temperature tube furnace, and place the optical fiber soaked in 10 mg / mL sodium molybdate solution in the second temperature zone. And the distance between the optical fiber and the sulfur source is controlled within 12cm.

[0048] (2) After using a vacuum pump to evacuate to 0.1Pa, introduce inert gas Ar as the carrier gas and protective gas, and maintain the pressure inside the tube to 220Pa.

[0049] (3) Control the second temperature zone to raise the temperature to 110°C, dry at low pressure for 30 minutes, and then raise the temperature to 820°C. At this time, the first temperature zone is controlled at...

Embodiment 2

[0052] exist figure 1 In the shown schematic diagram of the device of the present invention, a photonic crystal fiber is used as a substrate to prepare a molybdenum disulfide composite photonic crystal fiber material, and the specific steps are as follows:

[0053] (1) Put the sulfur powder in the first temperature zone of the high-temperature tube furnace, and place the optical fiber soaked in 12 mg / mL sodium molybdate solution in the second temperature zone. And the distance between the optical fiber and the sulfur source is controlled within 12cm.

[0054] (2) After using a vacuum pump to evacuate to 0.1Pa, introduce inert gas Ar as the carrier gas and protective gas, and maintain the pressure inside the tube to 220Pa.

[0055] (3) Control the second temperature zone to raise the temperature to 110°C, dry at low pressure for 30 minutes, and then raise the temperature to 820°C. At this time, the first temperature zone is controlled at 150°C and begins to enter the growth st...

Embodiment 3

[0058] exist figure 1 In the schematic diagram of the device of the present invention shown, an ordinary total reflection optical fiber with an inner diameter of 5um is used as the substrate, sodium tungstate is used as the tungsten source to infiltrate the optical fiber, and a tungsten disulfide composite optical fiber material is prepared under low pressure and high temperature conditions. The specific steps are as follows:

[0059] (1) Put the sulfur powder in the first temperature zone of the high-temperature tube furnace, and place the optical fiber soaked in 50 mg / mL sodium tungstate solution in the second temperature zone. And the distance between the optical fiber and the sulfur source is controlled within 10cm.

[0060] (2) After using a vacuum pump to evacuate to 0.1Pa, introduce inert gas Ar as the carrier gas and protective gas, and maintain the pressure inside the tube to 220Pa.

[0061] (3) Control the second temperature zone to raise the temperature to 110°C, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com