Method for performing powder material surface modification through plasma

A technology of plasma and powder materials, which is applied in metal material coating technology, gaseous chemical plating, coating, etc., can solve the problems of single material characteristics and cannot meet the application requirements of micron and nanometer powder materials, and achieve the purpose wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

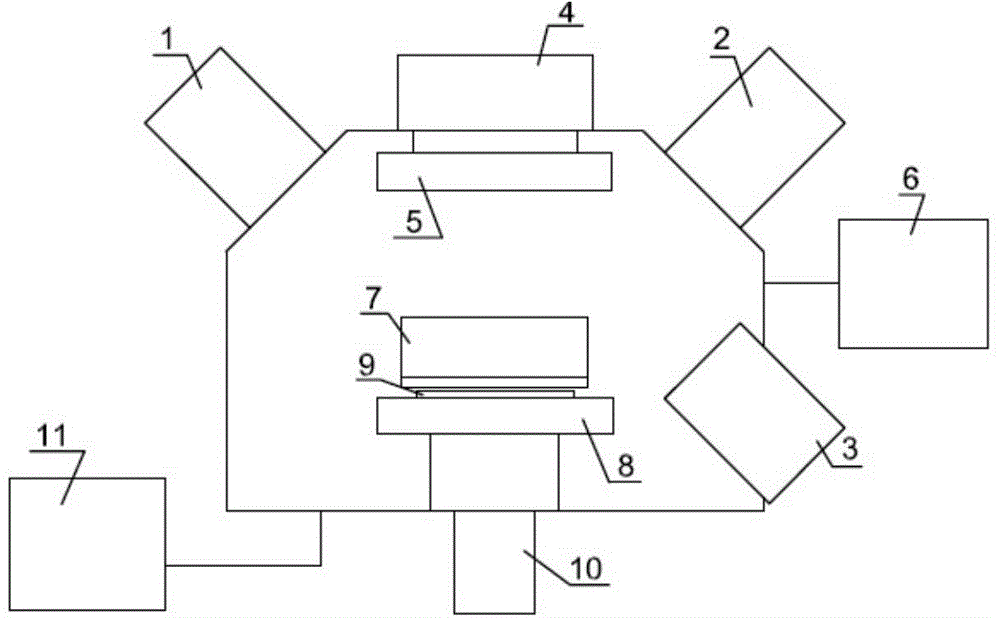

[0026] In this embodiment, the surface metallization modification of the prepared silicon carbide is as follows:

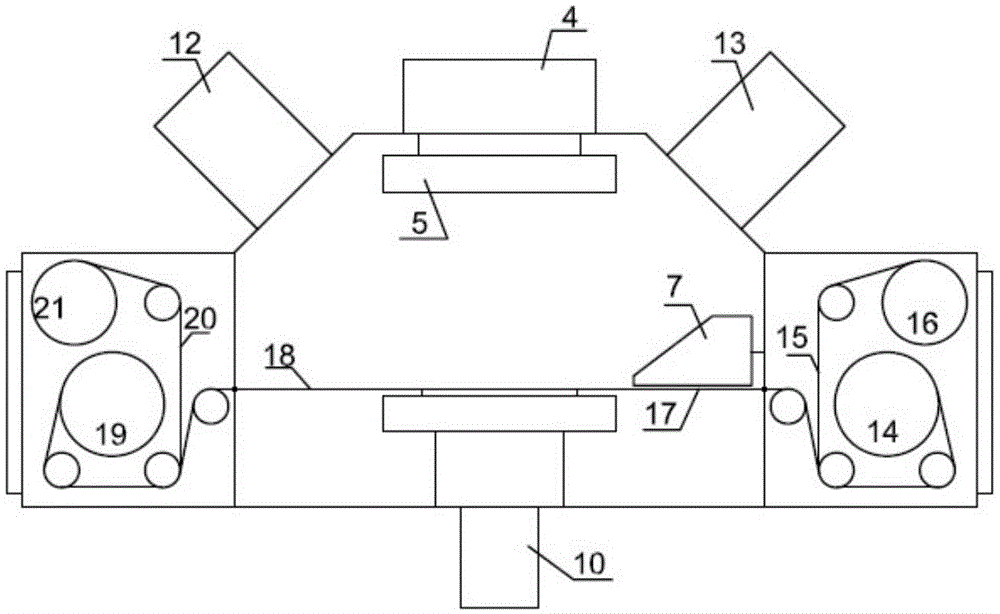

[0027] Select surface-cleaned silicon carbide powder with a particle size of about 5 microns and dry it and place it in the stocker 7 of the ultrasonic glass atomizer shown in Figure 1. The metal target 5 for modification is composed of nickel and titanium, and Use the assisted microetching ion source 1 and figure 2 The 17 powder electrostatic adsorption belt system is used to carry and transport the modified powder.

[0028] The silicon carbide surface metallization modification comprises the following steps:

[0029] 1. Uniform dispersion and film-making treatment of silicon carbide powder

[0030] Coat a layer of low-viscosity electrostatic adhesive coating on the aluminum film with a thickness of 20um and roll it up with anti-adhesive release paper. figure 2 For the coil 14 in the powder modification system, the layout of 16, 17, 19, and 21 in Figure 2 is...

Embodiment 2

[0035] This embodiment is to carry out metallization film formation to nano-graphene to improve its use environment process as follows:

[0036] Select the graphene nano-powder with surface cleaning treatment, its shape is 3 to 5 microns, the thickness of the sheet is about 1nm, dry it and place it in the ultrasonic atomizer stocker 7 in Figure 1, and modify the metal target 5 Composed of nickel and aluminum titanium, and using auxiliary microetching ion source 1 and shown figure 2 The 17 powder electrostatic adsorption belts carry and transport the modified powder.

[0037] Carrying out metallization film forming to nano-graphene comprises the following steps:

[0038] 1. Uniform dispersion of graphene powder to form a film

[0039] On the aluminum film with a thickness of 20um x660mm wide, first coat a layer of low-viscosity electrostatic adhesive coating and roll it up with anti-adhesive release paper. figure 2 Coil material 14 in, complete the layout of 16, 17, 19, 21...

Embodiment 3

[0045] This embodiment is to modify the honeycomb surface of single crystal or low-quality diamond as follows:

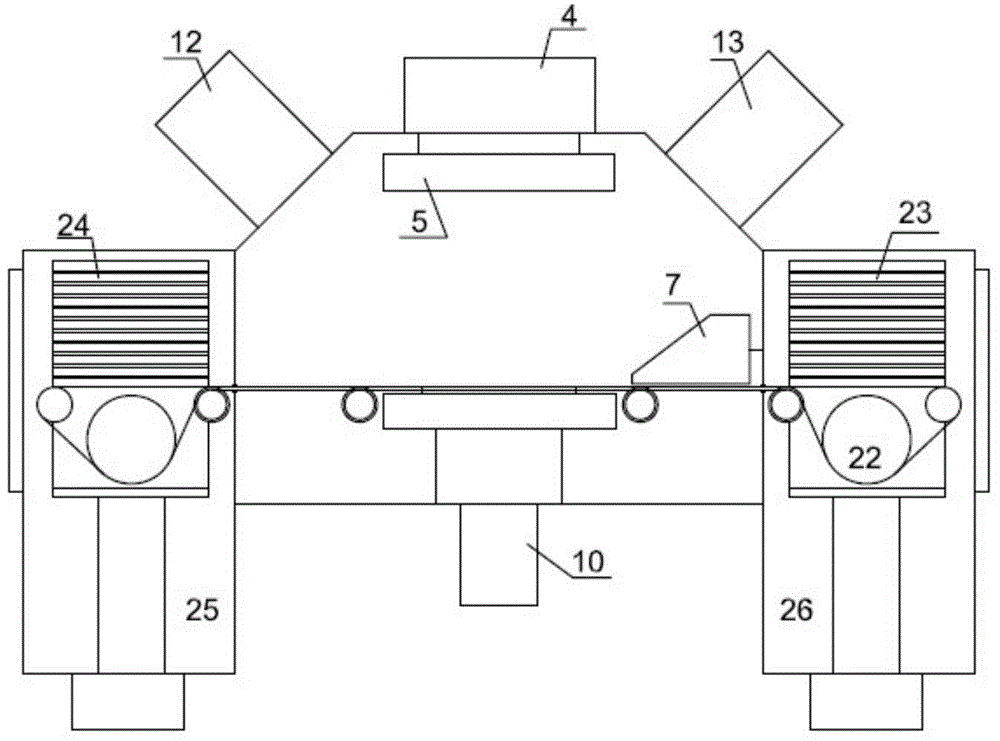

[0046] Select surface-cleaned diamond powder with a particle size between 2 and 10 microns. In this embodiment, select the diamond powder with a particle size of 3 microns and dry it and place it in the ultrasonic atomizer stocker 7 in Figure 1. The use of assisted microetching ion source 1 and image 3 The disk-type 23 powder electrostatic adsorption system in the machine is used to carry and transport the powder for modification.

[0047] The modification of described diamond surface honeycomb comprises the steps:

[0048] 1. Uniform dispersion of diamond powder

[0049] Evenly coat a layer of low-viscosity electrostatic adhesive coating on a 6-inch quartz glass wafer with a thickness of 5mm, and put it into the image 3 Complete the transmission layout of 22 in Figure 3 in the powder modification system on the wafer rack in 23, and add 100 grams of 3 micron di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com