Method of preparing hanging graphene support film by selectively etching growth substrate

A graphene film and graphene technology, applied in graphene, crystal growth, single crystal growth, etc., can solve the problems of large-scale preparation of graphene support film, unstable process, high cost, etc., to achieve high integrity, The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1. Selective etching of copper foil substrate to prepare graphene support film

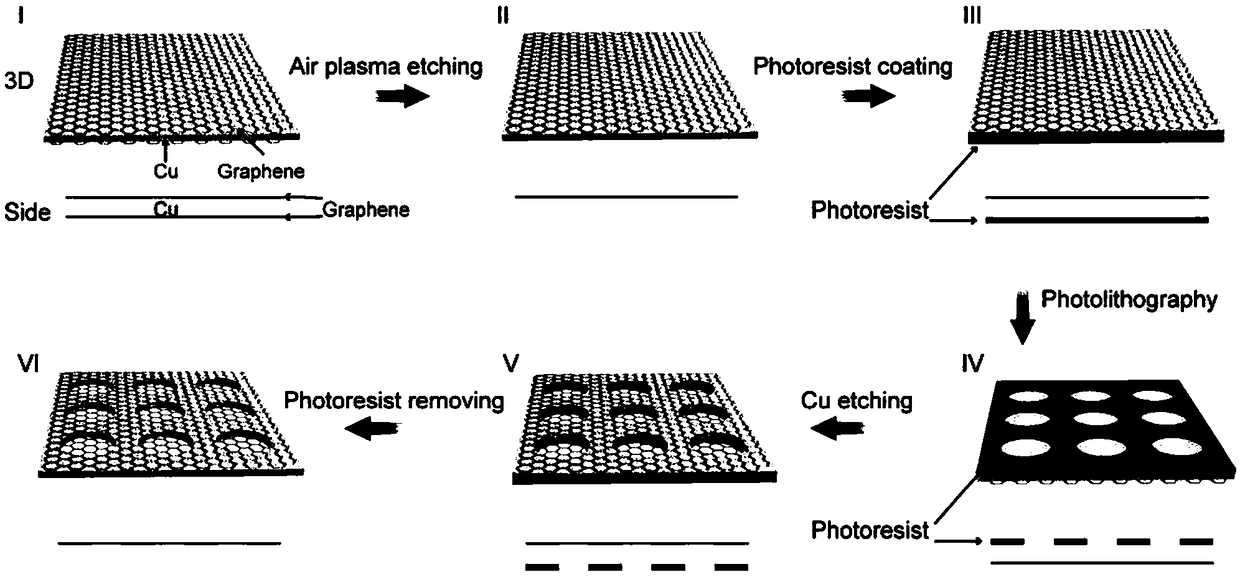

[0067] figure 1 It is a process flow diagram of the present invention. A specific implementation process is as follows:

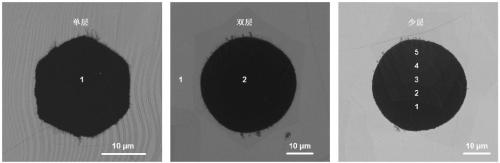

[0068] 1) A graphene film with a controllable number of layers is grown on a copper foil substrate by low-pressure chemical vapor deposition (LPCVD).

[0069] Growth of single-layer large single-crystal graphene: Copper foil (purity 99.8%, thickness 25 microns) is first annealed at 1030°C and 100 sccm hydrogen atmosphere for 30 minutes, and the pressure is kept at about 100 Pa to remove organic matter and oxide layer. Then anneal in 100 sccm argon for 30 minutes to passivate the active sites on the surface of the copper foil. After the annealing process is completed, the graphene is grown at 1030° C. in an atmosphere of 500 sccm hydrogen and 1 sccm methane, the pressure is about 500 Pa, and the growth time is 3 hours.

[0070] Growth of double-layer graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com